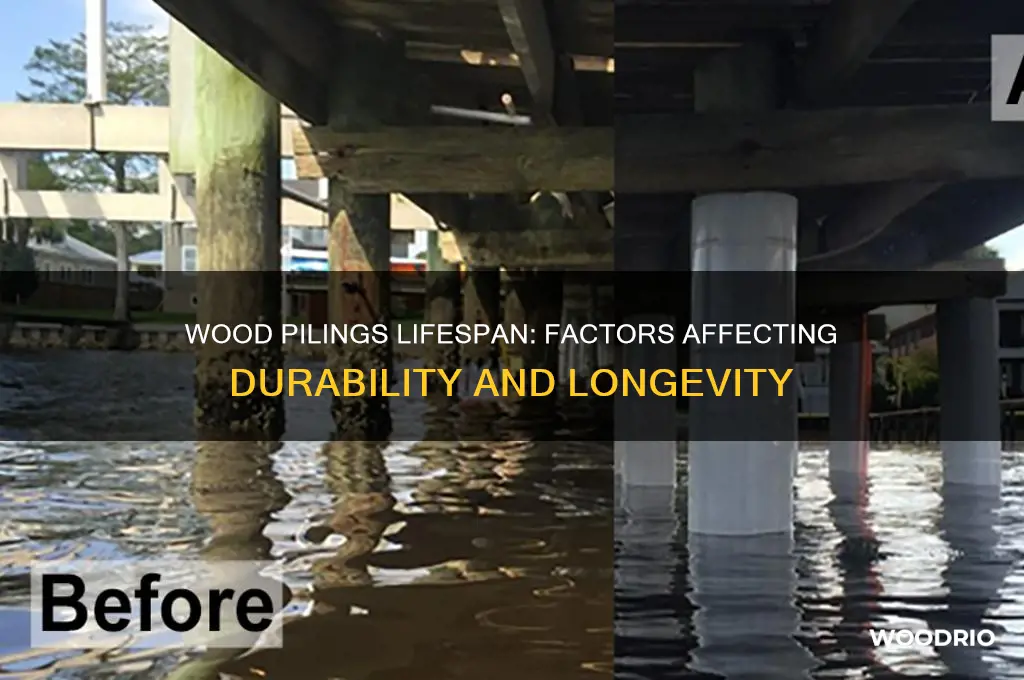

Wood pilings, commonly used in construction for foundations, docks, and bridges, have varying lifespans depending on factors like wood type, environmental conditions, and maintenance. Hardwoods like oak or Douglas fir, naturally resistant to decay, can last 20 to 40 years or more, especially when treated with preservatives. Softwoods, such as pine, typically last 10 to 20 years without treatment but can be extended with proper care. Exposure to moisture, saltwater, insects, and fungi significantly shortens their lifespan, while techniques like pressure treatment, wrapping, and regular inspections can prolong durability. Understanding these factors is crucial for estimating how long wood pilings will last in specific applications.

| Characteristics | Values |

|---|---|

| Lifespan (Untreated Wood) | 5-10 years |

| Lifespan (Pressure-Treated Wood) | 15-20 years |

| Lifespan (Cedar or Redwood) | 20-30 years |

| Lifespan (Tropical Hardwoods) | 40+ years |

| Factors Affecting Lifespan | Exposure to moisture, soil conditions, insect activity, and climate |

| Maintenance Requirements | Regular staining, sealing, or painting to extend lifespan |

| Common Causes of Failure | Rot, decay, insect damage, and physical damage |

| Environmental Impact | Biodegradable, but chemical treatments may have environmental concerns |

| Cost Considerations | Initial cost vs. long-term maintenance and replacement costs |

| Best Practices for Longevity | Proper installation, adequate drainage, and regular inspections |

Explore related products

What You'll Learn

Factors affecting pilking lifespan

Wood pilings, often used in marine environments or as structural supports, are subject to a variety of factors that determine their lifespan. One critical element is the type of wood used. Hardwoods like oak or Douglas fir inherently resist decay better than softer woods like pine, which may require additional treatments to extend their longevity. For instance, untreated pine pilings in saltwater environments can deteriorate within 5–10 years, while treated oak pilings can last upwards of 40 years. This disparity underscores the importance of material selection in predicting and maximizing piling lifespan.

Environmental conditions play a pivotal role in how quickly pilings degrade. Saltwater exposure accelerates decay due to its corrosive nature, while freshwater environments are generally less harsh. Temperature fluctuations also matter; in tropical climates, fungal growth and insect activity can shorten lifespan, whereas colder regions may slow these processes. For example, pilings in the Gulf of Mexico face more rapid deterioration compared to those in the Great Lakes due to warmer temperatures and higher salinity. Understanding these environmental variables allows for better planning and maintenance strategies.

Treatment methods significantly influence piling durability. Pressure-treating wood with preservatives like creosote or chromated copper arsenate (CCA) can add decades to its lifespan. However, the effectiveness of treatment depends on application quality and depth of penetration. Improperly treated pilings may fail prematurely, especially in harsh conditions. For optimal results, ensure treatments meet industry standards, such as the American Wood Protection Association (AWPA) guidelines, which specify retention levels (e.g., 60 pounds of preservative per cubic foot for marine environments).

