Soaking wood wicks is a crucial step in candle-making, as it ensures optimal performance and a clean, consistent burn. The duration of soaking depends on the type of wax used and the specific wood wick, but generally, wood wicks should be soaked in melted wax for at least 30 minutes to an hour. This process allows the wick to absorb the wax thoroughly, preventing it from burning too quickly and ensuring a stable flame. For best results, it’s recommended to follow the manufacturer’s guidelines, as some wicks may require longer soaking times or additional preparation steps. Properly soaked wood wicks enhance the overall quality of the candle, providing a crackling ambiance and even burn.

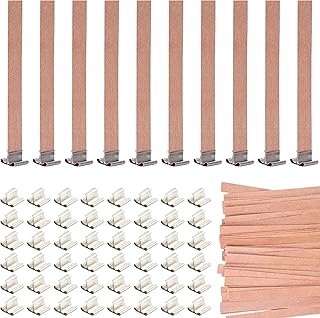

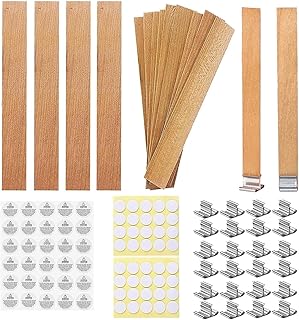

Explore related products

What You'll Learn

- Optimal Soaking Time: 6-24 hours for best results, depending on wax and wick type

- Wax Type Impact: Soy wax requires longer soaking than paraffin for proper absorption

- Wick Size Matters: Thicker wicks need more time to fully saturate with wax

- Soaking Techniques: Use room temperature wax for even absorption, avoid overheating

- Testing Readiness: A fully soaked wick stands straight without bending or collapsing

Optimal Soaking Time: 6-24 hours for best results, depending on wax and wick type

Soaking wood wicks is a crucial step in candle-making, often overlooked by beginners. The optimal soaking time, ranging from 6 to 24 hours, directly impacts the wick's performance and the overall quality of the candle. This duration allows the wick to absorb the wax thoroughly, ensuring a consistent and even burn. However, the exact time within this range depends on two key factors: the type of wax used and the specific characteristics of the wood wick.

For instance, softer waxes like soy or paraffin typically require a shorter soaking time, around 6 to 12 hours. These waxes have a lower melting point and are more readily absorbed by the wood fibers. In contrast, harder waxes such as beeswax or coconut wax may need the full 24 hours to penetrate the wick adequately. Similarly, thicker or denser wood wicks will take longer to soak compared to thinner ones. A general rule of thumb is to start with the minimum recommended time and adjust based on the wick's saturation level.

To determine if the wick has soaked sufficiently, gently press or bend it after the initial soaking period. If it feels pliable and fully saturated, it’s ready for use. If it still feels dry or brittle in spots, extend the soaking time. Over-soaking is generally not a concern, but under-soaking can lead to poor burning performance, such as tunneling or a weak flame. For best results, plan ahead and allow ample time for soaking, especially when working with larger batches or multiple candle types.

Practical tips can further enhance the soaking process. Submerge the wicks in a container of melted wax at a temperature slightly above the wax’s melting point to expedite absorption. Stirring the wax gently during the first hour can also help distribute heat evenly, ensuring thorough saturation. Labeling wicks with their corresponding wax type and soaking start time can prevent confusion, particularly when experimenting with different combinations.

In conclusion, mastering the optimal soaking time for wood wicks is a blend of science and observation. By considering the wax type, wick density, and practical techniques, candle makers can achieve consistent and high-quality results. Patience and attention to detail during this step will ultimately reward you with beautifully burning candles that showcase the natural charm of wood wicks.

Wood vs. Siding Sheds: Which Material Offers Greater Durability?

You may want to see also

Explore related products

Wax Type Impact: Soy wax requires longer soaking than paraffin for proper absorption

The type of wax you use significantly influences how long you should soak your wood wicks. Soy wax, a popular choice for its natural and eco-friendly properties, demands a longer soaking time compared to paraffin wax. This is because soy wax has a denser molecular structure, which slows down the absorption process. While paraffin wax, being more porous and less viscous, allows wood wicks to saturate more quickly, soy wax requires patience. For optimal results, soak wood wicks in soy wax for at least 24 hours, whereas paraffin wax typically only needs 12–16 hours. This difference is crucial for ensuring the wick burns evenly and efficiently.

