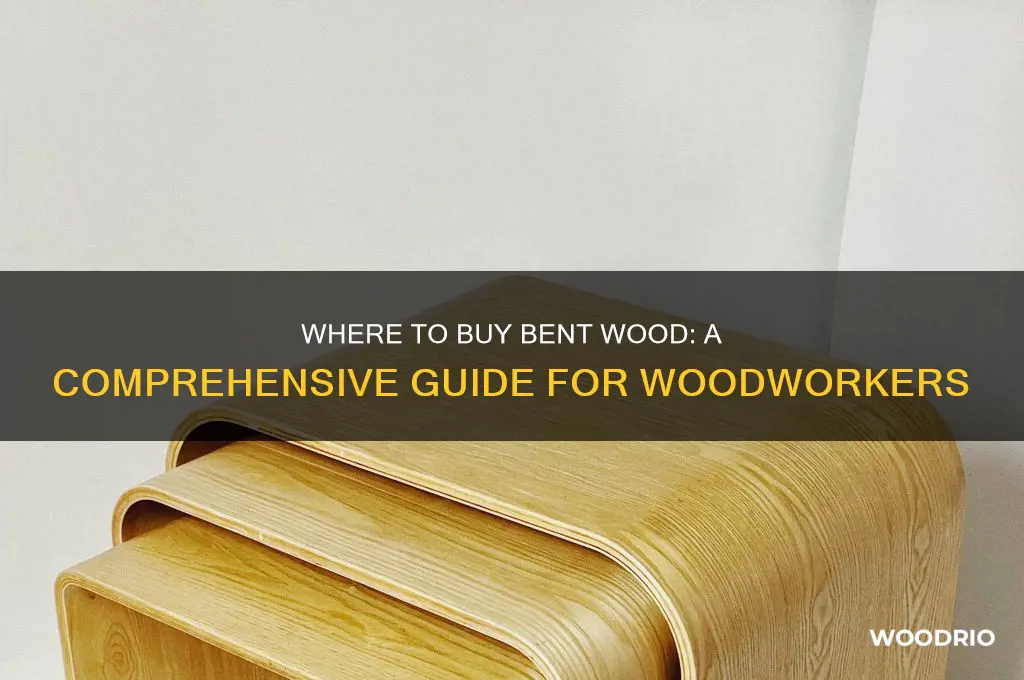

Bent wood, a versatile and aesthetically pleasing material, is widely used in furniture, architecture, and decorative items due to its unique curved shapes and structural integrity. Created by steaming or soaking wood to make it pliable, it is then bent and molded into desired forms before being dried to retain its shape. For those interested in purchasing bent wood, it is readily available from specialty woodworking suppliers, online retailers, and craft stores, often sold as pre-formed pieces, veneers, or custom-made components. Whether for DIY projects, professional craftsmanship, or artistic endeavors, buying bent wood allows individuals to incorporate its elegant curves and natural beauty into their creations.

| Characteristics | Values |

|---|---|

| Availability | Yes, bent wood is available for purchase from various suppliers and manufacturers. |

| Types | Plywood, MDF, solid wood (e.g., oak, maple, walnut), and engineered wood. |

| Bending Methods | Steam bending, kerf bending, laminating, and using flexible wood veneers. |

| Applications | Furniture (chairs, tables, cabinets), architectural elements (curved walls, ceilings), musical instruments, and decorative items. |

| Suppliers | Local lumberyards, specialty wood suppliers, online retailers (e.g., Amazon, eBay), and custom manufacturers. |

| Cost | Varies based on wood type, bending method, and complexity; generally more expensive than straight wood due to labor and materials. |

| Customization | Many suppliers offer custom bending services for specific shapes and sizes. |

| Durability | Depends on the wood type and bending method; properly bent wood can be as durable as straight wood. |

| Environmental Impact | Sustainable options available, such as using FSC-certified wood or recycled materials. |

| Maintenance | Requires regular care similar to straight wood, including sealing and finishing to prevent warping or damage. |

Explore related products

What You'll Learn

- Bent Wood Types: Explore various wood species suitable for bending, like oak, maple, and walnut

- Bending Techniques: Learn methods such as steam bending, kerf bending, and laminating for shaping wood

- Tools for Bending: Discover essential tools like steam boxes, clamps, and bending forms for precision

