Dry rot, caused by the fungus *Serpula lacrymans*, is a destructive wood-decaying organism that can significantly compromise the structural integrity of timber. The time it takes for dry rot to fully rot wood depends on various factors, including moisture levels, temperature, and the wood's condition. In ideal conditions—where wood remains consistently damp and temperatures are moderate—dry rot can begin to weaken wood within a few months, though visible damage may take longer to appear. Under less favorable conditions, the process can slow, but dry rot can still persist and spread over years if left untreated. Early detection and remediation are crucial to prevent extensive damage, as dry rot can spread to other building materials and even masonry if moisture conditions persist.

| Characteristics | Values |

|---|---|

| Time for Dry Rot to Start | 7–10 days in ideal conditions (high moisture, warm temperatures) |

| Visible Damage Appearance | 2–6 months after initial infestation |

| Structural Damage Timeline | 6 months to 2 years, depending on wood type and environmental factors |

| Complete Wood Decay | 2–5 years or more, if left untreated |

| Optimal Conditions for Dry Rot | 20–30°C (68–86°F) and moisture content above 20% |

| Wood Type Influence | Softwoods (e.g., pine) decay faster than hardwoods (e.g., oak) |

| Preventive Measures Effectiveness | Proper ventilation and moisture control can significantly slow or stop dry rot |

| Fungal Growth Rate | Rapid growth in damp, warm environments |

| Detection Difficulty | Early stages are hard to detect; visible signs appear later |

| Treatment Urgency | Immediate action required upon detection to prevent extensive damage |

Explore related products

$27.3 $32.15

What You'll Learn

Dry Rot Progression Timeline

Dry rot, caused by the fungus *Serpula lacrymans*, doesn’t strike overnight. It begins inconspicuously, often in damp, dark areas where wood moisture levels exceed 20%. The fungus first colonizes the wood, secreting enzymes that break down cellulose and lignin, the structural components of wood. This initial stage can last weeks to months, depending on conditions like temperature (optimal at 50–68°F) and humidity. During this phase, the wood may appear slightly discolored or feel softer, but the damage is largely internal, making early detection challenging.

As dry rot progresses, the wood undergoes visible deterioration. Fine, fluffy white strands called mycelium spread across the surface, often accompanied by a musty odor. The wood becomes brittle, cracking into cube-like shapes as the fungus consumes its structure. This stage typically unfolds over 6–12 months, accelerating in environments with persistent moisture. For instance, a leaky basement wall or poorly ventilated crawl space can shorten this timeline significantly. At this point, the fungus also begins to produce spore-bearing bodies, ensuring its spread to adjacent wood.

