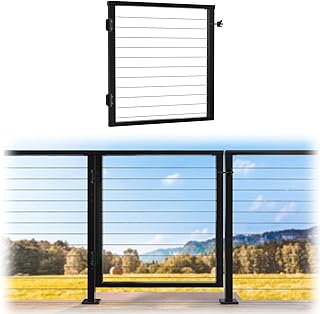

If you're considering building or upgrading a wood deck, one of the essential components to think about is the railing system. A complete wood deck rail kit offers a convenient and efficient solution for homeowners and DIY enthusiasts alike. These kits typically include all the necessary components, such as balusters, posts, caps, and hardware, ensuring a cohesive and professional finish. By opting for a pre-assembled kit, you can save time and effort compared to sourcing individual parts, making it an attractive option for those looking to streamline their deck construction or renovation project. The availability of various styles and finishes allows for customization to match your deck's aesthetic, providing both safety and visual appeal.

| Characteristics | Values |

|---|---|

| Availability | Yes, complete wood deck rail kits are widely available from various retailers and suppliers. |

| Materials | Typically includes pressure-treated wood, cedar, or composite materials. |

| Components | Rails, balusters, posts, brackets, hardware (screws, bolts, etc.), and sometimes post caps. |

| Sizes | Standard lengths (e.g., 6 ft, 8 ft) and customizable options based on deck dimensions. |

| Styles | Traditional, modern, and decorative designs available. |

| Installation | Pre-drilled and pre-cut components for easier DIY installation. |

| Cost | Varies by material and brand; generally ranges from $20 to $60 per linear foot. |

| Brands | Popular brands include Trex, TimberTech, Deckorators, and Home Depot’s exclusive lines. |

| Durability | Depends on material; pressure-treated wood and composites offer longer lifespans. |

| Maintenance | Wood requires periodic staining/sealing; composites are low-maintenance. |

| Retailers | Available at Home Depot, Lowe's, Amazon, and specialty decking suppliers. |

| Warranty | Varies by brand; typically 10–25 years for composites, shorter for wood. |

Explore related products

What You'll Learn

Pre-assembled railing kits

When selecting a pre-assembled railing kit, consider the deck’s height and local building codes, as these dictate railing height and baluster spacing. Most kits are designed to meet standard safety requirements, but it’s crucial to verify compliance. Installation typically involves attaching the posts to the deck frame and securing the rails, a process that can often be completed in a single day with basic tools. Manufacturers usually provide detailed instructions, though hiring a professional ensures precision, especially for uneven or complex deck layouts.

One of the standout advantages of pre-assembled kits is their cost-effectiveness compared to custom-built railings. By bundling materials and simplifying installation, these kits reduce labor costs and minimize waste. Additionally, many kits are treated for weather resistance, extending their lifespan and reducing long-term maintenance. For example, pressure-treated wood kits often come with a 15-20 year warranty against rot and insect damage, making them a practical choice for humid or rainy climates.

Despite their convenience, pre-assembled kits may not suit every project. Custom designs or unique deck shapes might require tailored solutions, as these kits are standardized. However, for straightforward installations, they offer a balance of quality, affordability, and ease. Brands like Trex, Deckorators, and Fortress Railing provide a range of styles and materials, ensuring homeowners can find a kit that aligns with their vision. With proper care, a pre-assembled railing kit can transform a deck into a safe, stylish outdoor space for years to come.

Best Places to Buy Seasoned Wood for Your Fireplace or Stove

You may want to see also

Explore related products

Baluster and post options

Wood deck rail kits offer a streamlined solution for homeowners, but the devil is in the details—specifically, the balusters and posts. These components are not just structural necessities; they define the aesthetic and safety of your deck. Balusters, the vertical supports between the top and bottom rails, come in a variety of materials, including wood, metal, and composite. Wood balusters provide a classic, natural look but require periodic staining or sealing to prevent rot. Metal balusters, often made of aluminum or steel, offer durability and a modern aesthetic, though they can be prone to rust if not powder-coated. Composite balusters combine the look of wood with low maintenance, making them ideal for humid climates.

Posts, the vertical pillars that anchor the railing, are equally critical. Pressure-treated lumber is a cost-effective choice, but it may warp or crack over time. Cedar or redwood posts offer better resistance to decay and insects, though they come at a higher price point. For a sleek, contemporary look, aluminum posts are lightweight and corrosion-resistant, often paired with glass balusters for an unobstructed view. When selecting posts, ensure they meet local building codes, which typically require a minimum height of 36 inches for residential decks.

