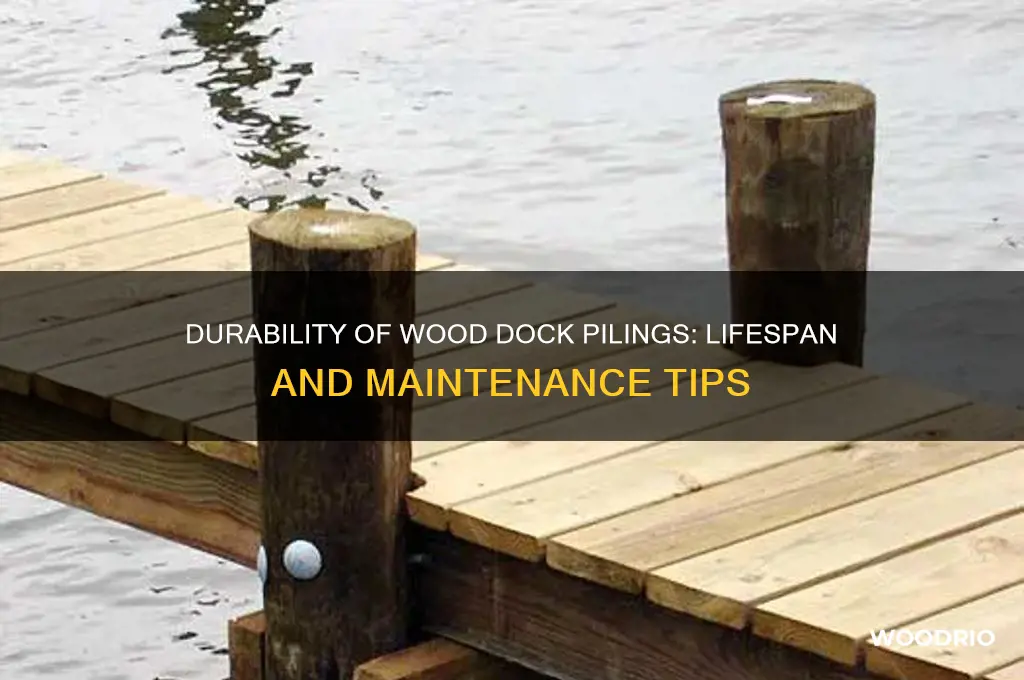

Wood dock pilings, essential for supporting structures like docks and piers, typically last between 15 to 40 years, depending on various factors such as the type of wood, environmental conditions, and maintenance practices. Hardwoods like treated pine or fir are commonly used due to their durability, while factors like saltwater exposure, marine borers, and fungal decay can significantly shorten their lifespan. Regular inspections, proper treatment, and proactive repairs can extend their longevity, making them a reliable but maintenance-dependent choice for waterfront infrastructure.

Explore related products

What You'll Learn

Factors affecting wood dock pilings lifespan

Wood dock pilings, when properly maintained, can last anywhere from 20 to 40 years, but their lifespan is heavily influenced by several key factors. One of the most critical is the type of wood used. Hardwoods like oak or cedar are naturally more resistant to decay and insect damage compared to softer woods like pine. For instance, cedar pilings, treated with preservatives, can outlast pine by a decade or more due to their inherent durability and resistance to rot.

Environmental conditions play a pivotal role in determining how long wood dock pilings endure. Pilings in saltwater environments face accelerated deterioration due to the corrosive nature of salt, which can weaken the wood fibers over time. Freshwater settings, while less harsh, still pose risks from moisture absorption and fungal growth. Additionally, pilings in areas with frequent tidal changes or strong currents are subjected to constant mechanical stress, leading to faster wear and tear. Installing pilings in calmer waters or using protective barriers can mitigate these effects.

Proper installation and maintenance are non-negotiable for maximizing the lifespan of wood dock pilings. Pilings should be set at the correct depth, ensuring they are embedded in stable soil or bedrock to prevent shifting. Regular inspections for cracks, splinters, or signs of marine borer infestation are essential. Applying a fresh coat of preservative treatment every 3–5 years can significantly extend their life. For example, creosote-treated pilings, when maintained, can last up to 30 years, while untreated pilings may fail in half that time.

The design and load-bearing requirements of the dock also impact piling longevity. Overloading pilings with excessive weight or failing to account for wave action can lead to premature failure. Engineers recommend calculating the maximum load based on the dock’s intended use and ensuring pilings are spaced appropriately to distribute weight evenly. For heavy-use docks, such as those in marinas, using larger diameter pilings or reinforcing them with steel sleeves can provide added durability.

Finally, local regulations and climate-specific challenges must be considered. In regions prone to hurricanes or ice formation, pilings may require additional bracing or deeper installation to withstand extreme forces. Compliance with environmental regulations, such as restrictions on certain chemical treatments, can also influence material choices and maintenance practices. By addressing these factors proactively, dock owners can ensure their pilings remain functional and safe for decades.

