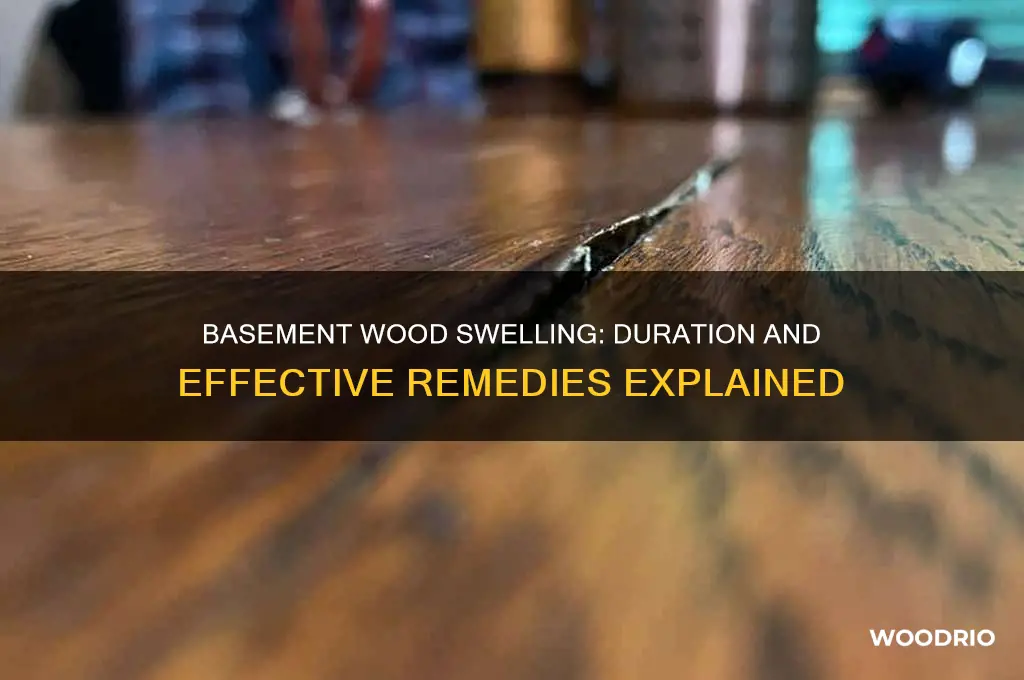

Basement wood swelling is a common issue that occurs when wood absorbs moisture from the surrounding environment, causing it to expand and potentially warp or crack. The duration of this swelling depends on several factors, including the type of wood, the extent of moisture exposure, and the humidity levels in the basement. Typically, if the source of moisture is addressed promptly, such as fixing leaks or improving ventilation, the swelling may subside within a few weeks as the wood dries out. However, in cases of prolonged or severe moisture exposure, the swelling could persist for months or even become permanent if the wood is irreparably damaged. Understanding the underlying causes and taking preventive measures are crucial to mitigating the effects of basement wood swelling.

| Characteristics | Values |

|---|---|

| Duration of Wood Swelling | Varies; typically resolves within 2-7 days after moisture removal |

| Factors Affecting Duration | Humidity levels, temperature, wood type, extent of moisture exposure |

| Permanent Damage Risk | Possible if swelling persists for weeks or months without intervention |

| Prevention Methods | Proper ventilation, dehumidification, waterproofing, prompt water cleanup |

| Common Basement Wood Types Affected | Plywood, studs, framing, furniture, paneling |

| Reversibility | Often reversible if addressed quickly; may require sanding or refinishing |

| Moisture Content Threshold | Wood absorbs moisture until it reaches equilibrium with the environment |

| Professional Intervention | Recommended for severe cases or structural concerns |

| Seasonal Impact | Worse in humid seasons (e.g., summer in humid climates) |

| Monitoring Tools | Moisture meters, visual inspection for warping or discoloration |

Explore related products

What You'll Learn

Factors affecting wood swelling duration

Wood swelling in basements is a common issue, but its duration varies widely based on several key factors. Understanding these can help predict how long the problem will persist and guide mitigation efforts. One critical factor is the moisture content of the wood. Wood absorbs and releases moisture in response to its environment, and the rate at which it swells depends on how saturated it becomes. For instance, wood exposed to a sudden influx of water, such as from a flood, may swell rapidly and remain expanded until the moisture content stabilizes, which can take weeks or even months.

The type of wood also plays a significant role. Softwoods like pine tend to swell more than hardwoods like oak due to their cellular structure. Softwoods have larger, more open cells that readily absorb moisture, whereas hardwoods have denser, more compact cells that resist swelling. Additionally, the age and condition of the wood matter. Older wood may have already undergone multiple swelling and shrinking cycles, making it more resilient, while newer wood is more susceptible to dramatic changes.

Environmental conditions are another major influence. Humidity levels in the basement directly impact wood swelling. High humidity accelerates moisture absorption, prolonging swelling, while controlled humidity levels can reduce its duration. Temperature also affects the process; warmer environments speed up moisture movement within the wood, potentially shortening swelling time if the wood dries faster. However, extreme temperature fluctuations can exacerbate swelling by causing repeated expansion and contraction.

