The longevity of a wooden ship's ability to float without being pumped depends on several critical factors, including the ship's construction quality, the type of wood used, the presence of waterproofing treatments, and the environmental conditions it encounters. Wooden ships, historically vital for exploration and trade, were often sealed with pitch or tar to prevent water infiltration, but over time, natural wear, rot, and hull breaches could compromise their integrity. Without active pumping to remove accumulated water, a well-maintained wooden ship might remain afloat for weeks or even months in calm waters, but rough seas, collisions, or prolonged exposure to moisture would significantly shorten this timeframe. Ultimately, the ship's buoyancy would diminish as waterlogged wood becomes heavier, leading to inevitable sinking if not addressed.

| Characteristics | Values |

|---|---|

| Duration Without Pumping | Varies widely; typically 12-24 hours depending on hull condition |

| Factors Affecting Duration | Hull integrity, wood type, seawater exposure, temperature, and leaks |

| Wood Type Influence | Hardwoods (e.g., oak) last longer than softwoods (e.g., pine) |

| Seawater Impact | Accelerates wood degradation due to salt and marine organism activity |

| Temperature Effect | Warmer waters increase wood swelling and leakage risk |

| Hull Condition | Well-maintained hulls can float longer (up to 48 hours in some cases) |

| Leak Rate | Small leaks may allow floating for days; large leaks reduce time |

| Historical Examples | Some wooden ships have survived weeks with minimal pumping |

| Modern Preservation Techniques | Treatments like epoxy coatings can extend floating time significantly |

| Environmental Factors | Calm waters vs. rough seas affect water ingress and stability |

| Cargo and Weight Distribution | Properly balanced ships float longer than overloaded ones |

| Emergency Measures | Temporary repairs (e.g., plugging leaks) can extend floating duration |

Explore related products

What You'll Learn

- Hull Design Impact: How ship shape and size affect water displacement and buoyancy over time

- Wood Type Influence: Different woods' density and durability in water, affecting float duration

- Seawater vs. Freshwater: Salinity differences and their effects on wood absorption and ship longevity

- Weather Conditions: Storms, waves, and temperature changes accelerating water intake and damage

- Maintenance Role: Regular upkeep, sealing, and repairs extending a ship's floating capability

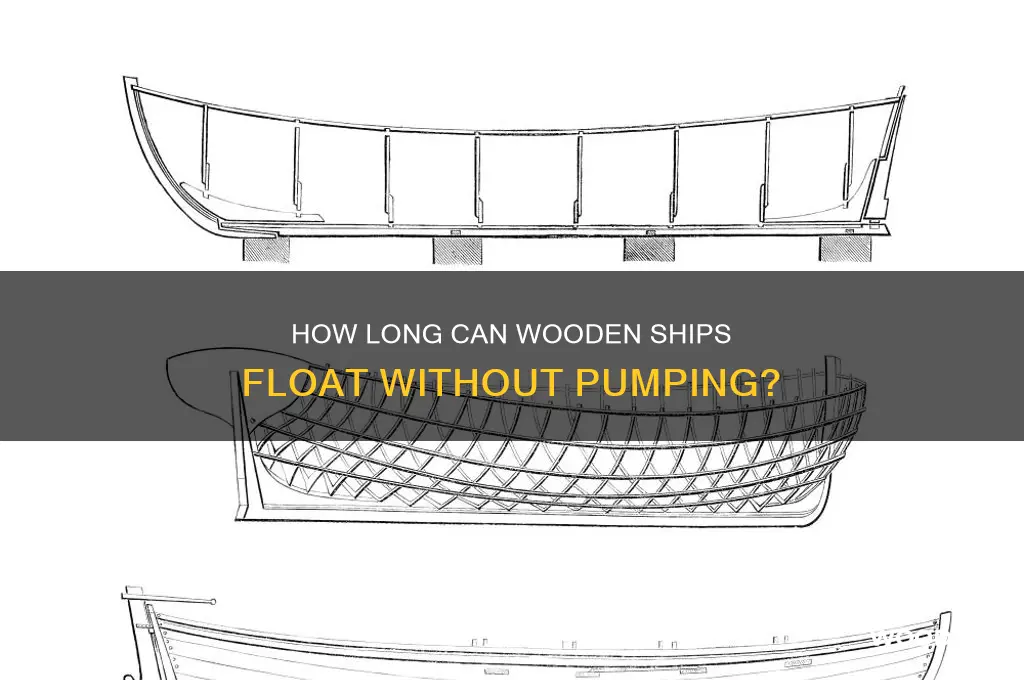

Hull Design Impact: How ship shape and size affect water displacement and buoyancy over time

The longevity of a wooden ship's buoyancy without pumping is intricately tied to its hull design, a factor often overlooked in favor of material durability or maintenance routines. A ship's shape and size dictate how it interacts with water, influencing not only its initial displacement but also its ability to maintain buoyancy over time. For instance, a vessel with a broad, flat bottom displaces more water at rest, providing greater stability but also increasing the risk of waterlogging if not properly sealed. Conversely, a narrow, V-shaped hull cuts through water more efficiently, reducing drag and minimizing the surface area exposed to potential leaks, thus prolonging the time it can float without intervention.