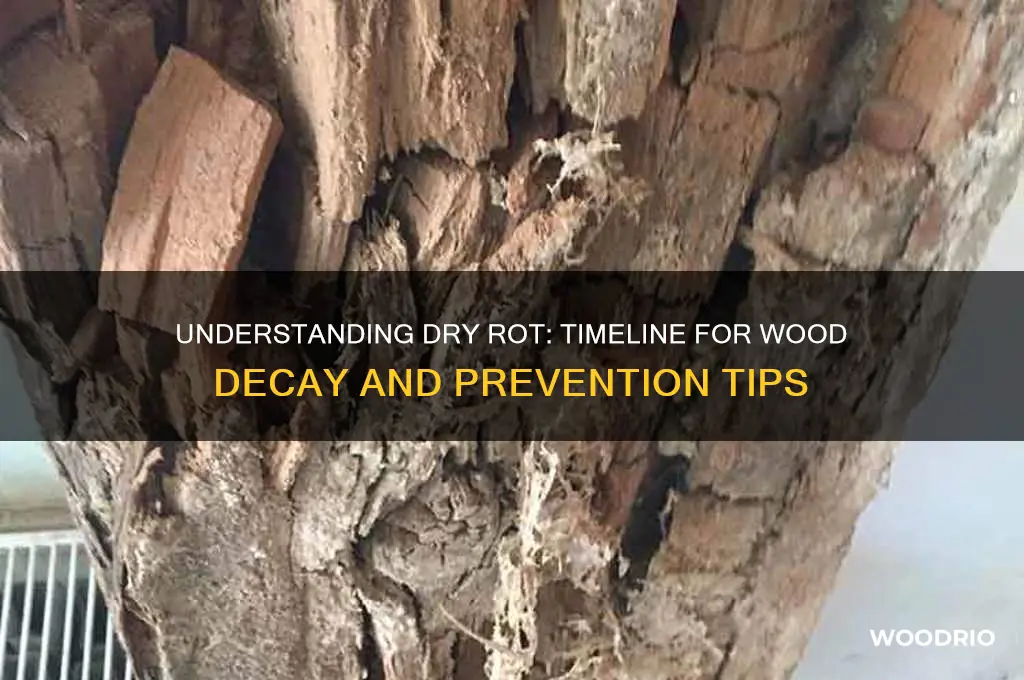

The final stage of dry rot is catastrophic. Wood loses all structural integrity, crumbling at the slightest touch. This advanced decay usually occurs within 1–2 years of initial infestation, though it can happen faster in ideal fungal conditions. The fungus doesn’t stop at the original wood source; it can travel across masonry and other materials via thread-like rhizomorphs, seeking new wood to colonize. By this stage, repair often requires replacing entire sections of timber and addressing the moisture source to prevent recurrence.

To mitigate dry rot’s progression, act at the first sign of moisture issues. Keep wood moisture levels below 20% using dehumidifiers, proper ventilation, and prompt leak repairs. Regularly inspect vulnerable areas like basements, attics, and window frames. If dry rot is suspected, consult a professional for accurate identification and treatment, which may include fungicidal solutions and wood hardening agents. Early intervention can save both time and money, halting the fungus before it renders wood irreparable.

Drying Wood Logs: Understanding the Time Required for Optimal Results

You may want to see also

Explore related products

Factors Speeding Up Decay

Moisture is the primary catalyst for dry rot, a deceptive term since the fungus responsible thrives in damp conditions. Wood with a moisture content exceeding 20% becomes a breeding ground for Serpula lacrymans, the fungus behind dry rot. This organism secretes enzymes that break down cellulose and lignin, the structural components of wood, reducing it to a crumbly, weakened state. The rate of decay accelerates as moisture levels rise; wood consistently exposed to water, such as in leaky roofs or poorly sealed foundations, can show significant deterioration within 6 to 12 months. Even intermittent moisture, like condensation in crawl spaces, can create conditions conducive to dry rot, though the process may take longer—up to 2 years—depending on humidity levels and temperature.

Temperature plays a critical role in the speed of dry rot progression. The fungus flourishes in temperatures between 50°F and 77°F (10°C and 25°C), with optimal growth occurring around 68°F (20°C). In colder climates, dry rot may slow or become dormant, but it does not die. Conversely, in warmer environments, the fungus can spread more rapidly if moisture is present. For instance, a basement with poor ventilation and temperatures consistently above 60°F (15°C) can see dry rot advance at an alarming pace, especially if paired with high humidity. Homeowners in temperate zones should monitor areas like attics, basements, and bathrooms, where temperature and moisture often converge to create ideal conditions for decay.

Poor ventilation exacerbates dry rot by trapping moisture against wood surfaces. Stagnant air prevents evaporation, keeping wood damp for extended periods. This is particularly problematic in enclosed spaces like crawl spaces, where air circulation is minimal. Installing vents or dehumidifiers can reduce humidity levels, slowing the spread of dry rot. For example, a crawl space with a relative humidity above 60% is at high risk; lowering it to 50% can significantly hinder fungal growth. Similarly, ensuring proper airflow in attics and around wooden structures, such as decks or fences, can prevent moisture buildup and delay decay.

The age and condition of wood also influence its susceptibility to dry rot. Older wood, especially if untreated or previously damaged, lacks the structural integrity to resist fungal invasion. Softwoods like pine, commonly used in construction, are particularly vulnerable due to their porous nature. Pressure-treated wood, on the other hand, contains preservatives that deter fungi but are not foolproof, especially if the treatment wears off over time. Regular inspections of wooden structures, particularly those over 10 years old, can identify early signs of decay. Applying wood preservatives or sealants every 3 to 5 years can extend the lifespan of vulnerable wood, especially in high-moisture areas.