Finally, the presence of sealants or treatments on the wood can significantly alter swelling duration. Untreated wood is more prone to prolonged swelling, while wood treated with water-repellent sealants or preservatives may swell less and recover faster. For example, applying a coat of polyurethane or epoxy can create a barrier that minimizes moisture penetration, reducing swelling time from weeks to just a few days. Regular maintenance and proactive treatment are essential for managing this issue effectively.

Durability of Wooden Planter Boxes: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Humidity impact on basement wood

Wood in basements is particularly susceptible to humidity due to the inherent dampness of below-grade spaces. Relative humidity levels above 50% can cause wood to absorb moisture from the air, leading to swelling, warping, or even mold growth. This is especially problematic for wooden structural elements like floor joists, support beams, or furniture stored in basements. Monitoring humidity with a hygrometer is the first step in prevention; ideally, basement humidity should be maintained between 30% and 50%. Dehumidifiers, particularly those with a capacity of 30-70 pints per day depending on basement size, are essential tools for controlling moisture levels.

The duration of wood swelling depends on how long the wood has been exposed to high humidity and the extent of moisture absorption. Minor swelling may resolve within a few days if humidity is promptly reduced and maintained at optimal levels. However, severe cases, where wood has absorbed significant moisture, can take weeks or even months to dry out completely. In some instances, the wood may retain permanent damage, such as warping or cracking, necessitating replacement. To expedite drying, improve air circulation by using fans or opening windows (if outdoor humidity is lower), and consider using a moisture meter to track progress.

Preventing humidity-related damage is far easier than addressing it after the fact. Seal basement walls and floors with waterproof coatings or membranes to reduce moisture infiltration. Ensure proper drainage around the foundation and install sump pumps if necessary to manage groundwater. For wooden items stored in basements, elevate them off the floor using pallets or moisture-resistant materials to minimize direct contact with damp surfaces. Regularly inspect wood for signs of moisture damage, especially after heavy rains or flooding, and address issues immediately to prevent long-term consequences.

Comparing basements with and without humidity control highlights the critical role of moisture management. In uncontrolled environments, wood swelling is almost inevitable, leading to structural instability and potential safety hazards. Conversely, basements with consistent humidity control not only preserve wood integrity but also enhance overall air quality and comfort. Investing in humidity management solutions, such as dehumidifiers and vapor barriers, is a cost-effective measure that pays dividends in the long run by protecting both the structure and its contents.

For those dealing with existing wood swelling, a systematic approach is key. Start by identifying and addressing the source of excess humidity, whether it’s poor ventilation, leaks, or inadequate waterproofing. Next, gradually reduce humidity levels to allow the wood to dry naturally, avoiding rapid changes that could cause further damage. If swelling persists or the wood shows signs of mold, consult a professional to assess structural integrity and recommend appropriate remediation steps. With patience and proactive measures, the impact of humidity on basement wood can be mitigated, ensuring longevity and stability.

Wood Putty Drying Time: Factors Affecting Cure and Finish

You may want to see also

Explore related products

Drying time for swollen wood

Wood swelling in basements is a common issue, often caused by prolonged exposure to moisture. The drying time for swollen wood can vary significantly depending on several factors, including the type of wood, the extent of moisture absorption, and the environmental conditions in the basement. Hardwoods like oak or maple may take longer to dry than softer woods like pine due to their denser structure. Understanding these variables is crucial for effectively restoring the wood to its original state.

To expedite the drying process, start by addressing the source of moisture. Ensure proper ventilation by using dehumidifiers or fans to circulate air, reducing humidity levels to below 50%. If the wood is part of a structural element, such as a beam or joist, avoid applying direct heat, as this can cause uneven drying and warping. Instead, opt for a gradual approach, allowing the wood to acclimate naturally over time. For smaller items like furniture, consider moving them to a drier area of the house or outdoors on a dry, sunny day, ensuring they are not exposed to direct sunlight for extended periods to prevent cracking.

A practical tip for monitoring the drying progress is to measure the moisture content of the wood using a moisture meter. Aim for a moisture level between 6% and 12%, which is typical for indoor wood. If the wood’s moisture content is significantly higher, it may take several weeks to months to dry completely. For example, a 2x4 pine stud with a moisture content of 25% could take approximately 4–6 weeks to dry in a well-ventilated basement, while a thicker oak beam might require 2–3 months. Patience is key, as rushing the process can lead to permanent damage.

Comparing natural drying methods to accelerated techniques highlights the trade-offs involved. While air drying is gentle and cost-effective, it requires time and consistent environmental conditions. Kiln drying, though faster, is expensive and typically reserved for professional settings. For basement wood, the most effective strategy often combines controlled ventilation, humidity management, and periodic inspection. By balancing these factors, you can minimize drying time while preserving the wood’s integrity, ensuring it remains functional and aesthetically pleasing.

