When considering woodworking projects, one common question that arises is whether you can buy pre-sanded and finished plywood. The answer is yes—many hardware stores and lumber suppliers offer pre-sanded and finished plywood options, saving time and effort for DIY enthusiasts and professionals alike. Pre-sanded plywood comes with a smooth surface, eliminating the need for additional sanding, while finished plywood is coated with a protective layer, such as paint, varnish, or laminate, making it ready for immediate use in various applications. This convenience is particularly beneficial for projects requiring a polished appearance or specific aesthetic, though it’s important to verify the quality and type of finish to ensure it meets your project’s needs.

| Characteristics | Values |

|---|---|

| Availability | Yes, pre-sanded and finished plywood is widely available. |

| Surface Finish | Smooth, ready-to-use surface without the need for additional sanding. |

| Thickness Options | Typically available in standard thicknesses (e.g., 1/4", 1/2", 3/4"). |

| Sizes | Common sheet sizes (e.g., 4' x 8', 2' x 4'). |

| Grades | Available in various grades (e.g., A, B, C, depending on quality). |

| Core Types | Veneer core, MDF core, or particleboard core options. |

| Finish Types | Natural wood, stained, painted, or laminated finishes. |

| Applications | Furniture, cabinetry, wall paneling, shelving, and DIY projects. |

| Durability | Enhanced durability due to pre-finishing and sanding. |

| Cost | Slightly higher than unfinished plywood due to additional processing. |

| Retailers | Home improvement stores (e.g., Home Depot, Lowe's), lumberyards, online. |

| Brands | Common brands include Columbia, PureBond, and others. |

| Environmental Impact | Some options available with eco-friendly finishes and certifications. |

| Customization | Limited customization; pre-finished options are standardized. |

| Ease of Use | Ready for immediate use, saving time on sanding and finishing. |

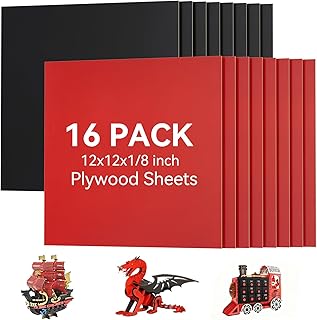

Explore related products

What You'll Learn

Availability of Pre-Sanded Plywood

Pre-sanded plywood is widely available at major home improvement retailers like Home Depot, Lowe's, and specialty lumberyards, offering a time-saving solution for DIY enthusiasts and professionals alike. This type of plywood comes in various grades, thicknesses, and finishes, catering to diverse project needs. For instance, Baltic birch plywood, known for its smooth, void-free surfaces, is often pre-sanded and ready for immediate use in cabinetry or furniture making. When selecting pre-sanded plywood, consider the project’s requirements—whether it needs a fine sanding finish or a more rugged texture—to ensure the material aligns with your goals.

While pre-sanded plywood is convenient, its availability can vary by region and supplier. In urban areas, large retailers typically stock a broad range of options, including pre-finished plywood with veneers or laminates. However, in rural or less populated regions, the selection may be limited, requiring special orders or sourcing from online suppliers. Websites like BuildDirect and Woodworkers Source offer extensive catalogs of pre-sanded plywood, often with detailed specifications and customer reviews to guide your purchase. Always verify the supplier’s return policy and shipping conditions, as plywood is heavy and prone to damage during transit.

For those seeking eco-friendly options, pre-sanded plywood with FSC (Forest Stewardship Council) certification is increasingly available. This ensures the wood is sourced from sustainably managed forests, aligning with green building practices. Additionally, some manufacturers offer pre-sanded plywood treated with low-VOC finishes, reducing harmful emissions and making it suitable for indoor projects like shelving or wall panels. When working with pre-finished plywood, avoid over-sanding, as this can damage the protective coating and compromise the material’s durability.

One practical tip for maximizing the value of pre-sanded plywood is to plan cuts carefully to minimize waste. Use a sharp carbide blade for clean edges and consider applying edge banding for a polished look. If the plywood requires additional finishing, such as staining or sealing, test the product on a scrap piece first to ensure compatibility with the pre-applied surface treatment. By leveraging the convenience of pre-sanded plywood and following these guidelines, you can streamline your workflow and achieve professional results with less effort.

Where to Buy Wooden Barrels: Top Retailers and Online Sources

You may want to see also

Explore related products

Types of Finished Plywood Options

Pre-sanded and finished plywood is readily available, offering a range of options tailored to specific applications and aesthetic preferences. From smooth, paint-ready surfaces to textured, decorative finishes, these products streamline projects by eliminating the need for extensive preparation. Understanding the types of finished plywood available helps in selecting the right material for your needs.

