When it comes to purchasing wood for specific projects, many individuals and businesses often wonder if they can buy custom wood sizes tailored to their unique needs. The good news is that most lumber suppliers and woodworking companies offer customization options, allowing customers to order wood in precise dimensions, shapes, and thicknesses. Whether you're working on a DIY project, a large-scale construction, or a specialized craft, custom wood sizes can save time, reduce waste, and ensure a perfect fit. To explore this option, it’s essential to research local or online suppliers, understand their customization capabilities, and provide detailed specifications for your order. With the right approach, buying custom wood sizes can be a seamless and cost-effective solution for any project.

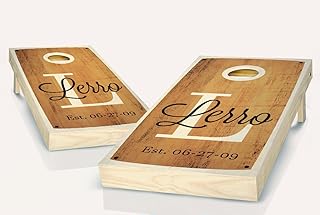

Explore related products

$14.95

What You'll Learn

- Standard vs. Custom Sizes: Differences in availability, pricing, and lead times for custom wood dimensions

- Ordering Process: Steps to request, measure, and confirm custom wood sizes from suppliers

- Cost Factors: How size, wood type, and quantity impact the price of custom cuts

- Supplier Options: Where to find mills or stores offering custom wood sizing services

- Limitations: Maximum and minimum size constraints for custom wood orders

Standard vs. Custom Sizes: Differences in availability, pricing, and lead times for custom wood dimensions

Custom wood sizes are readily available through specialty suppliers, but understanding the trade-offs between standard and custom dimensions is crucial for any project. Standard sizes, such as 2x4s or 4x8 plywood sheets, are mass-produced and stocked by most lumberyards and hardware stores. This high availability translates to lower costs due to economies of scale and immediate accessibility. For instance, a standard 2x4 pine stud might cost around $3 to $5, depending on length, whereas custom dimensions can start at $10 or more per piece. If your project aligns with standard sizes, you’ll save both time and money.

Opting for custom wood sizes introduces complexities in availability, pricing, and lead times. Specialty mills or suppliers often require a minimum order quantity, which can range from 50 to 500 board feet, depending on the species and dimensions. For example, ordering a custom 1.5x5.5-inch oak board might necessitate purchasing an entire batch, significantly increasing upfront costs. Additionally, lead times can extend from a few days to several weeks, as the wood must be milled, dried, and sometimes treated to meet specific requirements. This delay can disrupt project timelines, particularly for time-sensitive builds.

Pricing for custom wood sizes is influenced by several factors, including the wood species, dimensions, and order volume. Exotic or rare woods, such as teak or mahogany, will naturally cost more than common varieties like pine or cedar. Custom milling also incurs additional labor and machinery expenses. For instance, a custom 12-inch-wide walnut plank could cost $20 to $30 per board foot, compared to $8 to $12 for a standard 8-inch width. To mitigate costs, consider bundling orders with other customers or choosing a less exotic wood species that can be custom-milled.

Lead times for custom wood sizes vary widely based on the supplier’s workload and the complexity of the order. A simple custom cut might take 3 to 5 business days, while a large order of precision-milled pieces could require 4 to 6 weeks. To minimize delays, communicate your timeline clearly with the supplier and factor in additional time for shipping or local pickup. Some suppliers offer expedited services for an extra fee, which can be worthwhile for urgent projects. Always request a detailed quote and timeline before committing to ensure alignment with your project needs.

In summary, while custom wood sizes offer unparalleled flexibility for unique projects, they come with higher costs, longer lead times, and potential availability constraints. Standard sizes, on the other hand, provide convenience and affordability but limit design possibilities. Assess your project’s requirements carefully, balancing creativity with practicality. For small-scale projects, custom sizes may be feasible, but for larger builds, standard dimensions often prove more efficient. Always research suppliers thoroughly and plan ahead to navigate the challenges of custom wood procurement successfully.

Where to Buy Balsa Wood: Top Sources for Lightweight Crafting

You may want to see also

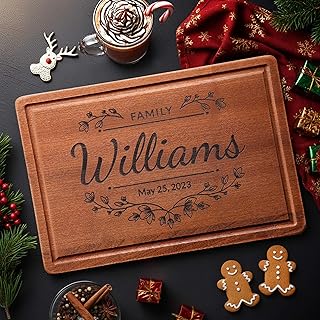

Explore related products

$7.9

Ordering Process: Steps to request, measure, and confirm custom wood sizes from suppliers

Custom wood sizes are not a one-size-fits-all solution, and the ordering process requires precision and clear communication. The first step is to identify your specific needs. Whether you're building furniture, constructing a deck, or crafting a unique piece of art, understanding the exact dimensions, wood type, and quantity required is crucial. For instance, if you're designing a custom bookshelf, you’ll need to determine the length, width, and thickness of each shelf, as well as the type of wood (e.g., oak, maple, or pine) that best suits your project. This initial clarity ensures that your request to the supplier is accurate and minimizes the risk of errors.