Physical stressors, such as tidal movement, wave action, and soil type, also impact piling lifespan. Pilings in areas with strong currents or frequent boat traffic endure more mechanical wear, leading to cracks or splintering. Additionally, pilings driven into sandy soil may shift over time, compromising stability, while clay soils can retain moisture, promoting rot. Regular inspections and reinforcement, such as installing protective caps or using steel sleeves, can mitigate these risks and extend piling life.

Finally, maintenance practices are crucial for prolonging piling lifespan. Periodic cleaning to remove marine growth, such as barnacles or algae, prevents moisture retention and wood softening. Reapplying preservatives every 5–10 years, depending on exposure, can also rejuvenate protection. For pilings in high-traffic areas, consider installing fenders or bumpers to reduce impact damage. By addressing these factors proactively, property owners can ensure pilings remain functional and safe for their intended lifespan.

Wild Wood Pigeons Lifespan: Understanding Their Survival in Nature

You may want to see also

Explore related products

Signs of pilking deterioration

Wood pilings, often used in marine environments or as foundational supports, are susceptible to deterioration over time. Recognizing the early signs of decay is crucial for maintaining structural integrity and preventing costly repairs. One of the first indicators is surface cracking, which may appear as fine lines or deeper fissures. These cracks allow moisture to penetrate deeper into the wood, accelerating rot and weakening the piling’s core. Inspect pilings annually, focusing on areas exposed to water or soil, and use a screwdriver to test for softness in cracked regions.

Another telltale sign is fungal growth, often visible as dark streaks, patches, or a fuzzy texture on the wood surface. Fungi thrive in damp conditions and break down cellulose, a primary component of wood. If left untreated, fungal infestations can lead to advanced decay, reducing the piling’s load-bearing capacity. To mitigate this, ensure proper drainage around pilings and apply fungicidal treatments as a preventive measure. For existing growth, remove affected wood and treat the area with a wood preservative.

Insect damage is a less visible but equally destructive sign of deterioration. Termites, carpenter ants, and marine borers create tunnels and galleries within the wood, compromising its structural strength. Look for small exit holes, sawdust-like frass, or hollow-sounding areas when tapped. Regularly inspect pilings for these signs, especially in warmer climates where insect activity is higher. Applying insecticidal treatments and using pressure-treated wood can significantly extend piling lifespan.

Finally, warping or leaning indicates advanced deterioration, often caused by prolonged moisture exposure or uneven soil settlement. A leaning piling poses an immediate safety risk and requires urgent attention. Measure pilings for plumb annually and monitor any deviations. If warping is detected, assess the surrounding soil conditions and consider reinforcing or replacing the affected piling. Early intervention can prevent catastrophic failure and ensure the longevity of the structure.

Understanding the Lifespan of Wood Boring Beetles: A Comprehensive Guide

You may want to see also

Explore related products

Maintenance tips for longevity

Wood pilings, when properly maintained, can last anywhere from 20 to 40 years or more, depending on environmental conditions and care. However, without consistent maintenance, their lifespan can be significantly shortened. The key to longevity lies in proactive measures that address moisture, pests, and structural integrity.

Inspect Regularly, Act Promptly

Begin with biannual inspections, ideally in spring and fall. Look for signs of rot, cracks, or pest activity, particularly termites or marine borers. Use a screwdriver to test the wood’s firmness—if it penetrates easily, the piling is compromised. Address issues immediately: replace damaged sections or apply epoxy fillers for minor cracks. For pilings in water, check for marine growth like barnacles, which can trap moisture and accelerate decay.

Seal and Protect Against Moisture

Moisture is the primary enemy of wood pilings. Apply a high-quality wood preservative or sealant every 2–3 years, focusing on the base where water and soil meet. For pilings in saltwater environments, use a copper-based preservative to combat marine organisms. Consider installing a physical barrier, such as a rubber boot or metal sleeve, around the base to minimize ground contact and moisture absorption.

Manage Surrounding Environment

The area around pilings plays a critical role in their durability. Ensure proper drainage to prevent standing water, which can lead to rot. Trim vegetation and remove debris to reduce humidity and discourage pests. For pilings in water, maintain a clearance of at least 6 inches above the waterline to minimize prolonged exposure. If possible, elevate pilings on concrete footings to reduce direct contact with soil or water.

Treat for Pests Proactively

Termites and marine borers can silently destroy pilings from within. Schedule annual pest inspections, especially in humid or coastal regions. Apply borate-based treatments to repel termites, and use pressure-treated wood for replacements. For pilings in water, consider wrapping the base with wire mesh to deter borers. If infestation is detected, consult a professional for fumigation or localized treatment options.

By combining regular inspections, moisture management, environmental control, and pest prevention, you can maximize the lifespan of wood pilings. While initial efforts require investment, the long-term savings in replacement costs and structural integrity make maintenance a wise strategy.