Mastering Wood Soaking Times for Perfect Smoke Flavor Every Time

You may want to see also

Explore related products

Preventing prolonged wood swelling

Wood swelling in basements is a persistent issue, often exacerbated by high humidity and moisture infiltration. To prevent prolonged swelling, start by addressing the root cause: excess moisture. Install a dehumidifier capable of reducing humidity levels to below 50%, the threshold at which wood begins to absorb moisture. For basements larger than 700 square feet, opt for a dehumidifier with a capacity of at least 70 pints per day. Pair this with regular monitoring using a hygrometer to ensure consistent conditions. Without controlling humidity, even treated wood will succumb to swelling over time.

Next, inspect and repair any water leaks or seepage points in the basement. Even minor cracks in the foundation or gaps around pipes can introduce enough moisture to trigger swelling. Apply hydraulic cement to seal foundation cracks and use waterproof caulking for smaller gaps. For persistent issues, consider installing a sump pump or interior drainage system to redirect water away from the structure. Ignoring these leaks not only prolongs wood swelling but also risks mold growth and structural damage.

Another critical step is to elevate wooden structures off the basement floor. Use pressure-treated wooden shims or plastic risers to create a barrier between the wood and the concrete, which naturally wicks moisture. For larger installations like paneling or furniture, incorporate a vapor barrier such as polyethylene sheeting beneath the wood. This simple physical separation can significantly reduce moisture absorption, even in damp environments.

Finally, choose wood species and treatments that resist moisture. Hardwoods like teak or oak are naturally more resistant to swelling than softwoods like pine. For existing installations, apply a water-repellent sealant or wood preservative annually, following manufacturer instructions for application rates (typically 1 gallon covers 150–300 square feet). While no treatment is foolproof, combining resistant materials with proactive maintenance minimizes the risk of prolonged swelling.

By systematically addressing moisture sources, creating physical barriers, and selecting appropriate materials, prolonged wood swelling in basements can be effectively prevented. Each step builds on the next, forming a comprehensive strategy that protects both the wood and the overall integrity of the space.

How Long Does a 1/4 Cord of Wood Typically Last?

You may want to see also

Explore related products

Signs of permanent wood damage

Wood swelling in basements is often a temporary issue, but prolonged exposure to moisture can lead to permanent damage. Identifying the signs early is crucial to prevent irreversible harm. One of the first indicators is warping, where the wood bends or twists out of its original shape. This occurs when moisture penetrates the fibers unevenly, causing them to expand differently. While slight warping might resolve as the wood dries, severe or persistent warping suggests the damage is permanent, especially if the wood has been exposed to moisture for weeks or months.

Another telltale sign is cracking or splitting, which happens when the wood swells beyond its structural limits. These cracks often appear along the grain and can deepen over time, even after the wood dries. If the cracks are wide enough to see through or if they extend deep into the wood, it’s a strong indication of permanent damage. Applying wood filler or glue might cosmetically repair small cracks, but structural integrity is compromised, particularly in load-bearing elements like beams or joists.

Discoloration and mold growth are also red flags. While surface mold can sometimes be removed, mold that has penetrated deep into the wood often signals prolonged moisture exposure. Dark stains or a persistent musty odor even after cleaning suggest fungal decay, which weakens the wood’s cellular structure. If the wood feels soft or spongy when pressed, it’s likely rotted and beyond repair. In such cases, replacement is the safest option to avoid further structural issues.

Finally, delamination—where layers of wood separate—is a clear sign of permanent damage, especially in plywood or engineered wood products. This occurs when the adhesive bonding the layers fails due to moisture. Delaminated wood loses its strength and stability, making it unsuitable for structural use. If you notice bubbling, peeling, or visible separation between layers, it’s time to replace the affected material.

To assess whether the damage is permanent, consider the duration and severity of moisture exposure. Wood exposed to high humidity or standing water for more than 48–72 hours is at high risk. If the wood remains damp for weeks, permanent damage is nearly inevitable. Regularly inspect basement wood for these signs, especially after flooding or leaks, and act promptly to mitigate further harm. Prevention, such as using moisture barriers or dehumidifiers, is always more cost-effective than repair or replacement.

Wood Pellets Lifespan: How Long Do They Last and Stay Effective?

You may want to see also

Frequently asked questions

Basement wood swelling typically lasts as long as the wood remains exposed to moisture. Once the source of moisture is addressed and the wood dries out, swelling usually resolves within a few days to a few weeks, depending on humidity levels and ventilation.

A: While wood swelling is often reversible, prolonged exposure to moisture can lead to permanent damage, such as warping, cracking, or rot. If the swelling persists for weeks or months, the wood may require repair or replacement.

A: To speed up drying, improve ventilation by using fans or dehumidifiers, ensure the basement is well-insulated, and fix any leaks or water sources. Direct airflow toward the affected wood to expedite moisture evaporation.

A: In many cases, swollen wood will return to its original shape once it dries completely. However, severe or prolonged swelling may cause irreversible damage, such as warping or splitting, requiring professional intervention or replacement.