If you're wondering whether you can buy wood directly from a sawmill, the answer is generally yes. Sawmills are facilities where logs are processed into lumber, and many of them offer their products for sale to both individual buyers and businesses. Purchasing wood from a sawmill can be cost-effective, as you’re buying directly from the source, often bypassing middlemen like lumberyards or retailers. However, it’s important to note that sawmills may have specific requirements, such as minimum order quantities or limited availability of certain wood types. Additionally, the wood might be rough-cut or unfinished, requiring further processing depending on your project needs. Before visiting a sawmill, it’s a good idea to call ahead to inquire about their offerings, pricing, and any restrictions they may have.

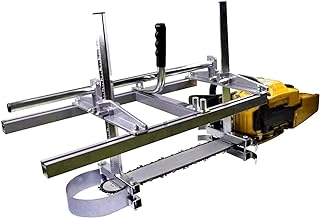

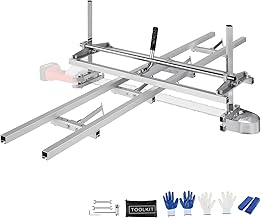

Explore related products

What You'll Learn

- Local Sawmill Locations: Find nearby sawmills selling wood directly to customers in your area

- Types of Wood Available: Explore varieties like oak, pine, or maple offered at sawmills

- Pricing and Quantity: Understand cost differences for bulk or small wood purchases

- Quality and Grading: Learn how sawmills grade wood for different uses and projects

- Delivery and Pickup Options: Check if sawmills offer wood delivery or require self-pickup

Local Sawmill Locations: Find nearby sawmills selling wood directly to customers in your area

Buying wood directly from a local sawmill can be a cost-effective and sustainable way to source materials for your projects. By cutting out middlemen, you often get fresher, higher-quality lumber at a lower price. To locate nearby sawmills, start with a simple online search using terms like “sawmills near me” or “local lumber mills.” Many sawmills have websites or social media pages listing their products and contact information. Additionally, local woodworking forums or community boards can be treasure troves of recommendations from fellow enthusiasts.

Once you’ve identified potential sawmills, call ahead to confirm they sell directly to customers. Some mills specialize in wholesale or custom orders, while others cater specifically to individuals. Ask about their inventory—whether they offer hardwoods like oak or maple, softwoods like pine, or specialty species like cedar. Inquire about pricing, as it often varies by wood type, quantity, and milling process (e.g., rough-cut vs. planed). Some mills may require a minimum purchase, so plan accordingly if you’re working on a small project.

Visiting the sawmill in person can be enlightening. You’ll see the milling process firsthand, inspect the wood quality, and discuss your needs with the experts. Bring measurements and a list of required materials to ensure you get exactly what you need. Many mills offer custom cutting services, allowing you to specify thickness, width, or length. Don’t hesitate to ask for advice—sawmill operators are often passionate about their craft and eager to help customers make informed choices.

One practical tip: check if the sawmill air-dries or kiln-dries their wood. Air-dried lumber is typically more affordable but may require additional drying time before use. Kiln-dried wood is ready for immediate use but tends to be pricier. If you’re working on a time-sensitive project, kiln-dried might be worth the investment. Also, inquire about delivery options, as transporting large quantities of wood can be challenging without proper equipment. Some mills offer delivery for a fee, while others may recommend local hauling services.

Finally, consider the environmental impact of your purchase. Local sawmills often source wood from nearby forests, reducing the carbon footprint associated with transportation. Ask about their sustainability practices—do they use locally harvested timber? Are they certified by organizations like the Forest Stewardship Council (FSC)? Supporting eco-conscious mills not only benefits the environment but also ensures you’re investing in responsibly sourced materials. By taking these steps, you’ll find a local sawmill that meets your needs while fostering a connection to your community and its natural resources.

Best Places to Buy Knotty Alder Wood for Your Next Project

You may want to see also

Explore related products

Types of Wood Available: Explore varieties like oak, pine, or maple offered at sawmills

Sawmills are treasure troves for wood enthusiasts, offering a diverse array of timber types that cater to various projects, from furniture making to construction. Among the most sought-after varieties are oak, pine, and maple, each with distinct characteristics that make them suitable for different applications. Oak, known for its durability and rich grain patterns, is a favorite for high-end furniture and flooring. Pine, on the other hand, is lightweight and easy to work with, making it ideal for DIY projects and interior trim. Maple, prized for its smooth texture and strength, is often used in cabinetry and musical instruments. Understanding these differences allows buyers to make informed decisions based on their project needs.

