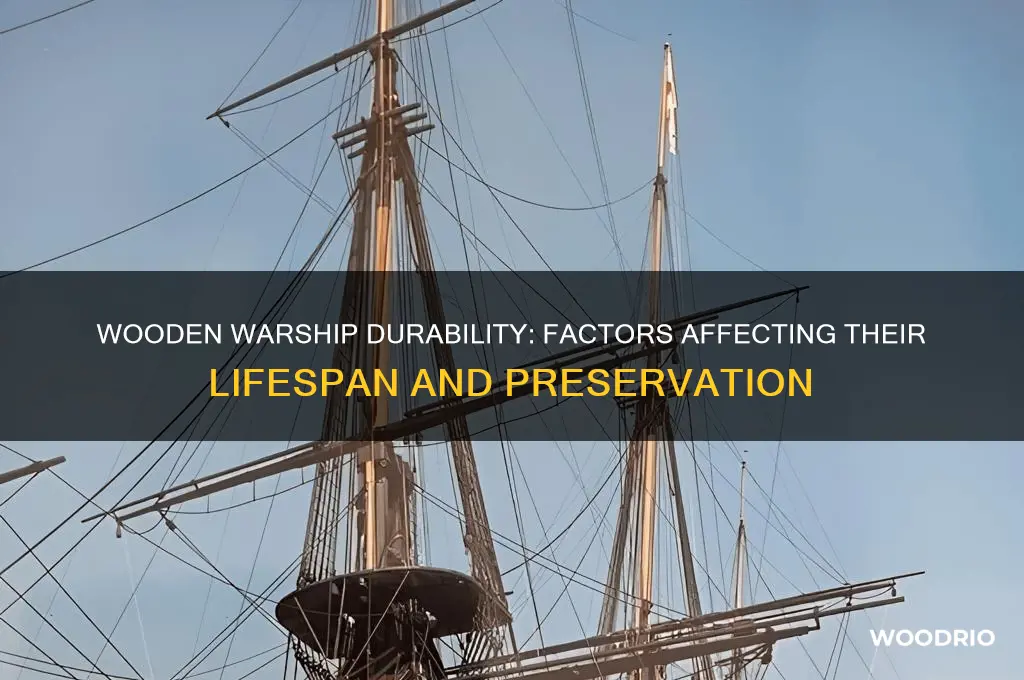

Wooden warships, once the backbone of naval fleets, have a lifespan that varies significantly depending on factors such as construction quality, maintenance, environmental conditions, and usage. Typically, a well-built and meticulously maintained wooden warship could last several decades, with some historical examples enduring for over a century. However, exposure to saltwater, marine organisms, and harsh weather accelerates deterioration, often requiring frequent repairs or replacement of wooden components. Without proper care, these vessels could become structurally unsound within a few decades, highlighting the delicate balance between their historical significance and the challenges of preservation.

| Characteristics | Values |

|---|---|

| Average Lifespan (Active Service) | 10–20 years (varies based on maintenance, usage, and environmental conditions) |

| Preservation in Waterlogged Conditions | Hundreds to thousands of years (e.g., Viking longships, Mary Rose) |

| Preservation in Dry Conditions | Decades to centuries (depends on climate, pests, and maintenance) |

| Impact of Marine Borers | Significantly reduces lifespan (e.g., Teredo worms can destroy ships in 1–2 years without treatment) |

| Effect of Copper Sheathing | Extends lifespan by 5–10 years by protecting against marine borers |

| Maintenance Requirements | Regular care (e.g., recaulking, repainting) can extend lifespan |

| Historical Examples | HMS Victory (launched 1765, still preserved), USS Constitution (launched 1797, still afloat) |

| Decay Rate in Saltwater | Faster than freshwater due to higher biological activity |

| Decay Rate in Freshwater | Slower, but still susceptible to fungi and bacteria |

| Archaeological Significance | Well-preserved wrecks provide insights into shipbuilding techniques and history |

Explore related products

$14.99

What You'll Learn

- Construction Techniques: Traditional vs. modern methods impact durability and lifespan of wooden warships significantly

- Maintenance Practices: Regular care, preservation, and repairs extend the longevity of wooden vessels

- Environmental Factors: Climate, water salinity, and exposure affect wood decay and structural integrity

- Material Quality: Type of wood, treatment, and craftsmanship determine resistance to wear and tear

- Historical Examples: Case studies of preserved wooden warships reveal average lifespan and preservation methods

Construction Techniques: Traditional vs. modern methods impact durability and lifespan of wooden warships significantly

The lifespan of a wooden warship hinges significantly on the construction techniques employed. Traditional methods, rooted in centuries-old craftsmanship, prioritized durability through meticulous handwork and natural materials. Shipwrights selected dense, rot-resistant woods like oak and teak, seasoned them for years, and joined planks with intricate mortise-and-tenon joints or treenailed fastenings. These techniques allowed for flexibility in the hull, crucial for withstanding the stresses of open water. However, traditional methods were labor-intensive, time-consuming, and reliant on skilled artisans, limiting scalability.

