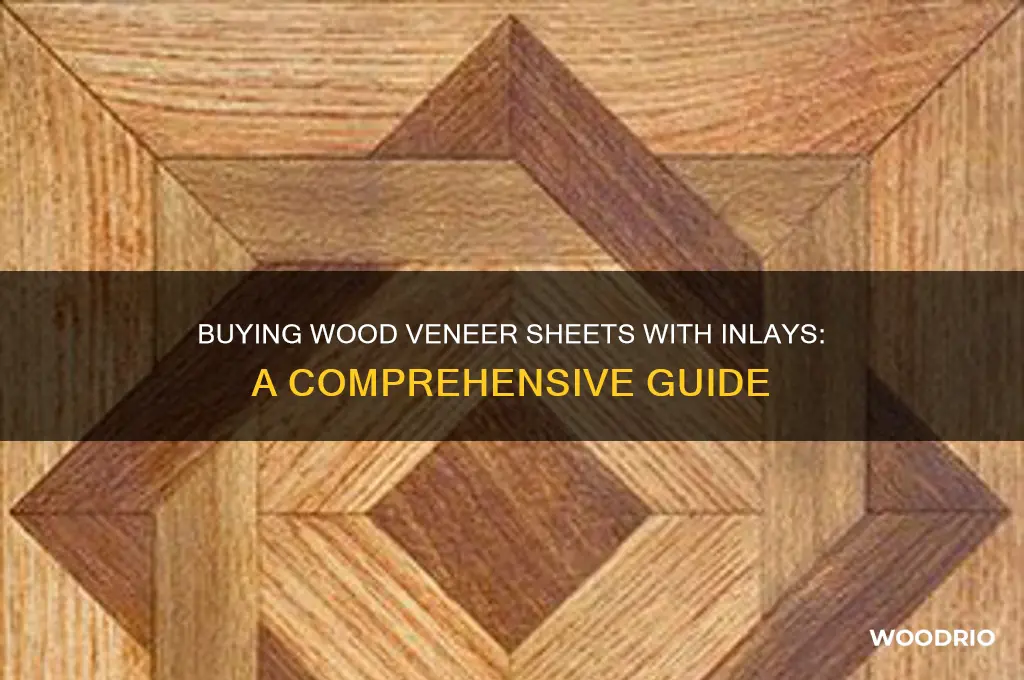

Wood veneer sheets with inlays offer a sophisticated and customizable option for enhancing interior design and furniture projects. These sheets combine the natural beauty of wood with intricate inlaid patterns, often made from contrasting materials like metals, resins, or other wood species, to create visually striking surfaces. Whether for cabinetry, wall panels, or decorative accents, wood veneer sheets with inlays provide a luxurious and unique aesthetic. They are available in various styles, finishes, and sizes, catering to both modern and traditional tastes. When considering a purchase, it’s essential to explore reputable suppliers who specialize in high-quality veneers and inlay craftsmanship to ensure durability and precision in the final product.

| Characteristics | Values |

|---|---|

| Availability | Yes, wood veneer sheets with inlays are available for purchase. |

| Materials | Various wood species (e.g., oak, walnut, maple, mahogany) combined with inlay materials like brass, copper, mother-of-pearl, or other woods. |

| Thickness | Typically ranges from 0.6mm to 3mm, depending on the manufacturer and intended use. |

| Sizes | Standard sheet sizes (e.g., 4' x 8', 2' x 8') and custom sizes available upon request. |

| Inlay Designs | Geometric patterns, borders, marquetry, custom designs, and traditional motifs. |

| Applications | Furniture making, cabinetry, wall paneling, decorative accents, and restoration projects. |

| Finish Options | Unfinished, pre-finished, or customizable finishes (e.g., stained, lacquered, oiled). |

| Durability | High durability, depending on the wood species and inlay material used. |

| Cost | Varies widely based on wood species, inlay complexity, and sheet size; generally more expensive than plain veneer. |

| Suppliers | Specialty woodworking stores, online retailers (e.g., Woodcraft, eBay, Etsy), and custom veneer manufacturers. |

| Customization | Many suppliers offer custom inlay designs and sizes to meet specific project needs. |

| Installation | Requires adhesive application and careful alignment for precise inlay placement. |

| Maintenance | Regular cleaning and occasional refinishing to preserve appearance and longevity. |