Optimal Length for Laminate Wood Pieces: A Comprehensive Guide

You may want to see also

Explore related products

$25.99

Common types of wood used for pilings

Wood dock pilings are a critical investment, and their lifespan hinges significantly on the type of wood chosen. Among the most common options, pressure-treated pine stands out for its affordability and widespread availability. Treated with preservatives like chromated copper arsenate (CCA) or alkaline copper quaternary (ACQ), this wood can resist rot, insects, and marine borers for 20 to 40 years, depending on environmental conditions. However, its durability diminishes in saltwater environments, where constant exposure accelerates degradation. For those on a budget, pressure-treated pine is a practical choice, but regular inspections and maintenance are essential to maximize its lifespan.

For a more robust solution, western red cedar is a premium option favored for its natural resistance to decay and insects. This wood contains tannins and oils that deter pests and fungi, making it ideal for pilings in both freshwater and saltwater settings. While it comes at a higher cost, western red cedar can last 30 to 50 years with minimal treatment, reducing long-term maintenance needs. Its lightweight yet strong nature also simplifies installation, though it’s crucial to source from sustainable suppliers to ensure quality and environmental responsibility.

Douglas fir is another popular choice, prized for its strength and durability. Often used in heavy-duty applications like commercial docks, this wood can withstand significant weight and environmental stress. When pressure-treated, Douglas fir pilings can last 25 to 40 years, though they are more susceptible to marine borers in saltwater. To enhance longevity, consider applying additional protective coatings or wraps, especially in high-moisture areas. Its availability and structural integrity make it a reliable option for those prioritizing strength over cost.

For the ultimate in durability, tropical hardwoods like greenheart or ipe are unparalleled. These dense, naturally rot-resistant woods can endure 50 years or more, even in harsh saltwater conditions. Their high density makes them impervious to most pests and fungi, though their weight and hardness can complicate installation. The primary drawback is cost, as these woods are expensive and often imported, raising sustainability concerns. For projects where longevity is non-negotiable, however, tropical hardwoods are a superior, if pricey, investment.

When selecting wood for pilings, consider not only lifespan but also environmental impact and maintenance requirements. Pressure-treated pine offers a balance of cost and durability, while western red cedar and Douglas fir provide natural or enhanced resistance tailored to specific conditions. Tropical hardwoods, though costly, deliver unmatched longevity for critical applications. Each type has its strengths, and the right choice depends on budget, location, and long-term goals. Regular inspections and proactive maintenance will further extend the life of any piling, ensuring your dock remains stable and secure for decades.

Hickory vs. Oak: Which Hardwood Offers Superior Durability and Longevity?

You may want to see also

Explore related products

Maintenance tips to extend piling longevity

Wood dock pilings, when properly maintained, can last 20 to 40 years, but their lifespan is heavily influenced by environmental factors and care practices. One of the most effective ways to extend their longevity is through regular inspection and proactive maintenance. Begin by inspecting pilings at least twice a year, focusing on areas below the waterline where decay often starts unnoticed. Look for signs of marine borer activity, such as small holes or frass (sawdust-like debris), and check for cracks or splintering caused by weathering. Early detection allows for targeted repairs before structural integrity is compromised.

A critical maintenance step is applying protective coatings to pilings. Use a high-quality, marine-grade wood preservative containing copper naphthenate or creosote, which repel marine organisms and resist rot. Apply the treatment every 3 to 5 years, ensuring complete coverage, especially on the submerged portion. For pilings in saltwater environments, consider wrapping the base with a protective barrier like a rubber sleeve or plastic guard to minimize exposure to corrosive elements. This simple measure can add years to a piling’s life by reducing direct contact with water and marine life.

Another overlooked aspect of piling maintenance is managing water flow around the structure. Ensure proper drainage by clearing debris from the dock surface and installing gutters or downspouts to direct rainwater away from pilings. Standing water accelerates rot and attracts wood-damaging insects. Additionally, trim vegetation near the dock to improve airflow and reduce moisture retention. In areas prone to heavy wave action, install protective bumpers or fenders to minimize impact damage from boats or floating debris, which can weaken pilings over time.

For pilings already showing signs of wear, consider reinforcing them with metal sleeves or composite wraps. These solutions provide structural support while shielding the wood from further damage. If a piling is severely compromised, partial replacement or splicing with new wood can be more cost-effective than full replacement. Always consult a marine contractor for repairs involving load-bearing pilings to ensure safety and compliance with local regulations. By combining preventive measures with timely interventions, you can significantly extend the lifespan of wood dock pilings and delay the need for costly replacements.

Metal vs. Wood Box Springs: Which Material Offers Greater Durability?

