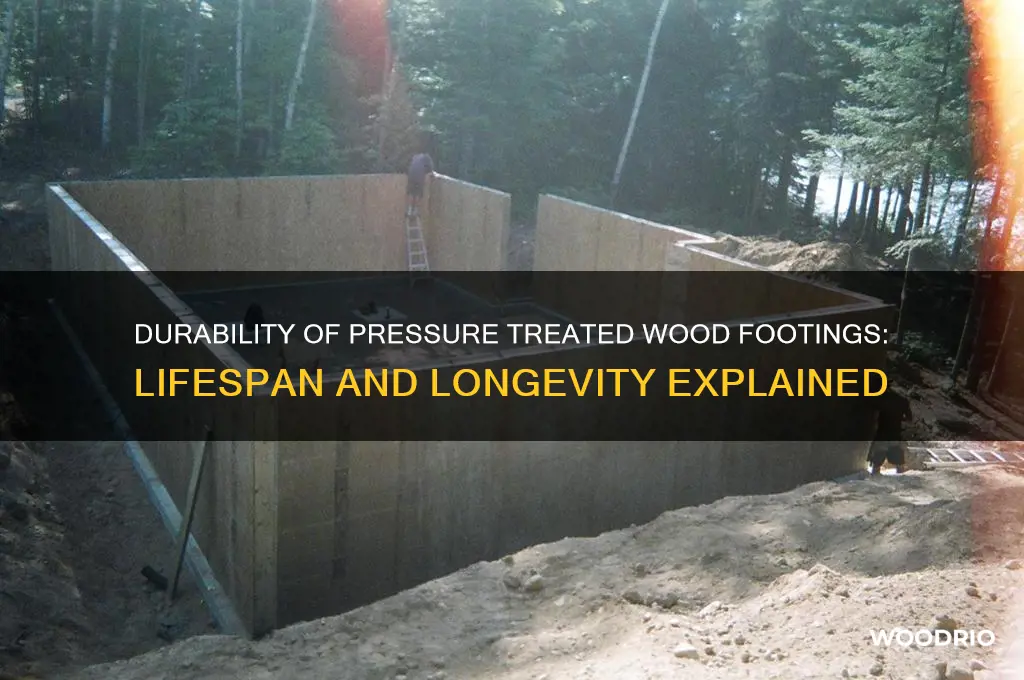

Pressure-treated wood footings are a popular choice for construction projects due to their durability and resistance to rot, decay, and insect damage. The lifespan of these footings can vary significantly depending on several factors, including the quality of the treatment, environmental conditions, and proper installation. On average, pressure-treated wood footings can last anywhere from 20 to 40 years or more, with some lasting even longer under ideal circumstances. However, exposure to moisture, soil acidity, and extreme weather conditions can accelerate deterioration. To maximize their longevity, it is essential to ensure proper installation, use appropriate preservatives, and consider additional protective measures such as gravel bases or moisture barriers. Understanding these factors can help homeowners and builders make informed decisions about using pressure-treated wood footings for their projects.

| Characteristics | Values |

|---|---|

| Expected Lifespan | 20-40 years (varies based on conditions) |

| Primary Factors Affecting Durability | Moisture exposure, soil type, climate, and wood treatment quality |

| Resistance to Rot and Decay | High, due to chemical preservatives (e.g., ACQ, CA-B) |

| Termite Resistance | Moderate to high, depending on treatment type |

| Maintenance Requirements | Minimal; periodic inspection for damage or wear |

| Environmental Impact | Lower than traditional treatments due to newer, eco-friendly chemicals |

| Cost-Effectiveness | High, as it is less expensive than concrete or metal alternatives |

| Common Applications | Decks, fences, retaining walls, and light-duty foundations |

| Vulnerability to Moisture | Lower if installed with proper drainage and above ground contact |

| Warranty Period | Typically 15-20 years from manufacturers |

| Sustainability | Improved with use of recycled materials and eco-friendly preservatives |

Explore related products

What You'll Learn

Factors affecting durability of pressure treated wood footings

Pressure-treated wood footings are designed to resist decay, insects, and moisture, but their longevity depends on several critical factors. One of the most significant is the retention level of preservatives, measured in pounds per cubic foot (lb/ft³). For ground-contact applications like footings, AWPA (American Wood Protection Association) Standard UC4A requires a minimum retention of 0.40 lb/ft³ for southern pine and 0.60 lb/ft³ for western species like Douglas fir. Higher retention levels generally correlate with increased durability, but exceeding recommended dosages can lead to surface residue or reduced wood strength. Always verify the treatment tag or stamp on the lumber to ensure compliance with UC4A standards.

