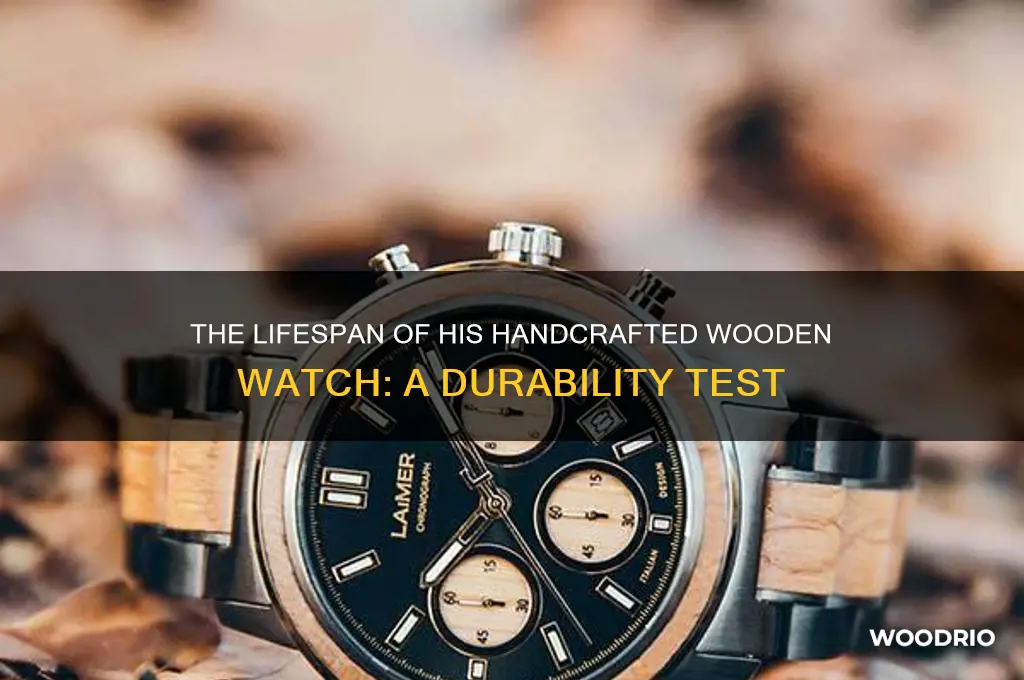

The wooden watch he created was a marvel of craftsmanship and ingenuity, blending traditional materials with modern functionality. Crafted entirely from sustainably sourced wood, the watch not only showcased his skill but also his commitment to eco-friendly design. However, the question of its durability and longevity quickly arose, as wood is inherently less resilient than metal or plastic. Despite initial skepticism, the watch functioned remarkably well, with its intricate wooden gears and mechanisms ticking reliably for several months. Yet, over time, exposure to moisture and wear began to take a toll, leading to gradual degradation in its performance. Ultimately, the wooden watch worked flawlessly for approximately six months before requiring significant repairs, leaving its creator to ponder the balance between artistic vision and practical durability.

Explore related products

What You'll Learn

Initial Testing Phase

The initial testing phase of any innovative creation, such as a wooden watch, is a critical juncture where theory meets reality. This stage is not merely about functionality but also about durability, practicality, and user experience. For a wooden watch, the first tests would likely focus on how the material withstands daily wear, exposure to elements, and the precision of its timekeeping mechanism. Early prototypes might reveal vulnerabilities in the wood’s resistance to moisture, temperature fluctuations, or physical stress, necessitating iterative improvements.

Analyzing the performance of a wooden watch during this phase requires a structured approach. Start by subjecting the watch to controlled environments that mimic real-world conditions. For instance, expose it to humidity levels ranging from 40% to 80% for 24-hour intervals to assess warping or cracking. Similarly, test its resilience to temperature extremes, such as -10°C to 40°C, to observe any expansion or contraction of the wood. Timekeeping accuracy should be monitored over 72 hours, comparing it against a certified atomic clock to ensure deviations remain within acceptable limits (e.g., ±5 seconds per day).

