Engineered wood flooring is a popular choice for homeowners due to its durability, versatility, and aesthetic appeal. However, proper acclimation is crucial to ensure its long-term performance and stability. Acclimation allows the engineered wood to adjust to the humidity and temperature conditions of its installation environment, minimizing the risk of gaps, warping, or buckling. The acclimation period typically ranges from 48 to 72 hours, depending on factors such as the specific product, local climate, and manufacturer guidelines. During this time, the flooring should be stored in the room where it will be installed, with the packaging unopened, to allow it to equilibrate with the surrounding conditions. Following the recommended acclimation process is essential to maintain the integrity and beauty of the engineered wood flooring for years to come.

| Characteristics | Values |

|---|---|

| Acclimation Time | 48–72 hours (2–3 days) |

| Purpose of Acclimation | Allows wood to adjust to the environment's humidity and temperature |

| Ideal Humidity Range | 30–50% relative humidity |

| Temperature Range | 60–80°F (15–27°C) |

| Factors Affecting Acclimation | Humidity, temperature, wood species, thickness, and installation area |

| Signs of Proper Acclimation | No visible warping, cupping, or gapping |

| Consequences of Skipping Acclimation | Increased risk of warping, gapping, or buckling after installation |

| Storage During Acclimation | Flat, horizontal stacking in the installation room |

| Manufacturer Recommendations | Follow specific guidelines provided by the engineered wood manufacturer |

| Testing for Readiness | Moisture meter reading matches the environment's moisture content |

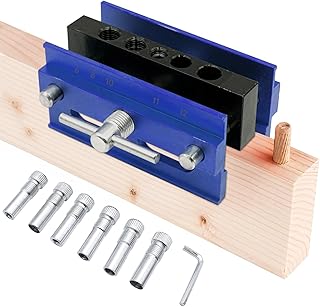

Explore related products

What You'll Learn

- Ideal acclimation time for engineered wood flooring in different humidity conditions

- Factors affecting acclimation duration, such as wood thickness and room temperature

- How to properly store engineered wood before installation for best results?

- Signs that engineered wood has fully acclimated to its environment

- Common mistakes to avoid during the acclimation process for engineered wood

Ideal acclimation time for engineered wood flooring in different humidity conditions

Engineered wood flooring, while more stable than solid hardwood, still requires acclimation to prevent warping, gapping, or buckling. The ideal acclimation time hinges on humidity levels, which dictate how the wood expands or contracts. In low-humidity environments (below 30% relative humidity), engineered wood typically acclimates within 2–3 days. The drier air causes the wood to release moisture, necessitating a shorter adjustment period. However, rushing this process risks shrinkage post-installation, so monitoring the flooring’s moisture content with a hygrometer is essential.

In moderate humidity conditions (30%–50% relative humidity), the sweet spot for most engineered wood, acclimation takes 3–5 days. This range aligns with the wood’s natural moisture content, allowing it to stabilize without significant expansion or contraction. Manufacturers often recommend this timeframe as a baseline, but environmental factors like temperature fluctuations can extend the need for acclimation. For instance, if the installation area experiences rapid temperature changes, add an extra day to ensure equilibrium.

High-humidity environments (above 50% relative humidity) demand the longest acclimation period, typically 5–7 days. Excess moisture in the air causes the wood to absorb water, leading to swelling or cupping if not properly acclimated. In such cases, using a dehumidifier to lower the room’s humidity to the 30%–50% range before and during acclimation is crucial. Additionally, storing the flooring in its packaging and stacking it horizontally allows for even moisture distribution, reducing the risk of uneven absorption.

A comparative analysis reveals that acclimation time is inversely proportional to humidity levels: lower humidity equals faster acclimation, while higher humidity requires patience. However, the goal remains consistent: achieving equilibrium between the flooring’s moisture content and the installation environment. Ignoring this step can void warranties and lead to costly repairs. Practical tips include acclimating the flooring in the room where it will be installed, maintaining consistent temperature and humidity, and consulting manufacturer guidelines for product-specific recommendations.

Ultimately, the ideal acclimation time for engineered wood flooring is not one-size-fits-all but a function of humidity conditions. By understanding this relationship and taking proactive measures, homeowners and installers can ensure a seamless, long-lasting installation. Treat acclimation as a non-negotiable step, not an optional precaution, to preserve the beauty and integrity of the flooring.

Playground Wood Chips Lifespan: Durability, Maintenance, and Replacement Guide

You may want to see also

Explore related products

Factors affecting acclimation duration, such as wood thickness and room temperature

Engineered wood, unlike its solid counterpart, is a composite material designed for stability. Yet, it still requires acclimation to its new environment before installation. This process allows the wood to adjust to the surrounding humidity and temperature, minimizing the risk of warping, cupping, or gapping after installation.

Understanding the factors influencing acclimation duration is crucial for a successful and long-lasting flooring project.

