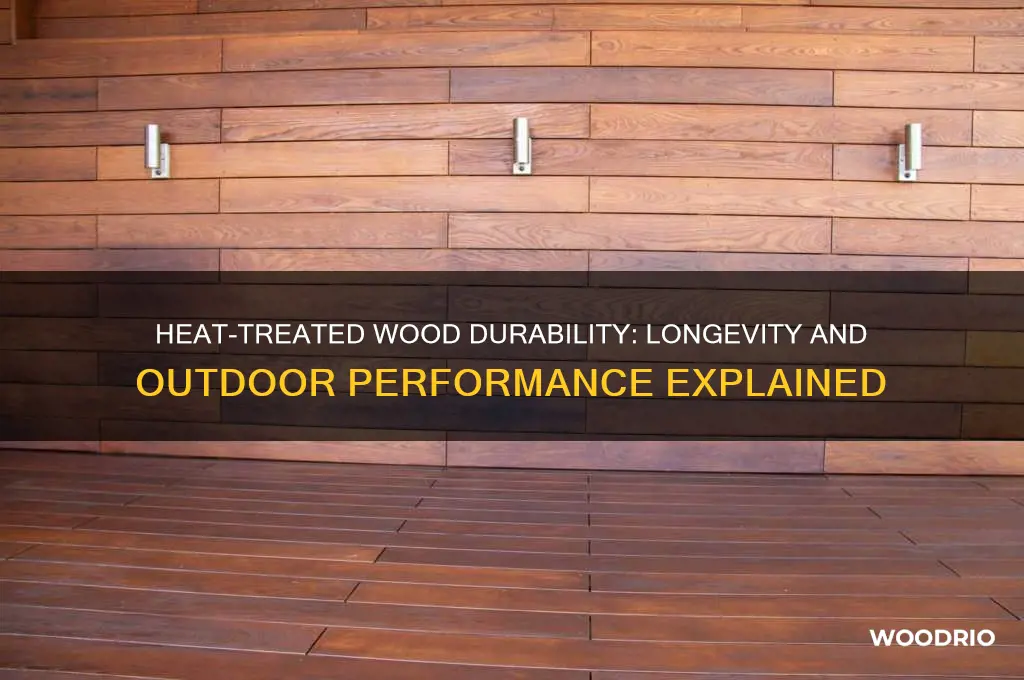

Heat-treated wood is a popular choice for outdoor applications due to its enhanced durability and resistance to decay, insects, and moisture. The longevity of heat-treated wood outside depends on several factors, including the type of wood, the specific heat treatment process used, and the environmental conditions it is exposed to. Generally, heat-treated wood can last anywhere from 15 to 30 years or more when properly maintained and protected from harsh weather elements. Unlike chemically treated wood, heat-treated wood is eco-friendly and safe for use in gardens, playgrounds, and other outdoor spaces. Regular sealing or staining can further extend its lifespan by minimizing water absorption and UV damage, making it a reliable and sustainable option for exterior projects.

| Characteristics | Values |

|---|---|

| Durability | 20-30 years or more, depending on maintenance and environmental factors |

| Resistance to Decay | Highly resistant to rot, fungi, and insects due to heat treatment |

| Moisture Resistance | Reduced moisture absorption compared to untreated wood |

| Chemical-Free Treatment | No chemicals used, making it environmentally friendly |

| Dimensional Stability | Improved stability, less prone to warping or shrinking |

| Maintenance Requirements | Periodic sealing or staining recommended for prolonged lifespan |

| Cost | Generally higher than untreated wood but lower than pressure-treated |

| Environmental Impact | Sustainable and eco-friendly, as it uses natural processes |

| Appearance | Natural wood look with possible slight color changes post-treatment |

| Applications | Ideal for outdoor furniture, decking, fencing, and structural elements |

| Temperature Tolerance | Withstands extreme temperatures without significant degradation |

| Biodegradability | Biodegradable at the end of its lifecycle |

Explore related products

$16.99

What You'll Learn

Factors affecting durability of heat-treated wood outdoors

Heat-treated wood, often marketed for its enhanced durability, can last 15 to 30 years outdoors, but this lifespan hinges on several critical factors. Moisture exposure is the primary adversary. While heat treatment reduces wood’s ability to absorb water, prolonged contact with soil or standing water accelerates decay. For example, a heat-treated deck board in a dry, elevated position may outlast one embedded in a damp garden border by a decade or more. To mitigate this, ensure proper drainage and elevate wood structures at least 6 inches above ground level.