- Buying Bent Wood: Find suppliers and retailers offering pre-bent wood for furniture and crafts

- DIY Bent Wood: Step-by-step guides and tips for bending wood at home for personal projects

Bent Wood Types: Explore various wood species suitable for bending, like oak, maple, and walnut

Bent wood is a versatile material prized for its strength, flexibility, and aesthetic appeal. When considering which wood species to use for bending, factors like grain pattern, moisture content, and natural flexibility come into play. Oak, maple, and walnut are among the most popular choices, each offering unique characteristics that make them suitable for different applications. Understanding these properties ensures you select the right wood for your project, whether it’s crafting furniture, musical instruments, or architectural elements.

Oak: The Robust Choice

Oak is a hardwood known for its durability and distinctive grain. While it’s less flexible than some other species, white oak, in particular, can be successfully bent when properly prepared. The key lies in its ability to withstand steam bending, a process where the wood is heated with steam to increase pliability. To bend oak effectively, ensure the wood is free of defects and has a moisture content of 25–30%. This species is ideal for structural components like chair legs or curved frames, where its strength and aesthetic appeal shine.

Maple: Smooth and Versatile

Maple, especially soft maple, is a favorite for bentwood projects due to its fine, even grain and ease of bending. Its light color and smooth texture make it a popular choice for furniture and decorative items. When bending maple, aim for a moisture content of 20–25% and use steam or soaking methods to soften the fibers. Hard maple, while denser, can also be bent but requires more effort. This wood’s versatility and workability make it a go-to for both beginners and experienced craftsmen.

Walnut: Elegance in Curves

Walnut is prized for its rich, dark tones and natural beauty, making it a premium choice for bentwood projects. Its moderate flexibility and responsiveness to steam bending allow it to hold intricate shapes well. For best results, use black walnut and maintain a moisture content of 25–30%. This species is particularly suited for high-end furniture, cabinetry, and artistic pieces where its luxurious appearance adds value. However, its cost and availability may influence project scope.

Practical Tips for Bending Success

Regardless of the wood species, successful bending requires careful preparation. Always select straight-grained, defect-free wood to minimize breakage. Use a moisture meter to monitor humidity levels, and apply heat evenly during bending to avoid cracking. For complex curves, consider kerf-cutting or laminating thin strips of wood. Finally, allow bent pieces to dry slowly under clamping pressure to retain their shape. With the right techniques, oak, maple, and walnut can transform into stunning, curved creations that showcase both craftsmanship and natural beauty.

Discover the Best Places to Buy Authentic Olive Wood Products

You may want to see also

Explore related products

Bending Techniques: Learn methods such as steam bending, kerf bending, and laminating for shaping wood

Wood bending is both an art and a science, offering crafters and designers the ability to shape this natural material into curves and contours that defy its rigid reputation. Among the most popular techniques are steam bending, kerf bending, and laminating, each with distinct advantages and applications. Steam bending, for instance, involves heating wood with steam to make it pliable, allowing it to be bent around a form and held until it cools and retains its new shape. This method is ideal for creating smooth, organic curves like those seen in chair backs or boat ribs. The process requires precision—wood must be steamed to a temperature of 212°F (100°C) for 15 to 60 minutes, depending on thickness, and clamped immediately to avoid springback.

Kerf bending, on the other hand, relies on strategic cuts to achieve flexibility. By making a series of parallel cuts (kerfs) along the inside of the bend line, the wood can flex without breaking. This technique is particularly useful for tighter radii or when working with thicker pieces. A key consideration is the depth and spacing of the kerfs—cuts should be no deeper than half the wood’s thickness and spaced no closer than twice the wood’s thickness to maintain structural integrity. Kerf bending is often used in cabinetry, signage, and decorative panels, where the cuts can be concealed or even highlighted for aesthetic effect.

Laminating offers a different approach altogether, involving the gluing of thin wood strips or veneers together to form a curved shape. This method is highly versatile, allowing for complex shapes and large-scale bends that would be impossible with solid wood. The process begins with cutting the wood into thin layers, applying a strong adhesive like epoxy or polyurethane glue, and clamping the pieces around a form. Once cured, the laminated wood retains its shape permanently. This technique is commonly used in furniture making, architectural elements, and even musical instruments, where precision and durability are paramount.

