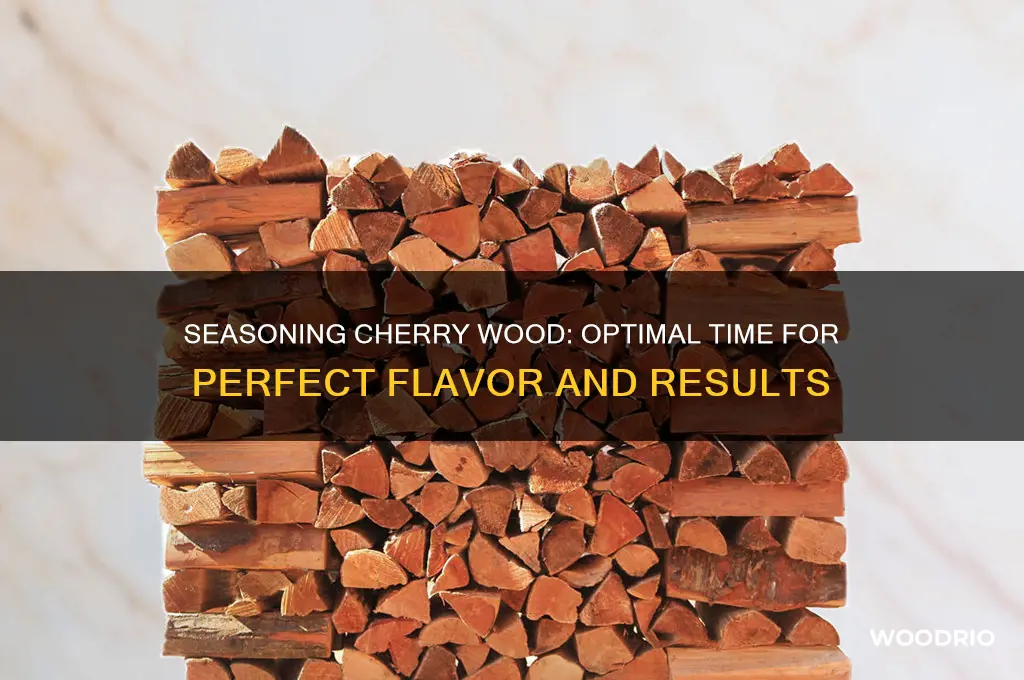

Seasoning cherry wood is a crucial process that involves drying the wood to reduce its moisture content, ensuring it is suitable for various applications like smoking, woodworking, or crafting. The duration required to season cherry wood depends on several factors, including the initial moisture level, the thickness of the wood, and the environmental conditions such as humidity and temperature. Typically, cherry wood can take anywhere from 6 months to 2 years to fully season, with thinner pieces drying faster than thicker ones. Proper seasoning is essential to prevent cracking, warping, or mold growth, making it a vital step for anyone working with this versatile and prized hardwood.

| Characteristics | Values |

|---|---|

| Seasoning Time | 6-12 months (varies based on climate and thickness) |

| Moisture Content Goal | 12-15% for optimal use |

| Ideal Conditions | Covered, well-ventilated area with moderate humidity |

| Wood Thickness | Thicker pieces take longer to season (e.g., 4+ inches may require 12+ months) |

| Climate Impact | Warmer, drier climates speed up seasoning; colder, humid climates slow it down |

| Splitting Risk | Higher if seasoned too quickly or improperly stored |

| Color Change | Darkens slightly as it seasons |

| Uses After Seasoning | Furniture, cabinetry, flooring, and firewood |

| Checking for Dryness | Wood feels lighter, ends crack slightly, and moisture meter reads 12-15% |

Explore related products

What You'll Learn

Optimal seasoning time for cherry wood

Cherry wood, prized for its rich color and fine grain, requires careful seasoning to unlock its full potential. The optimal seasoning time hinges on a delicate balance between moisture content and structural integrity. While general guidelines suggest 6 to 12 months for hardwoods, cherry wood’s density and natural oils demand a more nuanced approach. Aim for a moisture content of 8-12% for woodworking projects, as this range minimizes warping, cracking, and dimensional instability. Achieving this level typically takes 9 to 18 months, depending on climate and storage conditions.

The seasoning process begins with proper stacking. Split cherry logs into manageable sizes, ideally 4 to 6 inches in diameter, to increase surface area for moisture evaporation. Stack the wood in a single row, allowing air circulation between pieces. Elevate the stack off the ground using stickers or pallets to prevent moisture absorption from the soil. Choose a well-ventilated, covered area to protect the wood from direct rain while permitting airflow. In humid climates, consider using a moisture meter to monitor progress, as drying times may extend beyond the average range.

Accelerating seasoning without compromising quality is possible with strategic interventions. Kiln drying reduces the process to 2-4 weeks but requires specialized equipment and risks over-drying if not monitored closely. For DIY enthusiasts, a solar kiln offers a cost-effective alternative, harnessing sunlight to expedite moisture removal. However, this method still demands patience, as cherry wood’s natural oils slow the drying process compared to softer hardwoods. Avoid shortcuts like direct heat or forced air, as these can cause checking or uneven drying.