Moisture management is another pivotal factor. While pressure treatment protects against fungal decay, prolonged exposure to moisture accelerates deterioration. Footings in areas with poor drainage or high water tables are particularly vulnerable. To mitigate this, ensure proper grading around the structure to direct water away from the footing. Installing a gravel base or vapor barrier beneath the footing can also reduce moisture absorption. For footings in direct soil contact, consider using a sacrificial layer of untreated wood or a moisture-resistant barrier to extend lifespan.

The type of preservative chemical used plays a decisive role in durability. Chromated copper arsenate (CCA) was once the standard but has been largely replaced by alternatives like alkaline copper quaternary (ACQ) and copper azole (CA-B) due to environmental concerns. ACQ-treated wood, for instance, is highly resistant to fungal decay but may corrode metal fasteners more quickly than CCA. To avoid this, use stainless steel, hot-dipped galvanized, or polymer-coated fasteners with ACQ-treated wood. Understanding the chemical properties of the treatment ensures compatibility with surrounding materials and environmental conditions.

Environmental exposure varies widely and directly impacts footing longevity. In coastal regions, saltwater exposure can accelerate corrosion of both the wood and fasteners, reducing lifespan to 10–15 years. In contrast, footings in arid climates with minimal ground moisture may last 40 years or more. Temperature fluctuations also matter; freeze-thaw cycles in colder climates can cause cracking, while UV exposure in sunny areas may degrade exposed surfaces. Applying a sealant or water repellent to the wood can provide additional protection, though reapplication every 2–3 years is necessary for continued effectiveness.

Finally, installation practices are often overlooked but critical to durability. Footings should be set at least 12 inches below the frost line to prevent shifting during freeze-thaw cycles. Proper compaction of soil around the footing minimizes settling and reduces stress on the wood. Avoid direct contact with concrete, as alkaline leaching can degrade the preservative chemicals. Instead, use a non-corrosive spacer or barrier between the wood and concrete. Following manufacturer guidelines and local building codes ensures optimal performance and maximizes the footing’s service life.

Composite vs. Wood Fences: Which Lasts Longer in Your Yard?

You may want to see also

Explore related products

Average lifespan of pressure treated wood footings

Pressure-treated wood footings are a popular choice for construction projects due to their durability and resistance to rot, decay, and insect damage. The average lifespan of these footings can vary significantly, typically ranging from 20 to 40 years, depending on several critical factors. This longevity is primarily attributed to the chemical treatment process, which involves infusing preservatives like alkaline copper quaternary (ACQ) or chromated copper arsenate (CCA) into the wood. These chemicals create a barrier against moisture and pests, the primary culprits behind wood deterioration. However, environmental conditions play a pivotal role in determining how long these footings will last.

To maximize the lifespan of pressure-treated wood footings, proper installation is essential. Ensure the footings are embedded at least 12 inches below the frost line to prevent shifting during freeze-thaw cycles. Additionally, avoid direct contact with soil that retains high moisture levels, as this can accelerate decay despite the treatment. For added protection, consider applying a waterproof sealant to the wood’s surface, particularly in areas prone to heavy rainfall or humidity. Regular inspections every 2–3 years can help identify early signs of wear, such as cracking or splintering, allowing for timely repairs.

Comparatively, pressure-treated wood footings often outperform untreated alternatives, which may last only 5–10 years in similar conditions. However, they fall short of materials like concrete or galvanized steel, which can endure for 50 years or more. The trade-off lies in cost and ease of installation, as pressure-treated wood is generally more affordable and simpler to work with. For projects with shorter lifespans or budget constraints, pressure-treated wood remains a practical choice, provided maintenance guidelines are followed.