While these techniques enable woodworkers to create stunning bent forms, they each come with challenges. Steam bending requires specialized equipment and careful timing to avoid over-steaming or cracking. Kerf bending demands meticulous planning to ensure the cuts don’t weaken the wood excessively. Laminating, though forgiving in some ways, relies heavily on the quality of the adhesive and the precision of the clamping process. Despite these hurdles, mastering these methods opens up a world of creative possibilities, proving that wood’s limitations are often only as rigid as the techniques applied to it. Whether you’re crafting a bespoke chair or designing an architectural feature, understanding these bending techniques ensures you can shape wood to fit your vision.

Where to Find Extra Wood Dowels for Your IKEA Furniture

You may want to see also

Explore related products

Tools for Bending: Discover essential tools like steam boxes, clamps, and bending forms for precision

Bending wood is an art that demands precision, patience, and the right tools. Among the essentials, the steam box stands out as a cornerstone of the process. This simple yet ingenious device softens wood fibers by exposing them to steam at temperatures around 180°F to 212°F, making the material pliable enough to bend without breaking. A steam box can be as basic as a metal pipe with end caps and a steam source, or a more sophisticated setup with temperature controls for consistent results. For small-scale projects, a DIY steam box using PVC pipes and a steam generator is both affordable and effective. However, always ensure proper ventilation and safety measures when working with steam to avoid burns or accidents.

Clamps are another indispensable tool in the wood bender’s arsenal, serving as the hands that hold the wood in place as it cools and sets into its new shape. Parallel clamps, with their wide jaws and even pressure distribution, are ideal for larger bends, while smaller spring clamps can secure intricate details. The key to successful bending lies in applying uniform pressure along the entire length of the wood. Over-clamping can crush the softened fibers, while under-clamping may result in springback. A practical tip: use scrap wood as padding between the clamps and the workpiece to prevent marring the surface. For complex curves, consider using multiple clamps in tandem to maintain the desired shape.

Bending forms, often overlooked, are the unsung heroes of precision bending. These rigid structures guide the wood into its final shape, ensuring consistency and accuracy. Forms can be made from plywood, MDF, or even metal, depending on the project’s complexity. For tight radius bends, a form with a smooth, rounded edge is crucial to avoid sharp creases or weak spots. When designing a form, account for the wood’s springback by overbending it slightly during the cooling process. Custom forms can be CNC-cut for intricate designs, but for simpler projects, a handmade form with careful measurements will suffice. The takeaway: a well-crafted bending form transforms guesswork into science.

Combining these tools—steam boxes, clamps, and bending forms—creates a workflow that balances tradition with innovation. Start by steaming the wood for 15 to 30 minutes, depending on its thickness and species (hardwoods like oak require more time than softer woods like pine). Transfer the wood to the bending form immediately, using clamps to secure it in place. Allow the wood to cool slowly, either at room temperature or in a controlled environment, to minimize stress and maximize retention of the bend. While these tools are essential, practice and experimentation are equally vital. Each species of wood behaves differently, and mastering its unique characteristics is key to achieving flawless bends. With the right tools and techniques, bending wood becomes not just a skill, but a craft.

Should You Invest in Wood Group Shares? A Comprehensive Analysis

You may want to see also

Explore related products

Buying Bent Wood: Find suppliers and retailers offering pre-bent wood for furniture and crafts

Bent wood, with its graceful curves and structural versatility, is a sought-after material for furniture makers, crafters, and DIY enthusiasts. Fortunately, you don’t need to master the art of steam bending or laminating to incorporate it into your projects—pre-bent wood is readily available from specialized suppliers and retailers. Whether you’re crafting a rocking chair, building a custom guitar, or designing a unique shelving unit, knowing where to source pre-bent wood can save time, effort, and frustration.

Identifying Reliable Suppliers

Start by researching suppliers who specialize in woodworking materials. Companies like *Woodworkers Source* and *Bending Wood LLC* offer a range of pre-bent wood options, including curved slats, arches, and custom shapes. For larger projects, industrial suppliers such as *Formations* provide bent plywood and veneers in bulk. Online marketplaces like Etsy and eBay also host independent sellers offering smaller quantities or unique bends, ideal for crafts or one-off pieces. Always check reviews and request samples to ensure quality and compatibility with your project.