Modern construction techniques, in contrast, emphasize efficiency and precision. Computer-aided design (CAD) and CNC machining enable exacting cuts and fits, reducing human error and material waste. Epoxy resins and synthetic adhesives replace traditional pitch and tar, offering superior waterproofing and bonding strength. While these advancements streamline production, they often sacrifice the inherent flexibility of traditional joints, potentially compromising long-term durability under dynamic maritime conditions.

A comparative analysis reveals that traditional methods excel in longevity under ideal preservation conditions. For instance, the *Mary Rose*, a 16th-century English warship, survived over 400 years underwater due to the anaerobic environment and the robustness of its oak construction. Modern techniques, however, offer advantages in initial strength and resistance to biological degradation, particularly in tropical waters where shipworm and fungi pose significant threats. Yet, the long-term effects of synthetic materials on structural integrity remain less understood compared to the proven track record of traditional practices.

To maximize the lifespan of wooden warships, a hybrid approach may be optimal. Incorporating modern tools for precision while adhering to traditional joinery techniques could combine the best of both worlds. For example, using CNC-cut planks with traditional treenailing ensures tight fits while maintaining flexibility. Additionally, applying advanced preservatives like copper-based paints alongside natural treatments like creosote can enhance resistance to marine organisms. Practical tips include regular inspections, controlled humidity storage, and avoiding prolonged exposure to sunlight to mitigate UV damage.

Ultimately, the choice between traditional and modern methods depends on the intended use and preservation goals. For historical replicas or ceremonial vessels, traditional techniques preserve authenticity and proven durability. For functional warships or recreational craft, modern methods offer speed and enhanced initial performance. By understanding the strengths and limitations of each approach, shipbuilders can craft wooden warships that endure for generations, balancing heritage with innovation.

Wood Chips Decomposition Timeline: Factors Affecting Breakdown Process

You may want to see also

Explore related products

$68.95

Maintenance Practices: Regular care, preservation, and repairs extend the longevity of wooden vessels

Wooden warships, when subjected to rigorous maintenance practices, can endure for centuries, as evidenced by the HMS Victory, launched in 1765 and still preserved in dry dock. This longevity is not accidental but the result of meticulous care, preservation techniques, and timely repairs. Regular maintenance is the cornerstone of extending a wooden vessel’s lifespan, as it mitigates the effects of environmental stressors like water, sunlight, and marine organisms. Without such practices, even the sturdiest wooden structures succumb to rot, warping, and structural failure within decades.

Preventive Care: The First Line of Defense

The most effective maintenance begins with prevention. Wooden warships require routine cleaning to remove algae, barnacles, and salt deposits, which can degrade the wood over time. Applying a protective coating, such as a mixture of linseed oil and pine tar, every 12–18 months creates a barrier against moisture and UV damage. Inspecting the hull for cracks or splintering every six months allows for early intervention before minor issues escalate. For instance, replacing a single damaged plank promptly prevents water infiltration that could lead to widespread rot.

Preservation Techniques: Combating Time and Elements

Preservation goes beyond surface-level care. Creosote-soaked fabrics or copper sheathing can deter shipworms, a common threat to wooden vessels. In humid climates, dehumidifiers installed in storage areas reduce mold growth, while in dry environments, periodic misting prevents the wood from becoming brittle. For warships in active service, regular antifouling treatments using copper-based paints inhibit marine growth. Historical examples, like the Vasa Museum’s preservation efforts, demonstrate that controlled humidity levels (45–55%) and temperature (16–20°C) are critical for long-term storage.

Repairs: Restoring Integrity Without Compromise

When damage occurs, repairs must prioritize structural integrity while preserving historical authenticity. Traditional methods, such as using oak or teak for replacements, ensure compatibility with the original material. Modern adhesives like epoxy resins can be used sparingly to reinforce joints, but their application must be limited to avoid altering the wood’s natural properties. For example, the USS Constitution’s restoration involved replacing 10–15% of its hull planks every decade, using wood sourced from the same regions as the original timber.

