Sawmills play a crucial role in the timber industry by processing raw logs into lumber and other wood products, but a common question arises: do sawmills actually buy wood? The answer is yes, sawmills often purchase wood directly from landowners, loggers, or timber suppliers to ensure a steady supply of raw materials for their operations. They typically buy logs based on factors such as species, size, quality, and market demand, with prices influenced by current timber market conditions. By buying wood, sawmills support local economies, sustain their production, and contribute to the broader forestry and construction industries. However, the specifics of their purchasing practices can vary depending on regional regulations, environmental standards, and the sawmill’s business model.

| Characteristics | Values |

|---|---|

| Do Sawmills Buy Wood? | Yes, sawmills primarily buy wood as their raw material for processing into lumber and other wood products. |

| Types of Wood Purchased | Hardwoods (e.g., oak, maple, cherry), softwoods (e.g., pine, spruce, fir), and specialty woods depending on market demand. |

| Preferred Wood Sources | Standing timber from forests, logs from logging operations, and sometimes urban wood (e.g., trees removed from residential areas). |

| Quality Requirements | Straight, healthy logs with minimal defects (e.g., knots, cracks, rot) to maximize yield and product quality. |

| Volume Requirements | Large quantities, often measured in board feet or cubic meters, to justify processing costs. |

| Pricing Factors | Species, diameter, length, quality, market demand, and transportation costs. |

| Payment Terms | Typically paid per unit volume (e.g., per ton, per board foot) or through contracts with logging companies. |

| Sustainability Considerations | Many sawmills prioritize sustainably harvested wood, certified by organizations like FSC (Forest Stewardship Council). |

| Seasonal Influence | Buying may increase during logging seasons and decrease in harsh weather conditions. |

| Geographic Factors | Sawmills often buy locally to reduce transportation costs, but may source from farther regions for specific wood types. |

| Market Trends | Demand for wood fluctuates based on construction, furniture, and other wood product industries. |

| Regulatory Compliance | Must adhere to local and international regulations regarding timber sourcing and environmental impact. |

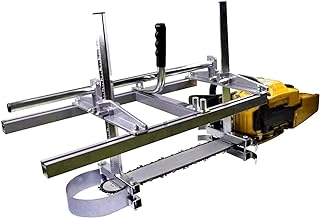

Explore related products

What You'll Learn

- Types of Wood Sawmills Purchase: Sawmills buy hardwoods, softwoods, logs, timber, and specialty wood species for processing

- Wood Sourcing Methods: Sawmills source wood from forests, logging companies, tree farms, and urban tree removal

- Quality Standards for Wood: Sawmills require wood to meet specific size, moisture, and defect-free standards for milling

- Pricing and Contracts: Sawmills negotiate prices based on wood volume, quality, and long-term supply contracts with sellers

- Sustainable Wood Practices: Many sawmills prioritize buying sustainably harvested wood to meet eco-friendly certifications

Types of Wood Sawmills Purchase: Sawmills buy hardwoods, softwoods, logs, timber, and specialty wood species for processing

Sawmills are the backbone of the timber industry, transforming raw wood into usable materials for construction, furniture, and countless other applications. At the heart of their operation is the procurement of various wood types, each serving distinct purposes. Hardwoods, such as oak, maple, and walnut, are prized for their durability and aesthetic appeal, making them ideal for high-end furniture, flooring, and cabinetry. Sawmills often purchase these species at premium prices due to their demand in luxury markets. Conversely, softwoods like pine, spruce, and cedar are more affordable and versatile, commonly used in framing, pallets, and paper production. Understanding the market demand for these categories is crucial for sawmills to optimize their inventory and profitability.

The raw material for sawmills typically begins as logs, which are harvested from forests or plantations. Logs are classified by diameter, length, and species, with larger, straighter logs commanding higher prices. Once delivered to the sawmill, logs are debarked and cut into timber, the primary product processed for sale. Timber is graded based on quality, with factors like knots, grain pattern, and moisture content influencing its end use. For instance, high-grade timber is reserved for structural beams or fine woodworking, while lower grades may be used for fencing or packaging materials. Efficient log-to-timber conversion is a key metric for sawmill operations, as it directly impacts yield and waste reduction.

