Wooden boats, with their timeless charm and classic craftsmanship, are often prized for their aesthetic appeal and historical significance. However, their longevity is a common concern among enthusiasts and owners. The lifespan of a wooden boat can vary significantly, typically ranging from 20 to 100 years or more, depending on factors such as the type of wood used, construction quality, maintenance practices, and environmental exposure. Proper care, including regular varnishing, sealing, and protection from harsh weather conditions, plays a crucial role in preserving the boat's structural integrity. Additionally, the choice of wood—whether it’s durable species like teak or mahogany—can greatly influence its durability. With meticulous attention and timely repairs, wooden boats can endure for generations, blending tradition and functionality in a way that few other materials can match.

| Characteristics | Values |

|---|---|

| Average Lifespan | 20-50 years (with proper maintenance) |

| Maintenance Level | High (regular upkeep required) |

| Rot Resistance | Varies by wood type (e.g., teak, oak, or cedar are more durable) |

| Environmental Factors | Affected by moisture, UV exposure, and temperature fluctuations |

| Construction Quality | Significantly impacts longevity (traditional methods vs. modern techniques) |

| Protective Coatings | Essential (varnish, paint, or epoxy resins extend lifespan) |

| Storage Conditions | Covered, dry storage prolongs life; exposure shortens it |

| Usage Frequency | Less frequent use can extend lifespan |

| Repairability | High (wood is easier to repair than fiberglass or metal) |

| Cost of Maintenance | Higher compared to modern materials (e.g., fiberglass) |

| Historical Lifespan | Some well-maintained wooden boats have lasted over 100 years |

| Susceptibility to Pests | Prone to damage from marine borers and termites |

| Weight | Heavier than modern materials, affecting performance and handling |

| Resale Value | Depends on condition, rarity, and historical significance |

Explore related products

What You'll Learn

Proper maintenance techniques for extending wood boat lifespan

Wood boats, with their timeless elegance and craftsmanship, can endure for generations—some even surpassing a century—but only with meticulous care. Proper maintenance is the linchpin to preserving their structural integrity and aesthetic appeal. Exposure to water, sunlight, and fluctuating temperatures accelerates wear, making routine upkeep essential. Neglect, on the other hand, invites rot, warping, and delamination, drastically shortening a boat’s lifespan. The key lies in understanding the unique vulnerabilities of wood and addressing them proactively.

One of the most critical maintenance practices is regular inspection and cleaning. After each outing, rinse the boat thoroughly with fresh water to remove salt, debris, and contaminants that can degrade the wood and finish. Pay special attention to areas prone to moisture accumulation, such as seams, joints, and the bilge. Inspect for cracks, splintering, or signs of rot, addressing issues immediately to prevent further damage. For boats stored in water, consider using a protective cover to minimize exposure to the elements, but ensure it allows for adequate ventilation to prevent mildew.

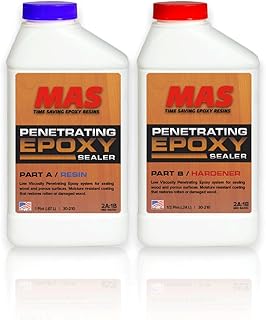

Coatings and sealants are your wood boat’s first line of defense against moisture and UV damage. Apply a high-quality marine varnish or epoxy annually, following the manufacturer’s guidelines for application thickness and drying times. For example, Epifanes or Interlux varnishes are popular choices, offering UV protection and durability. Reapply more frequently in high-exposure areas or if the finish shows signs of wear. Additionally, treat the wood with a preservative like copper naphthenate to deter rot and insect damage, particularly in submerged or frequently wet areas.

Moisture management is paramount in wood boat maintenance. Ensure proper drainage by keeping scuppers and through-hulls clear of obstructions. Store the boat in a dry, covered area during off-seasons, elevating it on stands to promote airflow. For boats with interior cabins, use a dehumidifier to control humidity levels, especially in climates prone to dampness. Periodically check for hidden moisture pockets using a moisture meter, addressing any readings above 18% to prevent rot.

