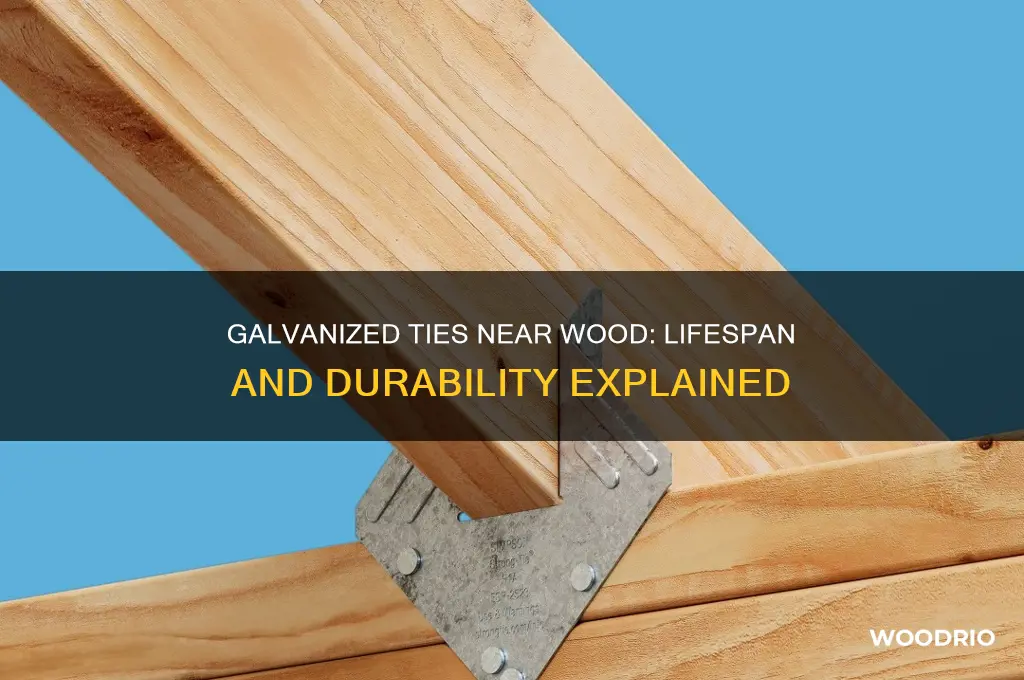

Galvanized ties used in construction, particularly those in contact with wood, are a popular choice due to their corrosion resistance and durability. However, the lifespan of galvanized ties next to wood can vary significantly depending on several factors, including the quality of the galvanization, the moisture content and treatment of the wood, and the environmental conditions they are exposed to. Typically, galvanized ties can last anywhere from 20 to 50 years or more when properly installed and maintained. The presence of wood, especially if it is untreated or frequently exposed to moisture, can accelerate corrosion due to the galvanic reaction between the metal and wood preservatives or naturally occurring acids. To maximize longevity, it is essential to use high-quality galvanized materials, ensure proper installation, and consider additional protective measures in harsh or humid environments. Understanding these factors is crucial for anyone looking to ensure the structural integrity and longevity of projects involving galvanized ties in proximity to wood.

| Characteristics | Values |

|---|---|

| Expected Lifespan | 30-50 years |

| Factors Affecting Durability | Moisture exposure, soil conditions, wood type, galvanization quality |

| Moisture Exposure | High moisture significantly reduces lifespan |

| Soil Conditions | Acidic or corrosive soils can accelerate corrosion |

| Wood Type | Treated wood can extend tie lifespan |

| Galvanization Quality | Thicker zinc coating increases durability |

| Maintenance Requirements | Minimal, but regular inspection recommended |

| Common Failure Modes | Corrosion, zinc layer depletion, mechanical damage |

| Comparative Lifespan (Untreated Ties) | 5-10 years |

| Environmental Impact | Longer lifespan reduces replacement frequency, lower environmental impact |

