If you're looking to replace or upgrade your garage door bottom, you might be wondering if you can buy a prefab wood garage door bottom. Prefabricated wood garage door bottoms are indeed available in the market, offering a convenient and cost-effective solution for homeowners. These prefab options are typically made from high-quality wood materials, such as cedar or hemlock, and are designed to fit standard garage door sizes. They often come with weatherstripping and insulation features, providing improved energy efficiency and protection against the elements. By opting for a prefab wood garage door bottom, you can save time and effort compared to custom-building one, while still achieving a durable and aesthetically pleasing result.

| Characteristics | Values |

|---|---|

| Availability | Yes, prefab wood garage door bottoms are available for purchase. |

| Materials | Typically made from cedar, hemlock, or pine wood. |

| Sizes | Standard sizes available (e.g., 8x7, 9x7, 16x7 feet), but custom sizes can be ordered. |

| Designs | Various styles, including raised panel, recessed panel, and flush designs. |

| Finish Options | Unfinished (ready for staining/painting), pre-stained, or pre-painted. |

| Weather Resistance | Treated wood options available for enhanced durability against moisture and rot. |

| Insulation | Some models come with insulation options for better energy efficiency. |

| Hardware Included | Often includes tracks, rollers, hinges, and handles, but confirm with the supplier. |

| Installation | DIY-friendly, but professional installation recommended for optimal performance. |

| Cost Range | $500 to $2,500+, depending on size, material, and features. |

| Retailers | Available at home improvement stores (e.g., Home Depot, Lowe's) and online (e.g., Amazon, specialty garage door websites). |

| Warranty | Varies by manufacturer, typically 1–5 years on materials and workmanship. |

Explore related products

$2849.05 $2999

What You'll Learn

Prefab wood garage door bottom options

Prefab wood garage door bottoms are readily available, offering a blend of durability, aesthetics, and ease of installation. These pre-assembled components are designed to fit standard garage door sizes, eliminating the need for custom carpentry. Popular materials include cedar, redwood, and treated pine, each offering unique benefits such as rot resistance and natural insulation. Most prefab options come with weatherstripping pre-installed, ensuring a tight seal against drafts and moisture. For those seeking a DIY solution, these bottoms are a practical choice, often requiring only basic tools for installation.

When selecting a prefab wood garage door bottom, consider the climate and exposure of your garage. Cedar and redwood excel in humid or wet environments due to their natural resistance to decay, while treated pine is a cost-effective option for drier climates. Thickness is another critical factor; a 1.5-inch to 2-inch profile provides robust protection without adding excessive weight. Ensure compatibility with your existing garage door by measuring the width and thickness of the bottom seal groove. Many manufacturers offer adjustable lengths, but double-checking dimensions avoids costly returns.

Installation of a prefab wood garage door bottom typically involves sliding the new piece into the existing track and securing it with screws or bolts. If your garage door lacks a track, some kits include a U-shaped bracket system for direct attachment. For optimal performance, apply a wood sealant annually to protect against warping and splitting. Pairing the bottom with a threshold seal enhances water resistance, particularly in flood-prone areas. Always follow the manufacturer’s guidelines, as improper installation can void warranties or compromise functionality.

Comparing prefab wood options to alternatives like aluminum or vinyl reveals distinct advantages. Wood offers superior thermal insulation, reducing energy loss in attached garages. Its natural grain and texture complement traditional or rustic exteriors, whereas metal and vinyl may appear stark or utilitarian. However, wood requires more maintenance, including periodic staining or painting. For those prioritizing longevity with minimal upkeep, composite materials that mimic wood’s appearance are a viable compromise, though they often come at a higher price point.

Incorporating a prefab wood garage door bottom into your home improvement project not only enhances curb appeal but also improves functionality. By addressing common issues like drafts, pests, and water intrusion, it adds value to your property. Whether you’re upgrading an aging garage door or customizing a new build, these pre-assembled components streamline the process, making it accessible even for novice DIYers. With proper care, a wood garage door bottom can last decades, blending timeless style with practical performance.

Best Places to Purchase Quality Wood for Crafting Walking Sticks

You may want to see also

Explore related products

Cost of prefab wood garage door bottoms

Prefab wood garage door bottoms are a practical solution for homeowners looking to replace or upgrade their garage door’s lower section without a full overhaul. The cost of these components varies widely based on material quality, size, and brand. On average, a prefab wood garage door bottom can range from $150 to $500, depending on whether it’s made from solid hardwood, engineered wood, or a composite material. High-end options, such as those crafted from cedar or mahogany, often sit at the upper end of this spectrum due to their durability and aesthetic appeal.