Once you’ve defined your requirements, the next step is to request a quote from suppliers. Reach out to multiple vendors to compare pricing, lead times, and capabilities. Provide detailed specifications, including measurements in inches or millimeters, the desired wood species, and any additional treatments like sanding or finishing. For example, if you need a 96-inch-long walnut board with a thickness of 1.5 inches, specify this clearly. Some suppliers may offer online forms or calculators to streamline this process, while others may require an email or phone call. Always ask for a written quote to avoid misunderstandings later.

Measuring accurately is non-negotiable in this process. If you’re unsure about your measurements, consider creating a scaled drawing or using digital tools to double-check. For complex projects, consult a professional carpenter or designer to ensure precision. Remember, custom orders are often non-refundable, so a small measurement error can lead to costly mistakes. A practical tip is to add a margin of 1-2 inches to your dimensions if you anticipate any cutting or adjustments during installation.

After receiving quotes, confirm the order details with your chosen supplier. Review the specifications, delivery timeline, and payment terms carefully. Ask for a confirmation email or invoice that outlines all agreed-upon details. If the supplier offers a sample or mockup, take advantage of this to verify the quality and accuracy of the wood. For large or high-value orders, consider requesting a deposit rather than full payment upfront to protect yourself in case of discrepancies.

Finally, inspect the delivery upon arrival. Check that the wood matches your specifications in terms of size, type, and condition. Measure each piece to ensure it aligns with your order. If there are discrepancies, document them with photos and contact the supplier immediately. Most reputable vendors have policies in place to address errors, but prompt communication is key to resolving issues efficiently. By following these steps, you can navigate the custom wood ordering process with confidence and achieve the exact results your project demands.

Discover the Best Sources to Buy Authentic Brazilian Wood Today

You may want to see also

Explore related products

Cost Factors: How size, wood type, and quantity impact the price of custom cuts

Custom wood cuts are not one-size-fits-all, and neither is their pricing. The cost of custom wood sizes hinges on three critical factors: size, wood type, and quantity. Each element plays a unique role in determining the final price, and understanding their interplay can help you budget effectively for your project.

Size Matters: The Larger the Cut, the Higher the Cost

The dimensions of your custom wood directly influence its price. Larger cuts require more raw material, increasing the cost per piece. For instance, a 4x8 sheet of plywood might cost $20, but a custom 5x10 cut could double the price due to the additional material and labor involved. Thicker cuts also add to the expense, as they demand more wood and specialized machinery. To save, consider optimizing your design to minimize waste or choose standard sizes when possible. However, if your project demands precision, the added cost may be justified for the perfect fit.

Wood Type: From Budget-Friendly to Premium

The species of wood you select significantly impacts the price. Softwoods like pine or cedar are generally more affordable, making them ideal for cost-conscious projects. Hardwoods, such as oak or walnut, come with a higher price tag due to their durability and aesthetic appeal. Exotic woods like teak or mahogany can be even more expensive, often costing 2-3 times more than softwoods. For example, a custom 2x4 cut in pine might cost $5, while the same size in walnut could run $20 or more. Choose the wood type based on your project’s needs and budget, balancing cost with functionality and appearance.

Quantity Discounts: Buying in Bulk Pays Off

Ordering custom wood in larger quantities can lead to significant savings. Suppliers often offer discounts for bulk orders, as it reduces their per-unit processing costs. For instance, ordering 10 custom cuts might cost $15 each, but purchasing 50 could drop the price to $12 each. If your project requires multiple pieces or you’re working on several projects, consolidating your order can yield substantial savings. However, ensure you have adequate storage and that the wood won’t go unused, as excess material can negate the cost benefits.

Labor and Complexity: Hidden Costs to Consider

Beyond size, wood type, and quantity, the complexity of your custom cut can add to the expense. Intricate shapes, precise angles, or special finishes require more labor and specialized tools, driving up the price. For example, a simple straight cut might add $2 to the cost, while a curved or beveled edge could add $10 or more. Discuss your design with the supplier early to understand these additional costs and explore ways to simplify without compromising your vision.

Practical Tips for Cost-Effective Custom Cuts

To maximize your budget, plan your project meticulously. Use digital tools to optimize material usage, reducing waste and costs. Research local suppliers and compare prices, as regional availability can affect wood costs. If possible, combine orders with others to take advantage of bulk discounts. Finally, consider using a mix of wood types—premium wood for visible areas and budget-friendly options for structural components. By strategically balancing these factors, you can achieve custom wood cuts that meet your needs without breaking the bank.

Where to Buy a North Woods Law Red Jacket Online

You may want to see also

Explore related products

Supplier Options: Where to find mills or stores offering custom wood sizing services

Local sawmills are often the first port of call for custom wood sizing. These facilities typically have the equipment and expertise to mill logs into specific dimensions, catering to both small-scale hobbyists and large construction projects. When approaching a sawmill, bring detailed measurements and specifications, including length, width, thickness, and any special requirements like grain orientation or moisture content. Many sawmills also offer kiln-drying services to ensure the wood is ready for immediate use. To find a local sawmill, check regional directories, agricultural extension offices, or online platforms like Wood-Mizer’s sawmill locator.