Comparing cherry wood to other hardwoods highlights its unique seasoning requirements. Unlike oak or maple, cherry’s natural resins act as a barrier to rapid moisture loss, necessitating a slower, more controlled approach. This characteristic also contributes to its stability once properly seasoned, making the wait worthwhile. For craftsmen, understanding this distinction ensures the wood’s beauty and durability are preserved in finished pieces. Patience and precision are the keys to mastering cherry wood’s seasoning timeline.

Foraging for Wood in The Long Dark: Essential Survival Tips

You may want to see also

Explore related products

Factors affecting cherry wood seasoning duration

Cherry wood seasoning duration varies significantly based on several key factors, each influencing how quickly the wood reaches optimal moisture levels for use. Understanding these variables allows for more precise control over the process, ensuring the wood is ready for woodworking, smoking, or other applications.

Moisture Content and Initial Conditions

The starting moisture content of cherry wood is a primary determinant of seasoning time. Freshly cut cherry wood, known as green wood, can have moisture levels exceeding 50%. Reducing this to the ideal 6–12% range for indoor use or 12–18% for outdoor applications requires time. For instance, air-drying green cherry wood typically takes 6–12 months per inch of thickness. Kiln-drying accelerates this process to days or weeks but requires careful monitoring to avoid cracking.

Environmental Factors: Humidity and Temperature

Climate plays a critical role in seasoning duration. In humid regions, cherry wood dries more slowly due to the air’s reduced capacity to absorb moisture. For example, seasoning in a humid coastal area may take twice as long as in a dry desert climate. Temperature also matters; warmer conditions speed evaporation, but extreme heat can cause surface checks. Ideal seasoning occurs in a well-ventilated space with temperatures between 60–80°F (15–27°C) and relative humidity below 60%.

Wood Thickness and Stacking Techniques

Thicker cherry wood pieces season more slowly than thinner ones due to the longer distance moisture must travel to escape. A 4-inch thick board may require 2–4 years to season properly, while a 1-inch board could be ready in 6–12 months. Proper stacking is equally important. Stickers (spacers) between boards promote airflow, reducing drying time. Stack wood in a single row or cross-pile pattern, ensuring gaps for ventilation and protection from direct ground contact.

Airflow and Shelter

Adequate airflow is essential for efficient seasoning. Wood stored in a covered but open-sided shed dries faster than wood left in a closed space. Avoid plastic tarps, which trap moisture, and instead use breathable covers to protect from rain. Position the stack to maximize exposure to prevailing winds, but shield it from direct sunlight to prevent warping.

Practical Tips for Optimal Seasoning

To expedite seasoning, split logs into manageable sizes before stacking. Monitor moisture levels using a wood moisture meter, aiming for consistency across the stack. For kiln-drying, follow a gradual schedule: start at 100°F (38°C) for 24 hours, then increase by 10°F daily until reaching 140°F (60°C). Regularly inspect wood for mold or insect infestation, especially in humid conditions.

By addressing these factors—moisture content, environment, thickness, airflow, and technique—you can tailor the seasoning process to your specific needs, ensuring cherry wood is ready for use in the shortest time possible without compromising quality.

Exploring the Length of Wooden Flutes: A Comprehensive Guide

You may want to see also

Explore related products

Signs cherry wood is fully seasoned

Cherry wood, prized for its rich color and fine grain, requires proper seasoning to unlock its full potential. But how do you know when it's ready? Here are key signs that your cherry wood has reached optimal seasoning:

Weight Loss and Stability: Freshly cut cherry wood is heavy with moisture. As it seasons, it loses weight significantly. A fully seasoned board will feel noticeably lighter than its green counterpart. This weight loss translates to dimensional stability, meaning the wood is less prone to warping, cracking, or shrinking after being worked.

Crackling Sound: Tap two seasoned cherry wood pieces together. A clear, sharp crackling sound indicates dryness. Green wood, still holding moisture, will produce a dull, thudding sound. This simple test is a quick and effective way to gauge moisture content.

Surface Changes: Seasoned cherry wood undergoes subtle visual transformations. The surface may develop a slightly darker patina compared to its freshly cut state. Additionally, the grain pattern becomes more pronounced and defined as the wood fibers tighten during the drying process.

Moisture Meter Reading: For precise measurement, a moisture meter is invaluable. Aim for a moisture content of 8-12% for optimal seasoning. This range ensures the wood is dry enough for most woodworking projects while retaining some natural flexibility.

Workability: Seasoned cherry wood is a joy to work with. It planes, saws, and sands smoothly, leaving clean edges and a fine finish. Green wood, in contrast, tends to tear, splinter, and resist shaping due to its higher moisture content.

