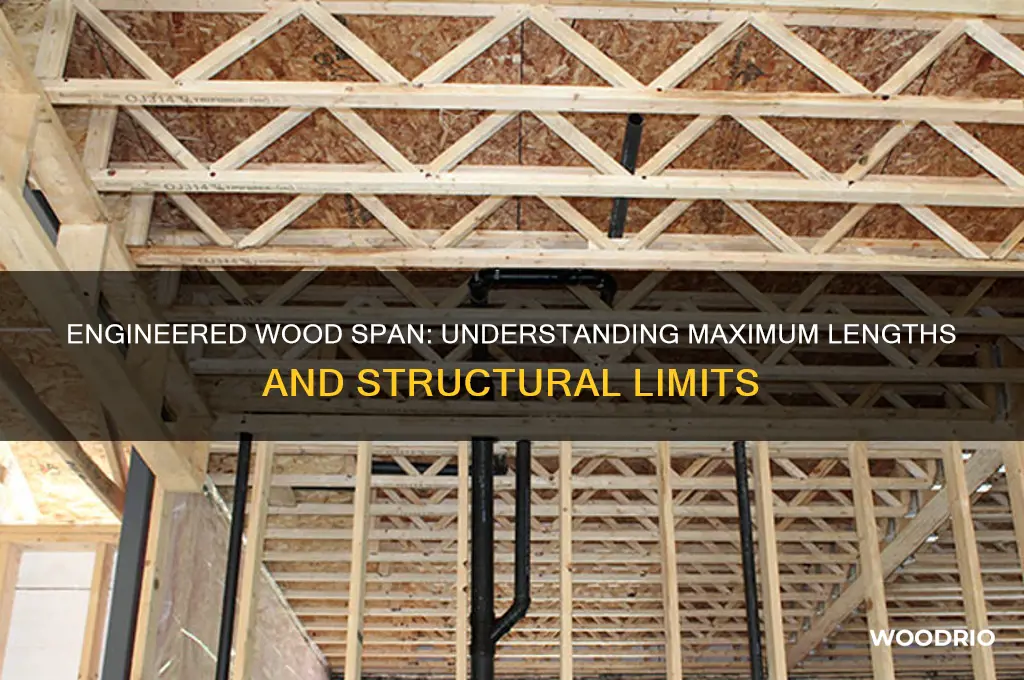

Engineered wood, a versatile and increasingly popular alternative to solid wood, is designed to offer enhanced structural performance and durability. One of the critical considerations when using engineered wood is its spanning capability, which refers to the maximum distance it can cover without additional support. The span length of engineered wood depends on several factors, including the type of engineered wood product (e.g., I-joists, laminated veneer lumber, or plywood), its thickness, the load it will bear, and the specific application (e.g., flooring, roofing, or wall framing). Manufacturers typically provide span tables and guidelines to help builders and designers determine the appropriate span for each product, ensuring structural integrity and safety. Understanding these specifications is essential for optimizing the use of engineered wood in construction projects while maintaining compliance with building codes and standards.

| Characteristics | Values |

|---|---|

| Span Length | Varies based on factors like wood species, load requirements, and beam size; typically ranges from 12 to 24 feet for residential applications. |

| Load Capacity | Depends on engineering design; can support heavier loads than solid wood due to layered construction. |

| Moisture Resistance | Generally more resistant to warping and shrinking compared to solid wood, but not fully waterproof. |

| Durability | Long-lasting with proper installation and maintenance; lifespan can exceed 50 years. |

| Cost | Typically more affordable than solid hardwood but varies by brand and quality. |

| Installation Flexibility | Easier to install due to lighter weight and consistent dimensions; suitable for long spans with proper support. |

| Environmental Impact | Often considered more sustainable due to efficient use of wood resources and reduced waste. |

| Aesthetic Options | Available in various finishes and styles to mimic solid wood or modern designs. |

| Structural Integrity | Engineered to meet or exceed building codes; provides consistent strength across the span. |

| Maintenance Requirements | Low maintenance; regular cleaning and occasional refinishing may be needed depending on usage. |

Explore related products

What You'll Learn

Span Limits by Thickness

Engineered wood's span capability hinges on its thickness, a critical factor that dictates structural integrity and load-bearing capacity. Thicker boards inherently offer greater strength, allowing them to bridge longer distances without sagging or compromising stability. For instance, a 3/4-inch thick engineered wood plank can typically span up to 20 inches between joists, while a 1-inch thick plank may extend up to 28 inches under similar conditions. This relationship between thickness and span is not linear but rather exponential, meaning each incremental increase in thickness yields a disproportionately larger span potential.