You may want to see also

Explore related products

Signs of deterioration in wood pilings

Wood dock pilings, typically made from durable species like treated pine or tropical hardwoods, can last 20 to 40 years under ideal conditions. However, their lifespan hinges on recognizing and addressing early signs of deterioration. One of the first indicators is cracking or splitting, often caused by repeated exposure to moisture and sunlight. These fissures may seem minor but allow water and pests to penetrate the wood, accelerating decay. Inspect pilings annually, focusing on areas near the waterline where stress is highest, and seal cracks promptly with marine-grade wood filler.

Another red flag is soft or spongy wood, a telltale sign of rot. This occurs when fungi break down cellulose in the wood, compromising its structural integrity. To test for rot, press a screwdriver into the piling; if it sinks easily, the wood is compromised. Rot often starts at the base, where pilings are in constant contact with water. Preventive measures include ensuring proper drainage and applying antifungal treatments every 2–3 years. If rot is detected, replace affected sections immediately to avoid collapse.

Pest infestations, particularly from marine borers and termites, can also hasten deterioration. Marine borers leave small, round holes in the wood, while termites create mud tubes along the piling’s surface. Regularly inspect for these signs, especially in warmer months when pest activity peaks. Treat pilings with borate-based preservatives during installation and reapply every 5 years. For active infestations, consult a pest control specialist to determine the appropriate treatment, such as injecting insecticides or using physical barriers.

Finally, warping or leaning indicates advanced deterioration, often due to uneven decay or soil erosion around the piling’s base. A leaning piling poses an immediate safety risk and should be replaced without delay. To mitigate this, monitor soil levels annually and reinforce the base with gravel or concrete if erosion is detected. Additionally, install bracing or supports for pilings showing early signs of movement to extend their functional life.

By vigilantly monitoring these signs and taking proactive measures, you can maximize the lifespan of wood dock pilings and ensure the safety and longevity of your dock structure.

Durability of Wood Countertops: Lifespan and Maintenance Tips Revealed

You may want to see also

Explore related products

Alternatives to traditional wood pilings

Wood dock pilings, while traditional, are susceptible to rot, insect damage, and environmental wear, typically lasting 15 to 25 years. This lifespan can be shorter in saltwater environments or areas with high moisture levels. As maintenance costs and environmental concerns rise, alternatives to wood pilings are gaining traction. These options offer extended durability, reduced maintenance, and often, a smaller ecological footprint.

One prominent alternative is composite pilings, made from a blend of recycled plastic and wood fibers. These pilings resist rot, insects, and splintering, often lasting 40 to 50 years with minimal upkeep. For example, brands like Trex and FiberPile offer composite options that mimic the look of wood while providing superior longevity. Installation is similar to wood pilings, but they are heavier, requiring proper equipment and techniques. While the initial cost is higher, the long-term savings on maintenance and replacement make them a cost-effective choice.

Concrete pilings are another durable option, particularly in high-traffic or industrial settings. They can last 50 years or more, depending on the quality of the concrete and environmental conditions. Reinforced with steel, these pilings withstand heavy loads and resist erosion. However, they are significantly heavier and more labor-intensive to install, often requiring specialized equipment. Additionally, concrete can contribute to environmental issues like thermal pollution in water bodies, making it less eco-friendly than other alternatives.

For those seeking an eco-conscious option, aluminum pilings are lightweight, corrosion-resistant, and can last 30 to 50 years. They are ideal for saltwater environments due to their natural resistance to rust and marine organisms. Aluminum pilings are also recyclable at the end of their lifespan, reducing waste. However, they are more expensive upfront and can be prone to denting or damage from heavy impacts. Proper installation, including secure anchoring, is critical to prevent shifting or instability.

Lastly, vinyl-wrapped pilings combine the traditional look of wood with enhanced durability. These pilings feature a wood core encased in a vinyl exterior, protecting against moisture, insects, and UV damage. With a lifespan of 20 to 30 years, they offer a middle ground between traditional wood and more advanced materials. Maintenance is minimal, typically requiring only occasional cleaning. However, the vinyl coating can degrade over time, especially in harsh conditions, necessitating periodic inspection.

When choosing an alternative to wood pilings, consider factors like budget, environmental impact, and specific site conditions. Each material has unique advantages and limitations, so selecting the right one ensures a longer-lasting, more sustainable dock structure.

Best Timing for Splitting Wood: Tips for Optimal Results

You may want to see also

Frequently asked questions

Wood dock pilings typically last between 15 to 40 years, depending on factors like the type of wood, environmental conditions, and maintenance.

Pressure-treated southern yellow pine and tropical hardwoods like cedar or cypress are the most durable, often lasting 20 to 40 years with proper care.

Yes, exposure to saltwater, moisture, insects, and marine borers can significantly shorten the lifespan of wood pilings, often reducing it to 10–20 years without proper protection.

Regular maintenance, such as applying waterproof sealants, using protective wraps, and inspecting for damage, can extend the lifespan of wood pilings by 5–10 years or more.

Wood pilings are generally less durable than composite or concrete pilings, which can last 50+ years. However, wood is often more cost-effective and easier to replace when damaged.