For those seeking convenience and a wider selection, specialty lumberyards often provide custom cutting services. Unlike big-box stores, these suppliers focus on high-quality, unique wood species and are equipped to handle precise sizing requests. Some, like Hardwick’s Building Supply or specialty hardwood dealers, maintain relationships with mills to source and cut wood to order. When working with a lumberyard, inquire about lead times, as custom orders may take longer to fulfill. Additionally, ask about minimum order quantities, as some suppliers require larger purchases for custom work.

Online platforms have revolutionized access to custom wood sizing, connecting buyers directly with mills and suppliers nationwide. Websites like Woodworkers Source, The Wood Mill, or even Etsy offer customization options for various wood types, from exotic hardwoods to reclaimed lumber. When ordering online, verify shipping costs and delivery times, as large or heavy pieces can be expensive to transport. Look for suppliers with clear return policies and customer reviews to ensure reliability. Some platforms also provide virtual consultations to discuss specific needs before placing an order.

For large-scale or commercial projects, partnering directly with a wood mill can yield cost savings and greater control over the process. Mills often have the capacity to handle bulk orders and can accommodate non-standard dimensions that smaller suppliers might struggle with. To locate a mill, search industry databases like the National Hardwood Lumber Association or attend trade shows like the International Woodworking Fair. When negotiating with a mill, discuss pricing structures, such as whether costs are based on board feet or linear feet, and clarify any additional fees for custom services.

Finally, consider joining woodworking communities or forums, where members often share recommendations for reliable suppliers. Platforms like Reddit’s r/woodworking or local Facebook groups can provide firsthand insights into which mills or stores deliver quality custom sizing. Networking with fellow woodworkers can also uncover hidden gems—small, family-owned operations that may not have a strong online presence but offer exceptional service. Always request samples or references before committing to a large order to ensure the supplier meets your standards.

Best Places to Buy Wood Shavings for Pets and Crafts

You may want to see also

Explore related products

Limitations: Maximum and minimum size constraints for custom wood orders

Custom wood orders offer unparalleled flexibility, but they are not without boundaries. Understanding the maximum and minimum size constraints is crucial for anyone planning a project that requires precise dimensions. These limitations are dictated by the capabilities of milling equipment, the natural properties of wood, and logistical considerations like transportation and handling. For instance, most lumber mills can handle boards up to 16 feet in length, but anything longer may require specialized equipment or incur additional costs. Conversely, very small pieces, such as those under 6 inches, may be difficult to process due to the limitations of cutting tools and the risk of waste.

When planning a project, it’s essential to consider how these constraints align with your design. For example, if you’re building a large dining table, you might need a single plank that’s 12 feet long and 24 inches wide. While this is feasible for many suppliers, exceeding these dimensions—say, requesting a 20-foot plank—could push beyond their capabilities. Similarly, intricate woodworking projects requiring tiny, precise pieces may necessitate alternative materials or methods if the desired size falls below the minimum threshold. Always consult with your supplier early in the planning process to avoid costly redesigns.

Logistics play a significant role in size constraints, particularly for maximum dimensions. Transporting oversized wood pieces requires specialized vehicles and handling equipment, which can drive up costs. For example, a 20-foot beam might need a flatbed truck and a crane for delivery, whereas a 12-foot beam could be managed with standard equipment. Additionally, storage and handling at the supplier’s facility can limit the maximum size they’re willing to produce. If your project demands unusually large pieces, be prepared to discuss these logistical challenges with your supplier and factor them into your budget.

On the other end of the spectrum, minimum size constraints are often driven by practicality and safety. Woodworking machinery, such as saws and planers, has physical limitations that prevent cutting pieces below a certain size. For instance, a table saw’s blade guard may restrict cutting strips narrower than 1 inch. Moreover, very small pieces pose a safety risk during processing, as they can become projectiles or get caught in machinery. If your project requires tiny components, consider alternatives like wood veneers, laser-cut pieces, or pre-fabricated parts that bypass these constraints.

Finally, the natural characteristics of wood itself impose limitations. Large, defect-free boards are rare and expensive, as they require sourcing from old-growth trees or premium lumber. Conversely, very small pieces may not retain the structural integrity needed for certain applications, especially if they’re cut against the grain. Understanding these material limitations can help you make informed decisions about size and quality. For example, if you need a 10-foot-long, knot-free board, expect to pay a premium, whereas smaller, less-critical pieces might allow for more flexibility in grade and cost. By balancing your design needs with these constraints, you can achieve a successful custom wood order.

Best Places to Purchase Dutch Lap Wood Siding for Your Home

You may want to see also

Frequently asked questions

Yes, many lumber suppliers and woodworking companies offer custom wood sizing services. You can specify the exact dimensions you need, and they will cut the wood to your requirements.

While most suppliers can accommodate a wide range of sizes, there may be limitations based on the type of wood, available machinery, or minimum/maximum dimensions. It’s best to check with the supplier beforehand.

The cost varies depending on the type of wood, the complexity of the cut, and the supplier. Custom cuts may incur additional fees compared to standard sizes, so it’s advisable to request a quote before placing an order.