Retailers for Crafters and Hobbyists

If you’re working on a smaller scale, craft-focused retailers like *Rockler Woodworking and Hardware* or *Craftsman Studio* carry pre-bent wood pieces tailored for hobbyists. These retailers often stock bentwood strips for chair seats, curved edges for decorative frames, or pre-shaped components for musical instruments. Local woodworking stores may also offer regional specialties, such as bent hickory for rustic furniture or steamed oak for modern designs. For convenience, many retailers provide online catalogs with detailed specifications, making it easy to match the right bend to your needs.

Custom Orders and Special Requests

For projects requiring precise dimensions or unusual shapes, consider reaching out to suppliers for custom orders. Companies like *Bentwood Designs* specialize in creating bespoke bends based on client specifications. Be prepared to provide detailed drawings or measurements, and factor in additional lead time and costs. Custom bent wood is particularly valuable for restoration projects, where matching historical curves or replicating antique furniture is essential.

Practical Tips for Buying Bent Wood

When purchasing pre-bent wood, prioritize durability and finish. Ask about the bending process—steam-bent wood, for example, retains its shape better than laminated alternatives. Check for cracks, warping, or uneven thickness, especially in longer pieces. If you’re working with a tight budget, consider purchasing factory seconds or offcuts, which are often available at discounted prices. Finally, plan for storage and transportation, as bent wood can be fragile and prone to damage if mishandled.

By tapping into the right suppliers and retailers, buying pre-bent wood becomes a seamless part of your creative process. Whether you’re a professional woodworker or a weekend crafter, the availability of ready-to-use bent wood opens up endless possibilities for bringing curved designs to life.

Best Places to Buy Quality Wood for DIY Shelving Projects

You may want to see also

Explore related products

DIY Bent Wood: Step-by-step guides and tips for bending wood at home for personal projects

Bending wood at home opens up a world of creative possibilities for DIY enthusiasts, from crafting unique furniture to building intricate models. While you can buy pre-bent wood, the satisfaction of shaping it yourself is unmatched. Here’s a step-by-step guide to help you master the art of bending wood in your own workshop.

Step 1: Choose the Right Wood

Not all wood bends equally. Opt for species like oak, cherry, or walnut, which are flexible yet durable. Avoid dense hardwoods like maple or exotic woods that may crack under pressure. Thinner strips (1/4” to 1/2” thick) are easier to bend than thicker pieces. For beginners, start with softer woods like pine to practice before moving to harder varieties.

Step 2: Prepare the Wood

Moisten the wood to increase its pliability. Submerge it in hot water (180°F to 200°F) for 1-2 hours, or use a steam box for 30-60 minutes. Alternatively, apply a damp cloth and heat with an iron. Ensure the wood is evenly heated to prevent uneven bending or splitting. For larger projects, consider using a steam generator for consistent results.

Step 3: Bend and Secure

Work quickly while the wood is pliable. Use a form or mold to shape the wood, clamping it securely in place. For tighter bends, apply gentle pressure with a clamp or weighted object. Hold the shape until the wood cools and sets, which can take several hours. Reinforce the bend with glue or laminating if needed for added strength.

Cautions and Troubleshooting

Overheating can weaken the wood, while underheating may cause it to snap. Always wear gloves when handling hot wood or steam. If the wood cracks, reduce the bending radius or reheat it gradually. For complex curves, consider laminating thin strips of wood instead of bending a single piece.

Bending wood at home is a rewarding skill that elevates DIY projects from ordinary to extraordinary. With the right materials, techniques, and patience, you can create stunning, custom pieces that rival store-bought bent wood. Start small, experiment, and soon you’ll be crafting curves like a pro.

Top Places to Purchase Quality Wood for Your Pergola Project

You may want to see also

Frequently asked questions

Yes, you can buy bent wood ready-made from specialty woodworking suppliers or manufacturers. It’s commonly available in various shapes, such as curves, arches, or custom profiles, for furniture, cabinetry, or decorative purposes.

Bent wood products are often made from flexible wood species like oak, ash, cherry, or beech. These woods are steam-bent or laminated to achieve the desired shape while maintaining strength and durability.

Yes, bent wood is generally more expensive than straight wood due to the labor-intensive process of bending and shaping the material. The cost also depends on the wood species, complexity of the bend, and whether it’s custom-made or pre-fabricated.