Thickness Matters: Think of engineered wood planks as sponges. Thicker planks, like thicker sponges, absorb and release moisture more slowly. This means they generally require a longer acclimation period compared to thinner planks. As a rule of thumb, allow 2-3 days of acclimation for every 1/8 inch of thickness. For example, a ½ inch thick plank would need approximately 8-12 days to acclimate properly.

Thinner planks, typically used for click-lock installations, may only require 2-3 days due to their reduced moisture absorption capacity.

Temperature and Humidity: The Dynamic Duo: Room temperature and humidity levels are inextricably linked when it comes to acclimation. Warmer temperatures accelerate moisture exchange, shortening acclimation time. Conversely, cooler temperatures slow down this process. Ideal acclimation conditions fall within a temperature range of 60°F to 80°F (15°C to 27°C).

Humidity plays an equally important role. Engineered wood is designed to perform optimally within a relative humidity range of 30% to 50%. If the room's humidity falls outside this range, acclimation time will be extended. In particularly dry environments, consider using a humidifier to expedite the process. Conversely, in humid climates, ensure proper ventilation to prevent excessive moisture absorption.

Practical Tips for Optimal Acclimation:

- Unbox and Stack: Remove the engineered wood planks from their packaging and stack them horizontally in the room where they will be installed. This allows for air circulation around the planks, facilitating moisture exchange.

- Maintain Consistent Conditions: Keep the room temperature and humidity as stable as possible during the acclimation period. Avoid drastic fluctuations, such as opening windows on a humid day or running a heater excessively.

- Monitor Moisture Content: For precise acclimation, consider using a moisture meter to measure the moisture content of both the wood and the subfloor. Aim for a moisture content difference of less than 4% between the two.

By understanding the interplay between wood thickness, room temperature, and humidity, you can ensure your engineered wood flooring acclimates properly, setting the stage for a beautiful and durable installation.

Wooden Windows Durability: Screens Enhance or Shorten Lifespan?

You may want to see also

Explore related products

How to properly store engineered wood before installation for best results

Engineered wood requires careful storage to ensure it acclimates properly before installation, a process that typically takes 48 to 72 hours but can extend to one week depending on humidity and temperature fluctuations. Proper storage isn't just about waiting; it's about creating an environment that mimics the conditions where the wood will be installed. This minimizes expansion, contraction, or warping, ensuring a seamless and durable finish.

Steps for Optimal Storage:

- Unbox Strategically: Leave the wood in its packaging until you’re ready to begin acclimation. Packaging protects against moisture and dust. Once unboxed, stack planks horizontally on a flat surface, allowing air circulation between layers.

- Maintain Ideal Conditions: Store the wood in the room where it will be installed, ensuring the temperature stays between 60°F and 80°F and humidity levels range from 30% to 50%. Use a dehumidifier or humidifier if necessary.

- Elevate and Space: Place the wood on wooden pallets or stickers to prevent moisture absorption from concrete floors. Leave a 1-inch gap between the wall and the stack to allow airflow.

Cautions to Avoid:

Avoid storing engineered wood in areas prone to extreme temperature changes, such as garages or basements without climate control. Direct sunlight can cause uneven acclimation, so keep stacks away from windows. Never stack wood directly on the floor, as this increases the risk of moisture absorption, leading to cupping or buckling.

Comparative Insight:

Unlike solid hardwood, engineered wood is more stable due to its layered construction, but it still requires acclimation. While solid wood may need up to two weeks to adjust, engineered wood’s shorter acclimation period makes it a more forgiving choice for time-sensitive projects. However, rushing this step can void warranties and compromise the installation.

Practical Tips for Success:

Use a hygrometer to monitor humidity levels daily. If the room’s humidity exceeds 55%, run a dehumidifier for 24 hours before rechecking. For colder climates, ensure the room is heated consistently for at least 48 hours before introducing the wood. Finally, consult the manufacturer’s guidelines, as some engineered wood products have specific acclimation requirements based on their composition.

By following these steps, you’ll ensure the engineered wood acclimates effectively, setting the stage for a flawless installation that stands the test of time.

Durability of Wood Ceilings: Lifespan and Maintenance Tips Revealed

You may want to see also

Explore related products

Signs that engineered wood has fully acclimated to its environment

Engineered wood, a versatile and popular flooring option, requires a crucial acclimation period before installation to ensure its long-term stability and performance. This process allows the wood to adjust to the humidity and temperature of its new environment, preventing issues like warping, gaps, or buckling. But how do you know when this acclimation is complete? Here are some telltale signs that your engineered wood is ready for installation.