Beyond the common hardwoods and softwoods, sawmills also seek out specialty wood species to meet niche market demands. Exotic woods like teak, mahogany, and ebony are highly sought after for their unique colors, textures, and resistance to decay. These species are often used in luxury items such as boat building, musical instruments, and decorative veneers. However, sourcing specialty woods requires careful consideration of sustainability and legality, as many are protected under international regulations like CITES. Sawmills must balance the profitability of these high-value species with ethical procurement practices to maintain their reputation and comply with laws.

For sawmill operators and wood suppliers, understanding the processing requirements of different wood types is essential. Hardwoods, for example, are denser and require sharper blades and slower cutting speeds to avoid damage. Softwoods, while easier to process, can vary widely in resin content, which affects blade maintenance. Specialty woods often demand additional steps, such as kiln drying to stabilize moisture levels or surface treatments to enhance durability. Investing in the right equipment and techniques ensures that the final product meets industry standards and customer expectations.

In summary, sawmills purchase a diverse range of wood types, from hardwoods and softwoods to specialty species, each with unique characteristics and applications. Logs and timber form the foundation of their operations, with processing methods tailored to maximize quality and efficiency. By staying informed about market trends, sustainability practices, and processing techniques, sawmills can thrive in a competitive industry while contributing to the responsible use of forest resources. Whether supplying construction sites or crafting bespoke furniture, the types of wood a sawmill buys are directly tied to its ability to meet diverse customer needs.

Where to Buy Nitro Wood Magnum: Top Retailers and Online Stores

You may want to see also

Explore related products

$139.98 $169.98

Wood Sourcing Methods: Sawmills source wood from forests, logging companies, tree farms, and urban tree removal

Sawmills are the backbone of the timber industry, transforming raw logs into lumber for construction, furniture, and countless other applications. But where does all this wood come from? The answer lies in a diverse network of sourcing methods, each with its own advantages and considerations.

From vast, ancient forests to carefully managed tree farms, and even urban landscapes, sawmills tap into a variety of resources to meet the ever-growing demand for wood products.

Forests: The Traditional Source

For centuries, natural forests have been the primary source of timber for sawmills. These ecosystems, ranging from dense old-growth forests to younger, managed woodlands, provide a wide variety of tree species and sizes. Logging companies carefully select trees based on factors like diameter, straightness, and species, ensuring sustainable harvesting practices to maintain forest health. While this method provides high-quality wood, it raises concerns about deforestation and habitat loss, necessitating responsible forest management practices.

Logging Companies: The Middlemen

Logging companies act as intermediaries between forests and sawmills. They specialize in felling, limbing, and transporting trees from the forest to the mill. These companies employ skilled workers and utilize specialized equipment to efficiently harvest timber while minimizing environmental impact. Their expertise in forest management and logistics is crucial for ensuring a steady supply of wood to sawmills.

Tree Farms: Sustainable Solutions

Tree farms, also known as plantations, offer a more controlled and sustainable approach to wood sourcing. These managed forests are specifically planted and cultivated for timber production. Species selection, planting density, and harvesting schedules are carefully planned to maximize yield and minimize environmental impact. Tree farms provide a reliable source of wood with predictable quality and quantity, contributing to long-term sustainability in the timber industry.

Urban Tree Removal: A Hidden Resource

An often overlooked source of wood for sawmills is urban tree removal. When trees in cities and towns become diseased, damaged, or pose safety hazards, they are often removed. Instead of being discarded as waste, this wood can be salvaged and processed by sawmills. This practice not only provides a valuable resource but also reduces waste and promotes urban sustainability.

Choosing the Right Source:

The choice of wood sourcing method depends on various factors, including the type of wood required, availability, cost, and environmental considerations. Sawmills must carefully evaluate each option, balancing economic viability with responsible environmental practices. By diversifying their sourcing methods and embracing sustainable practices, sawmills can ensure a continuous supply of wood while protecting our precious forest resources for future generations.