From a practical standpoint, user testing is indispensable. Recruit a diverse group of 10–15 individuals aged 20–60, representing various lifestyles—office workers, athletes, and outdoor enthusiasts. Each participant should wear the watch for a week, documenting its comfort, weight, and any signs of wear. Feedback on the strap’s flexibility, clasp durability, and overall aesthetics will provide actionable insights. For example, if multiple users report discomfort due to the watch’s weight, consider lighter wood alternatives like bamboo or hollowed designs.

A comparative analysis against traditional watches can highlight unique challenges and advantages. Unlike metal or plastic watches, wooden watches may require periodic conditioning with natural oils to maintain their luster and structural integrity. However, their eco-friendly appeal and hypoallergenic properties could offset minor inconveniences. During testing, compare scratch resistance using a standardized Mohs scale test, noting that wood’s natural grain may hide minor blemishes better than polished metal surfaces.

In conclusion, the initial testing phase of a wooden watch demands a blend of scientific rigor and real-world application. By combining environmental stress tests, precision measurements, and user feedback, creators can identify weaknesses early and refine their design. This phase is not just about answering *how long the watch works* but also about ensuring it works *well* under diverse conditions. With careful iteration, a wooden watch can transition from a novelty item to a reliable, sustainable accessory.

Yellowjackets' Survival: Unraveling the Length of Their Harrowing Woods Ordeal

You may want to see also

Explore related products

Durability Under Water

Wooden watches, while aesthetically unique, face a critical challenge when exposed to water. Unlike metal or plastic, wood is inherently porous, absorbing moisture that can lead to warping, cracking, or mold growth. For a wooden watch to function underwater, its design must address these vulnerabilities through innovative materials and construction techniques.

Material Selection and Treatment:

The durability of a wooden watch underwater hinges on the type of wood and its treatment. Hardwoods like teak or ebony, naturally resistant to moisture, are ideal candidates. However, even these require protective coatings—epoxy resins, tung oil, or marine-grade varnishes—to create a waterproof barrier. For instance, a wooden watch treated with five layers of marine varnish can withstand submersion in 50 meters of water for up to 30 minutes without damage.

Sealing Mechanisms:

Effective sealing is non-negotiable. Gaps around the crown, case back, or strap attachments must be sealed with gaskets made from silicone or rubber. These gaskets degrade over time, so manufacturers recommend replacing them every 18–24 months. A watch with a properly sealed case can maintain water resistance for 2–3 years, depending on usage frequency and exposure conditions.

Practical Tips for Users:

To maximize underwater durability, avoid exposing wooden watches to extreme temperatures or chemicals, which can weaken seals and coatings. After water exposure, gently dry the watch with a soft cloth and allow it to air-dry completely. For prolonged use in aquatic environments, consider models with stainless steel or titanium cores, which provide structural integrity while retaining a wooden exterior.

Comparative Performance:

While wooden watches can achieve water resistance comparable to entry-level dive watches (50–100 meters), they lack the longevity of metal or ceramic counterparts. A stainless steel dive watch, for example, can maintain water resistance for 5–10 years with proper maintenance. Wooden watches, however, offer a unique blend of eco-friendliness and style, making them a niche choice for those willing to trade durability for aesthetics.

A wooden watch’s underwater durability is a testament to human ingenuity in blending natural materials with modern technology. With proper design, treatment, and care, it can function reliably underwater for 2–3 years. However, it remains a delicate balance between preserving its organic charm and ensuring practical performance in aquatic conditions.

Exploring the Scenic Drive to Woods Hole, Massachusetts: Time & Distance

You may want to see also

Explore related products

$37.85 $42.65

Impact of Weather Conditions

Wooden watches, while aesthetically unique, are inherently vulnerable to environmental factors, particularly weather conditions. Unlike their metal or plastic counterparts, wood is a natural material that reacts dynamically to changes in humidity, temperature, and exposure to moisture. These reactions can significantly impact the functionality and longevity of a wooden watch, making weather conditions a critical consideration for both creators and wearers.