The spacing of balusters is another key consideration. Building codes mandate that balusters be no more than 4 inches apart to prevent accidents, particularly for households with children or pets. Pre-drilled rails in complete kits often simplify this process, but custom installations require careful measurement. For a decorative touch, mix and match baluster styles—for example, alternating square and twist designs—to add visual interest without compromising safety.

Installation techniques vary depending on the kit. Some systems use brackets or screws to attach balusters to the rail, while others employ a slip-over design for a cleaner appearance. Posts typically require anchoring to the deck frame with galvanized hardware to prevent rust. If you’re installing a kit on an existing deck, ensure the posts are securely fastened to the joists, not just the decking surface, to handle lateral pressure.

Finally, consider the long-term maintenance of your chosen materials. Wood balusters and posts may need refinishing every 2–3 years, while metal and composite options generally require only occasional cleaning. For coastal areas, stainless steel hardware is essential to combat salt corrosion. By carefully evaluating these options, you can select a baluster and post combination that balances durability, style, and compliance with safety standards.

Ashley Wood King Heater: Availability and Where to Buy Now

You may want to see also

Explore related products

Hardware and bracket inclusions

Complete wood deck rail kits often include a variety of hardware and brackets designed to simplify installation and ensure structural integrity. These components are typically made from corrosion-resistant materials like stainless steel or powder-coated metal to withstand outdoor conditions. Standard inclusions usually feature brackets for attaching the rail to posts, baluster connectors, and screws or bolts tailored to the kit’s design. Some kits also provide pre-drilled holes or templates to minimize guesswork during assembly, making them ideal for DIY enthusiasts. Always verify the hardware list against your deck’s dimensions and local building codes to ensure compatibility and safety.

Analyzing the hardware and bracket inclusions reveals their role in balancing aesthetics and functionality. For instance, adjustable brackets allow for precise leveling on uneven surfaces, while decorative caps or covers can enhance the rail’s visual appeal. Kits with hidden fasteners offer a sleek, seamless look but may require more precise alignment during installation. Conversely, exposed hardware can add a rustic or industrial charm, depending on the finish. Understanding these trade-offs helps homeowners prioritize between form and ease of installation when selecting a kit.

When installing a wood deck rail kit, follow these steps to maximize the effectiveness of included hardware and brackets: First, lay out all components and read the instructions thoroughly before beginning. Use a level to ensure posts are plumb and rails are aligned correctly. Pre-treat wooden elements with a sealant to prevent moisture penetration around hardware contact points. Tighten fasteners securely but avoid over-torquing to prevent wood splitting. Finally, inspect all connections for stability and adjust as needed before finalizing the installation.

A comparative look at hardware inclusions across different kits highlights variations in quality and convenience. Premium kits often include self-tapping screws or specialized tools, reducing the need for additional purchases. Budget options may rely on generic fasteners, requiring extra care during installation to avoid stripping or misalignment. Some kits offer modular brackets that accommodate future expansions, while others are designed for fixed configurations. Evaluating these differences ensures you choose a kit that aligns with your skill level, budget, and long-term plans for the deck.

Practical tips for working with hardware and brackets include using a magnetic wristband to keep screws organized during installation and applying thread lubricant to fasteners for smoother assembly. For kits with metal brackets, consider using galvanized or stainless steel components to prevent rust, especially in coastal or humid climates. If the kit lacks specific hardware, consult the manufacturer for recommended replacements rather than improvising. Regularly inspect and tighten hardware annually to maintain safety, as wood movement and weather exposure can loosen connections over time.

Where to Find and Buy Chicken of the Woods Mushrooms

You may want to see also

Explore related products

Material and finish choices

Wood deck rail kits offer a spectrum of material and finish choices, each with distinct advantages and aesthetic appeals. Pressure-treated pine is a cost-effective option, prized for its durability against rot and insects. However, its natural green tint may require staining or painting to match your deck’s design. Cedar provides a more upscale look with its rich, reddish-brown tones and natural resistance to decay, though it comes at a higher price point. Tropical hardwoods like ipe or cumaru offer unparalleled durability and a luxurious finish but demand regular oiling to maintain their deep, exotic hues. Composite materials, while not wood, mimic its appearance and provide low-maintenance alternatives, often with UV-resistant finishes to prevent fading.