Wood species plays a pivotal role in determining longevity. Dense hardwoods like oak or ash respond better to heat treatment than softwoods like pine, though treated softwoods remain viable for outdoor use. For instance, heat-treated southern yellow pine can withstand outdoor conditions for 20–25 years, while treated oak may endure closer to 30 years. When selecting wood, prioritize species with natural resistance to decay, even after treatment.

Temperature fluctuations and UV exposure introduce additional stress. Extreme heat can cause cracking, while freezing temperatures may exacerbate moisture absorption in untreated areas. UV rays degrade the wood’s surface, leading to discoloration and brittleness. Applying a UV-resistant sealant every 2–3 years can extend the wood’s aesthetic and structural integrity. In regions with harsh climates, consider combining heat treatment with additional preservatives for maximum protection.

Maintenance practices significantly influence durability. Regular inspections for cracks, splinters, or fungal growth allow for timely repairs. Cleaning the wood annually with a mild detergent and water removes debris that traps moisture. For high-traffic areas like decks, reapply a protective finish every 1–2 years to maintain the wood’s resilience. Neglecting maintenance can halve the expected lifespan, even for heat-treated wood.

Finally, application-specific stresses must be considered. Wood used for ground contact, such as fence posts, requires deeper treatment (e.g., Class 4 or higher) to combat soil-borne pests and fungi. Conversely, overhead structures like pergolas face less moisture but more UV exposure, necessitating frequent sealing. Tailoring treatment levels and maintenance routines to the wood’s intended use ensures optimal performance and longevity in outdoor environments.

Wood Pellets Burn Time: How Long 10kg Lasts

You may want to see also

Explore related products

$12.99

Average lifespan of heat-treated wood in exterior conditions

Heat-treated wood, when exposed to exterior conditions, typically lasts 15 to 30 years, depending on factors like wood species, treatment method, and environmental exposure. For instance, pine treated with high-temperature processes can endure up to 25 years, while denser hardwoods like oak may last closer to 30 years. This extended lifespan is due to the heat treatment process, which removes moisture and resins, making the wood more resistant to decay, insects, and fungi. However, this durability is not indefinite; proper maintenance and placement play critical roles in maximizing its outdoor longevity.

To understand the variability in lifespan, consider the treatment temperature and duration. Wood treated at temperatures between 190°C and 212°C (374°F to 414°F) for 1 to 2 hours achieves Class 1 or 2 durability, suitable for ground contact or harsh weather. Lower temperatures or shorter durations result in Class 3 or 4 wood, better suited for protected exterior use, with lifespans closer to 10–15 years. For example, a heat-treated pine deck in a rainy climate might require sealing every 2–3 years to reach the upper end of its lifespan, while the same wood in a dry region could last without additional treatment.

Comparing heat-treated wood to alternatives like pressure-treated lumber highlights its advantages and limitations. While pressure-treated wood often contains chemicals that leach over time, heat-treated wood is eco-friendly and safer for gardens or playgrounds. However, it lacks the same resistance to moisture absorption, making it more susceptible to warping or cracking without proper sealing. A persuasive argument for heat-treated wood is its sustainability—it relies on natural processes rather than chemical preservatives, appealing to environmentally conscious consumers.

Practical tips for extending the lifespan of heat-treated wood include strategic placement and regular maintenance. Avoid direct soil contact by using gravel or concrete bases for structures like fences or garden beds. Apply a UV-resistant sealant annually to protect against sun damage, and inspect for cracks or splinters biannually. For example, a heat-treated oak pergola in a sunny area will benefit from a light sanding and resealing every spring to prevent graying and maintain structural integrity.

In conclusion, the average lifespan of heat-treated wood in exterior conditions hinges on a combination of treatment quality, wood type, and aftercare. By selecting the right class of treated wood, applying protective measures, and monitoring wear, homeowners and builders can ensure this material remains functional and aesthetically pleasing for decades. While not maintenance-free, its natural durability and eco-friendly profile make it a compelling choice for outdoor projects.