Where to Buy Teak Wood: Top Sources and Tips for Quality Purchases

You may want to see also

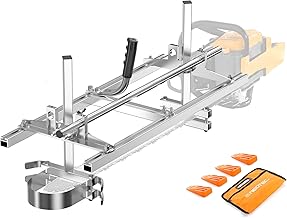

Explore related products

$79

Quality Standards for Wood: Sawmills require wood to meet specific size, moisture, and defect-free standards for milling

Sawmills are highly selective about the wood they purchase, demanding strict adherence to quality standards that ensure optimal milling efficiency and end-product value. Wood must meet precise size specifications, typically ranging from 8 to 20 inches in diameter for logs, with lengths varying between 8 and 16 feet. These dimensions are critical because they align with the capacity of sawmill equipment and the market demand for lumber products. Deviations from these size requirements can lead to inefficiencies in processing or produce waste, reducing profitability for both the sawmill and the supplier.

Moisture content is another non-negotiable criterion, with sawmills generally requiring wood to have a moisture level between 12% and 19%. This range is essential for preventing warping, cracking, or shrinkage during the drying and milling processes. Wood with excessive moisture can damage sawmill blades and machinery, while overly dry wood may be brittle and prone to defects. Suppliers often use kilns or air-drying methods to achieve the desired moisture content before delivery, ensuring the wood meets these stringent standards.

Defect-free wood is paramount for sawmills, as imperfections such as knots, splits, decay, or insect damage can compromise the structural integrity of the final product. Sawmills typically reject logs with defects larger than 1 inch in diameter or those that exceed 10% of the log’s surface area. Suppliers must carefully inspect and sort their wood to meet these criteria, as defective material not only reduces yield but also diminishes the quality of lumber produced. Investing in proper harvesting and handling practices can significantly reduce defects, making the wood more attractive to sawmills.

Meeting these quality standards is not just a requirement but a strategic advantage for wood suppliers. Sawmills are willing to pay premium prices for wood that aligns with their specifications, as it streamlines their operations and maximizes output. Suppliers who consistently deliver high-quality wood build stronger relationships with sawmills, often securing long-term contracts and preferential pricing. Conversely, those who fail to meet these standards risk rejection or lower prices, underscoring the importance of precision and attention to detail in the wood supply chain.

In summary, sawmills’ quality standards for wood are rigorous and purposeful, designed to optimize milling processes and produce high-value lumber. Suppliers must meticulously manage size, moisture content, and defect levels to meet these requirements. By doing so, they not only ensure their wood is accepted by sawmills but also position themselves as reliable partners in a competitive market. Understanding and adhering to these standards is essential for anyone looking to sell wood to sawmills successfully.

Discover Unique Exotic Wood Suppliers Near You: A Comprehensive Guide

You may want to see also

Explore related products

Pricing and Contracts: Sawmills negotiate prices based on wood volume, quality, and long-term supply contracts with sellers

Sawmills operate on a delicate balance of supply and demand, where the price of wood is not fixed but negotiated based on several critical factors. Volume plays a pivotal role—larger quantities often secure lower prices per unit, as sawmills benefit from economies of scale. However, quality is equally essential; wood with fewer defects, consistent grain, and optimal moisture content commands higher prices. Long-term supply contracts further stabilize pricing for both parties, ensuring sawmills have a steady stream of raw material while sellers gain predictable revenue. This dynamic negotiation process reflects the intricate relationship between sawmills and wood suppliers, where mutual benefit is the ultimate goal.

For sellers, understanding the pricing structure is key to maximizing profits. Sawmills typically assess wood quality using grading systems that evaluate factors like knot size, straightness, and species. For instance, hardwoods like oak or maple often fetch higher prices than softwoods like pine, but even within species, grades can vary significantly. Sellers can improve their negotiating position by ensuring their wood meets or exceeds industry standards. Practical tips include proper harvesting techniques, timely delivery to prevent degradation, and maintaining detailed records of wood characteristics. These steps not only enhance quality but also provide transparency, fostering trust in long-term contracts.

Long-term supply contracts are a cornerstone of sawmill operations, offering stability in an often volatile market. These agreements typically span several years and include clauses for price adjustments based on market conditions, ensuring fairness for both parties. For sellers, such contracts provide a guaranteed outlet for their wood, reducing the risk of unsold inventory. Sawmills, in turn, secure a reliable supply chain, which is critical for meeting production demands. However, sellers must carefully negotiate terms to avoid being locked into unfavorable prices. Including escalation clauses tied to inflation or market indices can protect against economic shifts, while periodic reviews allow for renegotiation based on changing circumstances.