Veneer-Finished Plywood stands out for its natural wood appearance, achieved by applying a thin layer of high-quality wood veneer to the surface. This option is ideal for furniture, cabinetry, and interior design projects where the warmth and texture of real wood are desired. Veneer-finished plywood often comes pre-sanded and sealed, requiring minimal additional work. However, it’s crucial to handle it with care to avoid damaging the delicate veneer layer. For best results, use fine-grit sandpaper (220-grit or higher) if touch-ups are needed before applying a final coat of polyurethane or varnish.

Laminated Plywood features a durable, decorative laminate surface, such as Formica or melamine, bonded under heat and pressure. This type is highly resistant to moisture, stains, and scratches, making it suitable for high-traffic areas like kitchens, bathrooms, and commercial spaces. Laminated plywood is typically pre-finished and requires no additional sanding or sealing. When cutting or shaping laminated plywood, use carbide-tipped blades to prevent chipping the laminate edge. For edge finishing, consider applying matching edge banding for a seamless look.

Paint-Grade Plywood is specifically designed for painting, with a smooth, void-free surface that minimizes grain telegraphing. This option is pre-sanded to a consistent finish, ensuring paint adheres evenly without additional preparation. It’s commonly used for interior walls, trim, and furniture. Before painting, lightly sand the surface with 120-grit sandpaper to remove any manufacturing residues and wipe clean with a tack cloth. Apply a primer coat to enhance paint adhesion and durability, especially in humid environments.

Textured Plywood offers a unique aesthetic with embossed or engraved patterns, mimicking materials like stone, tile, or distressed wood. This type is pre-finished and ready for installation, making it a popular choice for feature walls, accent panels, and decorative applications. While textured plywood is durable, it requires careful handling to preserve the intricate surface. Avoid dragging sharp objects across it and clean with a soft, damp cloth to maintain its appearance.

Each type of finished plywood serves distinct purposes, balancing functionality and aesthetics. By selecting the appropriate option, you can save time, reduce labor, and achieve professional results in your projects. Always consider the intended use, environmental conditions, and desired finish when making your choice.

Best Places to Buy Authentic Pimento Wood for Smoking and Grilling

You may want to see also

Explore related products

Cost Comparison: Pre-Finished vs. Raw

Pre-finished plywood offers a time-saving solution for projects requiring a polished look, but its convenience comes at a price. On average, pre-finished plywood costs 30-50% more than its raw counterpart. For instance, a 4x8 sheet of ¾-inch birch plywood might retail for $40 in its raw form, while the same sheet pre-sanded and finished could range from $60 to $75. This price difference is primarily due to the additional labor and materials involved in the finishing process, including sanding, staining, sealing, and quality control.

When deciding between pre-finished and raw plywood, consider the scale and complexity of your project. For small-scale DIY projects like building a single bookshelf or cabinet, the cost difference might be negligible compared to the time and effort saved by opting for pre-finished plywood. However, for larger projects such as flooring or wall paneling, the cumulative cost of pre-finished materials can become significant. In such cases, purchasing raw plywood and finishing it yourself could yield substantial savings, provided you have the necessary tools and skills.

Another factor to weigh is the quality and consistency of the finish. Pre-finished plywood often boasts a uniform, professional appearance that can be difficult to replicate by hand, especially for beginners. If your project demands a high-end finish or will be prominently displayed, the extra cost of pre-finished plywood may be justified. Conversely, if imperfections or a more rustic look are acceptable, raw plywood allows for customization at a lower cost. For example, you could experiment with different stains, paints, or distressing techniques to achieve a unique aesthetic.

To make an informed decision, calculate the total cost of both options, including materials, tools, and labor. If you choose raw plywood, factor in the expense of sandpaper, stain, sealant, and any specialized equipment like a belt sander or sprayer. Additionally, consider the time investment required for sanding and finishing, which can add hours or even days to your project timeline. For those with limited experience, the learning curve associated with finishing plywood might also impact the final result, potentially necessitating additional materials or professional assistance.

Ultimately, the choice between pre-finished and raw plywood hinges on your budget, project requirements, and personal preferences. While pre-finished plywood offers convenience and consistency, raw plywood provides flexibility and potential cost savings for those willing to invest time and effort. By carefully evaluating these factors, you can select the option that best aligns with your goals and resources, ensuring a successful and cost-effective outcome for your woodworking project.

Best Places to Purchase High-Quality Wood Shingles for Your Roof

You may want to see also

Explore related products

Common Brands Offering Pre-Sanded Plywood

Pre-sanded and finished plywood is a game-changer for DIY enthusiasts and professionals alike, offering a smooth, ready-to-use surface that saves time and effort. Several reputable brands have recognized this demand and now offer high-quality pre-sanded plywood options. Among these, Columbia Forest Products stands out as a leader in the industry. Known for their PureBond formaldehyde-free technology, Columbia’s pre-sanded plywood is not only smooth but also environmentally friendly. Their panels are available in various thicknesses and sizes, making them versatile for cabinetry, furniture, and interior projects. The pre-sanding ensures a consistent finish, reducing the need for additional prep work.

