When working with wood glue, understanding the appropriate drying and clamping times is crucial for achieving strong, durable joints. The duration required before unclamping wood glue depends on several factors, including the type of glue used, the wood species, humidity levels, and the size of the joint. Typically, standard wood glues like PVA (polyvinyl acetate) require a minimum clamping time of 30 minutes to an hour, but for maximum strength, it’s recommended to leave the clamp in place for at least 24 hours. Specialized glues, such as epoxy or polyurethane, may have different curing times, often ranging from a few hours to several days. Always refer to the manufacturer’s instructions for specific guidelines, as improper timing can compromise the bond and weaken the joint.

| Characteristics | Values |

|---|---|

| Clamping Time (Minimum) | 30 minutes to 1 hour (varies by glue type and manufacturer) |

| Full Cure Time | 24 hours for most wood glues (PVA, aliphatic resin) |

| Initial Set Time | 10-15 minutes (glue becomes tacky and holds pieces together) |

| Temperature Impact | Higher temperatures (70-80°F/21-27°C) speed up curing; lower slows it |

| Humidity Impact | Higher humidity can slightly accelerate curing |

| Glue Type Variations | Epoxy: 24-48 hours; Polyurethane: 6-8 hours; PVA: 24 hours |

| Wood Type Impact | Dense hardwoods may require longer clamping times |

| Joint Type Impact | End grain joints may need extended clamping |

| Manufacturer Recommendations | Always follow specific instructions on the glue packaging |

| Unclamping Safety | Ensure glue is fully cured before applying stress to the joint |

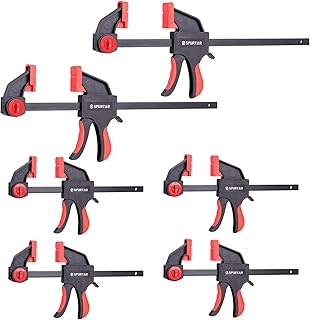

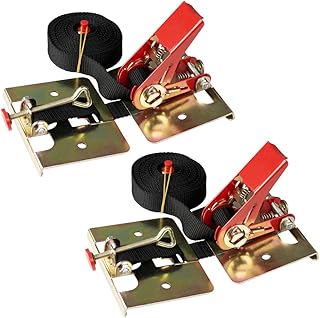

Explore related products

What You'll Learn

- Optimal Clamping Time: Recommended duration for different wood types and glue strengths

- Factors Affecting Drying: Humidity, temperature, and wood moisture impact curing time

- Testing Glue Strength: Methods to check if the glue is fully cured

- Accelerating Drying: Techniques to speed up glue curing time safely

- Risks of Early Unclamping: Potential joint failure or weak bonds if unclamped too soon

Optimal Clamping Time: Recommended duration for different wood types and glue strengths

The clamping time for wood glue varies significantly based on the type of wood and the adhesive's strength, making a one-size-fits-all approach impractical. Softwoods like pine or cedar, with their open grain structure, typically require shorter clamping times—around 30 minutes to an hour—for most PVA (polyvinyl acetate) glues. Harder woods such as oak or maple, however, demand more patience due to their denser fibers, often needing 2 to 3 hours to ensure a robust bond. Understanding these differences is crucial for preventing joint failure or unnecessary delays in your project.

For high-strength epoxies or polyurethane glues, the clamping duration extends further, regardless of wood type. Epoxies, for instance, may need 8 to 24 hours to cure fully, while polyurethane glues can take 4 to 6 hours to reach their maximum bond strength. These adhesives expand into the wood’s pores, creating a mechanical lock that requires ample time to set. Rushing this process risks weakening the joint, especially in load-bearing applications. Always refer to the manufacturer’s guidelines for specific curing times, as formulations can vary widely.

Practical tips can streamline the clamping process while ensuring optimal results. For instance, applying slight warmth (around 120°F or 49°C) to the glued joint can accelerate curing in PVA glues without compromising strength. However, avoid excessive heat, as it can degrade the adhesive. Additionally, using a clamp pressure of 250–500 psi ensures even distribution of the glue, particularly in hardwoods. For larger projects, consider clamping in stages, allowing initial sections to set before moving to the next, to maintain precision and alignment.

Comparing clamping times across adhesives highlights the importance of matching the glue to the task. While standard PVA glues are ideal for quick, indoor projects, exterior-grade PVA or waterproof epoxies require longer clamping times—up to 12 hours—to withstand environmental stresses. Polyurethane glues, with their foam expansion, are excellent for bridging gaps but necessitate patience to avoid joint distortion. Selecting the right adhesive and respecting its curing time ensures longevity and durability in your woodwork.

In conclusion, mastering optimal clamping times is a blend of science and craftsmanship. Tailor your approach to the wood type and adhesive strength, leveraging practical techniques to enhance efficiency without sacrificing quality. Whether you’re working with softwoods or tackling a hardwood masterpiece, patience and precision are your greatest tools for achieving a flawless bond.