Explore related products

What You'll Learn

Types of wood veneer sheets with inlays

Wood veneer sheets with inlays offer a blend of artistry and functionality, transforming ordinary surfaces into bespoke masterpieces. Among the most sought-after types are marquetry veneers, where intricate patterns are created by assembling contrasting wood species or materials like metals and shells. For instance, a walnut veneer sheet might feature inlaid maple or ebony motifs, adding depth and visual interest. These sheets are ideal for furniture, cabinetry, or wall panels, combining durability with aesthetic appeal.

For those seeking a more modern twist, laser-cut inlay veneers provide precision and versatility. Using advanced technology, intricate designs—geometric shapes, logos, or even custom artwork—are cut into the veneer surface and filled with contrasting materials. This method allows for finer details and is particularly popular in commercial interiors or high-end residential projects. However, it’s crucial to ensure the base veneer is thick enough to accommodate the inlay without compromising structural integrity.

Banded inlay veneers are another classic option, characterized by thin strips of contrasting wood inserted into grooves cut into the veneer surface. Often seen in traditional furniture styles, such as Chippendale or Hepplewhite, these veneers exude timeless elegance. For example, a mahogany veneer might be accented with thin bands of satinwood or holly. When working with banded inlays, precision is key—ensure the grooves are evenly spaced and the inlay strips are securely glued to prevent gaps or misalignment.

Finally, metal-inlaid veneers merge organic warmth with industrial sophistication. Brass, copper, or aluminum inlays are embedded into wood veneer sheets, creating striking contrasts and textures. This type is particularly popular in contemporary designs, such as tabletops or decorative panels. To maintain the metal’s luster, periodic polishing is recommended, and it’s advisable to avoid harsh chemicals that could tarnish the surface.

Whether you’re a designer, craftsman, or DIY enthusiast, understanding these types of wood veneer sheets with inlays allows you to select the perfect option for your project. Each style offers unique benefits, from the intricate detail of marquetry to the bold statement of metal inlays. With careful planning and execution, these veneers can elevate any space, blending artistry with practicality.

Best Places to Buy Slab Wood for Your Next Project

You may want to see also

Explore related products

Where to buy wood veneer sheets with inlays

Wood veneer sheets with inlays are a sophisticated way to elevate interior design projects, offering both aesthetic appeal and durability. If you’re seeking these specialized materials, start with niche suppliers like Woodcraft or Exotic Veneer, which cater to woodworking enthusiasts and professionals. These retailers often carry pre-designed inlay patterns or custom options, allowing you to match specific project requirements. For example, Woodcraft’s selection includes laser-cut inlays in geometric or floral designs, ideal for furniture or cabinetry.

For a broader selection, explore online marketplaces such as eBay or Etsy, where independent artisans and small businesses offer unique, handcrafted veneer sheets. Etsy, in particular, is a treasure trove for one-of-a-kind inlays, from marquetry designs to modern abstract patterns. When purchasing here, scrutinize seller reviews and request samples to ensure quality. Prices vary widely, with custom pieces ranging from $50 to $300 per sheet, depending on complexity and material.

If you prioritize sustainability, consider suppliers like EcoVeneer or Responsible Wood, which offer FSC-certified veneer sheets with inlays. These options ensure the materials are sourced ethically, appealing to eco-conscious buyers. For instance, EcoVeneer’s reclaimed wood inlays add a rustic, environmentally friendly touch to projects. However, sustainable options may come at a premium, typically 20–30% higher than standard veneer sheets.

For large-scale or commercial projects, wholesale distributors like Columbia Forest Products or Timber Products provide bulk purchasing options. These suppliers often work directly with manufacturers, offering competitive pricing and customization capabilities. When ordering in bulk, inquire about minimum order quantities, which usually start at 50 sheets. Additionally, request detailed specifications, such as veneer thickness (typically 0.6mm to 1.5mm) and adhesive compatibility, to ensure seamless application.

