The question of how long it takes for wood to undergo various processes—such as drying, seasoning, rotting, or decomposing—depends on several factors, including the type of wood, environmental conditions, and the specific process in question. For instance, air-drying hardwood can take anywhere from several months to a year, while softwoods may dry faster. Seasoning wood for optimal use in construction or furniture typically requires at least six months to two years. On the other hand, wood left exposed to moisture and fungi can begin to rot within a few months to several years, depending on humidity and temperature. Understanding these timelines is crucial for anyone working with wood, whether for construction, craftsmanship, or environmental management.

| Characteristics | Values |

|---|---|

| Dry (Air-Drying) | 6 months to 2 years (depending on wood type and climate) |

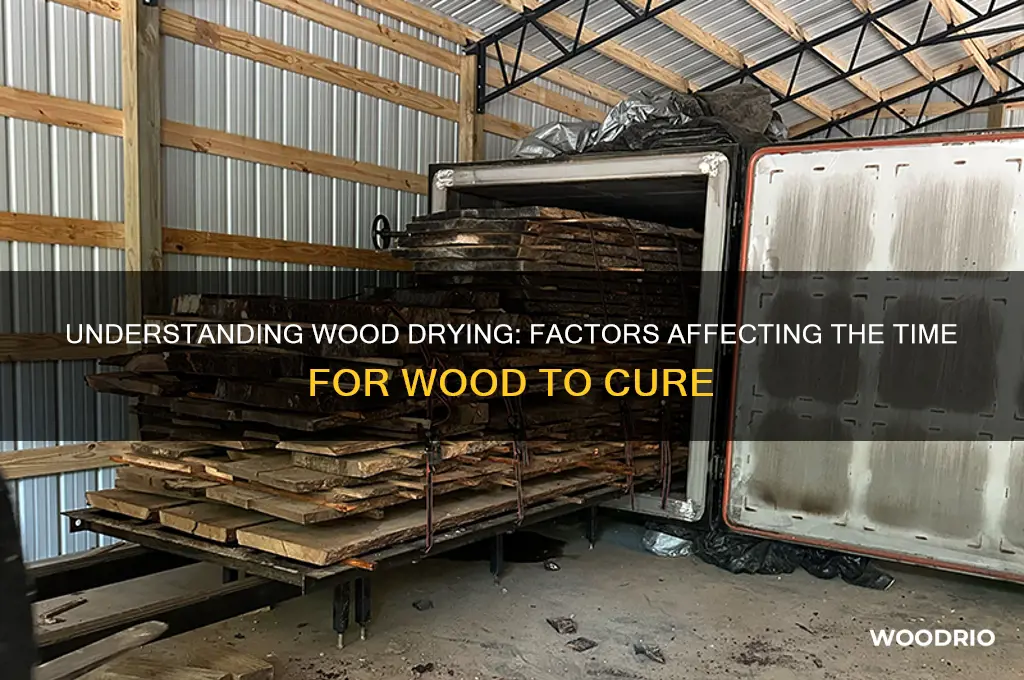

| Season (Kiln-Drying) | 2-6 weeks (controlled environment) |

| Rot (Decay) | 5-10 years (without treatment, varies by moisture and fungi presence) |

| Burn (Combustion) | 15-30 minutes (small pieces) to several hours (large logs) |

| Decompose (Natural Breakdown) | 10-50 years (depends on environment, wood type, and exposure) |

| Cure (for Use in Construction) | 1-2 years (to stabilize moisture content) |

| Weather (Outdoor Exposure) | 2-5 years (before significant degradation without treatment) |

| Settle (Shrink/Expand in Structures) | 6 months to 1 year (stabilizes with environmental conditions) |

| Fossilize (Petrifaction) | Millions of years (requires specific mineral-rich conditions) |

| Float (in Water) | Varies; some woods float indefinitely, others sink within hours |