The Takeaway: Investment in Maintenance Pays Dividends

The lifespan of a wooden warship is not predetermined but shaped by the diligence of its caretakers. Regular care, preservation, and repairs are not merely tasks but investments in the vessel’s future. By adopting a proactive approach, combining traditional techniques with modern innovations, and adhering to strict maintenance schedules, wooden warships can defy the centuries. The HMS Victory’s 250+ years of existence stand as a testament to what is possible when maintenance practices are treated as sacred rituals rather than optional chores.

Mastering Wood Soaking Times for Perfect Smoke Flavor Every Time

You may want to see also

Explore related products

$38.99

$116.99 $123.99

Environmental Factors: Climate, water salinity, and exposure affect wood decay and structural integrity

Wooden warships, once symbols of naval dominance, face relentless environmental adversaries that dictate their longevity. Among these, climate stands as a silent yet potent force. In tropical regions, where temperatures soar and humidity lingers, wood decays at an accelerated pace due to fungal and bacterial activity. Conversely, colder climates slow decay but introduce risks like frost damage, which can crack timber and compromise structural integrity. For instance, the Vasa, a 17th-century Swedish warship, survived centuries in the cold Baltic Sea, its wood remarkably preserved due to low temperatures and low oxygen levels. However, in warmer waters, such as the Caribbean, wooden ships like those from the Spanish Armada often succumbed to rot within decades.

Water salinity emerges as another critical factor, with saltwater posing a greater threat than freshwater. Salt acts as a natural preservative in small doses but becomes corrosive in higher concentrations, drawing moisture from wood and accelerating drying and cracking. Ships in brackish waters, like estuaries, face a unique challenge: fluctuating salinity levels that confuse wood’s natural defenses. For example, the Mary Rose, Henry VIII’s flagship, deteriorated significantly in the English Channel’s salty waters, while freshwater-immersed vessels like the Batavia in Australia’s Swan River retained more structural integrity. To mitigate salinity damage, modern preservation efforts often involve desalination treatments, where wood is soaked in freshwater or polyethylene glycol to replace salt ions with less harmful substances.

Exposure to the elements—sunlight, wind, and waves—further compounds wood’s deterioration. UV radiation breaks down cellulose fibers, making wood brittle, while constant wave action weakens joints and fastenings. Ships in shallow, turbulent waters suffer more than those in deeper, calmer seas. The HMS *Victory*, Nelson’s flagship, has endured centuries in Portsmouth Harbour, but its above-water timbers required frequent replacement due to sun and rain exposure. Below the waterline, however, the ship’s hull remains relatively intact, shielded from UV rays and stabilized by the water’s buoyancy. Practical tips for preservation include regular application of UV-resistant coatings and strategic placement of ships in sheltered waters or controlled environments like dry docks.

The interplay of these environmental factors creates a complex equation for wooden warship longevity. Climate, salinity, and exposure don’t act in isolation; their combined effects can either hasten decay or, in rare cases, preserve wood for centuries. For instance, the Antarctic’s *Endurance*, Shackleton’s lost ship, was discovered remarkably intact in 2022 due to the region’s cold, low-oxygen waters and minimal biological activity. Conversely, ships in the Mediterranean, with its warm, salty waters and intense sunlight, rarely survive more than a century without intervention. To maximize a wooden warship’s lifespan, preservationists must consider these factors holistically, employing strategies like climate-controlled storage, desalination, and protective coatings tailored to the vessel’s environment.

Ultimately, understanding these environmental factors is key to preserving wooden warships as historical artifacts. While no single solution fits all scenarios, a nuanced approach—informed by climate, salinity, and exposure—can significantly extend their life. For enthusiasts and historians alike, this knowledge transforms preservation from guesswork into a science, ensuring these maritime marvels endure for future generations.

From Forest to Factory: Crafting Long Wooden Planks Explained

You may want to see also

Explore related products

$135

Material Quality: Type of wood, treatment, and craftsmanship determine resistance to wear and tear

The lifespan of a wooden warship hinges on the quality of its materials, a principle as timeless as the vessels themselves. Oak, prized for its strength and durability, was the backbone of naval fleets for centuries. Its dense grain resists rot and withstands the constant stress of waves and wind. Teak, another favored choice, offers natural oils that repel water and insects, making it ideal for tropical climates. However, not all wood is created equal. Softer woods like pine, while cheaper, deteriorate rapidly in harsh marine environments, underscoring the critical role of material selection in a warship’s longevity.