Consider the example of a traditional Viking longship, renowned for its slender, elongated hull. This design allowed it to displace water with minimal resistance, enabling both speed and endurance. The long, shallow draft meant that even if water began to seep in, the ship could remain afloat for days, if not weeks, without pumping, as the hull’s shape distributed the weight of the water more evenly. In contrast, a broader, deeper hull, like that of a medieval cog, would displace more water initially but could become unstable or submerged more quickly if water accumulated in its bilges, necessitating frequent pumping.

Analyzing the impact of hull size reveals another layer of complexity. Larger ships, while capable of displacing more water, also have greater internal volume, which can lead to increased water accumulation over time. For example, a 100-foot wooden vessel with a spacious cargo hold might float for several days without pumping, but its larger bilge area could eventually fill, compromising buoyancy. Smaller vessels, like fishing boats, often have shorter float times without pumping due to their limited displacement capacity, but their compact design reduces the overall volume of water that can accumulate, delaying the need for intervention.

To maximize a wooden ship’s float time without pumping, designers must balance displacement, stability, and internal volume. A practical tip is to incorporate watertight compartments, which isolate leaks and prevent water from spreading throughout the hull. Additionally, using a hull shape with a fine entry (a sharp bow) and a flat run (a broad stern) can optimize displacement while minimizing water ingress. For DIY enthusiasts or historical reenactors, consider scaling down models to test how different hull designs affect buoyancy; a 1:10 scale model can provide valuable insights into water displacement and leak management.

Ultimately, the interplay between hull shape and size determines a wooden ship’s resilience to waterlogging. While no design can eliminate the need for pumping indefinitely, strategic choices in hull geometry can significantly extend float time. By prioritizing efficiency in displacement and minimizing internal water accumulation, shipbuilders can create vessels that not only float longer but also require less maintenance, ensuring safer and more reliable voyages.

Optimal Timing Between Penofin Wood Treatment Stages for Lasting Results

You may want to see also

Explore related products

Wood Type Influence: Different woods' density and durability in water, affecting float duration

The longevity of a wooden ship's buoyancy without pumping is intricately tied to the type of wood used in its construction. Different woods exhibit varying densities and durability when exposed to water, directly influencing how long a vessel can remain afloat. For instance, dense hardwoods like teak or oak have natural oils and resins that repel water, reducing absorption and maintaining structural integrity over time. In contrast, softer woods like pine or cedar, while lighter, absorb water more readily, compromising their strength and buoyancy. This fundamental difference in wood properties underscores the critical role material selection plays in ship design and maintenance.

To maximize float duration, shipbuilders must consider both the density and durability of the wood. Dense woods, though heavier, offer superior resistance to waterlogging, making them ideal for hulls and structural components. However, their weight can limit speed and maneuverability, a trade-off designers must weigh. Lighter woods, while more susceptible to water absorption, can be treated with preservatives or coatings to enhance durability. For example, applying creosote or epoxy resins can significantly extend the lifespan of softer woods in marine environments. Practical tip: Regularly inspect treated wood for cracks or wear, as these can compromise the protective barrier and accelerate water absorption.

A comparative analysis of wood types reveals that teak, with its high natural oil content, can remain structurally sound in water for decades without significant degradation. Oak, another popular choice, offers similar durability but requires more maintenance to prevent rot. On the other hand, pine, often used for its affordability and availability, may begin to lose buoyancy within a few years without proper treatment. For small boats or temporary structures, cedar’s lightweight and aromatic properties make it a viable option, though it demands vigilant upkeep. Takeaway: Match wood type to the intended use and environmental conditions to optimize float duration.

Instructively, the process of selecting wood for shipbuilding involves more than just density and durability. Factors like availability, cost, and environmental impact must also be considered. For instance, while teak is highly durable, its overexploitation has led to sustainability concerns, prompting the search for eco-friendly alternatives. Modern innovations, such as composite materials or sustainably harvested woods, offer promising solutions. Step-by-step, shipbuilders should assess the vessel’s purpose, budget, and environmental footprint before choosing a wood type. Caution: Avoid relying solely on traditional materials without exploring contemporary, sustainable options.