Understanding Standard Wood Fence Picket Lengths for Your Project

You may want to see also

Explore related products

Factors Affecting Drying: Humidity, temperature, and wood moisture impact curing time

Wood glue curing times are not set in stone; they're a delicate dance influenced by environmental factors. Humidity, temperature, and wood moisture content act as silent choreographers, dictating how long your glued joints remain clamped. Understanding their roles empowers you to predict drying times and ensure strong, lasting bonds.

Let's delve into these factors and their impact.

Humidity: The Moisture Maestro

Imagine humidity as a thirsty sponge. High humidity means the air is already saturated with moisture, slowing down the glue's evaporation process. Think of it like trying to dry clothes on a damp day – it takes longer. Conversely, low humidity acts like a dry desert wind, accelerating evaporation and shortening curing times. For optimal results, aim for a humidity range of 40-60%. Using a hygrometer to monitor humidity levels in your workspace can be invaluable.

If you're working in a particularly humid environment, consider using a dehumidifier to expedite drying.

Temperature: The Heat Conductor

Temperature plays a pivotal role in glue curing. Think of it as the conductor of an orchestra, setting the pace for the entire process. Higher temperatures generally accelerate curing, as heat increases molecular activity within the glue. Most wood glues perform best within a temperature range of 60-80°F (15-27°C). Colder temperatures can significantly slow down curing, potentially leading to weak bonds. Avoid gluing in chilly environments; if necessary, warm the glue slightly before application.

Wood Moisture: The Hidden Variable

The moisture content of the wood itself is a crucial, often overlooked factor. Wood with high moisture content can dilute the glue, weakening the bond and prolonging drying time. Ideally, wood moisture content should be around 8-12% for optimal gluing. Using a moisture meter to check the wood's moisture level before gluing is highly recommended. If the wood is too wet, allow it to acclimate to your workshop environment until it reaches the desired moisture content.

Practical Tips for Success

- Plan Ahead: Consider the environmental conditions when scheduling your gluing projects. Avoid gluing during periods of extreme humidity or temperature fluctuations.

- Control Your Environment: If possible, work in a temperature-controlled space with moderate humidity.

- Choose the Right Glue: Different wood glues have varying curing times and temperature tolerances. Select a glue suitable for your project and environmental conditions.

- Clamp Adequately: Apply sufficient clamping pressure to ensure proper contact between the glued surfaces.

- Be Patient: Don't rush the curing process. Allow ample time for the glue to fully dry and reach its maximum strength.

Understanding Cord of Wood Measurements: Length, Volume, and Stacking Tips

You may want to see also

Explore related products

Testing Glue Strength: Methods to check if the glue is fully cured

Wood glue manufacturers often recommend waiting 24 hours before unclamping, but this is a general guideline, not a guarantee of full cure. Testing glue strength ensures your joint is ready for stress, preventing costly failures. One method is the shear test: apply gentle pressure perpendicular to the joint, gradually increasing force until the glue either holds or fails. This simulates real-world stress and reveals weaknesses early. For example, a properly cured PVA glue joint should withstand several hundred pounds of shear force without separation.

Another approach is the flexural test, particularly useful for larger joints or curved pieces. Gently bend the glued area, observing for any movement or cracking sounds. Fully cured glue will remain rigid, while under-cured glue may allow slight flexing or emit a faint popping noise. This method is less quantitative than shear testing but provides a quick, intuitive assessment. Remember, excessive force can damage the wood, so proceed cautiously.

For a more scientific approach, consider the moisture content test using a wood moisture meter. Wood glue cures by releasing water, so residual moisture indicates incomplete curing. Measure the moisture content of the glued area and compare it to the surrounding wood. A difference of more than 2% suggests the glue is still curing. This method is especially useful for thick glue lines or humid environments, where drying times can double.

Lastly, the visual and tactile inspection is a simple yet effective technique. Examine the glue line for any gaps, discoloration, or tackiness. Fully cured glue should be transparent and smooth to the touch. Run your fingernail along the joint—if it leaves a mark, the glue isn’t fully cured. This method is best paired with other tests for confirmation, as it relies on subjective observation. Always err on the side of caution; if in doubt, allow additional curing time.

Ground Contact Wood Durability: Lifespan and Preservation Tips Explained

You may want to see also

Explore related products

Accelerating Drying: Techniques to speed up glue curing time safely

Wood glue curing times can be a bottleneck in woodworking projects, but accelerating drying safely is possible with the right techniques. One effective method is applying gentle heat, which increases molecular activity and speeds up curing. Use a heat lamp or space heater to warm the glued area to 100–120°F (38–49°C). Avoid exceeding 150°F (65°C), as excessive heat can weaken the bond or damage the wood. Monitor the temperature with a thermometer to ensure consistency. This method can reduce curing time from 24 hours to as little as 4–6 hours, depending on the glue type and wood density.