Explore related products

What You'll Learn

- Season wood properly for optimal use in construction and woodworking projects

- Rot or decay when exposed to moisture and environmental conditions

- Dry completely for safe and efficient burning in fireplaces or stoves

- Cure or harden after being treated with preservatives or chemicals

- Decompose naturally in outdoor environments like forests or compost piles

Season wood properly for optimal use in construction and woodworking projects

Wood seasoning is a critical step in preparing raw timber for construction and woodworking projects, ensuring durability, stability, and ease of use. Freshly cut wood, or "green wood," contains high moisture levels, typically between 30% and 200% of its dry weight, depending on the species. Using unseasoned wood can lead to warping, cracking, or shrinking as it dries, compromising the integrity of your project. Proper seasoning reduces moisture content to 12-15%, the ideal range for most applications, but this process requires time and technique.

Steps for Effective Wood Seasoning:

- Cut and Stack: Cut logs into desired lengths and stack them in a well-ventilated area. Use stickers (small pieces of wood) between layers to promote airflow.

- Cover and Protect: Shield the stack from rain while allowing air circulation. A roof or tarp with open sides works well.

- Air-Dry: For softwoods like pine, air-drying takes 6–12 months; hardwoods like oak may require 1–2 years. Thicker pieces need more time.

- Monitor Moisture: Use a moisture meter to check progress. Aim for 12-15% moisture content before use.

Cautions and Considerations: Avoid stacking wood directly on the ground to prevent rot and insect infestation. In humid climates, consider kiln-drying, which accelerates seasoning to 2–4 weeks but requires specialized equipment. Over-drying wood below 8% moisture can make it brittle, while under-seasoning risks dimensional instability.

Practical Tips for Success: Group wood by species and thickness for consistent drying. In colder months, store wood in a shed or garage to slow the process and prevent freezing. For small projects, purchase kiln-dried lumber, which is ready for immediate use but often more expensive.

Properly seasoned wood not only enhances the longevity of your project but also improves workability, reducing the risk of tools dulling or wood splitting. Patience and attention to detail during seasoning pay dividends in the finished product, whether it’s a sturdy frame or a finely crafted piece of furniture.

Wood Ducks in Captivity: Understanding Their Lifespan and Care

You may want to see also

Explore related products

Rot or decay when exposed to moisture and environmental conditions

Wood, when exposed to moisture and environmental conditions, begins to rot or decay at varying rates depending on several factors. The process is primarily driven by fungi and bacteria that thrive in damp environments, breaking down the wood’s cellular structure. In ideal conditions for these organisms—such as consistent moisture, temperatures between 70°F and 90°F (21°C and 32°C), and poor ventilation—wood can show signs of decay within 6 months to 2 years. However, in less favorable conditions, the timeline extends significantly, sometimes taking decades for noticeable deterioration.

To mitigate rot, consider the wood’s environment. For outdoor structures, ensure proper drainage to prevent water accumulation. Treat wood with preservatives like copper azole or borates, which inhibit fungal growth and insect damage. For example, pressure-treated lumber, infused with chemicals, can last 20–40 years in moist conditions. Alternatively, naturally rot-resistant woods like cedar or redwood offer 15–20 years of durability without treatment. Regular maintenance, such as sealing or staining every 2–3 years, further prolongs lifespan by reducing moisture absorption.

Comparing untreated and treated wood highlights the impact of intervention. Untreated pine, for instance, may rot within 5 years in a damp, shaded area, while the same wood treated with a preservative can withstand similar conditions for over a decade. Similarly, wood in direct contact with soil—a prime breeding ground for fungi—will decay faster than elevated or well-ventilated wood. This underscores the importance of design choices, such as using gravel bases or moisture barriers, to minimize ground contact.

Environmental conditions play a decisive role in decay rates. Coastal areas with high humidity and salt exposure accelerate rot, as do regions with frequent rainfall. In contrast, arid climates slow the process, though UV radiation can still weaken wood over time. For indoor applications, controlling humidity levels below 50% and ensuring adequate airflow can prevent decay entirely. Practical tips include using dehumidifiers in basements or attics and avoiding wood-to-concrete contact, which wicks moisture into the material.

