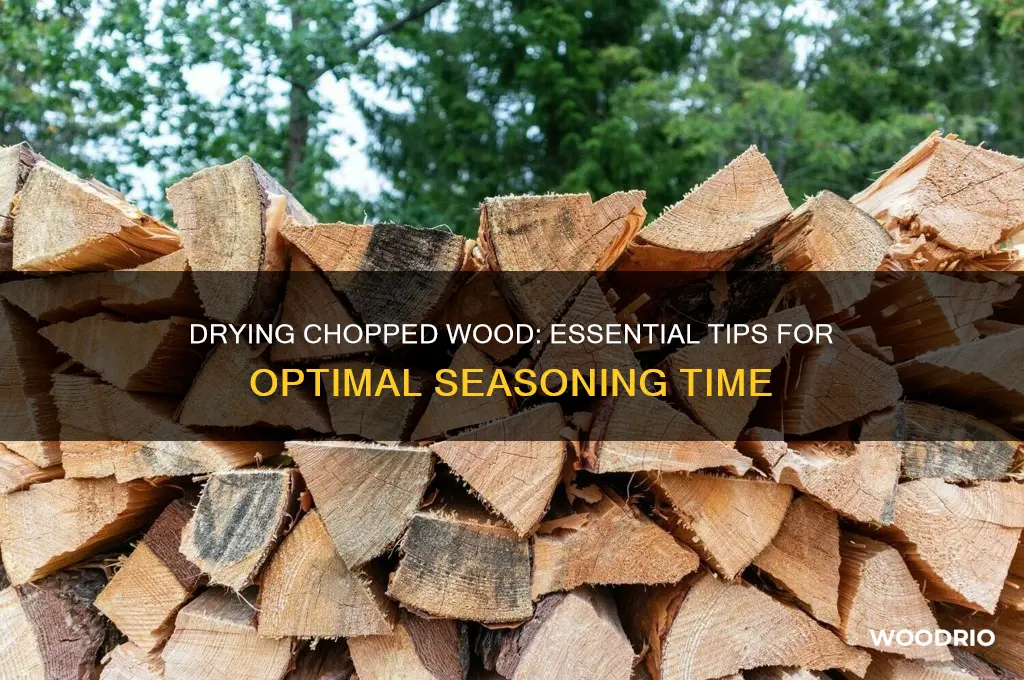

Drying chopped wood, also known as seasoning, is a crucial step in preparing firewood for efficient and safe burning. The time it takes for chopped wood to dry depends on several factors, including the type of wood, its initial moisture content, the climate, and the storage conditions. Hardwoods like oak or maple typically take longer to dry, often requiring 6 to 12 months, while softer woods like pine may dry in 3 to 6 months. Properly stacking wood in a dry, well-ventilated area, off the ground, and protected from rain can significantly speed up the drying process. Understanding these variables ensures the wood burns hotter, cleaner, and more efficiently once it’s ready for use.

| Characteristics | Values |

|---|---|

| Type of Wood | Hardwoods (e.g., oak, maple): 6–12 months; Softwoods (e.g., pine): 3–6 months |

| Moisture Content | Freshly cut wood: 30–50%; Ideal for burning: 20% or less |

| Splitting Size | Smaller pieces dry faster (e.g., 4–6 inches in diameter) |

| Stacking Method | Properly stacked with airflow (e.g., crisscross or using spacers) |

| Location | Covered, well-ventilated area; direct sunlight speeds drying |

| Humidity and Climate | Drier climates: faster drying; humid climates: slower drying |

| Season of Cutting | Wood cut in spring/summer dries faster due to higher temperatures |

| Kiln Drying (Accelerated Method) | 2–7 days depending on kiln settings and wood type |

| Air Drying (Natural Method) | 6 months to 2 years depending on factors above |

| Checking for Dryness | Wood feels lighter, ends crack, and moisture meter reads <20% |

Explore related products

What You'll Learn

- Factors Affecting Drying Time: Wood type, moisture content, climate, and storage conditions impact drying duration

- Seasoning Time for Hardwoods: Hardwoods like oak take 6–12 months to dry properly

- Softwood Drying Duration: Softwoods like pine dry faster, typically in 3–6 months

- Stacking and Airflow: Proper stacking with good airflow reduces drying time significantly

- Moisture Testing Methods: Use a moisture meter to ensure wood is below 20% moisture

Factors Affecting Drying Time: Wood type, moisture content, climate, and storage conditions impact drying duration

The drying time of chopped wood is not a one-size-fits-all scenario. It's a complex process influenced by several key factors, each playing a unique role in determining how long it takes for wood to reach optimal moisture levels for burning. Understanding these factors is crucial for anyone looking to season wood efficiently.

Wood Type: A Species-Specific Affair

Different wood species have inherent variations in density and cellular structure, which significantly impact drying time. Softwoods like pine and spruce, with their looser grain structure, dry faster than hardwoods such as oak or maple. For instance, pine can reach suitable moisture levels for burning in 6-12 months, while oak might require 18-24 months or more. This is because hardwoods have denser cell walls, making it harder for moisture to escape.