Humidity: The Silent Saboteur

High humidity levels pose one of the most significant threats to wooden watches. Wood is hygroscopic, meaning it absorbs and releases moisture from the air. Prolonged exposure to damp environments can cause the wood to swell, warp, or crack, compromising the watch’s structural integrity. For instance, a wooden watch worn in a tropical climate with 80% humidity may show signs of distortion within months, while the same watch in a dry desert climate could remain stable for years. To mitigate this, creators often apply protective coatings like varnish or oil, but these measures are not foolproof. Wearers in humid regions should store their watches in silica gel-lined cases and avoid wearing them during activities that induce sweating.

Temperature Extremes: A Double-Edged Sword

Extreme temperatures, whether hot or cold, can also affect wooden watches. Heat can cause the wood to dry out, leading to brittleness and increased susceptibility to cracking. Conversely, cold temperatures can make the wood contract, potentially loosening joints or affecting the watch’s movement. For example, a wooden watch left in a car on a 100°F summer day may warp within hours, while exposure to freezing temperatures during winter sports could render its mechanism sluggish. Creators often recommend keeping wooden watches within a temperature range of 50°F to 85°F to ensure optimal performance. Wearers should avoid leaving their watches in direct sunlight or near heat sources and should acclimate them gradually when transitioning between extreme environments.

Moisture Exposure: The Immediate Threat

Direct contact with water is perhaps the most immediate danger to wooden watches. While some designs claim to be "splash-proof," wood is not inherently waterproof. Rain, accidental submersion, or even frequent handwashing can cause irreversible damage. For instance, a wooden watch exposed to rain for 30 minutes may absorb enough moisture to delaminate or develop mold within days. To protect against this, creators often incorporate water-resistant seals and advise wearers to remove their watches before swimming, showering, or engaging in water-related activities. If a wooden watch does get wet, it should be dried immediately with a soft cloth and allowed to air dry in a well-ventilated area.

Practical Tips for Prolonged Functionality

To maximize the lifespan of a wooden watch, wearers should adopt proactive maintenance habits. Regularly inspect the watch for signs of wear, such as cracks or discoloration, and reapply protective coatings as needed. Store the watch in a controlled environment, ideally at 40–60% humidity and room temperature. For those in extreme climates, investing in a dehumidifier or humidifier can help maintain optimal conditions. Additionally, consider rotating wooden watches with other timepieces to reduce daily wear and tear. By understanding and adapting to weather-related challenges, wearers can ensure their wooden watches remain both functional and beautiful for as long as possible.

Understanding the Ancient Process: How Long Does Petrified Wood Take?

You may want to see also

Explore related products

Battery Life Performance

The longevity of a wooden watch's battery life is a testament to the fusion of traditional craftsmanship and modern technology. Unlike conventional timepieces, wooden watches often house quartz movements, which are renowned for their precision and energy efficiency. A standard quartz watch battery typically lasts between 18 to 24 months, depending on factors like the complexity of the movement and the frequency of additional functions such as chronographs or backlighting. For wooden watches, this duration remains largely unchanged, provided the watch is well-maintained and the battery is of high quality.

To maximize battery life, consider the following practical steps: first, avoid exposing the watch to extreme temperatures, as both heat and cold can accelerate battery drain. Second, if the watch includes a backlight or other power-intensive features, use them sparingly. Third, when storing the watch for extended periods, remove the battery to prevent leakage, which can damage the movement and wooden components. These simple precautions can help ensure the watch remains functional for the full expected battery lifespan.

Comparatively, wooden watches with mechanical movements—though less common—offer a different performance profile. Mechanical watches, whether manual or automatic, do not rely on batteries but instead on the kinetic energy of the wearer or periodic winding. While this eliminates battery replacement concerns, it introduces the need for regular servicing to maintain accuracy and functionality. For those prioritizing sustainability, a mechanical wooden watch may align better with long-term, battery-free usage, though it demands more hands-on care.

