Wood lathe carbide tools are renowned for their durability and longevity, making them a popular choice among woodturners. The lifespan of these tools can vary significantly depending on several factors, including the quality of the carbide, the frequency of use, the type of wood being turned, and the user's technique. High-quality carbide inserts, when properly maintained and used correctly, can last for hundreds of hours of turning, often outperforming traditional high-speed steel tools. However, factors such as aggressive cutting, improper sharpening, or turning abrasive woods like exotic hardwoods or reclaimed timber can shorten their lifespan. Regular inspection, timely rotation of cutting edges, and avoiding overheating are key practices to maximize the longevity of wood lathe carbide tools. Understanding these variables helps woodturners make informed decisions to ensure their tools remain effective and reliable over time.

| Characteristics | Values |

|---|---|

| Tool Material | Carbide (tungsten carbide) |

| Average Lifespan | 20–100 times longer than high-speed steel (HSS) tools |

| Factors Affecting Lifespan | Tool quality, wood hardness, cutting speed, feed rate, technique |

| Softwoods (e.g., pine, cedar) | 100–500 hours of use |

| Hardwoods (e.g., oak, maple) | 50–200 hours of use |

| Exotic/Dense Woods (e.g., ebony) | 20–100 hours of use |

| Maintenance Required | Minimal (occasional rotation or replacement of carbide inserts) |

| Sharpening Frequency | Rarely needed; replace inserts instead |

| Cost per Hour of Use | Lower than HSS due to longer lifespan |

| Wear Indicators | Dull cutting edge, increased chatter, rough finish |

| Compatibility | Works with most wood lathes and handle systems |

| Environmental Impact | Longer lifespan reduces waste compared to HSS tools |

| Skill Level Required | Beginner-friendly; less technique-dependent than HSS |

| Heat Resistance | High (carbide retains hardness at elevated temperatures) |

| Common Sizes | 10–15 mm square inserts (varies by manufacturer) |

| Replacement Cost | $5–$20 per insert (depending on brand and quality) |

| Overall Durability | Superior to HSS; ideal for heavy or repetitive turning tasks |

Explore related products

What You'll Learn

Factors Affecting Tool Life

The lifespan of wood lathe carbide tools is not set in stone; it's a dynamic interplay of factors that either extend or shorten their usability. Understanding these variables is crucial for woodturners aiming to maximize tool performance and minimize costs. One of the primary factors is the material being turned. Harder woods like maple or oak demand more from the carbide, leading to faster wear compared to softer woods like pine or cedar. For instance, a carbide cutter used on walnut might last 50% longer than when used on hickory under similar conditions.

Another critical factor is cutting speed and feed rate. Pushing the tool too aggressively or running the lathe at excessive speeds generates heat, which accelerates carbide wear. A general rule of thumb is to maintain a cutting speed between 1,000 and 2,000 surface feet per minute (SFPM) for most woods. Pairing this with a controlled feed rate—advancing the tool no more than 1/16 inch per pass—can significantly prolong tool life. Overloading the tool, even momentarily, can create microfractures in the carbide, leading to premature failure.

The quality and design of the carbide insert also play a pivotal role. Not all carbide is created equal; inserts with higher cobalt content (10–12%) tend to be more wear-resistant but less impact-resistant, while those with lower cobalt (6–8%) offer better toughness. Additionally, the shape and sharpness of the cutting edge matter. A rounded or dull edge forces the tool to work harder, increasing wear. Regularly rotating or replacing inserts when they show signs of wear—such as a radius greater than 0.010 inches—can double their effective lifespan.

Finally, maintenance and handling practices cannot be overlooked. Carbide tools are durable but not indestructible. Dropping them or storing them improperly can chip the cutting edge, rendering the tool useless. Cleaning the tool after each use to remove pitch and debris prevents buildup that can affect cutting efficiency. For those using indexable carbide inserts, keeping a log of usage hours and inspecting for wear patterns can help predict when a replacement is needed, avoiding mid-project failures.

By addressing these factors—material, cutting parameters, tool quality, and maintenance—woodturners can systematically extend the life of their carbide tools. While a single insert might last anywhere from 20 to 100 hours depending on these variables, the goal is not just longevity but consistent performance. Mastering these nuances ensures that each tool delivers its maximum potential, turning the question of lifespan from a guess into a calculated advantage.

Longhorn Beetles and Wood: Exploring Their Borrowing Habits

You may want to see also

Explore related products

Proper Tool Maintenance Tips

Carbide wood lathe tools are prized for their durability and longevity, often outlasting traditional high-speed steel (HSS) tools by a significant margin. However, their lifespan isn’t infinite. Proper maintenance is key to maximizing their performance and ensuring they remain sharp and effective. Neglecting care can lead to premature wear, dull edges, and even breakage, undermining their primary advantage.