From a practical standpoint, the soaking duration directly impacts the wick’s performance. Insufficient soaking in soy wax can lead to a wick that burns poorly or not at all, as the wax hasn’t fully penetrated the wood fibers. Paraffin wax, on the other hand, is more forgiving due to its faster absorption rate. To test if a wood wick is ready, gently tug at it after soaking. If it feels firmly rooted in the wax and doesn’t pull out easily, it’s adequately saturated. For soy wax, this test is particularly important, as its slower absorption means the wick may appear ready before it truly is.

The science behind this difference lies in the waxes’ melting points and molecular structures. Soy wax has a higher melting point (typically 120°F–180°F) and a denser composition, which slows down the absorption process. Paraffin wax, with a lower melting point (130°F–150°F) and a lighter structure, allows for quicker saturation. This means that while paraffin wicks can be used almost immediately after soaking, soy wax wicks require additional time to ensure the wood fibers are fully impregnated. Ignoring this difference can result in a wick that burns unevenly or extinguishes prematurely.

For candle makers, understanding this wax-specific soaking requirement is essential for achieving consistent results. If you’re transitioning from paraffin to soy wax, adjust your timeline accordingly. Label your wicks with the wax type and soaking start time to avoid confusion. Additionally, consider pre-soaking wood wicks in a small amount of melted soy wax before pouring the candle to jumpstart the absorption process. This technique can reduce the overall soaking time by a few hours while still ensuring proper saturation.

In conclusion, the wax type dictates the soaking duration for wood wicks, with soy wax requiring nearly double the time of paraffin wax. This difference is rooted in the waxes’ physical properties and directly affects the wick’s performance. By respecting these timelines and employing practical tips, such as pre-soaking or testing for saturation, you can ensure your wood wick candles burn beautifully, regardless of the wax type. Master this detail, and you’ll elevate the quality of your candles significantly.

How to Safely Haul One Cord of Wood in a Long Bed Truck

You may want to see also

Explore related products

Wick Size Matters: Thicker wicks need more time to fully saturate with wax

Thicker wood wicks, with their larger diameter and denser structure, require a longer soaking time to fully saturate with wax. This is because the wax must penetrate deeper into the wick’s fibers, a process that takes time. While thinner wicks may only need 15–30 minutes to absorb enough wax for a clean burn, thicker wicks can demand up to 2 hours or more. Rushing this step risks uneven burning or a wick that struggles to draw wax, leading to a weak flame or tunneling.

Consider the analogy of soaking a sponge: a thin sponge absorbs water quickly, while a thick one needs more time to become fully saturated. Similarly, thicker wicks act like a reservoir, holding more wax to sustain a steady flame. However, this reservoir can’t function properly if the wick isn’t fully soaked. For example, a 10mm thick wick might need twice as long to saturate as a 5mm wick, even when using the same type of wax.

To ensure proper saturation, follow these steps: first, prepare your wax at the recommended temperature for your specific wax type (typically 185°F–200°F for soy wax). Submerge the wick completely, ensuring no part is left exposed. For thicker wicks, use a container deep enough to accommodate their length. After soaking, allow the wick to cool and harden before use. A fully saturated wick will feel heavier and appear slightly darker, indicating it’s ready for candle-making.

One practical tip is to test the wick’s saturation by gently bending it after soaking. If it cracks or breaks, it hasn’t absorbed enough wax and needs more time. Conversely, a pliable, smooth wick is ready for use. This simple test can save you from the frustration of a poorly performing candle.

In conclusion, thicker wood wicks demand patience. By allowing them adequate soaking time, you ensure a strong, consistent burn that enhances the overall quality of your candle. Skipping this step undermines the wick’s functionality, so treat it as a critical part of the candle-making process.

Mayonnaise on Wood: Surprising Benefits and Ideal Application Time

You may want to see also

Explore related products

Soaking Techniques: Use room temperature wax for even absorption, avoid overheating

Room temperature wax is the unsung hero of wood wick soaking, ensuring even absorption without the risks of overheating. When wax is heated excessively, it can alter its chemical composition, leading to poor adhesion and inconsistent burning. By keeping the wax at room temperature, typically between 68°F and 72°F (20°C and 22°C), you create an ideal environment for the wood wick to absorb the wax uniformly. This method not only preserves the integrity of the wax but also enhances the wick’s capillary action, ensuring a steady and clean burn.