Finally, structural integrity requires periodic reinforcement. Inspect fastenings, such as screws and bolts, for corrosion or loosening, replacing them with stainless steel or bronze hardware as needed. Re-caulk seams with marine-grade sealant every 3–5 years, depending on exposure. For older boats, consider consulting a marine carpenter to assess and repair structural weaknesses, such as weakened frames or planking. By combining vigilance, preventive care, and timely repairs, you can ensure your wood boat remains seaworthy and beautiful for decades to come.

Wood Rot Timeline: Factors Affecting Decay and Prevention Tips

You may want to see also

Explore related products

Impact of environmental factors on wood boat durability

Wood boats, when properly maintained, can last for decades, even centuries. However, their longevity is significantly influenced by environmental factors that can either preserve or accelerate their deterioration. Understanding these factors is crucial for boat owners aiming to maximize the lifespan of their wooden vessels.

Moisture and Humidity: The Silent Killers

Water is the primary enemy of wood boats. Prolonged exposure to moisture, whether from rain, sea spray, or high humidity, can lead to rot, warping, and delamination. For instance, boats stored in humid coastal regions without adequate ventilation are at higher risk. To mitigate this, apply marine-grade sealants annually, ensuring all seams and joints are waterproofed. Additionally, store the boat in a dry, covered area during off-seasons, and use dehumidifiers if indoor storage is available. Regularly inspect for signs of moisture intrusion, such as dark spots or soft wood, and address issues immediately.

Sunlight and UV Radiation: The Invisible Threat

UV rays from sunlight degrade wood fibers and fade finishes over time, making the boat more susceptible to cracking and splintering. This is particularly evident in tropical climates where sunlight is intense year-round. To combat this, apply UV-resistant marine varnish or paint every 12–18 months. Consider using boat covers made from UV-protective materials when the vessel is not in use. For added protection, park the boat in shaded areas or under awnings whenever possible.

Temperature Fluctuations: The Stress Test

Extreme temperature swings cause wood to expand and contract, leading to structural stress and potential cracking. Boats in regions with hot summers and cold winters, such as the northeastern U.S., are especially vulnerable. To minimize damage, avoid storing the boat in areas prone to temperature extremes, like uninsulated garages. Instead, opt for climate-controlled storage facilities. During winterization, ensure the boat is properly shrink-wrapped to insulate it from freezing temperatures and ice buildup.

Saltwater Exposure: The Corrosive Challenge

Saltwater accelerates corrosion of metal fittings and can draw moisture into the wood, exacerbating rot. Boats used in marine environments require rigorous maintenance. After each saltwater outing, rinse the boat thoroughly with fresh water to remove salt residue. Inspect and replace corroded hardware annually, and use stainless steel or galvanized fittings for better resistance. Applying epoxy resins to the hull can also create a barrier against saltwater intrusion.

Biological Threats: The Hidden Danger

Marine organisms like barnacles, algae, and wood-boring worms can attach to hulls, compromising structural integrity. Regularly clean the hull and apply anti-fouling paint to deter these organisms. For boats in infested waters, consider using ultrasonic antifouling devices. Inspect the hull monthly for signs of infestation, such as small holes or discoloration, and take immediate action if detected.

By proactively addressing these environmental factors, wood boat owners can significantly extend their vessel’s lifespan, ensuring it remains seaworthy and beautiful for generations.

Transforming Wood Chips into Mulch: Timing and Process Explained

You may want to see also

Explore related products

$11.99

Differences in longevity between wood boat types

Wood boat longevity varies significantly based on the type of wood and construction method used. For instance, traditional carvel-built boats, where planks are fastened edge-to-edge, often outlast modern plywood or cold-molded designs if maintained meticulously. Teak, a dense and naturally oil-rich wood, can endure for over a century in carvel hulls, as seen in classic yachts like the *Dorade* (launched in 1929 and still racing). In contrast, plywood boats, while lighter and easier to build, typically last 30–50 years, depending on the quality of marine-grade plywood and epoxy encapsulation. Cold-molded boats, constructed with thin layers of wood and epoxy, strike a balance, offering durability up to 60–80 years with proper care. The key takeaway? Material density and construction complexity directly influence lifespan, with denser woods and traditional methods often outperforming modern alternatives in longevity.