To maximize span efficiency, consider the following practical steps. First, assess the intended load—whether it’s for residential flooring, heavy furniture, or commercial use—and consult manufacturer specifications for thickness recommendations. Second, ensure proper joist spacing, as wider gaps demand thicker boards to maintain rigidity. For example, a 1/2-inch thick engineered wood floor might only span 16 inches safely, making it unsuitable for wide-joist applications. Third, factor in environmental conditions like humidity, which can cause thinner boards to warp or expand, reducing their effective span over time.

A comparative analysis reveals that engineered wood thickness often outperforms solid hardwood in span efficiency due to its layered construction, which enhances dimensional stability. For instance, a 5/8-inch engineered plank can rival the span of a 3/4-inch solid hardwood board under comparable loads. However, thicker engineered wood also comes at a higher cost, both in material and installation, due to increased weight and complexity. Thus, balancing thickness with budget and structural requirements is key to optimizing span without overspending.

Descriptively, imagine a scenario where a homeowner is renovating a 12-foot-wide room with joists spaced 24 inches apart. A 1/2-inch thick engineered wood floor would likely fail to span this distance without support, leading to visible sagging or structural failure. In contrast, opting for a 1-inch thick board ensures not only a safe span but also a more resilient floor capable of withstanding decades of foot traffic and furniture loads. This example underscores how thickness directly correlates to both span and long-term durability.

In conclusion, understanding span limits by thickness is essential for any engineered wood project. By selecting the appropriate thickness based on load, joist spacing, and environmental factors, you can achieve both structural integrity and cost efficiency. Thicker boards offer greater span potential but require careful consideration of installation challenges and material costs. Always reference manufacturer guidelines and, when in doubt, consult a structural engineer to ensure your engineered wood installation meets safety and performance standards.

Woodpecker Mating Duration: Understanding Their Unique Pairing Process

You may want to see also

Explore related products

Load Capacity Factors

Engineered wood's span capabilities are heavily influenced by load capacity factors, which dictate how much weight a beam can support without compromising structural integrity. These factors are not one-size-fits-all; they vary based on the specific type of engineered wood product, its intended use, and environmental conditions. For instance, laminated veneer lumber (LVL) and glued laminated timber (glulam) have different load-bearing characteristics due to their distinct manufacturing processes and material compositions. Understanding these nuances is crucial for ensuring safety and efficiency in construction projects.

To determine the appropriate load capacity, engineers and builders must consider several key factors. The first is the span-to-depth ratio, which directly affects how much weight a beam can carry over a given distance. For example, an LVL beam with a span-to-depth ratio of 20:1 can typically support heavier loads than a traditional solid wood beam of the same dimensions. Another critical factor is the species and grade of the wood fibers used in the engineered product, as these influence strength and stiffness. Higher-grade materials often allow for longer spans and greater load capacities.

Environmental conditions also play a significant role in load capacity factors. Moisture content and temperature fluctuations can affect the dimensional stability and strength of engineered wood. For instance, prolonged exposure to high humidity can cause swelling or warping, reducing load-bearing capacity. To mitigate this, builders often incorporate protective measures, such as moisture barriers or proper ventilation, especially in areas prone to dampness. Additionally, live loads (temporary weights like furniture or people) and dead loads (permanent weights like roofing or flooring) must be factored into calculations to ensure the structure can withstand both everyday use and unexpected stresses.

Practical application of load capacity factors requires adherence to industry standards and guidelines. The American Wood Council’s National Design Specification (NDS) provides detailed tables and formulas for calculating maximum spans and loads for various engineered wood products. For example, a glulam beam designed for a residential floor system might support a live load of 40 pounds per square foot (psf) and a dead load of 15 psf, with a safety factor of 1.5 to account for unforeseen stresses. Builders should always consult these resources and, when in doubt, seek professional engineering advice to avoid costly mistakes or safety hazards.

