Wood router motors are essential components in woodworking tools, and their lifespan can significantly impact the efficiency and reliability of your projects. On average, a well-maintained wood router motor can last between 5 to 15 years, depending on factors such as usage frequency, quality of the motor, and adherence to maintenance practices. High-quality routers from reputable brands often feature durable motors designed for extended use, while lower-end models may wear out sooner. Regular maintenance, including cleaning, lubrication, and timely replacement of worn parts, can prolong motor life. Additionally, avoiding overloading the motor and using it within its recommended capacity can prevent premature failure. Understanding these factors helps woodworkers make informed decisions about their tools and ensures consistent performance over time.

Explore related products

What You'll Learn

Factors Affecting Motor Lifespan

The lifespan of a wood router motor is not set in stone; it’s a dynamic outcome shaped by usage patterns, maintenance practices, and environmental conditions. For instance, a motor used intermittently for light tasks like trimming edges may outlast one subjected to hours of heavy-duty mortising or rabbeting. Manufacturers often estimate motor life in hours of operation, with high-quality models rated for 1,000 to 2,000 hours under optimal conditions. However, real-world performance deviates sharply based on how well the tool is cared for and the demands placed on it.

Usage Intensity and Load Management

Routers pushed to their limits—running at maximum RPM for extended periods or cutting dense hardwoods without proper feed rates—experience accelerated wear. Overloading the motor generates excessive heat, which degrades insulation and bearings prematurely. To mitigate this, adhere to the manufacturer’s guidelines for material thickness and cutting speed. For example, when routing hardwoods, reduce feed pressure by 20–30% compared to softer woods. Similarly, avoid continuous operation; take 5-minute breaks after every 30 minutes of heavy use to allow the motor to cool.

Maintenance Practices and Component Care

Neglecting routine maintenance is a silent killer of motor longevity. Dust infiltration, a common hazard in woodworking, clogs vents and insulates the motor, trapping heat. Clean the router’s air intake vents weekly with compressed air, and inspect brushes (if applicable) for wear every 100 hours of use, replacing them when they’re down to 1/4 inch. Lubrication is equally critical: apply 2–3 drops of lightweight machine oil to ball bearings annually, but avoid over-lubricating, as excess oil attracts debris. Carbon brushes, found in universal motors, should be replaced every 500–700 hours of operation to maintain efficient electrical contact.

Environmental Factors and Storage Conditions

Motors stored in damp or corrosive environments face heightened risks. Moisture accelerates rust on windings and bearings, while airborne chemicals (e.g., from nearby painting or staining) degrade insulation. Store routers in a dry, temperature-controlled space, ideally in a sealed case with desiccant packs. For workshop use, position the router away from open windows or doors to minimize dust and humidity exposure. If operating in a high-humidity environment, consider using a dehumidifier to keep relative humidity below 60%.

Power Quality and Electrical Stability

Fluctuating voltage or inconsistent power supply can stress the motor’s windings, leading to insulation breakdown or burnt-out components. Use a voltage regulator if your workshop experiences frequent surges or drops. Avoid running the router on extension cords longer than 25 feet, as this increases resistance and reduces efficiency. For cordless routers, battery health directly impacts motor life; charge lithium-ion batteries to 80% capacity for daily use, and avoid complete discharge cycles, which strain the cells.

By addressing these factors systematically, users can extend a router motor’s lifespan significantly, often doubling or tripling the baseline expectancy. The key lies in balancing performance demands with proactive care, treating the motor not as a disposable component but as a precision instrument deserving of respect.

Understanding the Standard Lengths of Wood Turning Tools for Beginners

You may want to see also

Explore related products

Maintenance Tips for Longevity

Wood router motors, like any mechanical component, have a finite lifespan, but with proper care, they can operate efficiently for many years. The key to extending their longevity lies in consistent and thoughtful maintenance. Dust and debris are the silent killers of router motors, infiltrating bearings and clogging vents, which can lead to overheating and premature wear. Regularly cleaning the motor and its surrounding area with compressed air or a soft brush is a simple yet effective preventive measure. Additionally, ensuring the workspace is well-ventilated reduces the accumulation of fine wood particles that can accelerate deterioration.

Lubrication is another critical aspect often overlooked. Router motors rely on bearings to reduce friction, and these components require periodic lubrication to function optimally. Apply a high-quality machine oil or grease specifically designed for electric motors every 6 to 12 months, depending on usage frequency. Over-lubrication can be as harmful as neglect, so follow the manufacturer’s guidelines for the correct amount. For routers with sealed bearings, focus on keeping the exterior clean and monitoring for unusual noises, which may indicate internal wear.

Electrical maintenance is equally important to prevent motor burnout. Routinely inspect the power cord for fraying or damage, and replace it immediately if any issues are detected. Ensure the router is plugged into a grounded outlet to avoid electrical surges that can damage the motor’s windings. For routers with variable speed controls, periodically clean the potentiometer (speed dial) with electronic contact cleaner to maintain smooth operation and prevent erratic speed fluctuations.