Cleaning and Storage: The Foundation of Longevity

After each use, remove wood residue and pitch buildup from the carbide edges using a brass brush or a dedicated carbide cleaning tool. Avoid steel brushes, as they can damage the carbide surface. Store tools in a dry, organized space to prevent accidental damage. A simple magnetic strip or foam-lined case keeps them secure and accessible. Moisture is the enemy; ensure your storage area is free from humidity to prevent rust on the tool holders.

Sharpening: Less is More

One of the greatest advantages of carbide tools is their infrequent need for sharpening. When the time comes, use a diamond paddle or a carbide-specific sharpener to refresh the cutting edge. Unlike HSS tools, carbide requires minimal material removal—a few light passes are usually sufficient. Over-sharpening wastes carbide and shortens the tool’s life. Aim to maintain the original bevel angle for consistency.

Handling and Usage: Preventing Unnecessary Wear

Carbide tools are robust but not indestructible. Avoid excessive force or aggressive cuts, as these can chip the carbide insert. Let the tool do the work by maintaining a steady feed rate and light pressure. Regularly inspect the tool for signs of wear or damage, such as rounded edges or cracks. Replace inserts when they become too small or uneven to maintain a clean cut.

Lubrication and Cooling: A Debated Practice

While some woodturners advocate for using wax or oil to reduce friction, carbide tools generally don’t require lubrication. Excessive wax can build up and interfere with cutting performance. However, in hard or exotic woods, a light application of paste wax on the tool’s surface can minimize friction and heat. Always clean the tool thoroughly afterward to prevent residue buildup.

By adhering to these maintenance practices, carbide wood lathe tools can last for years, delivering consistent results and reducing the need for frequent replacements. Proper care not only extends their lifespan but also enhances your turning experience, ensuring smooth, precise cuts every time.

Soaking Pimento Wood: Essential Tips for Perfect Smoking Duration

You may want to see also

Explore related products

Carbide vs. HSS Durability

Carbide and HSS (High-Speed Steel) tools represent two distinct approaches to woodturning, each with its own durability profile. Carbide tools, known for their hardness and heat resistance, typically last 20 to 100 times longer than HSS tools under normal use. This longevity stems from carbide’s tungsten carbide composition, which retains its edge even when subjected to harder woods or prolonged turning sessions. HSS tools, while more affordable, require frequent sharpening due to their softer steel alloy, which wears down faster, especially in abrasive conditions. For woodturners, this means carbide tools are a long-term investment, while HSS tools demand more hands-on maintenance.

To maximize the lifespan of these tools, consider their application-specific strengths. Carbide tools excel in roughing and shaping operations, where their durability shines, but they are less versatile for intricate detailing. HSS tools, on the other hand, offer precision for fine cuts and detailing but require regular sharpening—ideally every 15 to 30 minutes of active use. A practical tip: invest in a high-quality sharpening system if you choose HSS, as improper sharpening accelerates wear. For carbide, focus on proper tool angles and light passes to avoid chipping, which remains its primary vulnerability.

A comparative analysis reveals that carbide’s durability comes at a higher upfront cost, often 2 to 3 times that of HSS tools. However, the reduced need for replacements and sharpening translates to long-term savings. For instance, a carbide cutter can last 50+ hours of turning, whereas an HSS tool may require resharpening after just 30 minutes of heavy use. This makes carbide ideal for professionals or frequent turners, while HSS suits hobbyists or those on a budget. The trade-off lies in balancing initial expense against ongoing maintenance demands.

Finally, environmental factors play a role in tool durability. Carbide tools are less affected by moisture or temperature fluctuations, making them suitable for humid workshops. HSS tools, however, are prone to rust and require rust-inhibiting oils or dry storage. A pro tip: for HSS users, apply a thin coat of machine oil after sharpening to prevent oxidation. By understanding these material properties and tailoring usage accordingly, woodturners can optimize tool life and performance, ensuring both carbide and HSS serve their intended purposes effectively.

John Wooden's Coaching Legacy: Uncovering His Remarkable Tenure Length

You may want to see also

Explore related products

Signs of Tool Wear

Wood lathe carbide tools are prized for their durability, but even these robust instruments eventually show signs of wear. Recognizing these indicators early can save you from compromised work quality and potential safety hazards. One of the most obvious signs is a noticeable decrease in cutting efficiency. If you find yourself applying more force than usual or experiencing increased vibration, the carbide edge may be dulling. This occurs as the sharp cutting surface wears down, forcing you to exert more effort to achieve the same results.