In summary, load capacity factors are the backbone of engineered wood’s spanning capabilities, requiring careful consideration of material properties, environmental conditions, and structural demands. By mastering these factors, builders can maximize the potential of engineered wood while ensuring long-term durability and safety. Whether designing a simple residential deck or a complex commercial structure, a thorough understanding of load capacity factors is indispensable for success.

Weathering Cherry Wood: Optimal Outdoor Time for Rich Darkening Results

You may want to see also

Explore related products

Support Spacing Rules

Engineered wood, with its layered construction and enhanced stability, can span impressive distances—often exceeding those of solid lumber. However, achieving these spans requires precise support spacing, a critical factor often overlooked in construction.

The 16-Inch Rule: A Starting Point

A common guideline for engineered wood flooring is to space supports (joists or beams) no more than 16 inches on center. This rule applies to standard ¾-inch thick engineered planks installed over a subfloor. Wider spacing risks deflection, where the wood bends under load, leading to squeaks, cracks, or structural failure. For thicker engineered wood (1 inch or more), supports can sometimes be spaced up to 24 inches apart, but always consult manufacturer specifications or local building codes.

Load Considerations: Beyond the Basics

Support spacing isn’t just about plank thickness—it’s also about anticipated loads. Residential floors typically support live loads (people, furniture) of 40 pounds per square foot (psf). For heavier loads, such as in commercial spaces (100 psf or more), supports must be closer together. For example, a 12-inch on-center spacing might be necessary for engineered wood in a high-traffic retail area. Always factor in dead loads (the weight of the structure itself) when calculating spacing.

Environmental Factors: Humidity and Temperature

Engineered wood’s dimensional stability is a selling point, but it’s not invincible. In humid environments, wood expands, increasing the risk of buckling if supports are too far apart. Conversely, dry conditions can cause contraction, creating gaps. For areas prone to moisture fluctuations, such as basements or coastal regions, reduce support spacing by 20% to accommodate movement. Additionally, use moisture barriers and acclimate the wood to the installation environment for 48–72 hours before laying it.

Practical Tips for Precision

To ensure proper support spacing, mark joist locations with chalk lines before installation. Use a laser level to maintain straight lines, especially in larger rooms. For DIYers, pre-drilling holes for screws reduces the risk of splitting the wood. When in doubt, hire a structural engineer to calculate the optimal spacing based on your project’s unique conditions. Remember, cutting corners on support spacing can void warranties and compromise safety.

The Takeaway: Spacing as a Structural Cornerstone

Support spacing isn’t just a detail—it’s the backbone of engineered wood’s performance. By adhering to manufacturer guidelines, accounting for loads, and considering environmental factors, you can maximize the material’s span capabilities while ensuring longevity. Proper spacing transforms engineered wood from a mere surface into a durable, reliable structural element.

Optimal Clamping Time for Wood Glue: A Comprehensive Guide

You may want to see also

Explore related products

Species & Quality Impact

The species of wood used in engineered wood products significantly influences their span capabilities. For instance, engineered wood made from dense hardwoods like oak or maple generally offers greater strength and durability compared to softer woods like pine. This is because hardwoods have a tighter grain structure, which enhances their load-bearing capacity. When selecting engineered wood for a project, consider the specific species and its inherent properties to ensure it meets the structural demands of the application.

Quality is another critical factor that impacts the span of engineered wood. Higher-quality products often undergo more rigorous manufacturing processes, including precise lamination and adhesive application. For example, engineered wood with phenol-formaldehyde resins tends to have superior moisture resistance and bond strength, allowing it to span longer distances without compromising stability. Conversely, lower-quality engineered wood may delaminate or warp under stress, reducing its effective span. Always inspect product certifications and manufacturer ratings to gauge quality before installation.