Finally, proper usage habits can significantly impact motor lifespan. Avoid overloading the router by selecting the appropriate bit size and feed rate for the material being worked. Pushing the motor beyond its capacity, even occasionally, can cause excessive heat buildup and strain. When not in use, store the router in a dry, dust-free environment to prevent corrosion and internal contamination. By integrating these maintenance practices into your routine, you can maximize the lifespan of your wood router motor and ensure reliable performance for years to come.

Wood Frogs' Duration in Vernal Pools: A Seasonal Survival Guide

You may want to see also

Explore related products

Signs of Motor Wear

Wood router motors, like any mechanical component, degrade over time, and recognizing the signs of wear is crucial for maintaining precision and safety. One of the earliest indicators is unusual noise, such as grinding, whirring, or squealing sounds during operation. These noises often stem from worn bearings, misaligned components, or debris trapped within the motor housing. While occasional humming is normal, persistent or escalating noise warrants immediate inspection to prevent further damage.

Another telltale sign is reduced power or efficiency, where the motor struggles to maintain consistent RPMs under load. This can manifest as slower cutting speeds, increased stalling, or difficulty handling denser materials. Overheating is a related symptom, often caused by friction from worn brushes or a clogged ventilation system. If the motor feels excessively hot to the touch after moderate use, it’s a clear signal that internal components are under stress.

Physical wear on external parts, such as frayed power cords or cracked housings, should not be overlooked. These issues can compromise electrical safety and expose the motor to dust and moisture, accelerating internal deterioration. Similarly, excessive vibration during operation may indicate loose mounting hardware or unbalanced rotor components, both of which can lead to premature failure if left unaddressed.

To mitigate these issues, regular maintenance is key. Inspect brushes for wear and replace them if they’re less than 1/4 inch long—a common threshold for most routers. Clean air vents and filters monthly to ensure proper cooling, and lubricate bearings as per the manufacturer’s guidelines. For hobbyists, tracking usage hours can help anticipate wear patterns, while professionals should consider annual servicing by a certified technician. Ignoring these signs not only shortens the motor’s lifespan but also risks costly repairs or accidents.

Wood Duck Fledglings: Water Duration and Survival Insights

You may want to see also

Explore related products

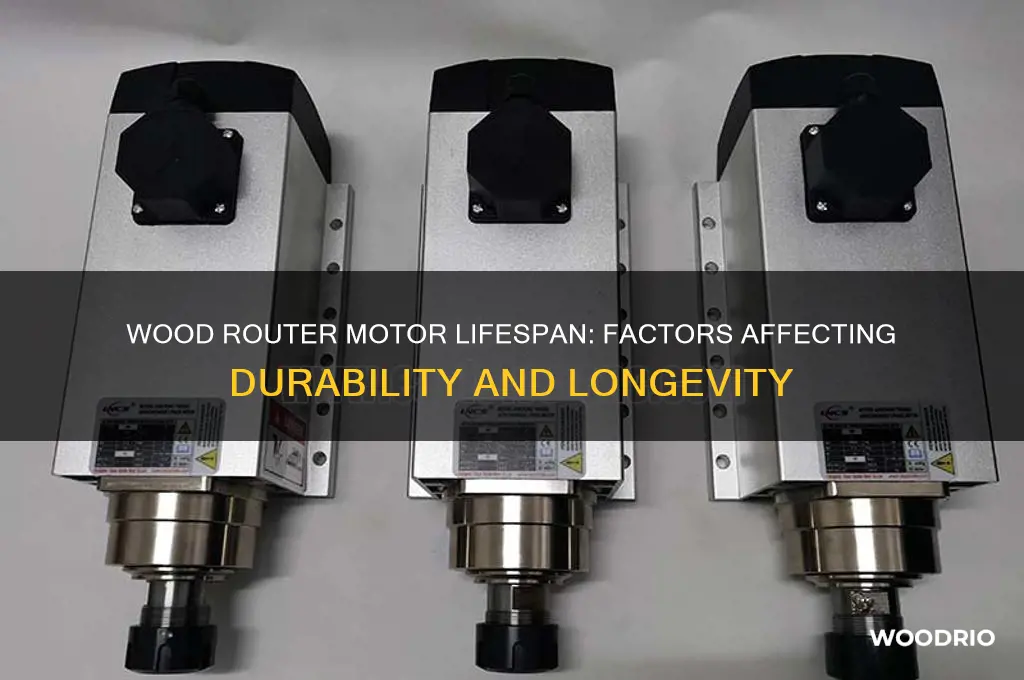

Average Lifespan by Brand

The lifespan of a wood router motor varies significantly by brand, influenced by factors like build quality, usage intensity, and maintenance. High-end brands like Bosch and DeWalt often boast motors lasting 10–15 years under moderate use, thanks to their robust construction and premium components. These brands typically use ball-bearing motors and durable windings, reducing wear and tear. Mid-range brands such as Porter-Cable and Makita fall into the 7–12 year range, balancing cost and longevity with slightly less rugged materials. Budget brands, while more affordable, may only last 3–7 years due to cheaper components and less stringent quality control. Understanding these brand-specific lifespans helps woodworkers make informed decisions based on their needs and budget.