When visiting a sawmill, it’s essential to consider the specific qualities of each wood type. For instance, oak’s hardness and resistance to wear make it a long-lasting choice but also more challenging to cut and shape. Pine, while softer and more forgiving, may dent or scratch more easily, requiring careful handling in high-traffic areas. Maple’s fine grain and light color offer a sleek, modern aesthetic but can be more expensive due to its demand in specialized industries. Asking the sawmill operator about the wood’s origin and treatment can also provide insights into its quality and sustainability, ensuring you get the best value for your project.

A practical tip for buyers is to assess the intended use of the wood before making a purchase. For outdoor projects, consider treated pine or oak, which can withstand moisture and pests. For indoor applications, maple or unfinished pine might be more cost-effective. Additionally, inquire about the sawmill’s milling options—some offer custom cuts, kiln-drying, or planing services, which can save time and effort in the long run. Bringing a sample or sketch of your project can help the sawmill staff recommend the most suitable wood type and dimensions.

Comparing prices and availability is another crucial step. While oak and maple are generally pricier due to their density and demand, pine often provides a budget-friendly alternative without compromising on versatility. Seasonal availability can also impact pricing, so planning your purchase during off-peak times might yield better deals. Some sawmills offer bulk discounts or leftover pieces at reduced rates, perfect for smaller projects or experimentation. Always measure twice and order a bit extra to account for mistakes or future repairs.

Finally, sustainability should be a key consideration when buying wood from a sawmill. Many mills now prioritize eco-friendly practices, such as sourcing from certified forests or recycling waste materials. Asking about their sustainability policies not only supports responsible forestry but also ensures you’re getting wood that’s ethically produced. By choosing the right type of wood and supporting sustainable practices, you can create projects that are both beautiful and environmentally conscious.

Top Places to Purchase Quality Wood for Your Pergola Project

You may want to see also

Explore related products

$29.99 $32.99

Pricing and Quantity: Understand cost differences for bulk or small wood purchases

Buying wood directly from a sawmill can offer significant cost savings, but the price per board foot varies dramatically based on quantity. Small purchases (under 100 board feet) often incur higher costs due to fixed handling and processing fees. For instance, a hobbyist buying 50 board feet of oak might pay $6–$8 per board foot, while a contractor purchasing 500 board feet could secure rates as low as $3–$5 per board foot for the same material. This disparity highlights the economies of scale at play in sawmill pricing.

To maximize savings, consider pooling orders with others if you’re buying small quantities. Sawmills often offer discounts for orders over 500 board feet, and some may even waive delivery fees for bulk purchases exceeding 1,000 board feet. For example, a community woodworking group could collectively order 1,500 board feet of pine, reducing individual costs by 30–40% compared to buying separately. Coordination is key—organize through local forums or social media groups to aggregate demand.

Another factor influencing price is wood grade and type. Premium hardwoods like walnut or maple command higher prices regardless of quantity, but bulk purchases can still yield better rates. For instance, 100 board feet of walnut might cost $12–$15 per board foot, while 1,000 board feet could drop to $9–$12 per board foot. Conversely, softwoods like pine or cedar show smaller price gaps between small and bulk orders, making them more accessible for smaller projects.

Finally, timing matters. Sawmills often have seasonal surpluses or slow periods when they’re more willing to negotiate prices. Late winter or early spring, when construction activity is low, can be ideal for securing bulk deals. Conversely, peak seasons like summer may limit bargaining power. Always ask about current inventory levels and inquire about discounts for off-grade or irregular pieces, which can be 20–50% cheaper and perfectly usable for many projects.

By understanding these dynamics, you can strategically plan purchases to balance quantity, quality, and cost. Whether you’re a DIY enthusiast or a professional builder, leveraging bulk pricing and smart timing can make sawmill-direct wood purchases both affordable and efficient.

Best Places to Purchase Efficient Wood Stoves for Your Home

You may want to see also

Explore related products

Quality and Grading: Learn how sawmills grade wood for different uses and projects

Sawmills employ a meticulous grading system to ensure wood meets specific standards for various applications, from construction to fine furniture. This process involves evaluating factors like grain pattern, moisture content, and the presence of defects such as knots or cracks. For instance, hardwoods like oak or maple are often graded based on the clarity and uniformity of their grain, with higher grades reserved for pieces free of blemishes. Softwoods, such as pine, may be assessed for structural integrity, with grades indicating suitability for load-bearing roles or decorative purposes. Understanding these grades helps buyers select wood that aligns with their project’s functional and aesthetic requirements.