A comparative analysis reveals that sawmills often prioritize long-term relationships over one-time transactions. While spot purchases may offer immediate liquidity for sellers, they lack the stability and potential for price optimization that comes with sustained partnerships. For example, a seller with a 5-year contract might start at a base price but see incremental increases tied to volume or market trends. In contrast, spot sales are subject to fluctuating market prices, which can be unpredictable. By investing in quality and reliability, sellers position themselves as valuable partners, making long-term contracts a win-win scenario. This approach not only secures better pricing but also fosters a collaborative environment that benefits both parties over time.

In conclusion, pricing and contracts in the sawmill industry are nuanced, driven by volume, quality, and the longevity of supplier relationships. Sellers who understand these dynamics can strategically position themselves to negotiate favorable terms. By focusing on delivering high-quality wood in consistent quantities and embracing long-term agreements, they can achieve stable, profitable partnerships with sawmills. This approach not only ensures financial security but also contributes to a sustainable and efficient supply chain, benefiting the entire industry.

Where to Buy a Block of Wood: Top Sources and Tips

You may want to see also

Explore related products

$39.5

Sustainable Wood Practices: Many sawmills prioritize buying sustainably harvested wood to meet eco-friendly certifications

Sawmills are increasingly becoming gatekeepers of forest sustainability, with many prioritizing the purchase of sustainably harvested wood to meet eco-friendly certifications like FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification). These certifications ensure that the wood is sourced from forests managed to rigorous environmental, social, and economic standards. By demanding certified wood, sawmills not only reduce their environmental footprint but also respond to growing consumer demand for responsibly produced timber products. This shift is critical in a world where deforestation and habitat loss are pressing concerns.

To implement sustainable wood practices, sawmills must establish clear sourcing guidelines and build relationships with certified suppliers. For instance, a sawmill might partner with local foresters who adhere to selective logging practices, where only mature trees are harvested, and the ecosystem remains intact. Additionally, sawmills can invest in tracking technologies, such as blockchain, to verify the origin of their wood and ensure it meets certification criteria. Practical steps include conducting regular audits of suppliers and training staff to recognize and prioritize sustainably harvested materials.

The benefits of prioritizing sustainable wood extend beyond environmental preservation. Sawmills that adopt these practices often gain a competitive edge in the market. Eco-friendly certifications can open doors to premium pricing, government incentives, and access to green building projects that require certified materials. For example, LEED (Leadership in Energy and Environmental Design) projects mandate the use of FSC-certified wood, creating a lucrative market for sawmills that align with these standards. This economic incentive reinforces the business case for sustainability.

However, challenges exist in transitioning to sustainable wood practices. Smaller sawmills may face higher costs associated with certification and sourcing, while others might struggle to find consistent supplies of certified wood. To overcome these hurdles, sawmills can collaborate with industry associations to pool resources, share best practices, and advocate for policies that support sustainable forestry. Governments and NGOs can also play a role by offering subsidies or grants to ease the financial burden of certification.

In conclusion, sustainable wood practices are not just an ethical choice but a strategic imperative for sawmills in the modern marketplace. By prioritizing sustainably harvested wood and pursuing eco-friendly certifications, sawmills contribute to forest conservation, meet consumer expectations, and secure long-term profitability. The journey requires commitment and innovation, but the rewards—for both business and the planet—are well worth the effort.

Why People Buy Wood: Exploring Its Timeless Appeal and Practical Uses

You may want to see also

Frequently asked questions

Yes, many sawmills buy wood directly from landowners, especially if the timber meets their specific quality and quantity requirements.

Sawmills typically purchase a variety of wood types, including hardwoods (like oak, maple, and walnut) and softwoods (like pine, spruce, and fir), depending on their production needs.

Sawmills often buy both standing timber and harvested logs, though they may prefer one over the other based on their operations and the condition of the wood.

Sawmills determine the price based on factors like wood species, quality, volume, market demand, and transportation costs.

Sawmills buy wood from both individuals and logging companies, as long as the wood meets their standards and is delivered in a usable form.