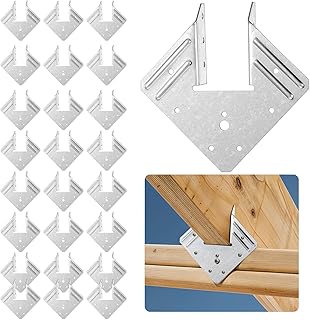

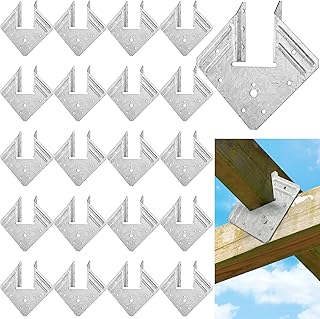

Explore related products

What You'll Learn

Galvanized Tie Lifespan Factors

Galvanized ties, when used in proximity to wood, face a unique set of challenges that influence their longevity. The primary factor is the galvanization itself—a zinc coating applied to steel to prevent corrosion. This protective layer is crucial, but its effectiveness diminishes when exposed to moisture and wood’s natural acids. Wood, particularly untreated varieties, releases tannins and other organic compounds that accelerate the breakdown of zinc. In ideal conditions, galvanized ties can last 20–50 years, but this range narrows significantly when wood is involved. Understanding this interaction is key to predicting and extending their lifespan.

Environmental conditions play a pivotal role in how galvanized ties perform next to wood. High humidity, frequent rainfall, or direct soil contact create a corrosive environment that weakens the zinc coating. For instance, ties used in coastal areas or regions with acidic soil may degrade in as little as 10–15 years due to heightened moisture and chemical exposure. Conversely, ties in dry, well-ventilated environments can retain their integrity for closer to 30–40 years. To mitigate these risks, consider using barriers like plastic or rubber spacers between the tie and wood, reducing direct contact and moisture absorption.

The type of wood used in conjunction with galvanized ties also impacts their durability. Pressure-treated wood, often infused with copper-based preservatives, can be particularly aggressive toward zinc, shortening the tie’s lifespan to 15–25 years. Untreated woods like cedar or redwood, while less corrosive, still pose a threat due to their natural tannins. For optimal longevity, pair galvanized ties with non-corrosive materials like composite lumber or use sacrificial anodes to divert corrosion away from the ties. Regular inspections and maintenance, such as reapplying galvanizing paint or replacing compromised ties, can further extend their service life.

Installation practices are another critical factor in determining how long galvanized ties last next to wood. Proper spacing, drainage, and ventilation minimize moisture accumulation and reduce the risk of corrosion. For example, ensuring ties are elevated above ground level or using gravel backfill can prevent water pooling. Additionally, avoiding tight contact between the tie and wood allows air circulation, slowing the degradation process. Following manufacturer guidelines for installation and using corrosion-resistant fasteners, such as stainless steel screws, can add years to the tie’s lifespan.

Finally, the purpose and load-bearing requirements of the structure influence the tie’s longevity. Galvanized ties in high-stress applications, like retaining walls or heavy fencing, may wear out faster due to increased mechanical strain and exposure to the elements. In such cases, over-engineering the structure or using thicker, higher-quality galvanized materials can provide a buffer against premature failure. Periodic load testing and visual inspections are essential to identify signs of corrosion or weakening before they compromise the structure’s integrity. By addressing these factors, you can maximize the lifespan of galvanized ties used in conjunction with wood.

Wood Glue Drying Time: Essential Tips for Strong, Durable Joints

You may want to see also

Explore related products

Wood Contact Impact on Durability

Galvanized ties, when in direct contact with wood, face a unique challenge that significantly impacts their longevity. The wood’s natural moisture content and acidity can accelerate corrosion of the galvanized coating, a process known as galvanic corrosion. This occurs because wood acts as an electrolyte, facilitating the transfer of electrons between the galvanized steel and the surrounding environment. Studies show that galvanized ties in direct wood contact can degrade up to 50% faster than those isolated from wood, reducing their lifespan from an average of 20–30 years to as little than 10–15 years in high-moisture environments.

To mitigate this, consider using non-conductive barriers such as plastic or rubber spacers between the galvanized tie and wood. These materials act as insulators, disrupting the galvanic corrosion process. For example, installing a 1/8-inch thick polyethylene sheet between the tie and wood can extend the tie’s lifespan by 3–5 years. Additionally, ensure the wood is pressure-treated with preservatives like ACQ (Alkaline Copper Quaternary) rather than CCA (Chromated Copper Arsenate), as ACQ is less corrosive to galvanized steel.

Another practical strategy is to maintain proper drainage around the wood-to-tie connection. Standing water or prolonged moisture exposure exacerbates corrosion. Elevate the wood slightly above ground level or use gravel backfill to improve water runoff. Regular inspections every 6–12 months can help identify early signs of corrosion, such as white rust or flaking, allowing for timely intervention.