The grading process begins with sorting logs by species, size, and quality before milling. Once cut into lumber, each piece is inspected for defects that could compromise its strength or appearance. For example, a board with tight, small knots might be suitable for framing, while one with larger, loose knots would be downgraded to a lower grade. Moisture content is another critical factor; wood with excessive moisture can warp or shrink, so sawmills often kiln-dry lumber to achieve optimal levels (typically 6-8% for indoor use). These steps ensure consistency, allowing buyers to trust that the wood they purchase will perform as expected.

For DIY enthusiasts or professionals, knowing how to interpret wood grades can save time and money. Common grading systems include the National Hardwood Lumber Association (NHLA) rules for hardwoods and the Southern Pine Inspection Bureau (SPIB) standards for softwoods. For instance, NHLA grades range from FAS (First and Seconds, the highest quality) to No. 3 Common (suitable for utilitarian purposes). Softwoods might be labeled as Select Structural for heavy-duty construction or Standard for general use. By familiarizing themselves with these classifications, buyers can avoid overpaying for premium grades when a lower grade will suffice or ensure they invest in top-tier wood for critical projects.

Practical tips for purchasing directly from a sawmill include asking about grading practices and inspecting samples before buying in bulk. Some sawmills offer custom milling, allowing buyers to specify dimensions or finishes tailored to their needs. Additionally, purchasing directly can often yield cost savings, as middlemen are eliminated. However, buyers should inquire about moisture content and acclimate the wood to their workspace to prevent warping. For example, storing lumber in a controlled environment for 1-2 weeks before use can mitigate issues caused by humidity fluctuations. This proactive approach ensures the wood performs optimally in its intended application.

In conclusion, sawmill grading systems are designed to match wood quality with specific project demands, providing clarity for buyers across industries. Whether crafting a bespoke piece of furniture or framing a house, understanding these grades empowers informed decision-making. By combining knowledge of grading standards with practical purchasing strategies, buyers can source wood that not only meets but exceeds their expectations, ensuring both durability and aesthetic appeal in their projects.

Where to Buy a North Woods Law Red Jacket Online

You may want to see also

Explore related products

$54.99 $59.99

Delivery and Pickup Options: Check if sawmills offer wood delivery or require self-pickup

Sawmills often provide both delivery and pickup options for purchasing wood, but availability varies widely based on location, order size, and mill policies. Before finalizing your purchase, inquire about these options to align with your logistical needs. Some mills offer free delivery for bulk orders, while others charge based on distance or weight. Self-pickup is typically more cost-effective but requires adequate transportation and labor to handle the wood.

When considering delivery, ask about lead times, as they can range from a few days to several weeks depending on the mill’s schedule and your location. For example, local sawmills may deliver within 2–3 days, while regional suppliers might take longer. If you’re ordering specialty or custom-cut wood, delivery times may extend further. Always confirm whether the delivery includes unloading assistance or if you’ll need to arrange additional help.

Self-pickup is a straightforward option if you have a truck or trailer and can transport the wood yourself. However, be mindful of the wood’s weight and dimensions. A standard pickup truck can handle up to 1,000–2,000 pounds, but larger orders may require a trailer or multiple trips. Bring tie-down straps, tarps, and gloves to secure and protect the wood during transport. Some mills also offer on-site loading assistance, but it’s wise to call ahead to confirm.

For those without transportation, third-party delivery services or freight companies can be an alternative, though costs can add up quickly. If you’re purchasing small quantities, such as firewood or hobbyist-sized pieces, some mills may allow you to ship via courier services. Always compare the total cost of delivery versus self-pickup to determine the most economical choice for your project.

Ultimately, understanding delivery and pickup options ensures a smoother transaction and avoids unexpected delays or expenses. Whether you opt for convenience or cost savings, clear communication with the sawmill is key. Plan ahead, especially for large or time-sensitive projects, to secure the wood you need without logistical headaches.

Where to Buy Wooden Roses: Top Retailers and Online Stores

You may want to see also

Frequently asked questions

Yes, many sawmills sell wood directly to customers, offering a variety of lumber types and sizes at competitive prices.

Sawmills typically offer a range of wood species, including hardwoods (like oak, maple, and walnut) and softwoods (like pine and cedar), depending on their sourcing.

Often, buying directly from a sawmill is more cost-effective because you’re purchasing closer to the source, cutting out middlemen and retail markups.

Yes, many sawmills offer custom milling services, allowing you to specify dimensions, thickness, and other requirements for your project.

It’s helpful to know the type of wood, quantity, and dimensions you need. Additionally, ask about moisture content and drying options, as freshly cut wood may need time to season.