Ultimately, the timeline for wood rot is not fixed but a function of its surroundings and treatment. By understanding the interplay of moisture, temperature, and microbial activity, you can predict and extend wood’s lifespan. Whether through chemical treatments, strategic placement, or environmental controls, proactive measures are key to preserving wood’s integrity in the face of decay.

CCA Treated Wood Durability: Longevity and Factors Affecting Lifespan

You may want to see also

Explore related products

Dry completely for safe and efficient burning in fireplaces or stoves

Wood that’s not fully dried, often called "green wood," contains up to 50% water by weight. Burning it in a fireplace or stove is inefficient and risky. The moisture absorbs heat, reducing the wood’s energy output, and releases creosote—a tar-like substance that clings to chimney walls. Over time, creosote buildup can ignite, causing chimney fires. For safe and efficient burning, wood must reach a moisture content of 20% or less. This isn’t just a recommendation; it’s a necessity for both performance and safety.

Achieving this level of dryness takes time—typically 6 months to 2 years, depending on the wood type and drying conditions. Hardwoods like oak or maple take longer to dry than softwoods like pine due to their denser structure. Proper stacking and storage accelerate the process. Wood should be split into logs no thicker than 4 inches, allowing air to circulate, and stored off the ground on a raised platform or in a well-ventilated shed. Cover the stack with a tarp, leaving the sides open to prevent moisture buildup while protecting from rain.

Seasoning wood isn’t just about waiting; it’s about monitoring. A moisture meter, available for $20–$50, is a practical tool to test readiness. Insert it into the wood’s end grain for an accurate reading. If the meter shows 20% or less, the wood is ready. Without a meter, look for visual cues: cracks in the ends, lighter weight, and a dull grayish color. However, these signs are less reliable than a direct measurement, especially for beginners.

Burning properly seasoned wood offers tangible benefits. It produces more heat per log, reducing the amount needed and saving costs. It also burns cleaner, with less smoke and fewer emissions, contributing to better indoor and outdoor air quality. For wood stove owners, this means less frequent chimney cleanings and reduced risk of fire. Fireplace users will notice fewer sparks and a more consistent flame. The effort invested in drying wood pays off in both safety and efficiency.

For those in a hurry, kiln-dried wood is a viable alternative, though pricier. Kiln drying reduces moisture content to 20% in days or weeks, not months. It’s ideal for immediate use or when seasoning time is limited. However, sourcing locally seasoned wood remains the most cost-effective and environmentally friendly option. Whether seasoning your own or purchasing, ensuring wood is fully dried is non-negotiable for anyone relying on wood heat.

Durability of Faux Wood Blinds: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Cure or harden after being treated with preservatives or chemicals

Treating wood with preservatives or chemicals is a common practice to enhance its durability and resistance to decay, insects, and moisture. However, the process doesn’t end with application—the wood must cure or harden to ensure the treatment is fully effective. This curing time varies depending on the type of preservative, environmental conditions, and the wood species. For instance, water-based preservatives like copper azole (CA-B) or alkaline copper quaternary (ACQ) typically require 2 to 7 days to cure under optimal conditions (temperatures between 60°F and 90°F with moderate humidity). Oil-based treatments, such as creosote or pentachlorophenol, may take longer, often 7 to 14 days, due to their slower absorption and drying rates. Always refer to the manufacturer’s guidelines for specific curing times, as these can differ based on product formulation.

Environmental factors play a critical role in the curing process. High humidity or cold temperatures can significantly extend curing times, as moisture evaporation slows down. For example, wood treated in a damp, cool environment (below 50°F) may take twice as long to cure compared to wood treated in a warm, dry setting. To expedite curing, ensure proper ventilation and, if possible, store treated wood in a temperature-controlled area. Avoid stacking treated wood too tightly, as this can trap moisture and hinder the drying process. If time is a constraint, consider using fans or dehumidifiers to create an optimal curing environment.