Maintenance practices play a pivotal role in extending the life of wood boats, but the type of boat dictates the required effort. For example, carvel-built boats demand regular caulking and inspection for plank movement, a labor-intensive process that must be repeated every 5–10 years. Plywood boats, on the other hand, require vigilant monitoring for delamination and rot, especially at joints and fastenings, with epoxy repairs needed every 10–15 years. Cold-molded boats, while more resistant to rot due to their epoxy-saturated construction, still need periodic checks for stress cracks and blistering. Owners of teak-built boats benefit from the wood’s natural resistance to decay but must apply oils or sealants every 1–2 years to prevent drying and cracking. The lesson here is clear: understanding your boat’s construction type is essential for tailoring a maintenance plan that maximizes its lifespan.

Environmental factors further differentiate the longevity of wood boat types. Boats in freshwater environments, such as lakes, generally last longer than those in saltwater due to reduced corrosion and marine organism growth. For instance, a mahogany runabout in a freshwater lake might retain its structural integrity for 70–90 years, while the same boat in saltwater could suffer from rot and fastener corrosion within 40–60 years. Plywood boats are particularly vulnerable in saltwater, as moisture can penetrate the layers more easily, accelerating delamination. Cold-molded boats fare better in saltwater due to their epoxy protection but still require antifouling treatments every 1–2 years to prevent barnacle and algae buildup. To protect your investment, consider the boat’s operating environment and choose a wood type and construction method suited to those conditions.

Finally, the intended use of the boat influences its longevity across wood types. Racing sailboats, subjected to high stresses and frequent repairs, may see their lifespan reduced by 20–30% compared to leisure cruisers, regardless of construction. For example, a cold-molded racing yacht might last 50–60 years, while a similar cruising yacht could endure for 70–80 years. Plywood boats used for fishing or day trips in sheltered waters can last 40–50 years with minimal wear, but those exposed to rough seas or heavy loads may fail within 20–30 years. Even teak-built classics can suffer premature aging if overused or improperly stored. The practical tip? Match your boat’s design and wood type to its intended use, and adjust maintenance frequency accordingly to preserve its structural integrity and aesthetic appeal.

Transporting Oversized Wood: Practical Tips for Moving Long Lumber Safely

You may want to see also

Explore related products

$34.99

Role of wood quality in boat longevity

Wood quality is the cornerstone of a wooden boat's longevity, dictating its resilience against the relentless forces of water, weather, and time. The choice of wood species, grain orientation, and moisture content at the time of construction are critical factors that determine how well a boat withstands decades of use. For instance, teak, known for its natural oils and tight grain, is highly resistant to rot and warping, making it a premium choice for boatbuilders. In contrast, pine, while more affordable, requires meticulous maintenance to prevent decay. Understanding these material properties allows builders and owners to predict and extend a wooden boat's lifespan, often surpassing 50 years with proper care.

Selecting the right wood is only the first step; proper treatment and maintenance are equally vital to preserving its integrity. Wood must be sealed effectively to prevent water absorption, which can lead to swelling, cracking, and eventual structural failure. Epoxy resins and marine-grade varnishes are commonly used to create a protective barrier, but application techniques vary. For example, cold-molding—a process of layering thin wood strips with epoxy—enhances strength and durability, often extending a boat's life by 20–30 years compared to traditional planking methods. Regular inspections for signs of wear, such as delamination or blistering, are essential to address issues before they compromise the hull.

The role of wood quality becomes particularly evident when comparing boats of the same age but different construction standards. A well-built wooden boat using high-quality materials and techniques can outlast a poorly constructed one by several decades. For instance, a mahogany-hulled boat built in the 1950s with proper joinery and regular maintenance might still be seaworthy today, while a similarly aged boat made from lower-grade wood and inadequate sealing could have deteriorated beyond repair. This disparity highlights the long-term value of investing in superior materials and craftsmanship.

Practical tips for maximizing wood boat longevity include monitoring humidity levels in storage to prevent warping, using breathable covers to avoid moisture buildup, and avoiding prolonged exposure to direct sunlight, which can dry out and weaken the wood. For restoration projects, replacing rotted sections with wood of matching density and grain is crucial to maintaining structural integrity. Additionally, documenting maintenance activities—such as resealing schedules and repairs—provides a valuable record for future owners, ensuring the boat’s continued care and longevity. By prioritizing wood quality and adhering to best practices, wooden boats can remain functional and beautiful for generations.