Stability in Moisture Content: One of the primary indicators of acclimation is the stabilization of the wood's moisture content. Engineered wood is designed to be more resistant to moisture fluctuations than solid wood, but it still needs to reach equilibrium with its surroundings. Use a moisture meter to measure the wood's moisture content regularly during the acclimation period. When the readings remain consistent over several days, typically within a range of 6-8% for most indoor environments, it's a strong sign that the wood has acclimated. This stability ensures the wood won't expand or contract significantly after installation.

Dimensional Consistency: Acclimated engineered wood will exhibit uniform dimensions across the planks. Before installation, lay out several pieces and inspect them for any visible gaps or variations in width and length. Fully acclimated wood should fit together seamlessly, with joints aligning perfectly. If you notice any cupping, crowning, or uneven edges, it's a clear indication that the wood hasn't yet adjusted to the environment and requires more time.

Absence of Visible Stress: Engineered wood under stress from improper acclimation may show physical signs of distress. Look for cracks, splits, or delamination between the layers of the wood. These issues can occur if the wood expands or contracts too rapidly. A well-acclimated plank will appear smooth and intact, with no visible signs of tension or separation. Running your hand over the surface should feel consistent, with no unexpected bumps or ridges.

Adhesive Readiness: For engineered wood that requires gluing during installation, the acclimation process is particularly vital. The wood's moisture content directly affects the adhesive's performance. When the wood is fully acclimated, the adhesive will cure properly, creating a strong bond. Test this by applying a small amount of the recommended adhesive to a scrap piece of acclimated wood and another non-acclimated piece. The adhesive on the acclimated wood should set uniformly, while the other may show signs of uneven curing or failure to bond effectively.

In summary, determining when engineered wood has fully acclimated involves a combination of measurements, visual inspections, and practical tests. By monitoring moisture content, checking for dimensional consistency, and ensuring the wood shows no signs of stress, you can be confident in its readiness for installation. This attention to detail during the acclimation process is essential for achieving a durable and aesthetically pleasing engineered wood floor.

Wood County Ohio Probate Records Retention: How Long Are They Kept?

You may want to see also

Explore related products

Common mistakes to avoid during the acclimation process for engineered wood

Engineered wood requires a meticulous acclimation process to ensure stability and longevity, but many installers overlook critical details that can lead to warping, gaps, or delamination. One common mistake is ignoring manufacturer guidelines, which often specify acclimation times ranging from 48 hours to 7 days depending on the product and environmental conditions. For instance, a ½-inch thick engineered plank may need 3–5 days in a climate-controlled space (60–80°F, 30–50% humidity), while thicker planks could require up to a week. Skipping this step or rushing the process can void warranties and compromise performance.

Another frequent error is improper storage during acclimation. Stacking bundles directly on concrete floors or against walls traps moisture, as concrete can leach humidity into the wood. Instead, use wooden pallets or a vapor barrier to elevate the material, ensuring air circulation around all sides. Additionally, storing engineered wood in areas with extreme temperature fluctuations, such as garages or unfinished basements, can cause expansion or contraction, leading to structural issues post-installation.

A third oversight is failing to acclimate the subfloor simultaneously. Engineered wood expands and contracts based on its environment, so the subfloor must be within the same moisture and temperature range. For example, if the subfloor’s moisture content exceeds 12% (measured with a moisture meter), the wood may cup or buckle after installation. Acclimating both the flooring and subfloor in the same space for the recommended duration ensures compatibility and reduces the risk of movement.

Lastly, neglecting to monitor humidity levels during acclimation can derail the entire process. A hygrometer should be used to confirm the room’s relative humidity stays within the manufacturer’s specified range. If humidity drops below 30%, the wood may shrink; above 50%, it can swell. In regions with high humidity, a dehumidifier may be necessary, while a humidifier can help in dry climates. Regularly checking these conditions ensures the wood stabilizes properly before installation.

By avoiding these mistakes—disregarding guidelines, improper storage, neglecting the subfloor, and ignoring humidity—installers can ensure engineered wood acclimates effectively, setting the stage for a durable and visually appealing floor. Attention to these details not only preserves the material’s integrity but also maximizes its lifespan, making the extra effort well worth the investment.

Do Long Wood Pieces Break Easier Under Compression in Bridges?

You may want to see also

Frequently asked questions

Engineered wood flooring typically needs to acclimate for 48 to 72 hours before installation, depending on the manufacturer's recommendations and environmental conditions.

Yes, acclimation time can vary by climate. In humid or dry environments, engineered wood may require additional time to adjust, often up to 7 days, to ensure proper moisture balance.

Engineered wood can acclimate in the installation room, provided the room’s temperature and humidity levels are consistent with the expected living conditions. Ensure the HVAC system is operational during acclimation.

Installing engineered wood without proper acclimation can lead to issues like warping, gapping, or buckling, as the wood may expand or contract after installation due to moisture changes.

Generally, thicker engineered wood may require slightly longer acclimation time compared to thinner options, but the difference is minimal. Always follow the manufacturer’s specific guidelines for your product.