Ground Contact Wood Durability: Lifespan and Preservation Tips Explained

You may want to see also

Explore related products

Comparing pilking types and durability

Wood pilings, often used in construction and marine environments, vary significantly in durability based on the type of wood and treatment methods employed. Hardwoods like oak and Douglas fir naturally resist decay and insect damage, typically lasting 25 to 40 years in moderate conditions. In contrast, softer woods like pine or spruce degrade faster, often lasting only 10 to 15 years without treatment. However, even hardwoods can fail prematurely when exposed to harsh conditions, such as saltwater or constant moisture, underscoring the importance of material selection for specific environments.

Pressure-treated wood pilings extend lifespan dramatically by infusing preservatives deep into the wood fibers. Common treatments include chromated copper arsenate (CCA) and alkaline copper quaternary (ACQ), which protect against fungi, insects, and rot. CCA-treated pilings can last 30 to 50 years, while ACQ-treated ones typically endure 20 to 30 years. However, CCA is restricted in residential applications due to arsenic toxicity, making ACQ a safer but slightly less durable alternative. Proper installation, such as ensuring pilings are not buried in soil where moisture accumulates, further maximizes their longevity.

Composite pilings, made from recycled plastic and wood fibers, offer a low-maintenance alternative with a lifespan of 50 years or more. These pilings resist warping, splitting, and insect damage, making them ideal for high-moisture environments like docks and seawalls. While the initial cost is higher than treated wood, their durability and minimal upkeep often provide long-term savings. However, composites can be more challenging to cut and install, requiring specialized tools and techniques.

Concrete pilings outlast wood and composites, with a lifespan exceeding 100 years in most conditions. Their resistance to rot, insects, and marine borers makes them a reliable choice for heavy-duty applications. However, concrete is prone to cracking under extreme temperature fluctuations and can be costly to transport and install. For projects requiring maximum durability, concrete remains unmatched, but its weight and rigidity limit its use in certain scenarios.

When comparing pilings, consider the trade-offs between cost, durability, and environmental impact. Hardwoods and treated wood offer affordability and moderate durability, while composites provide longevity with higher upfront costs. Concrete delivers unparalleled durability but at a premium. For optimal results, match the piling type to the specific demands of the environment and project requirements, ensuring both performance and cost-effectiveness. Regular inspections and maintenance, such as reapplying preservatives or repairing cracks, can further extend the life of any piling type.

Wood Pigeon Hatching Timeline: From Egg to Chick Explained

You may want to see also

Explore related products

$9.99

Environmental impact on pilking life

The lifespan of wood pilings is significantly influenced by their environmental exposure, with factors like moisture, temperature, and biological activity playing critical roles. In coastal or wetland areas, where pilings are constantly in contact with water, the risk of rot and decay accelerates due to fungal growth and insect infestation. For instance, in regions with high humidity and frequent rainfall, untreated wood pilings may deteriorate within 5–10 years, while those in drier climates can last up to 40 years. Understanding these environmental stressors is essential for predicting and extending piling longevity.

To mitigate the environmental impact on piling life, proactive measures are key. One effective strategy is pressure-treating wood with preservatives like chromated copper arsenate (CCA) or creosote, which can double or triple lifespan by inhibiting fungal and insect damage. However, this approach must be balanced with environmental concerns, as CCA-treated wood can leach toxins into water bodies. Alternatively, using naturally rot-resistant species like cedar or redwood can reduce chemical reliance, though these materials are often more expensive. Regular inspections and maintenance, such as reapplying protective coatings, are also crucial for preserving pilings in harsh environments.

A comparative analysis reveals that the choice of material can drastically alter piling durability in specific environments. For example, concrete pilings, while more expensive upfront, offer superior resistance to moisture and biological degradation, often lasting 50–75 years in marine settings. Composite materials, such as fiberglass-reinforced polymers, provide another eco-friendly option, combining longevity with minimal environmental impact. However, wood remains a popular choice due to its cost-effectiveness and ease of installation, making it vital to optimize its performance through environmentally conscious practices.

Finally, environmental regulations and sustainability practices are reshaping how pilings are managed. In ecologically sensitive areas, restrictions on chemical treatments necessitate innovative solutions like thermal modification, which enhances wood’s durability without toxins. Additionally, recycling or repurposing old pilings reduces waste and minimizes habitat disruption. By integrating these strategies, stakeholders can balance structural integrity with environmental stewardship, ensuring pilings serve their purpose without compromising ecosystems.

Wood vs. Metal: Which Material Offers Superior Longevity?

You may want to see also

Frequently asked questions

Wood pilings can last anywhere from 20 to 50 years, depending on factors like the type of wood, environmental conditions, and maintenance.

Yes, treating wood pilings with preservatives like creosote or pressure-treated chemicals can significantly extend their lifespan, often adding 10 to 20 years.

Exposure to moisture, saltwater, insects, and marine borers can shorten the lifespan of wood pilings, while drier, less exposed conditions can prolong it.

While wood pilings are cost-effective, they generally do not last as long as concrete or steel pilings, which can endure for 50 to 100+ years with proper maintenance.