Trex vs. Wood: Which Material Offers Superior Longevity for Decks?

You may want to see also

Explore related products

Maintenance tips to extend outdoor wood longevity

Heat-treated wood, often lasting 20–30 years outdoors, outperforms untreated alternatives due to its enhanced resistance to decay and insects. However, longevity isn’t guaranteed without proper care. Exposure to moisture, UV rays, and temperature fluctuations accelerates wear, making maintenance essential. By adopting proactive measures, you can significantly extend its lifespan, ensuring it remains both functional and aesthetically pleasing.

Sealants and Finishes: The First Line of Defense

Applying a high-quality sealant or wood finish every 1–2 years is critical. Opt for products containing UV inhibitors to combat sun damage, and choose water-repellent formulas to minimize moisture absorption. For horizontal surfaces like decks, use a thicker coat to account for heavier wear. Reapply after cleaning or when water no longer beads on the surface. This simple step can add 5–10 years to the wood’s life, depending on climate and exposure.

Cleaning: Preventing Accumulation Before It’s Too Late

Dirt, mildew, and debris trap moisture, fostering rot and discoloration. Clean wood surfaces semi-annually with a mild detergent and a soft-bristle brush. For stubborn stains, use a specialized wood cleaner or a mixture of oxygen bleach and water (1 cup bleach per gallon of water). Pressure washing is effective but risky—keep the pressure below 1,500 PSI to avoid damaging the wood fibers. Regular cleaning not only preserves appearance but also ensures sealants adhere properly during reapplication.

Structural Inspections: Catching Issues Early

Annually inspect joints, fasteners, and supports for signs of wear or corrosion. Replace rusted screws or nails with stainless steel or galvanized alternatives to prevent wood splitting. Check for cracks, warping, or splintering, addressing minor issues before they worsen. For raised structures like decks, ensure proper drainage by clearing debris from gaps and maintaining a slight slope away from the house. Early intervention can prevent costly repairs and extend structural integrity.

Strategic Placement and Design: Reducing Environmental Stress

Minimize direct ground contact by using gravel beds or concrete footings beneath wooden structures. Incorporate overhangs or awnings to shield wood from rain and snow, reducing moisture exposure by up to 50%. For gardens, elevate planters or use liners to prevent soil-borne moisture from seeping into the wood. Thoughtful design choices, combined with regular maintenance, create an environment where heat-treated wood thrives for decades.

By combining these strategies, you transform maintenance from a chore into an investment, ensuring your outdoor wood not only lasts but excels in durability and appearance.

Exploring the Length of Night in the Woods: A Detailed Guide

You may want to see also

Explore related products

Comparison with untreated wood lifespan outdoors

Heat-treated wood typically lasts 20 to 30 years outdoors, a lifespan significantly longer than untreated wood, which often deteriorates within 5 to 10 years under similar conditions. This durability gap stems from the heat treatment process, which removes moisture and resins, making the wood more resistant to decay, insects, and fungal growth. Untreated wood, lacking such modifications, remains vulnerable to environmental stressors, leading to faster degradation.

Consider the practical implications for outdoor projects. For a garden fence or deck, untreated wood may require replacement within a decade, whereas heat-treated wood could endure for three times as long. This longevity reduces maintenance frequency and material costs over time. However, untreated wood remains a viable option for short-term or budget-conscious projects, provided it’s regularly sealed or painted to extend its life.

Analyzing the environmental impact reveals another layer of comparison. Heat-treated wood, while durable, requires energy-intensive processing, which may offset its sustainability benefits. Untreated wood, though less durable, is often sourced locally and requires minimal processing, making it a greener choice for those prioritizing eco-friendliness over longevity. Balancing these factors depends on the project’s specific needs and the user’s environmental priorities.

For optimal results, pair heat-treated wood with proper installation techniques, such as using stainless steel fasteners to prevent corrosion. Untreated wood, on the other hand, benefits from annual inspections and treatments like linseed oil or wood preservatives. Both materials demand care, but the nature of that care differs sharply, reflecting their distinct lifespans and vulnerabilities.