Another telltale sign is the appearance of rough or uneven cuts. Fresh carbide tools leave clean, smooth surfaces, but as they wear, the edges become rounded or chipped, leading to tear-out or jagged edges in your workpiece. Inspect the cut surface closely; if you notice splintering or a rough texture, it’s time to assess your tool’s condition. Additionally, examine the tool itself for visible chips or cracks in the carbide insert. Even small imperfections can significantly impact performance and should not be ignored.

A less obvious but equally important sign is an increase in heat buildup during operation. Carbide tools are designed to dissipate heat efficiently, but as the cutting edge wears, friction increases, causing the tool and workpiece to heat up more than usual. Excessive heat can alter the wood’s properties, leading to discoloration or burning. If you notice a burning smell or see scorch marks on your project, it’s a clear indication that your carbide tool is past its prime.

Finally, listen to the sound of the tool in action. A well-maintained carbide cutter operates with a consistent, smooth hum. As wear progresses, you may hear a higher-pitched whine or a grinding noise, signaling that the tool is struggling to cut effectively. This auditory cue, combined with the other signs, provides a comprehensive assessment of your tool’s condition. Regularly monitoring these indicators ensures your carbide tools remain in optimal shape, prolonging their lifespan and maintaining the quality of your woodworking projects.

Mr. Garrison's Woodland Life: Duration and Survival Story Explored

You may want to see also

Explore related products

$68.98

Extending Carbide Tool Lifespan

Carbide tools for wood lathes are prized for their hardness and heat resistance, but their lifespan varies widely based on usage and maintenance. On average, a carbide insert can last anywhere from 20 to 100 hours of turning time, depending on factors like wood density, cutting speed, and technique. Hardwoods like oak or maple wear tools faster than softer woods like pine. To maximize longevity, understanding and mitigating these factors is key.

One of the most effective ways to extend carbide tool lifespan is by optimizing cutting techniques. Reduce the depth of cut to minimize stress on the tool, especially when working with dense or figured wood. Aim for a depth of 1/16 to 1/8 inch per pass, adjusting based on the wood’s hardness. Maintain a consistent cutting speed—between 1,000 and 2,000 RPM for most projects—to avoid overheating the tool. Proper tool presentation is equally critical; ensure the tool rests flat on the tool rest and is presented at the correct angle (typically 10–15 degrees) to reduce chatter and uneven wear.

Regular maintenance is another cornerstone of tool longevity. Inspect carbide inserts for signs of wear, such as rounding or chipping, and rotate or replace them as needed. Keep the tool clean by removing built-up pitch and debris after each session. A light coating of oil on the tool’s body can prevent rust, but avoid applying oil to the cutting edge, as it can interfere with performance. For inserts, consider using a diamond file or sharpening system to restore sharpness, though this is only practical for certain styles of carbide cutters.

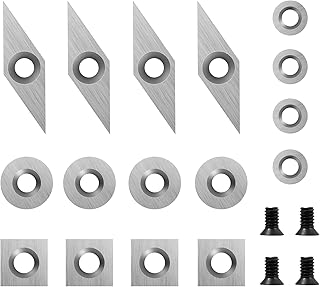

Finally, selecting the right tool for the job can significantly impact lifespan. Square carbide inserts excel at roughing and heavy cuts but wear faster than round or diamond-shaped inserts, which are better suited for detail work and finishing. For bowl turners, a negative rake scraper can reduce friction and heat buildup, prolonging tool life. Investing in high-quality carbide and toolholders also pays dividends, as cheaper materials often dull or break prematurely. By combining proper technique, maintenance, and tool selection, woodturners can dramatically extend the lifespan of their carbide tools.

Granville T. Woods: Revolutionizing Long-Distance Communication with Innovative Inventions

You may want to see also

Frequently asked questions

The lifespan of wood lathe carbide tools varies depending on usage, wood hardness, and cutting techniques, but they generally last 20 to 100 times longer than traditional high-speed steel (HSS) tools.

Factors include the type of wood being turned (hardwoods wear tools faster), cutting speed, tool pressure, and proper tool maintenance, such as keeping the carbide inserts sharp and clean.

Carbide tools do not need frequent resharpening like HSS tools. Instead, the carbide inserts can be rotated or replaced when dull, significantly extending the tool's overall lifespan.

Replace the carbide insert or tool when it becomes chipped, excessively worn, or no longer holds a sharp edge, even after rotation or replacement of the insert.