The finish you choose can dramatically alter the rail’s appearance and longevity. Clear sealers preserve the wood’s natural color while protecting against moisture and UV damage—ideal for cedar or redwood. Semi-transparent stains enhance the wood grain with a hint of color, available in shades like cedar, walnut, or gray. For a bolder statement, solid stains or paints offer full coverage, masking imperfections while providing robust protection. When applying finishes, ensure the wood is clean and dry, and follow manufacturer guidelines for coats and drying times. For example, oil-based finishes typically require 24–48 hours between coats, while water-based options dry faster but may need more layers for even coverage.

Consider the climate when selecting materials and finishes. In humid or coastal areas, opt for materials with high moisture resistance, such as composite or ipe, paired with marine-grade finishes. In arid regions, UV protection becomes critical—choose finishes with built-in UV inhibitors to prevent cracking and discoloration. For high-traffic areas, prioritize scratch-resistant finishes, especially if using softer woods like pine. Regular maintenance, such as annual inspections and reapplication of sealants every 2–3 years, will extend the life of your railing system.

Finally, sustainability and personal style should guide your choices. Reclaimed wood or FSC-certified options reduce environmental impact while adding character. For a modern look, sleek aluminum balusters paired with stained cedar rails create a contemporary contrast. Rustic designs benefit from rough-sawn cedar with a matte finish, while traditional styles often feature painted pine with decorative spindles. Always test finishes on a small area to ensure the desired effect before full application. By balancing functionality, aesthetics, and environmental considerations, you can create a deck railing that enhances both your outdoor space and your lifestyle.

Best Places to Purchase Dutch Lap Wood Siding for Your Home

You may want to see also

Explore related products

Installation tools required

Installing a complete wood deck rail kit is a straightforward task, but having the right tools ensures precision and efficiency. At a minimum, you’ll need a power drill with a screwdriver bit for securing screws, a tape measure for accurate spacing, and a level to ensure your railings are plumb and aligned. A circular saw or miter saw is essential for cutting wood to size, especially if your deck has unique dimensions or angles. For marking cut lines and measurements, a carpenter’s pencil or fine-tip marker is indispensable. These tools form the core of your installation arsenal, turning a potentially complex project into a manageable DIY endeavor.

Beyond the basics, specialized tools can streamline the process and enhance the final result. A stud finder is useful for locating joists beneath the deck surface, ensuring screws are anchored securely. A clamp set helps hold components in place while you work, particularly when aligning balusters or attaching rails. If your kit includes metal brackets or connectors, a wrench or socket set may be required for tightening bolts. For decks with intricate designs or tight spaces, a jigsaw can handle curved cuts or notches with precision. Investing in these additional tools not only saves time but also reduces the risk of errors that could compromise safety or aesthetics.

While power tools dominate the installation process, hand tools play a critical role in fine-tuning your work. A hammer is essential for tapping components into place without damaging the wood, while a rubber mallet provides a gentler alternative for adjusting fittings. Sandpaper or a power sander smooths rough edges and ensures a professional finish, especially after cutting wood. Safety gear, such as gloves and safety glasses, is non-negotiable, protecting you from splinters, dust, and accidental injuries. These hand tools and safety measures bridge the gap between functionality and craftsmanship, ensuring your deck railing is both sturdy and visually appealing.

For those new to deck installation, renting or borrowing tools can be a cost-effective strategy. Many hardware stores offer tool rental services, allowing access to high-quality equipment like miter saws or power sanders without the expense of purchasing them. Online tutorials or in-store workshops can also familiarize you with tool usage, reducing the learning curve. If precision is a concern, consider hiring a professional for specific steps, such as cutting angles or securing brackets. By combining the right tools with practical knowledge, even a novice can achieve a polished, durable deck railing installation.

Best Places to Purchase Wood Stove Pellets: A Comprehensive Guide

You may want to see also

Frequently asked questions

Yes, complete wood deck rail kits are widely available at home improvement stores, online retailers, and specialty lumberyards.

A complete kit usually includes pre-cut wood balusters, top and bottom rails, posts, hardware (screws, brackets), and sometimes post caps or other accessories.

Many kits offer customization options, such as choosing wood type (e.g., cedar, pressure-treated pine), rail height, and style, but designs may vary by brand.

Yes, most kits include detailed installation instructions, and some brands offer online tutorials or customer support for additional guidance.

Yes, these kits are designed for DIY installation, though basic carpentry skills and tools (e.g., drill, saw) are typically required for assembly and mounting.