Moisture Content: The Starting Point Matters

The initial moisture content of freshly cut wood is a critical factor. Wood can contain up to 50% moisture when first chopped, and this needs to be reduced to around 20% for efficient burning. The higher the initial moisture content, the longer the drying process. A simple moisture meter can help you assess this, with readings above 30% indicating a need for extended drying.

Climate: Nature's Role in the Drying Process

Environmental conditions play a pivotal role in wood drying. In regions with hot, dry summers, wood can season much faster compared to humid, rainy climates. Ideal drying conditions include low humidity (below 60%) and temperatures above 70°F (21°C). In contrast, cold, damp weather can significantly prolong drying, sometimes requiring additional measures like kiln drying or using a dehumidifier in storage areas.

Storage Conditions: Stacking Up for Success

How and where you store wood during the drying process is just as important as the wood itself. Proper stacking allows for adequate air circulation, which is essential for moisture evaporation. A well-stacked woodpile should be off the ground, using pallets or a base of branches, and arranged in a crisscross pattern to promote airflow. Covering the top of the pile with a tarp while leaving the sides open protects from rain but still allows air movement.

In conclusion, the drying time of chopped wood is a multifaceted process, influenced by the wood's natural characteristics, environmental factors, and human intervention in storage and handling. By understanding and managing these factors, you can significantly reduce the time it takes for your wood to be ready for the fireplace or wood stove.

Durability of Wood Pallets: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Seasoning Time for Hardwoods: Hardwoods like oak take 6–12 months to dry properly

Hardwoods, such as oak, are prized for their density and durability, but these very qualities make them slower to season. Unlike softwoods like pine, which can dry in 6–12 months, hardwoods typically require 6–12 months of seasoning time under optimal conditions. This extended period is essential to reduce moisture content to below 20%, ensuring the wood burns efficiently and minimizes creosote buildup in chimneys. Rushing this process risks using wood that’s too wet, leading to poor combustion, excess smoke, and potential safety hazards.

The seasoning time for hardwoods isn’t arbitrary—it’s rooted in their cellular structure. Hardwoods have denser fibers and larger pores, which trap moisture more stubbornly. For example, freshly cut oak can have a moisture content of 50–70%, meaning it must lose over half its water weight to be ready for use. Stacking wood in a well-ventilated, covered area accelerates drying by allowing air to circulate while protecting it from rain. Splitting logs into smaller pieces further expedites the process by increasing surface area exposure.

To maximize efficiency, monitor the wood’s moisture level with a wood moisture meter, aiming for 15–20%. If you’re in a humid climate, expect the upper end of the 6–12 month range, as moisture evaporates more slowly. Conversely, dry, windy conditions can shorten seasoning time but may require additional measures to prevent the wood from drying too quickly and cracking. Properly seasoned hardwood will have checks (small cracks) along the ends and a dull, grayish appearance, signaling it’s ready for use.

For those planning ahead, cut and stack hardwoods at least a full year before the heating season to ensure it’s fully seasoned. If you’re in a pinch, consider mixing partially seasoned hardwood with drier softwood to improve burn quality. However, relying on unseasoned hardwood can damage your fireplace or stove, as the excess moisture condenses into creosote, a flammable substance that clings to chimney walls. Patience in seasoning hardwoods pays off in cleaner burns, higher heat output, and prolonged appliance lifespan.

Mineral Spirits on Wood: Optimal Drying Time for Perfect Finish

You may want to see also

Explore related products

Softwood Drying Duration: Softwoods like pine dry faster, typically in 3–6 months

Softwoods, such as pine, spruce, and fir, are known for their relatively quick drying times compared to hardwoods. This is primarily due to their lower density and higher resin content, which allows moisture to evaporate more rapidly. For those looking to season softwood for firewood or construction, understanding the drying duration is crucial for planning and efficiency. Typically, softwoods like pine can dry within 3 to 6 months under optimal conditions, making them a practical choice for projects requiring quicker turnaround times.

To maximize drying efficiency, stack softwood logs or planks in a well-ventilated area, ensuring they are off the ground to prevent moisture absorption. A crisscross pattern allows air to circulate freely, accelerating the process. Additionally, covering the stack with a waterproof tarp on top while leaving the sides open protects the wood from rain while still permitting airflow. Monitoring humidity levels is also beneficial; aim for a relative humidity below 65% for faster drying. If natural conditions are unfavorable, consider using a kiln, which can reduce drying time to just a few weeks, though this method is more resource-intensive.

Comparatively, hardwoods like oak or maple can take 6 to 24 months to dry, highlighting the advantage of softwoods for time-sensitive applications. However, it’s essential to balance speed with quality. Rapid drying can lead to cracking or warping, especially in thicker pieces. To mitigate this, gradually acclimate the wood to its intended environment after drying, particularly if it will be used indoors. For firewood, ensure the moisture content drops below 20% to achieve efficient burning and minimize creosote buildup in chimneys.