Finally, don’t overlook local specialty woodworking stores or lumberyards, which may stock or order veneer sheets with inlays tailored to regional preferences. Visiting these stores allows you to inspect the material firsthand and receive expert advice on installation techniques. For example, using a veneer hammer and contact cement ensures a smooth, bubble-free application. Combining online research with local resources maximizes your chances of finding the perfect inlaid veneer for your project.

Where to Buy Wood Ash: Uses, Benefits, and Purchasing Options

You may want to see also

Explore related products

$19.99

Cost of wood veneer sheets with inlays

Wood veneer sheets with inlays offer a luxurious aesthetic, blending natural beauty with intricate craftsmanship. However, this elegance comes at a price. The cost of these sheets varies widely, influenced by factors such as the type of wood, complexity of the inlay design, and the manufacturer’s reputation. For instance, a basic maple veneer with simple geometric inlays might start around $50 per sheet, while exotic woods like ebony or rosewood with custom, hand-crafted inlays can soar to $500 or more. Understanding these price drivers is essential for budgeting and selecting the right product for your project.

When considering cost, the type of wood veneer is a primary determinant. Domestic woods like oak or cherry are generally more affordable, while imported or rare species like macassar ebony or burl walnut command premium prices. Inlays further escalate costs, as they require skilled labor and precision. Laser-cut inlays are less expensive than hand-crafted ones, but the latter offer unparalleled detail and uniqueness. For example, a 4x8 sheet of walnut veneer with laser-cut marquetry might cost $200, whereas a custom, hand-inlaid design could easily exceed $1,000.

Another factor affecting cost is the thickness and quality of the veneer. Standard veneer sheets are typically 0.6mm thick, but thicker options (up to 2mm) provide greater durability and are priced higher. Additionally, the substrate material—whether MDF, plywood, or solid wood—impacts the overall expense. High-quality substrates ensure better adhesion and longevity but add to the cost. For instance, a sheet with a premium hardwood substrate can be 30-50% more expensive than one with a basic MDF base.

For those on a budget, there are cost-saving strategies. Pre-designed inlay patterns are more affordable than custom designs, and purchasing in bulk often yields discounts. DIY enthusiasts can also explore veneer repair kits or smaller sheets for accent pieces, reducing material costs. However, cutting corners on quality may compromise the final result, so balance affordability with the desired outcome.

In conclusion, the cost of wood veneer sheets with inlays reflects the artistry and materials involved. By understanding the factors driving price—wood type, inlay complexity, thickness, and substrate—you can make informed decisions. Whether opting for a high-end custom piece or a budget-friendly option, the investment enhances interiors with timeless elegance. Always request samples and compare quotes to ensure the best value for your project.

Where to Buy Wood Ducks: A Guide for Enthusiasts

You may want to see also

Explore related products

$21.99

Customization options for inlaid veneer sheets

Wood veneer sheets with inlays offer a unique blend of artistry and functionality, allowing designers and craftsmen to elevate interiors with bespoke elegance. Customization options abound, from material selection to intricate patterns, ensuring each piece is a singular creation. The first step in tailoring inlaid veneer sheets involves choosing the base veneer and inlay materials. Exotic woods like ebony, rosewood, or maple can be paired with contrasting metals, resins, or even mother- pearl for striking visual effects. For instance, a walnut veneer base with brass inlays creates a warm, luxurious aesthetic, while a birch veneer with turquoise resin inlays evokes a modern, coastal vibe. Material compatibility is key—ensure the inlay material’s expansion and contraction rates align with the veneer to prevent cracking over time.

Once materials are selected, the design phase opens up endless possibilities. Geometric patterns, such as herringbone or chevron, offer timeless sophistication, while organic motifs like leaves or waves introduce fluidity. For a truly personalized touch, incorporate laser-cut initials, family crests, or custom logos. Advanced technology allows for precision inlays as fine as 1mm, enabling intricate details without compromising structural integrity. When designing, consider the scale of the pattern relative to the application—a large-scale design may overwhelm a small cabinet door, while a delicate pattern could get lost on expansive wall panels.