Environmental factors significantly influence the longevity of pressure-treated wood footings. In regions with high humidity, frequent rainfall, or proximity to bodies of water, the lifespan may be reduced to 20–25 years. Conversely, in drier climates with well-drained soil, footings can last up to 40 years or more. To mitigate environmental risks, elevate the footings slightly above ground level where possible and ensure proper grading to direct water away from the foundation. Incorporating gravel or crushed stone around the footings can also improve drainage and reduce moisture retention.

In conclusion, while pressure-treated wood footings offer a robust and cost-effective solution, their lifespan is not indefinite. By understanding the factors that impact durability and implementing proactive maintenance measures, you can ensure these footings perform optimally for decades. Whether for residential decks, fences, or small structures, pressure-treated wood footings remain a reliable choice when installed and cared for correctly.

Durability of Wooden Condos: Lifespan and Maintenance Tips Revealed

You may want to see also

Explore related products

$14.84 $16.57

Maintenance tips to extend footing longevity

Pressure-treated wood footings, when properly maintained, can last 20 to 40 years or more, depending on environmental conditions and care. To maximize their lifespan, proactive maintenance is key. Start by inspecting footings annually for signs of wear, such as cracks, splintering, or fungal growth. Early detection allows for timely intervention, preventing minor issues from escalating into structural failures.

One critical maintenance step is ensuring proper drainage around the footings. Water pooling near the base accelerates rot and decay, even in treated wood. Install gutters, downspouts, or grading adjustments to redirect water away from the foundation. For existing moisture problems, consider adding gravel or French drains to improve soil permeability and reduce saturation.

Applying a sealant every 2–3 years can significantly enhance durability. Use a high-quality, water-repellent wood preservative designed for pressure-treated lumber. Avoid paints or solid stains, as they can trap moisture and cause premature deterioration. Reapply sealant after cleaning the surface with a mild detergent and allowing it to dry completely.

For footings in contact with soil, monitor for termite activity, especially in warmer climates. Install physical barriers like metal shields or use termite-resistant mulch around the perimeter. Regularly inspect for mud tubes or wood damage, and consult a pest control professional if infestations are suspected.

Finally, avoid mechanical damage by keeping heavy equipment or vehicles away from the footing area. Even treated wood can weaken under repeated stress or impact. Trim nearby tree roots to prevent them from shifting or cracking the footings. By combining these strategies, you can preserve the integrity of pressure-treated wood footings and extend their functional life well beyond the average expectancy.

Wood County Ohio Probate Records Retention: How Long Are They Kept?

You may want to see also

Explore related products

Signs of deterioration in wood footings

Pressure-treated wood footings are designed to resist decay and insect damage, but they are not immune to deterioration over time. Recognizing the early signs of wear can help you address issues before they compromise the structural integrity of your project. One of the first indicators of trouble is surface cracking or splitting, which often occurs due to prolonged exposure to moisture and temperature fluctuations. These cracks may seem minor initially but can allow water to penetrate deeper into the wood, accelerating decay. Inspect footings annually, especially after harsh weather seasons, and seal any visible cracks with a wood preservative to extend their lifespan.

Another telltale sign of deterioration is soft or spongy wood, which suggests fungal decay or rot. This typically happens when footings are in constant contact with soil that retains moisture, such as in poorly drained areas. To test for softness, press a screwdriver into the wood—if it penetrates easily, the footing is likely compromised. Prevent this by ensuring proper drainage around the footing and using gravel or a moisture barrier between the wood and soil during installation. If rot is detected, replace the affected sections promptly to avoid further damage.

Insect damage is a less obvious but equally damaging issue, particularly from termites or carpenter ants. Look for small holes, sawdust-like frass, or hollow-sounding wood when tapped. Pressure-treated wood is treated with insecticides, but these chemicals can leach out over time, leaving the wood vulnerable. Regularly inspect footings for signs of infestation and consider applying a topical insecticide as a preventive measure. If insects are present, consult a pest control professional to address the problem effectively.