The process is straightforward: melt your wax to its recommended temperature, then allow it to cool naturally to room temperature before submerging the wood wick. Avoid the temptation to speed up cooling with fans or refrigerators, as rapid temperature changes can introduce air bubbles or uneven cooling. Once cooled, fully immerse the wick in the wax for 15 to 20 minutes. This duration allows the wood fibers to saturate completely without becoming oversaturated, which can lead to a wick that’s too heavy or prone to drowning in the container.

A common mistake is overheating the wax during the initial melting phase. Most soy waxes, for example, should not exceed 185°F (85°C), while paraffin waxes typically max out at 200°F (93°C). Exceeding these temperatures can cause the wax to thin out excessively, reducing its ability to coat the wick effectively. Always use a thermometer to monitor the temperature and remove the wax from heat just before it reaches its maximum melting point. This precision ensures the wax remains in a state optimal for soaking.

For best results, pair room temperature soaking with high-quality, untreated wood wicks. Pre-waxed wicks can be soaked for a shorter duration, around 10 minutes, as they already have a base layer of wax. Untreated wicks, however, benefit from the full 20-minute soak to ensure thorough saturation. After soaking, gently shake off excess wax and allow the wick to dry for at least 2 hours before placing it in your candle container. This drying period prevents the wick from shifting during pouring and ensures it remains centered.

The takeaway is clear: room temperature wax soaking is a simple yet effective technique that maximizes wood wick performance. By avoiding overheating and adhering to precise timing, you can achieve a wick that burns evenly, efficiently, and without the frustration of tunneling or flickering. This method not only elevates the quality of your candles but also streamlines your crafting process, making it a must-try for both beginners and seasoned candle makers.

Stardew Valley Wood Chipper Efficiency: Time to Process Wood Explained

You may want to see also

Explore related products

Testing Readiness: A fully soaked wick stands straight without bending or collapsing

A wood wick's readiness for candle-making hinges on its ability to stand tall. This simple test—observing whether a fully soaked wick remains straight without bending or collapsing—is a critical indicator of its structural integrity and functionality. When a wick fails this test, it suggests insufficient soaking, which can lead to poor burning performance, such as tunneling or uneven flame distribution. Achieving the right balance of moisture absorption is key to ensuring the wick burns efficiently and supports the candle's overall quality.

To perform this test, start by soaking the wood wick in wax for the recommended duration, typically 10 to 15 minutes for smaller wicks and up to 30 minutes for larger ones. After soaking, allow the wick to cool slightly but not harden completely. Then, gently lift it from the wax and hold it vertically. A wick that is fully prepared will maintain its shape, standing straight without any visible drooping or kinking. If it bends or collapses, it indicates that the wick has not absorbed enough wax, requiring additional soaking time.

The science behind this test lies in the wick's cellulose structure. Wood wicks need to absorb wax thoroughly to become rigid and self-supporting. When properly saturated, the wax fills the wick's microscopic channels, providing the necessary stiffness. This process is similar to how a sponge becomes firm when soaked in water. Insufficient soaking leaves these channels partially empty, resulting in a wick that lacks the structural integrity to burn effectively.

Practical tips can enhance the accuracy of this test. For instance, ensure the wax temperature is consistent, ideally between 185°F and 195°F (85°C to 90°C), as this range optimizes wax absorption. Additionally, use a timer to track soaking duration precisely, as even a few minutes can make a difference. If the wick fails the test, re-soak it for 5-minute increments until it passes. This iterative approach ensures the wick is fully prepared without over-soaking, which can lead to excessive wax buildup and hinder burning.

In conclusion, the "stand straight" test is a reliable method to determine if a wood wick is ready for use. It combines simplicity with precision, offering immediate feedback on the wick's soaking adequacy. By mastering this test, candle makers can ensure their wood wicks perform optimally, contributing to a cleaner, more consistent burn. This small but crucial step underscores the importance of attention to detail in crafting high-quality candles.

Bleaching Wood: Optimal Time to Leave Bleach for Best Results

You may want to see also

Frequently asked questions

Wood wicks should be soaked in oil or wax for at least 30 minutes to 2 hours before use. This helps them burn more efficiently and reduces the risk of tunneling.

While you can skip soaking, it’s not recommended. Soaking ensures the wick absorbs enough wax or oil, improving its burn quality and longevity.

Use the same type of wax or oil you’re using for your candle. For example, if making a soy wax candle, soak the wick in melted soy wax.

The wick should appear fully saturated, with no dry spots. It will feel heavier and more pliable after proper soaking.

Yes, wood wicks can be reused if they’re in good condition. Simply trim and soak them again before using in a new candle.