For those in coastal or humid climates, where moisture levels are consistently high, consider using stainless steel ties instead of galvanized ones. While more expensive, stainless steel is highly resistant to corrosion and can last 40+ years in wood-contact applications. Alternatively, apply a zinc-rich epoxy coating to the galvanized tie before installation, providing an additional protective layer against moisture and wood acids.

In summary, the durability of galvanized ties in wood contact hinges on proactive measures to minimize moisture exposure and galvanic corrosion. By employing barriers, proper drainage, and alternative materials, you can significantly extend their lifespan, ensuring structural integrity for years to come.

Extracted Contestants' Survival Time: How Long Were They in the Woods?

You may want to see also

Explore related products

Corrosion Resistance Over Time

Galvanized ties, when used in proximity to wood, face a unique corrosion challenge due to the interaction between the metal and the organic material. The zinc coating on galvanized steel is designed to provide a sacrificial layer that corrodes instead of the underlying steel, but this process is accelerated in moist, wood-adjacent environments. Wood naturally retains moisture, creating a humid microclimate that promotes the electrochemical reactions leading to corrosion. Additionally, tannins and other organic acids in wood can leach out, further degrading the zinc layer. Understanding this dynamic is crucial for predicting the lifespan of galvanized ties in such applications.

To mitigate corrosion, proper installation techniques are paramount. Ensure that galvanized ties are not in direct contact with untreated wood, as this maximizes moisture transfer and acid exposure. Instead, use a barrier such as a plastic shim or treated wood, which reduces the wood’s ability to transfer moisture. Regular inspections are also essential, particularly in the first year after installation, as this is when the most rapid corrosion often occurs. If signs of rust appear, clean the area and apply a zinc-rich primer or paint to restore the protective layer. For high-moisture environments, consider using stainless steel ties instead, though this comes at a higher cost.

Comparing galvanized ties to alternative materials highlights their strengths and limitations. While stainless steel offers superior corrosion resistance, its cost is prohibitive for many projects. Hot-dipped galvanized ties, on the other hand, provide a cost-effective solution with a lifespan of 10–20 years in wood-adjacent applications, depending on environmental conditions. In contrast, untreated steel ties may fail within 2–5 years under similar circumstances. The key advantage of galvanized ties lies in their ability to self-heal minor scratches and damage, as the zinc coating continues to protect exposed areas. However, this self-healing property diminishes over time as the zinc layer depletes.

For those seeking to maximize the lifespan of galvanized ties, proactive maintenance is critical. Apply a corrosion inhibitor annually, particularly in coastal or humid climates where salt and moisture accelerate degradation. Monitor the pH level of the surrounding soil, as acidic conditions (pH < 6) can hasten corrosion. If replacing ties, remove old fasteners completely to prevent galvanic corrosion between new and old metals. Finally, consider using larger-diameter ties, as thicker zinc coatings provide extended protection. By combining these strategies, the functional life of galvanized ties next to wood can be extended significantly, ensuring structural integrity and reducing long-term maintenance costs.

Pressure Washing: Extending the Lifespan of Pressure-Treated Wood?

You may want to see also

Explore related products

$156.59

Environmental Conditions Effect

Galvanized ties placed next to wood are subject to a variety of environmental conditions that can significantly impact their lifespan. Moisture, temperature fluctuations, and chemical exposure are among the most influential factors. In regions with high humidity or frequent rainfall, the constant presence of moisture can accelerate the corrosion process, even on galvanized surfaces. This is particularly true when wood retains water, creating a damp microenvironment that fosters rust formation. Understanding these dynamics is crucial for predicting and extending the durability of galvanized ties in different settings.

Consider the role of temperature extremes, which can exacerbate the wear on galvanized ties. In areas with hot summers, the expansion and contraction of metal due to heat can weaken the zinc coating over time. Conversely, freezing temperatures in winter can cause moisture to seep into microscopic cracks, leading to frost-induced corrosion. For instance, in climates with temperature swings of 50°F or more between seasons, galvanized ties may degrade 20-30% faster than in more temperate zones. To mitigate this, applying a silicone-based sealant to the tie-wood junction can reduce moisture infiltration and thermal stress.