The inlay technique itself is another avenue for customization. Traditional methods involve hand-cutting and fitting each piece, a labor-intensive process that yields unparalleled craftsmanship. Alternatively, CNC machining offers speed and consistency for complex designs, though it may lack the handmade charm. A hybrid approach, combining machine precision with hand finishing, strikes a balance between efficiency and artistry. For durability, ensure the inlays are flush with the veneer surface and sealed with a compatible finish to protect against moisture and wear.

Finally, the finish applied to the inlaid veneer sheet can dramatically alter its appearance and longevity. Oil-based finishes enhance the natural grain and warmth of the wood, while polyurethane provides a durable, high-gloss sheen. For a matte, contemporary look, consider a water-based sealant. When applying finishes, test on a sample piece to ensure compatibility with both the veneer and inlay materials. Proper finishing not only preserves the beauty of the piece but also ensures it withstands the test of time, making customization a lasting investment.

Where to Buy Bamboo Wood: A Sustainable and Stylish Choice

You may want to see also

Explore related products

$29.99 $34.99

Best uses for wood veneer sheets with inlays

Wood veneer sheets with inlays offer a blend of elegance and versatility, making them ideal for high-end furniture restoration. When reviving antique pieces or updating modern designs, these sheets provide a cost-effective way to achieve intricate patterns without the expense of solid wood. For example, a mid-century dresser can be transformed by applying a veneer sheet with marquetry inlays, preserving its structural integrity while enhancing its aesthetic appeal. The key is to match the inlay pattern to the piece’s original style, ensuring a seamless integration that honors its history.

In architectural applications, wood veneer sheets with inlays serve as a striking solution for feature walls and ceiling panels. Their thin profile allows for easy installation over existing surfaces, minimizing disruption during renovations. A geometric inlay design in a walnut veneer can add warmth and sophistication to a contemporary office space, while a floral pattern in maple veneer can create a timeless focal point in a residential foyer. To maximize durability, apply a protective finish like polyurethane, especially in high-traffic areas.

For custom cabinetry, wood veneer sheets with inlays elevate both functionality and design. Kitchen cabinets, for instance, can incorporate inlaid borders or motifs that complement the overall decor theme. A herringbone inlay in oak veneer adds texture and visual interest, while a minimalist linear pattern in teak veneer suits modern kitchens. Ensure precise measurements and use a strong adhesive to prevent peeling or warping over time. This approach combines practicality with artistry, making even utilitarian spaces feel bespoke.

Crafters and hobbyists can leverage wood veneer sheets with inlays for small-scale projects like jewelry boxes, picture frames, or decorative trays. The inlays add a professional touch, turning simple items into cherished gifts or marketable products. For instance, a jewelry box with a delicate floral inlay in cherry veneer becomes a keepsake. When working on such projects, use a sharp utility knife for clean cuts and a small roller to ensure even adhesion. This method allows creativity to flourish without requiring advanced woodworking skills.

Finally, wood veneer sheets with inlays are perfect for creating statement pieces in hospitality settings. Hotels, restaurants, and boutiques can use them for reception desks, bar fronts, or room dividers to establish a memorable ambiance. A bold, abstract inlay in ebony veneer can evoke luxury, while a subtle wave pattern in birch veneer conveys tranquility. Pair these elements with strategic lighting to highlight the inlays, enhancing their impact. This approach not only impresses guests but also reinforces brand identity through thoughtful design.

Revive Retro Charm: Best Sources for 70s Wood Paneling Today

You may want to see also

Frequently asked questions

Yes, wood veneer sheets with inlays are available for purchase from specialty woodworking suppliers, online retailers, and custom veneer manufacturers.

Common inlays include geometric patterns, marquetry designs, and decorative motifs using contrasting wood species, metals, or other materials.

Yes, many suppliers offer custom inlay services, allowing you to create unique designs tailored to your specific project needs.

These sheets are often used for furniture, cabinetry, wall paneling, and decorative accents to add elegance and visual interest to woodworking projects.