When budgeting for a prefab wood garage door bottom, consider additional expenses beyond the unit price. Installation costs, if hiring a professional, can add $100 to $200 to the total. DIY installation is possible but requires basic carpentry skills and tools like a drill, level, and measuring tape. Weatherstripping, which is often sold separately, is another essential add-on to ensure the door seals properly against the elements, typically costing $20 to $50.

Comparing prefab wood options to other materials, such as steel or aluminum, reveals a trade-off between cost and longevity. While wood offers a classic, warm aesthetic, it generally requires more maintenance, such as staining or sealing every 2–3 years, to prevent warping or rot. Steel or aluminum bottoms are cheaper upfront, ranging from $100 to $300, but lack the natural charm of wood. For those prioritizing low maintenance, composite wood alternatives provide a middle ground, often priced between $200 and $400.

To maximize value, look for prefab wood garage door bottoms with features like rot-resistant treatments or integrated insulation. Some manufacturers offer customizable sizes, which can increase costs but ensure a perfect fit. Online retailers and home improvement stores frequently run promotions or bundle deals, so timing your purchase strategically can save up to 20%. Additionally, check for warranties, as some brands offer coverage for 5–10 years, providing long-term peace of mind.

Ultimately, the cost of a prefab wood garage door bottom reflects its quality, functionality, and aesthetic contribution to your home. By balancing material choice, installation method, and additional features, homeowners can find a solution that fits their budget while enhancing curb appeal and performance. Researching brands, reading reviews, and measuring accurately before purchasing will ensure a worthwhile investment.

Understanding Prop 65 Warnings: Can You Safely Buy Wood Products?

You may want to see also

Explore related products

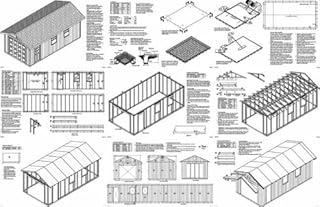

Installation process for prefab wood garage door bottoms

Prefab wood garage door bottoms are readily available for purchase, offering a cost-effective and aesthetically pleasing solution for homeowners. These pre-assembled units simplify the installation process, making it accessible even for DIY enthusiasts. However, proper installation is crucial to ensure functionality, durability, and safety. Here’s a step-by-step guide to installing a prefab wood garage door bottom.

Step 1: Prepare the Garage Door

Begin by cleaning the bottom edge of the garage door to remove any debris, dust, or old sealant. Inspect the door for damage or warping that could interfere with the installation. If the existing bottom seal is still in place, carefully remove it using a flathead screwdriver or pliers. Ensure the surface is smooth and dry before proceeding. This preparation ensures a secure fit and prevents future issues like water infiltration or uneven sealing.

Step 2: Measure and Cut the Prefab Bottom

Prefab wood garage door bottoms typically come in standard lengths, but customization may be necessary. Measure the width of your garage door and mark the prefab bottom accordingly. Use a fine-toothed saw to cut the wood to the exact size, ensuring a clean edge. Double-check the fit by placing the prefab bottom against the door without securing it. Minor adjustments can be made at this stage to avoid gaps or misalignment.

Step 3: Attach the Prefab Bottom

Most prefab wood garage door bottoms come with pre-drilled holes for easy installation. Align the bottom with the door’s edge, ensuring it sits flush against the surface. Secure it using galvanized screws or nails to prevent rust and corrosion. Work from one end to the other, tightening each fastener evenly to avoid warping the wood. If your prefab bottom includes a weather seal, ensure it is properly seated to provide effective insulation against the elements.

Step 4: Seal and Finish

Once the prefab bottom is securely attached, apply a bead of exterior-grade sealant along the edges to create a watertight barrier. This step is critical for preventing moisture damage and prolonging the life of the wood. Allow the sealant to dry according to the manufacturer’s instructions. Finally, apply a coat of weather-resistant stain or paint to match your garage door’s finish. This not only enhances the appearance but also protects the wood from UV rays and weathering.

Cautions and Tips

Avoid over-tightening screws or nails, as this can split the wood. If your garage door operates frequently, consider using a flexible adhesive in addition to fasteners for added stability. Regularly inspect the prefab bottom for signs of wear or damage, especially after extreme weather conditions. For those in humid climates, opt for prefab bottoms treated with a moisture-resistant finish to combat rot and mold.

By following these steps, you can successfully install a prefab wood garage door bottom, enhancing both the functionality and curb appeal of your garage. With proper care, this upgrade will serve you well for years to come.

Should You Invest in Wood Group Shares? A Comprehensive Analysis

You may want to see also

Explore related products

Best brands for prefab wood garage door bottoms

Prefab wood garage door bottoms are a practical solution for homeowners seeking durability, aesthetics, and ease of installation. When selecting a brand, consider factors like material quality, weather resistance, and compatibility with your existing garage door system. Among the top contenders, Clopay stands out for its premium hardwood options, which offer a natural, rustic appeal while ensuring longevity. Their prefab bottoms are treated to resist rot and warping, making them ideal for humid climates. For those prioritizing affordability without compromising quality, Wayne Dalton provides excellent mid-range options. Their engineered wood designs mimic the look of solid wood but come with enhanced durability and lower maintenance requirements.