For those seeking maximum longevity, investing in a Bosch or DeWalt router is a strategic move. Bosch’s 1617EVSPK model, for instance, is renowned for its variable-speed motor and aluminum construction, which dissipates heat efficiently, extending motor life. DeWalt’s DW618PK offers a similar advantage with its heavy-duty 2-1/4 HP motor. To maximize lifespan, users should adhere to maintenance routines: clean dust from vents monthly, lubricate moving parts annually, and avoid overloading the motor with materials beyond its capacity. These practices can add years to even mid-range models, making them a viable option for hobbyists.

In contrast, budget-conscious woodworkers might opt for brands like Ryobi or Black+Decker, which are ideal for light-duty projects. However, these motors require meticulous care to reach their upper lifespan limits. For example, Ryobi’s RE100 router, priced under $100, can last up to 7 years if used sparingly and maintained rigorously. Overheating is a common issue with budget models, so limiting continuous runtime to 15–20 minutes per session is crucial. Pairing these routers with a thermal overload protector can further safeguard the motor, though this adds to the initial cost.

Comparatively, professional woodworkers often prioritize reliability over cost, making Bosch and DeWalt the go-to choices. These brands not only offer longer lifespans but also come with better warranties—typically 1–3 years—and readily available replacement parts. Mid-range brands like Makita provide a middle ground, with models like the RT0701C offering 8–10 years of service under moderate use. For professionals, the added expense of a premium brand is justified by reduced downtime and lower long-term costs.

Ultimately, the brand of a wood router motor is a critical determinant of its lifespan, but user behavior plays an equally vital role. Regardless of brand, consistent maintenance and mindful usage can significantly extend motor life. For instance, using sharp bits reduces strain on the motor, while regular inspections can catch issues before they escalate. By aligning brand choice with usage needs and adopting proactive care practices, woodworkers can ensure their router motors perform reliably for years to come.

Unabomber's Wilderness Life: How Long Did He Survive in the Woods?

You may want to see also

Explore related products

Replacing vs. Repairing Motors

The lifespan of a wood router motor varies widely, typically ranging from 5 to 15 years, depending on usage frequency, maintenance, and quality. When a motor begins to fail—exhibiting symptoms like reduced power, unusual noise, or overheating—the decision to replace or repair becomes critical. This choice hinges on factors such as the motor’s age, the cost of parts, and the availability of skilled labor.

Analyzing the Cost-Benefit Tradeoff

Repairing a motor often costs less upfront, especially if the issue is minor, such as a worn brush or faulty capacitor. For instance, replacing brushes on a universal motor might cost $10–$20, while a new motor could range from $50 to $200. However, older motors may suffer from cumulative wear, making repairs a temporary fix. If the motor is over 10 years old and repairs exceed 50% of the replacement cost, investing in a new motor is generally more economical.

Steps to Evaluate Repair Feasibility

- Diagnose the Issue: Use a multimeter to check for continuity in the windings or test the brushes for wear.

- Estimate Repair Costs: Research part prices and labor fees, if applicable.

- Assess Motor Condition: Inspect for physical damage, such as cracked housings or burnt insulation, which may render repairs impractical.

- Compare to Replacement: Factor in the new motor’s efficiency and warranty, which can offset higher initial costs.

Cautions in DIY Repairs

While repairing a motor can be cost-effective, it requires technical skill. Mishandling components like capacitors (which store high voltage) or misaligning bearings can lead to safety hazards or further damage. Always disconnect power before servicing and wear protective gear. If unsure, consult a professional to avoid voiding warranties or creating risks.

Replacement is the better option if the motor is nearing the end of its expected lifespan, repair costs are high, or the model is outdated. Modern motors often feature improved efficiency and quieter operation, providing long-term value. For routers used professionally, upgrading to a brushless motor can extend lifespan to 20+ years, though at a premium cost. Ultimately, weigh the immediate savings of repair against the reliability and performance of a new motor.

Into the Woods Runtime: How Long is the Play?

You may want to see also

Frequently asked questions

With regular use and proper maintenance, a wood router motor can last between 5 to 15 years, depending on the quality of the motor and how frequently it is used.

Overloading the motor, insufficient cooling, lack of lubrication, and exposure to dust or debris can significantly shorten the lifespan of a wood router motor.

Yes, regular maintenance such as cleaning, lubricating bearings, checking for wear, and ensuring proper ventilation can help extend the life of your wood router motor.