Durability of Wood Playsets: Lifespan and Maintenance Tips Revealed

You may want to see also

Explore related products

Methods to speed up cherry wood seasoning

Cherry wood, prized for its rich color and fine grain, requires proper seasoning to enhance its durability and workability. Typically, this process can take 6 to 12 months, depending on environmental conditions. However, for those eager to expedite this timeline, several methods can significantly reduce the waiting period without compromising the wood’s quality.

One effective technique is kiln drying, a controlled process that uses heat and airflow to remove moisture from the wood. Kiln drying can reduce seasoning time to as little as 2 to 4 weeks, depending on the kiln’s settings and the wood’s thickness. For optimal results, maintain a temperature of 120°F to 140°F (49°C to 60°C) and gradually increase it over several days. This method requires specialized equipment but ensures uniform drying and minimizes the risk of warping or cracking.

Another practical approach is solar seasoning, which harnesses sunlight to accelerate moisture evaporation. Stack the cherry wood in a single layer under a clear, sloped roof to allow sunlight penetration while protecting it from rain. Orient the stack to maximize southern exposure for consistent solar gain. This method works best in warm, dry climates and can reduce seasoning time by 30% to 50%. Pair it with a fan to improve air circulation for even faster results.

For those without access to kilns or ideal weather, microwave-vacuum drying offers a high-tech solution. This method involves placing the wood in a vacuum chamber and applying microwave energy to heat the moisture within the cells, which is then removed by the vacuum. While expensive and typically used for small batches, it can season cherry wood in just a few hours. However, caution is necessary to avoid overheating, which can damage the wood’s structure.

Lastly, chemical treatments like applying wood preservatives or anti-sapstain solutions can complement traditional seasoning methods. These treatments inhibit fungal growth and reduce moisture absorption, allowing the wood to dry more efficiently. For example, dipping cherry wood in a solution of 2% borax and 2% boric acid can expedite the process while protecting against decay. Always follow manufacturer guidelines and ensure proper ventilation when handling chemicals.

By combining these methods—kiln drying for precision, solar seasoning for cost-effectiveness, microwave-vacuum drying for speed, and chemical treatments for protection—woodworkers can significantly reduce cherry wood seasoning time while maintaining its integrity. Each technique has its advantages and limitations, so the choice depends on available resources, desired timeline, and specific project needs.

Durability of Wood Frame Futons: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Common mistakes in seasoning cherry wood

Seasoning cherry wood is a delicate process that demands precision, yet many enthusiasts inadvertently sabotage their efforts through common mistakes. One of the most frequent errors is rushing the seasoning timeline. Cherry wood, like other hardwoods, requires patience; it typically takes 6 to 12 months to season properly, depending on humidity and thickness. Attempting to accelerate this by using heat or placing the wood in direct sunlight can lead to cracks, warping, or uneven drying. The takeaway? Resist the urge to expedite the process—nature’s timeline is non-negotiable.

Another critical misstep is stacking wood improperly. Cherry wood needs adequate airflow to dry evenly. Piling logs haphazardly or stacking them too tightly restricts ventilation, trapping moisture and fostering mold or rot. The ideal setup involves stacking wood in a single row or using stickers (small spacers) between layers to promote air circulation. For best results, ensure the stack is off the ground, protected from rain, and exposed to natural airflow.

Ignoring moisture content is a third common pitfall. Cherry wood should reach a moisture content of 12-15% for optimal use in woodworking or smoking. Failing to monitor this with a moisture meter can result in wood that’s either too wet (prone to warping) or too dry (brittle and difficult to work with). Regularly check moisture levels, especially during the first few months of seasoning, to ensure the wood is drying at a steady pace.

Lastly, neglecting to seal the ends of logs is a mistake that amplifies moisture loss. Cherry wood loses moisture most rapidly through its ends, leading to splits and checks. Applying a sealant like wax or latex paint to the cut ends minimizes this issue, preserving the wood’s integrity. This simple step, often overlooked, can significantly improve the final quality of the seasoned wood.

By avoiding these mistakes—rushing the process, improper stacking, ignoring moisture content, and neglecting end sealing—you’ll ensure your cherry wood seasons evenly and retains its prized qualities for woodworking or smoking. Patience and attention to detail are your greatest tools in this endeavor.

Perfect Shellac Finish: Optimal Drying Time for Wood Projects

You may want to see also

Frequently asked questions

Cherry wood should be seasoned for at least 6 months to a year to ensure it burns efficiently and imparts the best flavor.

No, freshly cut cherry wood contains too much moisture, which can result in poor combustion and off-flavors. Seasoning is essential.

Seasoned cherry wood should have a moisture content of 20% or less for optimal smoking performance.

Yes, seasoning time can vary; in humid climates, it may take up to 18 months, while in drier climates, 6–9 months is often sufficient.

Fully seasoned cherry wood will feel lighter, have cracks in the ends, and make a sharp, hollow sound when two pieces are knocked together.