A practical tip for homeowners is to cut and split softwood logs during late spring or early summer, allowing them to dry fully by winter. This seasonal approach aligns with natural weather patterns, leveraging warmer temperatures and lower humidity for optimal drying. For those in humid climates, pairing natural drying with periodic kiln use can strike a balance between cost and speed. Ultimately, softwoods’ faster drying time makes them an ideal choice for both novice and experienced woodworkers, provided proper techniques are employed to preserve their integrity.

The Rise and Fall of Bretton Woods: A 27-Year Legacy

You may want to see also

Explore related products

Stacking and Airflow: Proper stacking with good airflow reduces drying time significantly

Chopped wood drying times vary widely—from six months to two years—depending on factors like wood type, moisture content, and environmental conditions. However, one of the most controllable variables to accelerate this process is how the wood is stacked. Proper stacking with good airflow can reduce drying time by up to 50%, making it a critical step for anyone looking to season wood efficiently. The principle is simple: air needs to circulate freely around the wood to carry away moisture, and the stack’s structure plays a pivotal role in enabling this.

To achieve optimal airflow, start by stacking wood in a single row or a crisscross pattern, ensuring gaps between logs. A common technique is the "stair-step" method, where each layer is slightly offset to create natural air channels. Avoid stacking wood directly on the ground; instead, use pallets or a foundation of branches to elevate the pile, preventing moisture absorption from the soil. For larger stacks, leave spaces between rows—at least 4 inches—to allow air to flow horizontally. The goal is to maximize surface exposure while maintaining stability, as a collapsed stack can trap moisture and hinder drying.

Comparing poorly stacked wood to properly arranged piles highlights the difference. A dense, tightly packed stack retains moisture, leading to mold, rot, or insect infestations, while a well-ventilated stack dries uniformly. For example, hardwoods like oak or maple, which naturally take longer to dry, benefit significantly from strategic stacking. Softwoods like pine, though quicker to dry, still require adequate airflow to prevent warping or cracking. The key takeaway is that regardless of wood type, airflow is non-negotiable for efficient drying.

Practical tips include choosing a sunny, well-drained location for your woodpile, as sunlight and wind aid in evaporation. Cover the top of the stack with a tarp to protect it from rain, but leave the sides open to maintain airflow. Regularly inspect the pile, rotating logs if necessary to ensure even drying. For those in humid climates, consider using a moisture meter to monitor progress, aiming for a moisture content below 20% for optimal burning efficiency. Proper stacking isn’t just about organization—it’s a science that transforms waiting time into usable firewood faster.

Exploring Muir Woods: Average Visitor Time and Tips for Your Trip

You may want to see also

Explore related products

Moisture Testing Methods: Use a moisture meter to ensure wood is below 20% moisture

Freshly chopped wood, often called green wood, can contain moisture levels upwards of 50%. For firewood to burn efficiently and safely, this moisture content must drop below 20%. While seasoning times vary based on wood type, climate, and stacking methods, a moisture meter is the only reliable way to confirm readiness.

Simply guessing based on appearance or weight can lead to using wood that's still too wet, resulting in smoky fires, creosote buildup, and reduced heat output.

Moisture meters designed for firewood are inexpensive and easy to use. They work by sending a small electrical current through the wood, measuring the resistance, which correlates to moisture content. Pin-type meters require you to press two metal probes into the wood, while pinless meters scan the surface. For accuracy, take readings from multiple spots on each piece, focusing on the end grain where moisture is most concentrated. Aim for readings consistently below 20% – ideally around 15-20% for optimal burning.

Moisture meters are particularly valuable for those in humid climates or working with denser hardwoods, which take longer to dry.

It's important to note that moisture meters aren't just for firewood. They're also essential tools for anyone working with wood in construction, woodworking, or flooring. In these applications, moisture content directly impacts the wood's dimensional stability, susceptibility to rot, and adhesion properties. While the target moisture level varies depending on the use, the principle remains the same: accurate measurement is key to preventing problems down the line.

Calibrating your moisture meter regularly and using it on freshly split wood will ensure the most accurate readings.

While seasoning times provide a general guideline, relying solely on time can be risky. A moisture meter takes the guesswork out of the equation, ensuring you're using wood that's truly ready. This not only improves your fires but also protects your chimney from creosote buildup, a leading cause of chimney fires. Investing in a moisture meter is a small price to pay for safer, more efficient, and more enjoyable fires. Remember, properly seasoned wood burns cleaner, hotter, and leaves less mess – all benefits that start with accurate moisture testing.

Baby Wood Ducks' Stay Duration: A Complete Growth Timeline

You may want to see also

Frequently asked questions

Chopped wood typically takes 6 months to 2 years to dry, depending on factors like wood type, moisture content, and drying conditions.

Yes, hardwoods like oak and hickory take longer to dry (1–2 years), while softwoods like pine dry faster (6–12 months).

Yes, stacking wood in a dry, sunny, and well-ventilated area, covering the top, and splitting it into smaller pieces can accelerate drying.

Fully dried wood has a moisture content of 20% or less, feels lighter, has cracks at the ends, and makes a sharp, hollow sound when knocked together.

Burning wet wood is inefficient, produces more smoke, creosote buildup, and less heat. It’s best to let it dry properly before use.