If customization is your priority, Amarr offers a wide range of prefab wood garage door bottoms with various finishes and textures. Their products are designed to integrate seamlessly with their garage door systems, ensuring a cohesive look. Amarr’s use of sustainable wood sources also appeals to eco-conscious consumers. For a budget-friendly yet reliable option, CHI Overhead Doors delivers prefab bottoms that balance cost and performance. Their products are lightweight yet sturdy, making installation a breeze for DIY enthusiasts.

When comparing brands, pay attention to warranty terms. Clopay and Amarr typically offer longer warranties, reflecting their confidence in product durability. However, Wayne Dalton and CHI Overhead Doors provide competitive pricing, making them attractive for cost-sensitive projects. To ensure the best fit, measure your garage door’s width and thickness before purchasing. Additionally, check for compatibility with your door’s track system to avoid installation headaches.

For optimal performance, pair your prefab wood bottom with weatherstripping from the same brand. This ensures a tight seal, reducing energy loss and protecting against pests and debris. Regular maintenance, such as annual staining or sealing, will prolong the life of your wood bottom, especially in regions with extreme weather conditions. By choosing a reputable brand and following these tips, you can enhance both the functionality and curb appeal of your garage door.

Who Buys Wood Pallets? Industries and Buyers Explained

You may want to see also

Explore related products

Maintenance tips for prefab wood garage door bottoms

Prefab wood garage door bottoms are susceptible to moisture damage, especially in humid climates or areas prone to flooding. To prevent warping, cracking, or rot, inspect the bottom seal regularly for gaps or deterioration. Replace the seal every 3–5 years, depending on exposure, using a weather-resistant rubber or vinyl option. Apply a silicone-based waterproofing sealant to the wood surface annually, focusing on the bottom edge where water tends to pool. This simple routine can extend the lifespan of your prefab wood garage door bottom by up to 50%.

Unlike metal or composite alternatives, wood requires periodic refinishing to maintain its appearance and structural integrity. Sand the surface lightly every 18–24 months to remove old finishes and smooth rough patches. Apply a high-quality exterior wood stain or paint in thin, even coats, allowing proper drying time between applications. Avoid oil-based products, which can trap moisture and accelerate decay. Instead, opt for water-based or acrylic formulas designed for outdoor use. This process not only enhances curb appeal but also acts as a protective barrier against UV rays and temperature fluctuations.

Pests like termites and carpenter ants are drawn to untreated or poorly maintained wood. To deter infestations, keep the garage door bottom clean and free of debris, as clutter provides hiding spots for insects. Treat the wood with a borate-based solution during installation or refinishing, following the manufacturer’s dilution instructions (typically 1 gallon of solution per 100 square feet). Schedule annual inspections with a pest control professional, especially if you live in regions with high termite activity. Early detection and preventive measures can save hundreds, if not thousands, in repair costs.

Over time, the hardware securing the prefab wood garage door bottom may loosen due to vibration or wear. Tighten all screws, bolts, and brackets quarterly, using a torque wrench to avoid over-tightening, which can strip threads or damage the wood. Lubricate moving parts like hinges and rollers with a silicone-based spray, avoiding petroleum-based products that can degrade rubber seals. If the bottom panel sags or misaligns, adjust the tension on the garage door springs according to the manufacturer’s guidelines—a task best left to professionals to prevent injury.

For those in coastal or industrial areas, corrosion from salt or chemicals can compromise metal components attached to the wood bottom. Rinse the garage door monthly with fresh water to remove corrosive residues, and inspect metal parts for rust. Replace corroded hardware promptly, choosing galvanized or stainless steel options for longevity. Applying a rust-inhibiting primer to metal surfaces during installation provides an additional layer of protection. These proactive steps ensure the prefab wood garage door bottom remains functional and aesthetically pleasing despite harsh environmental conditions.

Best Places to Buy Fluted Wood Panels for Stylish Interiors

You may want to see also

Frequently asked questions

Yes, prefab wood garage door bottoms are available for purchase from various manufacturers and suppliers.

A prefab wood garage door bottom offers durability, aesthetic appeal, and ease of installation compared to custom-built options.

Not always. Ensure the prefab bottom matches your garage door’s size, style, and track system before purchasing.

Installation typically involves attaching the prefab bottom to the existing door using screws or adhesive, following the manufacturer’s instructions.

You can purchase them from home improvement stores, online retailers, or directly from garage door manufacturers.