Biological factors, such as the presence of insects or other fungi, can compound the effects of dry rot. Termites, for instance, weaken wood by feeding on it, creating entry points for moisture and fungi. Similarly, mold growth, often a precursor to dry rot, softens wood fibers, making them more susceptible to decay. Integrated pest management, including regular inspections and treatments, can mitigate these risks. For example, borate-based insecticides not only repel termites but also act as fungicides, providing dual protection. Addressing these biological threats in tandem with moisture control creates a comprehensive defense against rapid wood decay.

Durability of Wood Carvings: Lifespan, Preservation, and Longevity Tips

You may want to see also

Explore related products

Early Detection Signs

Dry rot, caused by the fungus *Serpula lacrymans*, can compromise the structural integrity of wood in as little as 6 months under ideal conditions—high moisture, warmth, and darkness. However, early detection can prevent extensive damage. The first visible sign is often a white, fluffy mycelium growth resembling cotton wool, typically found in hidden areas like crawl spaces or behind walls. This is the fungus’s reproductive stage, signaling active decay. Ignoring this stage allows the fungus to progress to the next phase: gray-brown strands called rhizomorphs, which resemble roots and transport moisture to sustain the fungus. By this point, wood becomes brittle, cracks easily, and takes on a dark, damp appearance. Catching the mycelium stage is critical, as it’s easier to treat before rhizomorphs form and wood disintegration accelerates.

To identify early dry rot, inspect areas prone to moisture—basements, attics, and window frames—using a sharp tool like an awl or screwdriver. Healthy wood resists penetration, while infected wood feels soft and crumbly, often with a musty odor. Another telltale sign is shrinking or warping wood, as dry rot dehydrates cells while breaking down cellulose. Compare suspect areas to nearby wood; dry rot often spreads in a patchwork pattern, leaving unaffected sections adjacent to severely damaged ones. For homeowners, investing in a moisture meter (available for $20–$50) can help detect elevated moisture levels (above 20%) in wood, a key condition for dry rot growth.

While visual and tactile inspections are effective, advanced tools like thermal imaging cameras can reveal hidden moisture pockets by detecting temperature variations in walls or floors. These devices, though costly ($200–$1,000), are invaluable for comprehensive assessments. For renters or those without access to such tools, focus on indirect signs: peeling paint, blistering wallpaper, or sudden increases in pest activity (termites and beetles are attracted to decaying wood). Early intervention at this stage can limit damage to surface treatments and localized wood replacement, avoiding the expense of structural repairs.

Preventive measures complement detection efforts. Maintain indoor humidity below 50% using dehumidifiers, ensure proper ventilation in damp areas, and promptly fix leaks. Regularly inspect wooden structures after heavy rain or flooding, as dry rot thrives in waterlogged conditions. For at-risk wood, apply fungicidal treatments (e.g., borate-based solutions) as a proactive barrier. While these steps require time and vigilance, they are far less costly than addressing advanced dry rot, which can necessitate replacing entire sections of flooring, framing, or support beams. Early detection isn’t just about saving wood—it’s about preserving safety and avoiding financial strain.

Durability of Charred Wood: Lifespan in Ground Explained

You may want to see also

Explore related products

$38.66

Preventive Measures Overview

Dry rot, caused by the fungus *Serpula lacrymans*, can compromise the structural integrity of wood in as little as 6 months under ideal conditions—high moisture, warmth, and poor ventilation. However, the timeline varies widely based on environmental factors. To prevent dry rot, proactive measures are essential, focusing on moisture control, ventilation, and regular inspections.

Step 1: Eliminate Moisture Sources

Water is the primary catalyst for dry rot. Start by fixing leaks in roofs, pipes, or gutters immediately. Ensure proper drainage around foundations to prevent water accumulation. For wooden structures, maintain a moisture content below 20% using dehumidifiers in damp areas. Apply waterproof sealants to exposed wood, reapplying every 2–3 years for maximum efficacy.

Step 2: Improve Air Circulation

Stagnant air traps moisture, creating a breeding ground for fungi. Install vents in crawl spaces and attics to promote airflow. For enclosed areas, use fans or open windows periodically. When storing firewood or wooden furniture, stack items off the ground and leave gaps between pieces to allow air movement.