Ultimately, the influence of wood type on a ship’s float duration cannot be overstated. By understanding the unique properties of different woods and applying appropriate treatments, shipbuilders can significantly extend the time a vessel remains buoyant without pumping. Whether prioritizing durability, weight, or sustainability, the choice of wood is a decisive factor in maritime engineering. Practical tip: Maintain detailed records of wood type, treatment methods, and inspection schedules to ensure long-term performance and safety. This proactive approach not only enhances buoyancy but also preserves the ship’s structural integrity for generations to come.

Rip Van Winkle's Slumber: Unraveling the Length of His Enchanted Sleep

You may want to see also

Explore related products

Seawater vs. Freshwater: Salinity differences and their effects on wood absorption and ship longevity

Wooden ships face distinct challenges depending on whether they navigate seawater or freshwater, primarily due to salinity differences. Seawater, with an average salinity of 3.5% (35 grams of salt per liter), is significantly denser and more corrosive than freshwater, which typically contains less than 0.5 grams of salt per liter. This salinity disparity directly influences how wood absorbs moisture and, consequently, the longevity of the vessel. In seawater, the osmotic pressure drives water into the wood, causing it to swell and weaken over time. Conversely, freshwater lacks the same osmotic force, leading to slower absorption and less structural degradation. Understanding these differences is crucial for predicting how long a wooden ship can remain afloat without pumping.

To mitigate the effects of salinity, shipbuilders historically employed specific techniques. For instance, oak, known for its natural resistance to rot, was often used in shipbuilding due to its dense grain structure, which slows water absorption. In seawater, the salt acts as a preservative, inhibiting microbial growth that would otherwise decay the wood. However, this comes at a cost: the salt crystallizes within the wood as it dries, causing internal stress and cracking. In freshwater, while microbial activity is higher, the absence of salt reduces the risk of crystallization, allowing the wood to retain its integrity longer. Ship maintenance, therefore, must account for these environmental factors to ensure longevity.

A practical example illustrates these effects: the *Mary Rose*, a 16th-century warship preserved in seawater, exhibited significant salt crystallization in its oak hull, leading to structural failure over centuries. In contrast, freshwater-recovered vessels like the *Vasa* show less internal damage but more signs of microbial decay. For modern wooden boat owners, this means freshwater vessels require vigilant antifouling measures to prevent rot, while seawater vessels need regular desalination treatments to avoid salt-induced cracking. Applying a preservative like copper naphthenate (at a rate of 1-2 gallons per 100 square feet) can extend the life of wooden ships in both environments by inhibiting both microbial growth and salt penetration.

From a maintenance perspective, monitoring moisture content is key. In seawater, wood can absorb up to 50% of its dry weight in water, compared to 30% in freshwater. Installing moisture meters at critical points in the hull allows owners to detect saturation early. For ships operating in mixed environments, periodic freshwater rinsing can flush out accumulated salts, reducing long-term damage. Additionally, coating the hull with epoxy resins provides a barrier against both water and salt, though this must be reapplied every 5–10 years depending on exposure. By tailoring maintenance to the specific salinity environment, wooden ships can remain seaworthy for decades without constant pumping.

Ultimately, the salinity of the water a wooden ship navigates dictates its maintenance needs and lifespan. Seawater’s preservative qualities come with the risk of salt crystallization, while freshwater’s gentleness on wood is offset by heightened microbial threats. By understanding these dynamics, shipowners can implement targeted strategies—from material selection to treatment schedules—to maximize longevity. Whether in salt or fresh water, proactive care ensures that wooden ships can float safely, even without constant pumping, for years to come.

Cedar Wood Durability: How Long It Lasts Outdoors and Why

You may want to see also

Explore related products

$135

$78.95 $85.95

Weather Conditions: Storms, waves, and temperature changes accelerating water intake and damage

Storms are a wooden ship’s worst enemy, not just for their immediate danger but for the insidious way they accelerate water intake. High winds whip waves into crests that slam against hulls, driving water through seams and cracks that would otherwise remain sealed. A single storm can compromise a ship’s integrity faster than months of calm sailing. For instance, during the 18th century, ships caught in hurricanes often reported flooding rates that required pumping every 15 minutes to stay afloat. The relentless pounding of waves acts like a battering ram, widening gaps in wooden planks and forcing water into the bilge at an alarming rate. Without constant attention, a ship in a storm can sink within hours, not days.

Waves, even outside of storms, play a critical role in water intake, particularly in rough seas. The constant rise and fall of a ship in heavy swells creates a pumping action, forcing water through seams and around fasteners. This is especially true for older vessels, where the caulking between planks has deteriorated. A study of 19th-century sailing ships revealed that in seas with waves over 10 feet, water intake could double compared to calmer conditions. Sailors had to pump every 30 minutes to maintain buoyancy, a task that exhausted crews and limited their ability to navigate or rest. The lesson here is clear: wave height and frequency directly correlate to how quickly a wooden ship takes on water, making rough seas a silent but deadly threat.