Playground Wood Chips Lifespan: Durability, Maintenance, and Replacement Guide

You may want to see also

Explore related products

Repair vs. replacement: cost-effective strategies for aging wood boats

Wooden boats, with their timeless elegance and craftsmanship, can endure for decades, even centuries, with proper care. However, as they age, owners face a critical decision: repair or replace? This choice hinges on cost-effectiveness, which requires a nuanced understanding of the boat’s condition, the scope of work needed, and long-term value. A 50-year-old wooden boat, for instance, may retain 70-80% of its structural integrity if maintained well, making repairs a viable option. Conversely, a neglected vessel with extensive rot or compromised frames might demand replacement, despite the sentimental appeal of restoration.

Assessing the Damage: When to Repair

Minor issues like localized rot, cracked seams, or worn varnish are prime candidates for repair. For example, replacing a single plank or re-caulking seams costs between $500 and $2,000, depending on the boat’s size and wood type. Epoxy treatments, a modern repair staple, can extend a boat’s life by 10-15 years if applied correctly. A 30-year-old boat with surface-level damage often benefits more from targeted repairs than full replacement, especially if its hull shape and design remain structurally sound. Always consult a marine surveyor to evaluate the extent of damage before committing to repairs.

The Replacement Threshold: When to Let Go

Replacement becomes the cost-effective choice when repairs exceed 50-60% of the boat’s current value. For instance, a 40-year-old wooden sailboat valued at $15,000 might require $10,000 in repairs due to extensive rot, delamination, or compromised structural members. In such cases, investing in a newer fiberglass or aluminum boat, which offers lower maintenance costs and longer durability, may be wiser. Sentimentality aside, prioritize practicality: a boat beyond 60 years with recurring issues often drains resources better allocated to a modern vessel.

Cost-Effective Strategies for Prolonging Lifespan

Prevention is the most cost-effective strategy. Regular maintenance, such as annual inspections, bi-yearly varnish coats, and prompt addressing of leaks, can double a wooden boat’s lifespan. For example, applying a marine-grade epoxy barrier coat every 5 years costs $1,000-$3,000 but prevents rot and extends the hull’s life by decades. Additionally, storing the boat in a covered, dry environment reduces weathering, while using breathable covers minimizes moisture buildup. These measures, though requiring upfront investment, save thousands in future repairs.

Balancing Sentimentality and Economics

While wooden boats hold irreplaceable charm, emotional attachment should not overshadow financial practicality. A classic wooden yacht restored to its original glory can appreciate in value, but only if the restoration is executed meticulously and authentically. For instance, a 1930s mahogany runabout restored with period-correct materials might fetch $50,000 at auction, justifying a $20,000 restoration cost. However, if the goal is recreational use rather than preservation, a modern replica or alternative material boat may offer better value. Always weigh the boat’s historical significance, restoration costs, and intended use before deciding.

Final Takeaway: Tailor the Approach to the Boat’s Story

Every wooden boat tells a story, and its repair or replacement should honor that narrative while aligning with the owner’s goals. For boats with historical or sentimental value, invest in repairs and preservation techniques, even if costly. For utilitarian vessels, prioritize practicality and long-term savings. By combining expert assessments, preventive care, and a clear understanding of costs, owners can ensure their wooden boats remain seaworthy and cost-effective for years to come.

Optimal Timing for Applying Multiple Coats of Paste Wax on Wood

You may want to see also

Frequently asked questions

With proper care, a wooden boat can last 50 years or more, depending on the type of wood, construction quality, and maintenance practices.

Yes, hardwoods like teak, oak, and mahogany are more durable and can extend a boat's lifespan compared to softer woods like pine, which may require more frequent repairs.

A wooden boat should be refinished every 3–5 years, depending on exposure to water, sun, and weather conditions, to protect the wood from rot and deterioration.

While fiberglass boats are generally more durable and require less maintenance, a well-maintained wooden boat can last just as long, though it demands more consistent care.

Exposure to moisture without proper sealing, lack of regular maintenance, and poor storage conditions (e.g., leaving it in water year-round) are the primary factors that reduce a wooden boat's lifespan.