In conclusion, the choice between heat-treated and untreated wood hinges on project duration, budget, and environmental considerations. While heat-treated wood offers superior longevity, untreated wood serves well for temporary applications or when sustainability is paramount. Understanding these differences ensures informed decision-making for outdoor projects.

Understanding the Lifespan of Wood Boring Beetles: A Comprehensive Guide

You may want to see also

Explore related products

Environmental impact on heat-treated wood durability

Heat-treated wood, often marketed for its enhanced durability, is not immune to the environmental factors that can accelerate its degradation. While the process of heat treatment improves resistance to decay and insects, external conditions play a pivotal role in determining its lifespan outdoors. Understanding these impacts is crucial for maximizing the wood’s longevity and minimizing maintenance needs.

Moisture Exposure: The Silent Degradation Catalyst

Moisture is the primary environmental adversary of heat-treated wood. Prolonged exposure to water, whether from rain, humidity, or ground contact, can lead to swelling, warping, and eventual cracking. Even though heat treatment reduces the wood’s moisture absorption rate, it doesn’t eliminate it entirely. In regions with high rainfall or humidity, such as coastal areas, the wood’s lifespan may decrease by 20–30% compared to drier climates. To mitigate this, apply a water-repellent sealant annually and ensure proper drainage around structures. For ground-contact applications, consider using a barrier like gravel or plastic sheeting to reduce moisture absorption.

UV Radiation: The Invisible Wood Weakener

Sunlight, particularly its ultraviolet (UV) component, causes surface degradation, discoloration, and fiber breakdown in heat-treated wood. Over time, UV exposure can reduce the wood’s structural integrity, making it more susceptible to splintering and surface erosion. In arid, sun-intensive regions like deserts, UV damage can shorten the wood’s lifespan by up to 40%. To combat this, use UV-resistant stains or paints, which act as a protective barrier. Reapply these coatings every 2–3 years, depending on exposure levels. For a more natural look, opt for oils enriched with UV inhibitors, such as linseed or tung oil.

Temperature Fluctuations: The Stress Test for Wood

Extreme temperature variations, common in continental climates, subject heat-treated wood to repeated expansion and contraction. This thermal stress can lead to micro-cracks, which, over time, compromise the wood’s stability and appearance. In areas with temperature swings exceeding 30°C (86°F) between day and night, the wood’s lifespan may be reduced by 15–25%. To minimize this impact, choose wood species with inherently lower thermal expansion rates, such as oak or ash. Additionally, pre-drilling holes for fasteners can reduce stress points, and using flexible sealants can accommodate movement without causing damage.

Biological Threats: The Persistent Challenge

While heat treatment significantly reduces susceptibility to fungi and insects, it doesn’t provide absolute immunity. In environments with high organic matter, such as forests or gardens, microbial activity can still occur, especially if the wood’s surface is compromised by scratches or cracks. To enhance protection, treat the wood with eco-friendly preservatives like borate or copper azole. These treatments penetrate the wood, providing an additional layer of defense without harming the environment. Inspect the wood annually for signs of infestation or decay, and address any issues promptly to prevent further damage.

Practical Takeaway: Tailoring Durability to Your Environment

Maximizing the lifespan of heat-treated wood outdoors requires a proactive, environment-specific approach. Assess your local climate conditions—moisture levels, UV exposure, temperature fluctuations, and biological risks—and tailor your maintenance strategy accordingly. By combining the right protective measures with regular inspections, you can ensure that heat-treated wood remains a durable and sustainable choice for decades, even in challenging environments.

Cypress Wood Durability: Lifespan, Maintenance, and Longevity Explained

You may want to see also

Frequently asked questions

Heat-treated wood can last 15 to 25 years outdoors, depending on the environment, wood species, and maintenance.

Heat-treated wood generally lasts slightly less than chemically treated wood, which can last 30+ years, but it is a more eco-friendly option.

Exposure to moisture, sunlight, insects, and temperature fluctuations can reduce its lifespan, as can lack of proper sealing or maintenance.

While heat treatment improves durability, heat-treated wood is not completely rot-resistant and can still decay over time, especially in wet or humid conditions.

Regularly seal or stain the wood, keep it clean, ensure proper drainage, and avoid direct contact with soil to maximize its longevity.