Finally, warping or shifting of the footing can indicate both wood deterioration and underlying soil issues. Warping often results from uneven moisture absorption or drying, while shifting may occur if the footing is no longer stable in the ground. Both can lead to structural instability, particularly in load-bearing applications. Monitor footings for any changes in alignment and reinforce or replace them if movement is detected. Proper initial installation, including compacting the surrounding soil and using appropriate supports, can minimize these risks.

By staying vigilant for these signs of deterioration, you can maximize the lifespan of pressure-treated wood footings, typically ranging from 20 to 40 years depending on environmental conditions and maintenance. Regular inspections and proactive measures are key to preserving their functionality and ensuring the longevity of your structures.

Exploring the Ancient Origins of Wood Formation and Age

You may want to see also

Explore related products

Comparison with alternative footing materials

Pressure-treated wood footings, while cost-effective and widely used, face stiff competition from alternative materials like concrete, steel, and composite lumber. Each material brings unique advantages and trade-offs in terms of durability, cost, and environmental impact. Understanding these differences is crucial for making informed decisions in construction projects.

Concrete footings, the traditional gold standard, offer exceptional longevity, often exceeding 50 years in optimal conditions. Their compressive strength and resistance to rot, pests, and moisture make them ideal for heavy-duty applications. However, concrete is labor-intensive to install, requires precise mixing and curing, and has a higher upfront cost compared to pressure-treated wood. Additionally, its production contributes significantly to carbon emissions, raising environmental concerns. For projects requiring maximum durability and load-bearing capacity, concrete remains unparalleled, but its ecological footprint and installation complexity must be weighed against its benefits.

Steel footings provide another durable alternative, boasting a lifespan of 75+ years when properly galvanized or coated to prevent corrosion. Steel’s high tensile strength and minimal material waste make it efficient for large-scale projects. However, its susceptibility to rust in wet environments necessitates meticulous waterproofing and maintenance. Steel is also more expensive than both wood and concrete, and its thermal conductivity can lead to energy inefficiencies in certain applications. For projects in dry climates or where minimal ground disturbance is required, steel offers a robust, long-lasting solution, but its cost and maintenance demands are non-negligible.

Composite lumber, made from recycled plastic and wood fibers, presents an eco-friendly alternative with a lifespan of 20–30 years. It resists rot, insects, and moisture without the chemical treatments required for pressure-treated wood. However, composite materials are less structurally sound than traditional wood or concrete, limiting their use to lighter-duty applications like decks or small outbuildings. Their higher cost and limited load-bearing capacity make them less competitive for large-scale or high-stress projects. For environmentally conscious builders prioritizing low maintenance, composite lumber offers a viable, though niche, option.

When comparing these materials, pressure-treated wood footings typically last 15–25 years, depending on factors like soil moisture, climate, and installation quality. While they fall short of concrete and steel in terms of longevity, their affordability and ease of installation make them a popular choice for residential projects. However, their reliance on chemical preservatives raises environmental and health concerns, particularly in water-sensitive areas. For short- to medium-term applications where cost is a primary factor, pressure-treated wood remains a practical choice, but it’s outpaced by alternatives in terms of durability and sustainability.

In summary, the choice of footing material hinges on project-specific needs, budget, and environmental considerations. Concrete and steel offer superior durability but at higher costs and ecological impacts, while composite lumber provides an eco-friendly, low-maintenance option for lighter applications. Pressure-treated wood strikes a balance between affordability and functionality, though its lifespan and environmental drawbacks limit its suitability for long-term or high-stress projects. Careful evaluation of these trade-offs ensures the selection of the most appropriate material for each unique scenario.

Preserved Wood Foundations: Lifespan, Durability, and Long-Term Performance Explained

You may want to see also

Frequently asked questions

Pressure treated wood footings can last 20 to 40 years or more, depending on factors like soil conditions, moisture exposure, and quality of installation.

Yes, footings in wet or humid climates may degrade faster due to increased moisture, while those in dry climates can last longer, often exceeding 40 years.

While pressure treated wood is resistant to rot, prolonged exposure to moisture or soil with high acidity can still cause deterioration, reducing their lifespan.

Proper installation, ensuring good drainage, using gravel or concrete bases, and regular inspections can help extend the lifespan of pressure treated wood footings.