Another technique involves improving air circulation around the glued joint. Position a fan to blow air directly onto the clamped area, ensuring the airflow is steady but not strong enough to disturb the clamp pressure. This helps evaporate moisture more quickly, particularly with PVA glues, which cure through water evaporation. Combine this with low heat for optimal results, but avoid drafts that could introduce dust or debris into the joint. Proper ventilation also prevents the buildup of fumes, especially when using solvent-based adhesives.

For small or intricate pieces, using thin CA glue (cyanoacrylate) can be a game-changer. CA glue cures in seconds to minutes when activated by moisture in the wood or air. Apply a thin layer to one surface, join the pieces, and clamp lightly for 30–60 seconds. While CA glue is strong, it lacks the gap-filling properties of PVA, so ensure joints fit tightly. For added durability, follow up with a bead of PVA glue along the joint after the CA has cured. This hybrid approach combines speed with strength.

Lastly, pre-treating wood can significantly reduce curing time. Lightly sanding the wood surfaces to remove oils or sealers ensures better glue adhesion. For oily woods like teak or walnut, wipe the surfaces with acetone or mineral spirits before gluing. Additionally, applying a thin coat of glue to both surfaces and letting it dry for 5–10 minutes before reassembling creates a stronger bond with less moisture to evaporate. This "two-step gluing" method is particularly effective for large joints or humid environments.

While these techniques accelerate drying, safety and precision remain paramount. Always follow manufacturer guidelines for glue application and curing conditions. Overheating or over-stressing the joint can compromise the bond, so err on the side of caution. Test techniques on scrap wood before applying them to your project. With the right approach, you can reduce unclamping time without sacrificing the integrity of your work.

Unveiling the Age: How Long Ago Was the Wood Formed?

You may want to see also

Explore related products

Risks of Early Unclamping: Potential joint failure or weak bonds if unclamped too soon

Unclamping wood glue prematurely can lead to joint failure or weak bonds, undermining the structural integrity of your project. Wood glue requires sufficient time to cure, typically 24 hours for initial strength, but full curing can take up to 72 hours depending on the adhesive type and environmental conditions. Early unclamping disrupts the bonding process, leaving the joint vulnerable to stress and movement. For example, PVA (polyvinyl acetate) glues, commonly used in woodworking, form hydrogen bonds between wood fibers and the adhesive. If clamping pressure is removed too soon, these bonds may not fully develop, resulting in a brittle or incomplete connection.

Consider the scenario of joining two pieces of hardwood for a table leg. If the clamp is removed after only 6 hours, the glue may appear dry on the surface but remain uncured internally. Applying weight or stress to the joint before full curing can cause the wood to shift or separate, rendering the bond ineffective. This risk is amplified in humid or cold environments, where curing times are prolonged. Always refer to the manufacturer’s guidelines for specific curing times, as formulations like epoxy or polyurethane glues may require even longer periods.

The consequences of early unclamping extend beyond immediate failure. Over time, weak bonds can lead to creeping, where the joint gradually loosens under repeated stress. This is particularly problematic in load-bearing applications, such as chair frames or cabinet joints. For instance, a dovetail joint glued and clamped for only 12 hours may appear stable initially but could fail after months of use due to insufficient bond strength. To mitigate this, plan your workflow to allow for uninterrupted clamping time, and use additional supports or secondary bonding methods if immediate handling is necessary.

Practical tips include testing the glue’s readiness by gently tapping the joint with a mallet. If it feels solid and resists movement, it may be safe to unclamp, but this method is unreliable for critical joints. Instead, err on the side of caution and adhere strictly to recommended curing times. For urgent projects, consider using fast-setting glues like cyanoacrylate (super glue) or two-part epoxies, which can cure in as little as 30 minutes to 2 hours. However, these alternatives may lack the flexibility or strength of traditional wood glues, so choose based on the project’s requirements.

Instructively, treating wood glue curing as a non-negotiable step ensures long-term durability. Think of clamping time as an investment in the joint’s future performance. For example, a well-clamped and fully cured mortise-and-tenon joint can withstand decades of use, while a rushed bond may fail within months. By respecting the chemistry of the adhesive and the physics of the joint, you avoid the costly and time-consuming process of disassembling and re-gluing failed connections. Patience in this stage is not just a virtue—it’s a necessity for professional-quality results.

Wood Rot Timeline: Factors Affecting Decay and Prevention Tips

You may want to see also

Frequently asked questions

For PVA wood glue, wait at least 30 minutes to 1 hour before unclamping, but allow 24 hours for the glue to fully cure for maximum strength.

Yes, once the glue feels dry to the touch (usually within 15–30 minutes), it’s safe to unclamp, but avoid stressing the joint until it fully cures.

Epoxy wood glue typically requires 8–24 hours of clamping time, depending on the product, so check the manufacturer’s instructions for specific guidance.

After 2 hours, most wood glues are sufficiently set to unclamp, but for optimal strength, allow the glue to cure for 24 hours before subjecting the joint to heavy use.