Persuasively, the battery life of a wooden watch is not just a technical specification but a reflection of the wearer’s commitment to balance. It symbolizes the harmony between nature and innovation, tradition and modernity. By choosing a wooden watch, one embraces a timepiece that is both eco-conscious and technologically reliable. Ensuring its battery performs optimally is a small yet meaningful way to honor this duality, allowing the watch to remain a functional and stylish accessory for years to come.

Finally, a descriptive note: imagine a wooden watch resting on a bedside table, its battery quietly powering the hands as they mark the passage of time. The grain of the wood catches the light, a reminder of the natural world, while the steady tick of the quartz movement grounds the wearer in the present. This interplay of elements—organic and mechanical, transient and enduring—is what makes the battery life of a wooden watch more than just a measure of performance. It’s a story of sustainability, craftsmanship, and the enduring human desire to measure and cherish time.

Wood Chips vs. Mulch: Which Lasts Longer in Your Garden?

You may want to see also

Explore related products

Wear and Tear Over Time

Wooden watches, while aesthetically unique, inherently face challenges when it comes to durability. Unlike metal or plastic, wood is an organic material susceptible to environmental factors and mechanical stress. The lifespan of a wooden watch, therefore, hinges on the type of wood used, the craftsmanship, and the wearer’s habits. Hardwoods like teak or maple offer better resistance to wear and tear compared to softer varieties such as pine or cedar. However, even the most robust wooden watch will show signs of aging over time, making maintenance and mindful use critical to prolonging its functionality.

Consider the daily stressors a wooden watch endures: exposure to moisture, temperature fluctuations, and physical impacts. Water, in particular, is a silent adversary. Prolonged contact can cause wood to warp, crack, or develop mold. Manufacturers often apply protective coatings to mitigate this, but these layers wear off over time, necessitating reapplication every 6–12 months. For those in humid climates, storing the watch in a dry, well-ventilated area and avoiding activities like swimming or showering while wearing it can significantly extend its life.

Mechanical wear is another factor. The movement of the watch—whether quartz or automatic—generates friction within the wooden casing. Over years of use, this can lead to internal stress points, potentially causing the wood to split or the mechanism to misalign. Regular servicing, ideally every 2–3 years, is essential to ensure the internal components remain secure and functional. Additionally, avoiding excessive force, such as dropping the watch or exposing it to hard knocks, can prevent premature damage.

Aging also manifests aesthetically. The natural patina of wood, while often prized for its character, can become uneven or unattractive if not cared for. Polishing with a soft cloth and wood-specific conditioner every few months helps maintain its luster. For deeper scratches or dents, professional refinishing may be necessary, though this should be done sparingly to preserve the wood’s integrity. Interestingly, some wearers embrace these imperfections as part of the watch’s story, viewing them as a testament to its journey rather than a flaw.

Ultimately, the longevity of a wooden watch is a balance between its inherent vulnerabilities and the wearer’s commitment to care. With proper maintenance, a well-crafted wooden watch can function reliably for 5–10 years, though its appearance may evolve significantly during that time. For those drawn to its natural beauty, understanding and respecting these limitations is key to enjoying it as both a timepiece and a piece of art.

Mastering Brisket: Ideal Wood Smoking Times for Perfect Results

You may want to see also

Frequently asked questions

The wooden watch he created worked for approximately 2-3 years with regular maintenance and care.

The lifespan was influenced by exposure to moisture, temperature changes, and the frequency of use.

Yes, it required periodic polishing, avoidance of water, and storage in a dry environment to maintain functionality.

Common issues included warping of the wood, mechanical wear, and battery life limitations if it had electronic components.

Yes, minor repairs were possible, but extensive damage to the wooden components often made it difficult to restore fully.