The wood species also influences curing time. Dense hardwoods like oak or maple absorb preservatives more slowly than softwoods like pine or cedar, resulting in longer curing periods. For example, pressure-treated pine might cure within 3 to 5 days, while oak could require up to 10 days. Additionally, the thickness of the wood matters—thicker pieces will take longer to cure as the preservative needs more time to penetrate and dry completely. Always allow extra time for larger or denser wood projects to ensure thorough curing.

Practical tips can make the curing process smoother. First, apply preservatives evenly and follow recommended dosage rates—overapplication can lead to prolonged curing times and surface residue. For pressure-treated wood, allow it to dry naturally without forcing the process with excessive heat, as this can cause uneven curing. Second, plan projects around weather conditions, avoiding treatment during rainy or excessively humid periods. Finally, test the wood’s readiness by pressing a gloved finger onto the surface—if no residue transfers, it’s likely cured. Proper curing not only maximizes the preservative’s effectiveness but also ensures the wood is safe for use in its intended application.

Morning Wood and Penis Size: Separating Fact from Fiction

You may want to see also

Explore related products

Decompose naturally in outdoor environments like forests or compost piles

Wood decomposition in outdoor environments is a natural process influenced by factors like wood type, climate, and microbial activity. Hardwoods such as oak or hickory can take 10 to 50 years to fully decompose, while softer woods like pine or cedar break down in 5 to 15 years. This variation is due to the density and lignin content of the wood, with denser woods resisting decay longer. In forests, fallen trees become habitats for fungi, insects, and bacteria, which gradually break down the cellulose and lignin, returning nutrients to the soil.

To accelerate wood decomposition in a compost pile, follow these steps: shred or chip the wood into smaller pieces to increase surface area, mix it with nitrogen-rich materials like grass clippings or food scraps, and maintain moisture levels similar to a wrung-out sponge. Avoid using treated or painted wood, as chemicals can leach into the soil. Turning the pile every few weeks introduces oxygen, which boosts microbial activity. Under optimal conditions, wood in a compost pile can decompose in 6 months to 2 years, depending on the size of the pieces and the balance of carbon and nitrogen.

For those seeking to decompose wood in a forest setting, patience is key. Leave the wood undisturbed to allow natural processes to take over. In humid, warm climates, decomposition occurs faster due to higher microbial activity, while dry or cold environments slow the process. Adding a layer of soil or leaves over the wood can retain moisture and attract decomposers. This hands-off approach not only mimics nature but also supports biodiversity by providing habitat for organisms during the decay process.

Comparing forest and compost pile decomposition highlights the trade-off between speed and ecological impact. Compost piles offer faster results but require active management, while forest decomposition is slower but more sustainable and beneficial to the ecosystem. For gardeners, composting wood chips creates nutrient-rich soil amendments, whereas in forests, decomposing wood fosters long-term soil health and carbon sequestration. Both methods serve distinct purposes, depending on your goals and resources.

Finally, consider the environmental benefits of allowing wood to decompose naturally. Unlike burning or landfilling, natural decomposition avoids releasing carbon dioxide or methane into the atmosphere. It also enriches soil structure and fertility, supporting plant growth. Whether in a forest or compost pile, this process turns waste into a resource, demonstrating how small actions can contribute to a healthier planet. By understanding and facilitating wood decomposition, you participate in a cycle that sustains ecosystems for generations.

Pine Wood Seasoning Time: How Long Does It Take?

You may want to see also

Frequently asked questions

It typically takes 6 to 12 months for wood to season properly, depending on the type of wood, moisture content, and environmental conditions.

Wood decomposition can take anywhere from 10 to 50 years or more, depending on factors like wood type, climate, and exposure to elements.

Air-drying wood can take 1 to 3 years, while kiln-drying reduces this time to 2 to 4 weeks, depending on thickness and wood species.

Wood buried in the ground can rot in 5 to 10 years, but this varies based on moisture levels, soil type, and wood density.

The time for wood to burn completely depends on its size and moisture content, ranging from a few minutes for small pieces to several hours for large logs.