Treatment of the wood is equally vital, transforming a vulnerable hull into a resilient barrier. Creosote, tar, and pitch were traditional preservatives, sealing the wood against moisture and marine borers. Modern methods, such as pressure-treating with copper compounds or synthetic chemicals, provide even greater protection. For instance, applying a 5% solution of copper naphthenate can extend a wooden structure’s life by decades. Yet, improper application or overuse of treatments can weaken the wood, highlighting the need for precision in this process.

Craftsmanship is the final pillar, where skill and attention to detail determine how well the wood withstands the test of time. Master shipwrights understood the importance of tight joints, proper caulking, and strategic reinforcement. A poorly fitted plank or a missed seam could lead to leaks, accelerating decay. Today, combining traditional techniques with modern tools, such as laser-guided cutting and CNC milling, ensures unparalleled precision. However, even the finest craftsmanship cannot compensate for subpar materials or inadequate treatment, making all three factors interdependent.

Consider the *HMS Victory*, launched in 1765, which remains preserved today due to meticulous maintenance and the superior quality of its oak construction. Conversely, countless lesser ships have crumbled into the sea, victims of inferior wood, neglect, or shoddy workmanship. For those restoring or building wooden vessels, the lesson is clear: invest in the best materials, apply treatments rigorously but judiciously, and demand excellence in craftsmanship. These steps, though labor-intensive, are the only path to ensuring a wooden warship’s survival across generations.

Wooden Balcony Lifespan: Factors Affecting Durability and Longevity

You may want to see also

Explore related products

$62.85

$95.85

Historical Examples: Case studies of preserved wooden warships reveal average lifespan and preservation methods

The average lifespan of a wooden warship, as revealed by historical examples, varies significantly depending on factors like construction quality, environmental conditions, and preservation efforts. The Mary Rose, an English warship that sank in 1545, lay submerged for over 400 years before its recovery in 1982. Despite centuries underwater, its hull remained remarkably intact due to the protective layer of silt and cold seawater. This case underscores how environmental factors can either hasten decay or preserve wooden structures for centuries.

Preservation methods play a critical role in extending the lifespan of wooden warships. The USS Constitution, launched in 1797, remains afloat today thanks to meticulous maintenance and periodic restoration. Known as "Old Ironsides," it has undergone multiple overhauls, including replacing decaying wooden planks with white oak, a durable material resistant to rot and pests. This example highlights the importance of proactive conservation, combining traditional craftsmanship with modern techniques to ensure longevity.

In contrast, the Vasa, a Swedish warship that sank on its maiden voyage in 1628, offers a cautionary tale. Raised in 1961, it was found to have suffered significant damage due to improper preservation during its early years above water. Exposure to air and fluctuating humidity caused the wood to shrink and crack. Today, the Vasa is preserved in a climate-controlled museum, where humidity levels are maintained at 50–55% and temperature at 18–20°C to prevent further deterioration. This case illustrates the delicate balance required in preserving wooden artifacts once they are removed from their original environment.

Comparing these examples reveals a pattern: wooden warships can endure for centuries, but their survival hinges on specific conditions. Submerged vessels like the Mary Rose benefit from anaerobic environments that slow decay, while above-water ships like the USS Constitution require continuous human intervention. The Vasa’s story emphasizes the need for controlled environments to mitigate the effects of exposure to air. Collectively, these case studies suggest that with the right preservation strategies, wooden warships can outlast their operational lifespan by hundreds of years.

Practical takeaways for preserving wooden warships include regular inspections, timely replacement of damaged components, and controlled storage conditions. For submerged wrecks, in situ preservation—leaving them underwater—may be the most effective method, as seen with the Mary Rose. For recovered vessels, climate-controlled environments and the use of durable materials like white oak are essential. By studying these historical examples, modern conservators can develop tailored strategies to ensure the survival of wooden warships for future generations.

Understanding Standard Wood Fence Picket Lengths for Your Project

You may want to see also

Frequently asked questions

A wooden warship can last anywhere from 20 to 50 years, depending on factors like maintenance, usage, and environmental conditions.

The lifespan is influenced by regular maintenance, exposure to saltwater and weather, the quality of wood used, and how frequently the ship is used in combat or harsh conditions.

Yes, with meticulous preservation techniques, such as regular repairs, protective coatings, and controlled storage, a wooden warship can last over 100 years, though it may no longer be seaworthy.

Wooden warships deteriorate faster due to the susceptibility of wood to rot, insect damage, and saltwater corrosion, unlike modern ships made of steel or other durable materials.