A comparative analysis reveals that engineered wood made from premium species and high-quality manufacturing processes can span up to 20 feet in residential applications, while lower-quality options may be limited to 12–16 feet. For example, I-joists made from Southern Yellow Pine, a softer wood, typically span shorter distances compared to those made from Douglas Fir, a harder and more resilient species. This highlights the importance of matching species and quality to the project’s structural requirements.

Practical tips for maximizing engineered wood span include avoiding overloading, ensuring proper installation, and protecting the material from moisture. For instance, applying a waterproof sealant to the edges of engineered wood can prevent swelling and warping, which could otherwise reduce its span. Additionally, always follow manufacturer guidelines for spacing and support to maintain structural integrity. By prioritizing species selection and quality, you can achieve longer, safer spans in your construction projects.

Night in the Woods DLC: Unveiling the Length of Its Nights

You may want to see also

Explore related products

Environmental Influence

Engineered wood's lifespan is deeply intertwined with its environmental exposure, a factor that can either extend its durability or hasten its deterioration. Moisture, temperature fluctuations, and UV radiation are the primary culprits. For instance, engineered wood used in outdoor structures like decks or pergolas without proper sealing can absorb moisture, leading to warping, swelling, or even mold growth within 3–5 years. In contrast, indoor applications with controlled humidity levels (ideally between 30–50%) can see engineered wood last upwards of 25 years, provided it’s shielded from direct water exposure.

To mitigate environmental damage, proactive measures are essential. Applying a high-quality, UV-resistant sealant every 1–2 years is critical for outdoor installations, as it forms a barrier against sunlight and moisture. For areas prone to high humidity, such as bathrooms or kitchens, opt for engineered wood with a higher laminate thickness (at least 0.6mm) and ensure proper ventilation to reduce condensation. Additionally, using waterproof adhesives during installation can prevent delamination in moisture-prone zones, adding years to the material’s lifespan.

A comparative analysis reveals that engineered wood’s environmental resilience varies by type. Plywood, with its cross-laminated structure, offers better dimensional stability in humid conditions compared to particleboard, which tends to disintegrate when exposed to moisture. Similarly, engineered hardwood flooring with a wear layer of at least 2mm can withstand foot traffic and minor spills for 20–30 years, whereas thinner options may show wear within a decade. Choosing the right product for the specific environment is therefore paramount.

From a persuasive standpoint, investing in engineered wood with enhanced environmental resistance is not just practical but also sustainable. Products treated with low-VOC finishes or certified by organizations like the Forest Stewardship Council (FSC) minimize ecological impact while ensuring longevity. For example, engineered wood with a phenolic resin coating can resist temperatures up to 150°F, making it suitable for sun-exposed areas without compromising structural integrity. Such choices align with eco-conscious practices while maximizing the material’s lifespan.

Finally, a descriptive approach highlights the transformative effects of environmental care on engineered wood. Imagine a coastal home’s engineered wood siding, regularly maintained with marine-grade sealant, retaining its sleek appearance and structural soundness for decades despite salty air and intense sunlight. Contrast this with an untreated balcony railing, which might crack and splinter within five years due to neglect. The takeaway is clear: environmental influence is not a passive factor but an active variable that homeowners and builders can control through informed decisions and consistent maintenance.

Bondo Wood Filler Drying Time: Quick Guide for Perfect Repairs

You may want to see also

Frequently asked questions

The span of engineered wood depends on factors like the type of engineered wood, load requirements, and spacing. For example, engineered I-joists can span up to 24 feet or more, while laminated veneer lumber (LVL) can span up to 20 feet under typical residential loads.

Yes, thicker engineered wood products generally allow for longer spans. Deeper sections, such as 12-inch or 14-inch I-joists, can span farther than shallower ones under the same load conditions.

Closer spacing (e.g., 12 inches or 16 inches on center) allows for shorter spans, while wider spacing (e.g., 24 inches on center) reduces the maximum span length due to increased load distribution.

Yes, engineered wood often spans longer than solid wood due to its consistent strength, reduced warping, and ability to be manufactured in larger, more uniform sizes.

Higher load requirements (e.g., heavy flooring or snow loads) reduce the maximum span length, while lighter loads allow for longer spans. Always consult manufacturer specifications or an engineer for precise calculations.