Another notable brand is Roseburg, which offers pre-sanded plywood under their Apex line. Roseburg’s products are prized for their durability and uniformity, with a focus on structural integrity. Their pre-sanded panels are ideal for applications requiring a high-quality finish, such as shelving or wall paneling. The brand’s commitment to sustainability is evident in their use of responsibly sourced materials, making them a top choice for eco-conscious builders. For those seeking a premium option, Hardwood Plywood & Veneer provides pre-sanded plywood with a luxurious finish. Their products are often used in high-end furniture and architectural projects, where precision and aesthetics are paramount.

For budget-conscious buyers, Georgia-Pacific offers pre-sanded plywood that balances affordability with quality. Their Plytanium line is widely available at home improvement stores and is suitable for general-purpose applications. While it may not have the same level of refinement as higher-end brands, it’s a reliable option for projects where cost is a primary concern. Lastly, Boise Cascade deserves mention for their BC Sanded Plywood, which is known for its smooth surface and ease of use. This brand is particularly popular among contractors for its consistency and availability in standard sizes.

When selecting a brand, consider the specific requirements of your project. For instance, if sustainability is a priority, Columbia or Roseburg might be the best fit. If you’re working on a high-end project, Hardwood Plywood & Veneer’s premium finish could be worth the investment. Practical tips include checking the plywood’s grade and thickness to ensure it meets your needs, and verifying the sanding quality by running your hand over the surface to detect any imperfections. With these brands, pre-sanded plywood is no longer a niche product but a widely accessible solution for achieving professional results with minimal effort.

Best Places to Buy Kindling Wood for Cozy Fires

You may want to see also

Explore related products

Best Uses for Pre-Finished Plywood

Pre-finished plywood is a game-changer for DIY enthusiasts and professionals alike, offering a smooth, ready-to-use surface that saves time and effort. Its factory-applied finish ensures consistency and durability, making it ideal for projects where appearance and longevity are key. Whether you're crafting furniture, cabinetry, or wall paneling, pre-finished plywood eliminates the need for sanding and staining, allowing you to focus on assembly and design.

For furniture makers, pre-finished plywood is a top choice due to its versatility and aesthetic appeal. Its smooth, uniform surface enhances the look of modern and minimalist designs, while its durability makes it suitable for high-traffic pieces like tables and chairs. When selecting pre-finished plywood for furniture, opt for a thickness of at least ¾ inch to ensure structural integrity. Pair it with edge banding for a polished look, and consider using waterproof finishes for pieces exposed to moisture, such as bathroom vanities or kitchen cabinets.

In interior design, pre-finished plywood shines as a cost-effective alternative to traditional hardwood panels. Its clean, contemporary appearance makes it perfect for accent walls, ceiling treatments, or room dividers. For a seamless installation, use construction adhesive and finish nails, ensuring joints are staggered for stability. When working with large panels, enlist a helper to avoid damage during handling. Pre-finished plywood’s ease of installation and low maintenance make it a favorite for both residential and commercial spaces.

For outdoor projects, pre-finished plywood with a weather-resistant coating is a practical solution. While it’s not as durable as marine-grade plywood, it’s suitable for structures like garden sheds, planters, or decorative screens when properly sealed. Apply an additional coat of exterior-grade polyurethane to extend its lifespan, and avoid prolonged exposure to standing water. Its pre-sanded surface ensures paint or stain adheres evenly, giving you a professional finish with minimal effort.

In summary, pre-finished plywood’s best uses span furniture, interior design, and outdoor projects, offering a blend of convenience, durability, and aesthetic appeal. By choosing the right thickness, finish, and application techniques, you can maximize its potential while minimizing labor. Whether you’re a seasoned craftsman or a weekend warrior, pre-finished plywood simplifies the process, letting you achieve high-quality results with less hassle.

Where to Buy Retique It Liquid Wood: Top Retailers & Online Stores

You may want to see also

Frequently asked questions

Yes, pre-sanded and finished plywood is widely available at most hardware stores, lumberyards, and home improvement retailers.

Pre-sanded and finished plywood saves time and effort by eliminating the need for sanding and finishing, ensuring a smooth, ready-to-use surface for projects like cabinetry, furniture, or interior paneling.

Yes, pre-sanded plywood can come with various finishes, including natural, stained, painted, or sealed options, depending on the manufacturer and intended application.