Step 3: Conduct Regular Inspections

Early detection can prevent extensive damage. Inspect wooden structures quarterly, focusing on areas prone to moisture, such as basements, bathrooms, and exterior walls. Look for signs like cracked or shrinking wood, fungal growth, or a musty odor. Use a moisture meter to check wood moisture levels; readings above 20% indicate potential risk.

Caution: Avoid Common Mistakes

Painting over damp wood or using untreated lumber in wet environments can accelerate rot. Avoid overcrowding spaces with wooden items, as this restricts airflow. Never ignore minor leaks or cracks, as they can quickly escalate into major issues.

Preventing dry rot is far more cost-effective than repairing damage. By controlling moisture, enhancing ventilation, and staying vigilant, you can protect wooden structures for decades. Remember, dry rot thrives in neglect—consistent care is your best defense.

Perfecting Activated Charcoal: Optimal Wood Cooking Time Explained

You may want to see also

Explore related products

$16.95

Wood Type Vulnerability Differences

The susceptibility of wood to dry rot varies significantly depending on its type, density, and natural resistance. Hardwoods like teak and oak, with their dense cellular structures and natural oils, inherently resist fungal invasion, often delaying dry rot for decades. In contrast, softwoods such as pine and spruce, with larger cell cavities and lower resin content, can succumb to dry rot within 1–5 years under favorable conditions. This disparity underscores the importance of selecting wood types based on environmental exposure and structural demands.

Consider the role of moisture content, a critical factor in dry rot progression. Softwoods, with their higher absorption rates, can retain moisture more readily, creating an ideal breeding ground for fungi. For instance, untreated pine exposed to persistent dampness may show signs of dry rot within 12–18 months, while teak, with its natural water-repellent properties, can endure similar conditions for 10–15 years without significant degradation. To mitigate risk, treat softwoods with fungicidal preservatives or opt for naturally resistant species in high-moisture areas.

Analyzing wood density reveals another layer of vulnerability. Dense woods like mahogany and cedar have compact cell structures that hinder fungal penetration, slowing dry rot progression. Conversely, lightweight woods like balsa or fir, prized for their ease of use, lack this protective density and can deteriorate rapidly. A practical tip: when using less dense wood, apply a moisture barrier and regular inspections to detect early signs of fungal activity, such as cracking or a musty odor.

Environmental factors further amplify wood type differences. In humid climates, even moderately resistant woods like redwood may degrade faster than expected, while in arid regions, the same wood can last for generations. For outdoor applications, pair wood selection with preventive measures: use pressure-treated softwoods or invest in hardwoods with proven durability. Regular maintenance, such as sealing cracks and ensuring proper ventilation, can extend the lifespan of any wood type, regardless of its inherent resistance.

Finally, the age and condition of the wood play a pivotal role in its vulnerability. Older wood, particularly if untreated or previously damaged, is more susceptible to dry rot due to weakened cellular integrity. For example, a 50-year-old pine beam may show advanced dry rot within 2 years of exposure to moisture, while a similarly aged oak beam could remain structurally sound for another decade. When assessing existing structures, prioritize replacing aged softwoods and reinforcing hardwoods with protective coatings to delay fungal encroachment.

Seasoning Elm Wood: Understanding the Time Required for Optimal Results

You may want to see also

Frequently asked questions

Dry rot can begin to affect wood within a few weeks to several months, depending on moisture levels, temperature, and the presence of fungal spores.

High humidity (above 20%), poor ventilation, and temperatures between 50°F and 100°F (10°C and 38°C) accelerate the spread of dry rot.

Yes, dry rot can completely destroy wood, typically within 6 months to 2 years, depending on the severity of conditions and the extent of the infestation.

No, dry rot progresses faster in softwoods like pine compared to hardwoods like oak, as softwoods are more susceptible to fungal decay.

Dry rot can be stopped if the source of moisture is eliminated, the affected area is treated with fungicides, and the wood is replaced or repaired promptly. Without intervention, it will continue to spread.

![Boatlife Git Rot Kit - 4oz [1063]](https://m.media-amazon.com/images/I/51Csyv2VbOL._AC_UL320_.jpg)