Chemical exposure is another critical factor, especially in industrial or coastal environments. Saltwater, for example, contains chloride ions that penetrate the zinc layer, causing pitting corrosion. Galvanized ties near coastal areas or treated wood (which often contains copper azole or alkaline copper quaternary preservatives) can experience reduced lifespans by up to 40%. In such cases, using stainless steel ties or adding a sacrificial anode can provide additional protection. Regular inspections every 6-12 months are recommended to identify early signs of corrosion in these high-risk environments.

The pH level of the surrounding soil also plays a subtle yet significant role. Acidic soils with a pH below 5.5 can dissolve the zinc coating more rapidly, while alkaline soils above pH 8.5 may cause the formation of white, powdery zinc oxide. For optimal longevity, ensure the soil pH around the ties remains neutral (pH 6.5-7.5). Adding lime to acidic soil or sulfur to alkaline soil can help balance pH levels. Additionally, elevating the ties slightly above ground level can minimize direct soil contact and reduce chemical interaction.

Finally, the orientation and exposure of the ties to environmental elements cannot be overlooked. Ties facing prevailing winds or direct sunlight are more prone to drying and cracking of the zinc layer, while those in shaded, sheltered areas may retain moisture longer. Strategic placement, such as angling ties away from dominant wind directions or using partial shading, can extend their lifespan. Combining these environmental considerations with proper installation techniques ensures galvanized ties next to wood perform optimally, even in challenging conditions.

Polyurethane Application Guide: Ideal Timing Between Coats on Pine Wood

You may want to see also

Explore related products

Maintenance Tips for Longevity

Galvanized ties used in conjunction with wood can last anywhere from 20 to 50 years, depending on environmental conditions and maintenance practices. However, this longevity is not guaranteed without proper care. Exposure to moisture, soil acidity, and wood preservatives can accelerate corrosion, reducing their lifespan significantly. To maximize durability, proactive maintenance is essential.

Inspect Regularly for Early Signs of Wear

Begin by examining the ties at least twice a year, focusing on areas where metal meets wood or soil. Look for white rust (a zinc oxide layer), red rust (indicating galvanization failure), or flaking. Use a wire brush to remove surface corrosion gently, but avoid abrasive tools that could strip the protective zinc layer. For ties in contact with treated wood, check for chemical staining, as preservatives like copper azole can degrade galvanization faster. Document changes to track deterioration patterns and address issues before they worsen.

Create a Protective Barrier Against Moisture

Moisture is the primary enemy of galvanized ties. Apply a silicone-based sealant or zinc-rich paint to exposed surfaces every 3–5 years, especially in humid climates or near water sources. Ensure the wood adjacent to the ties is well-sealed with a water-repellent preservative to minimize moisture transfer. In soil-contact applications, consider embedding ties in a gravel base to improve drainage, reducing the risk of soil-borne corrosion.

Mitigate Chemical Exposure from Wood Treatments

If using treated wood, opt for less corrosive preservatives like borate or ACQ (alkaline copper quaternary) instead of CCA (chromated copper arsenate), which is highly aggressive to galvanized metals. Maintain a 1-inch gap between ties and wood to limit chemical contact, and use non-conductive spacers like plastic shims. After installation, rinse ties with fresh water to remove any chemical residue from wood treatment processes.

Strategic Replacement and Reinforcement

Despite maintenance, ties in high-stress areas (e.g., load-bearing structures) may require replacement after 15–20 years. Monitor these zones quarterly and replace ties showing advanced corrosion, even if others appear intact. For critical structures, consider using stainless steel or composite ties in place of galvanized ones during partial replacements to extend overall system life. Always follow manufacturer guidelines for compatibility when mixing materials.

By combining regular inspections, protective treatments, chemical mitigation, and strategic replacements, you can push the lifespan of galvanized ties closer to the 50-year mark, ensuring structural integrity and reducing long-term costs.

Drying Wood Post-Rain: Understanding the Timeframe for Optimal Results

You may want to see also

Frequently asked questions

Galvanized ties next to wood can last 20–30 years or more, depending on environmental conditions, moisture levels, and maintenance.

Yes, prolonged exposure to moisture accelerates corrosion, reducing the lifespan of galvanized ties near wood, especially in humid or wet environments.

No, galvanized ties near wood in dry conditions can last significantly longer (up to 50+ years) compared to those in moist or humid environments.

Yes, treated wood with chemicals can shorten the lifespan of galvanized ties due to increased corrosion, while untreated wood has less impact.

Regular inspections, proper installation, using barriers between the tie and wood, and maintaining low moisture levels can extend their lifespan.