Temperature changes, often overlooked, can exacerbate water intake by causing the wood to expand and contract. In colder climates, freezing temperatures can crack wooden planks, creating pathways for water infiltration. Conversely, in warmer regions, heat and humidity can cause caulking to dry out and shrink, leaving gaps. For example, ships traveling from the Arctic to the tropics often reported increased leakage due to these thermal stresses. A practical tip for maintaining wooden ships in varying climates is to inspect and recaulk seams regularly, especially after significant temperature shifts. Ignoring this can turn minor leaks into major flooding, reducing a ship’s floating time from weeks to mere days.

The combined effect of storms, waves, and temperature changes creates a perfect storm for water damage, drastically shortening the time a wooden ship can remain afloat without pumping. A well-maintained vessel in calm, temperate conditions might last weeks or even months without intervention. However, in harsh weather, that timeframe shrinks to hours or days. The takeaway is that weather conditions are not just external challenges but active agents of deterioration. Sailors must anticipate these factors, preparing with robust pumping systems, regular maintenance, and strategic route planning to mitigate their impact. In the battle against the elements, foresight and preparation are the only lifelines.

Natalie Wood and Richard Long: Rumored Romance or Just Friends?

You may want to see also

Explore related products

Maintenance Role: Regular upkeep, sealing, and repairs extending a ship's floating capability

Wooden ships, marvels of craftsmanship, rely heavily on meticulous maintenance to defy the relentless forces of water and time. Without regular upkeep, sealing, and repairs, even the sturdiest vessel will succumb to leaks, rot, and structural failure. The lifespan of a wooden ship afloat without pumping is directly tied to the diligence of its caretakers. Historical examples, such as the *Mary Rose* and *USS Constitution*, demonstrate that consistent maintenance can keep a wooden ship seaworthy for centuries. However, neglect accelerates deterioration, reducing its floating capability to mere months or years.

Regular upkeep begins with inspection—a systematic examination of the hull, joints, and seams for signs of wear, cracks, or water intrusion. This should be done at least quarterly, with more frequent checks in harsh conditions. Sealing is the next critical step, using traditional materials like pitch, tar, or modern epoxy resins to waterproof the wood. For instance, applying a fresh coat of pitch annually can significantly reduce water absorption, especially in tropical climates where wood expands and contracts rapidly. Repairs must address not only visible damage but also hidden issues like dry rot, which weakens the structure from within.

The role of maintenance extends beyond surface-level fixes; it involves understanding the ship’s unique characteristics and environmental stressors. For example, ships in cold waters face ice damage, while those in warm, humid climates battle fungal growth. Tailoring maintenance routines to these conditions is essential. Caulking seams with cotton and oakum, a centuries-old practice, remains effective in preventing leaks, but it requires reapplication every 2–3 years. Similarly, replacing damaged planks promptly prevents water from reaching the ship’s interior, where it can cause irreversible harm.

Persuasively, investing in regular maintenance is far more cost-effective than dealing with catastrophic failures. A well-maintained wooden ship can float indefinitely with minimal pumping, while a neglected one becomes a sinking liability. Take the *HMS Victory*, which has remained afloat since 1765 due to continuous care. Conversely, the *Vasa* sank on its maiden voyage in 1628, partly due to rushed construction and inadequate sealing. The lesson is clear: maintenance is not optional—it is the lifeblood of a wooden ship’s longevity.

In conclusion, the floating capability of a wooden ship is not a fixed trait but a dynamic outcome of its maintenance regimen. By prioritizing regular inspections, meticulous sealing, and timely repairs, shipowners can extend their vessel’s life far beyond what might seem possible. This proactive approach transforms maintenance from a chore into an art, ensuring that wooden ships continue to grace the waters for generations to come.

Wood Putty Drying Time: Factors Affecting Cure and Finish

You may want to see also

Frequently asked questions

The duration a wooden ship could float without being pumped depends on its design, the integrity of its hull, and the rate of water ingress. A well-maintained ship with minimal leaks could float for days or even weeks, while a damaged ship might sink within hours if not pumped.

Factors include the ship's construction quality, the presence of leaks, the size and number of watertight compartments, the weight of cargo, and external conditions like rough seas or damage from collisions or storms.

Theoretically, a wooden ship with no leaks and proper buoyancy could float indefinitely without pumping, as it would not take on water. However, in practice, all wooden ships have some degree of natural seepage, so periodic pumping would still be necessary over time.