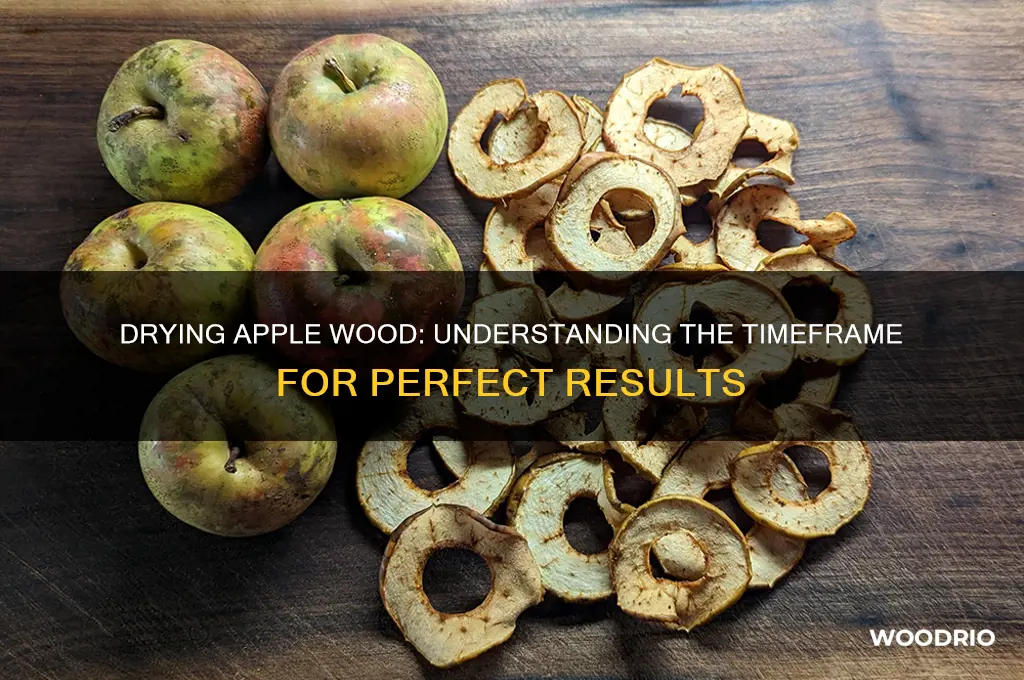

Drying apple wood is a crucial process for enhancing its usability in various applications, such as smoking meats, crafting, or firewood. The time it takes to dry apple wood depends on several factors, including the moisture content of the wood, the drying method used, and environmental conditions like humidity and temperature. Typically, air-drying apple wood can take anywhere from 6 months to 2 years, while kiln-drying significantly reduces this time to a few days or weeks. Properly dried apple wood is essential for achieving optimal results, whether for flavor infusion in cooking or ensuring durability in woodworking projects. Understanding the drying process and its variables is key to effectively preparing apple wood for its intended use.

| Characteristics | Values |

|---|---|

| Drying Time (Air Drying) | 6 months to 2 years |

| Drying Time (Kiln Drying) | 2-4 weeks |

| Moisture Content (Fresh Cut) | 30-50% |

| Moisture Content (Air Dried) | 15-20% |

| Moisture Content (Kiln Dried) | 8-12% |

| Ideal Moisture Content for Use | 10-15% |

| Factors Affecting Drying Time | Humidity, temperature, airflow, thickness of wood |

| Recommended Drying Method | Air drying for natural seasoning, kiln drying for faster results |

| Uses of Dried Apple Wood | Smoking meats, woodworking, crafting |

| Density (Dry) | Approximately 45 pounds per cubic foot (720 kg/m³) |

| Color (Dry) | Light to medium brown with a reddish hue |

| Grain Pattern | Fine and uniform |

| Workability | Easy to work with hand and machine tools |

| Durability | Moderately durable, susceptible to decay if not properly dried |

| Aroma When Burned | Sweet, fruity fragrance |

Explore related products

What You'll Learn

- Factors Affecting Drying Time: Moisture content, humidity, temperature, airflow, and wood thickness impact drying duration

- Seasoning Methods: Air drying vs. kiln drying and their respective timeframes for apple wood

- Ideal Conditions: Optimal temperature (60-90°F) and humidity (50-70%) for efficient drying

- Time Estimates: Air drying takes 6-12 months, while kiln drying speeds up to 2-4 weeks

- Testing Dryness: Check moisture content (below 20%) using a wood moisture meter for readiness

Factors Affecting Drying Time: Moisture content, humidity, temperature, airflow, and wood thickness impact drying duration

The initial moisture content of apple wood is a critical determinant of drying time. Freshly cut apple wood can contain up to 50% moisture, while air-dried wood typically stabilizes around 12-15%. To expedite drying, start by seasoning the wood outdoors for 6-12 months, allowing rain and sun to naturally reduce moisture. For faster results, kiln-drying can reduce moisture to 8-10% in 2-4 weeks, but this method requires specialized equipment. Always measure moisture content with a wood moisture meter, aiming for 20% or less before use in smoking or crafting.

Humidity levels in the drying environment directly oppose the wood’s moisture release. In regions with 60% or higher humidity, drying time can double compared to drier climates. To counteract this, store wood in a well-ventilated shed or garage with a dehumidifier running at 50% relative humidity. If outdoor drying, stack wood on pallets with spacers to elevate it from damp ground, and cover with a breathable tarp to shield from rain while allowing airflow. For indoor drying, maintain consistent airflow with fans or open windows to prevent moisture stagnation.

Temperature accelerates evaporation, making it a key factor in drying speed. Apple wood dries optimally between 70°F and 90°F (21°C–32°C). Below 50°F (10°C), drying slows significantly, while temperatures above 100°F (38°C) can cause cracking. For controlled drying, use a kiln set to 120°F (49°C) with gradual temperature increases over 2-3 weeks. Alternatively, place wood in a sunny, sheltered area during summer months, ensuring it’s not exposed to direct sunlight for prolonged periods to avoid uneven drying. Monitor temperature with a thermometer to maintain ideal conditions.

Airflow is the unsung hero of efficient wood drying, as stagnant air traps moisture. Stack wood in a crisscross pattern, leaving 1-2 inches between pieces to allow air circulation. For larger logs, cut them into 4-6 inch thicknesses to reduce drying time by up to 50%. If using a kiln, ensure fans are positioned to create cross-ventilation. Outdoors, orient stacks perpendicular to prevailing winds to maximize exposure. Poor airflow not only slows drying but also increases the risk of mold or rot, so prioritize this factor regardless of drying method.

Wood thickness dictates drying time exponentially—a 2-inch thick piece dries in 6-12 months, while a 6-inch log may take 2-3 years. To streamline the process, split logs into quarters or eighths before drying. For crafting or smoking, prioritize thinner cuts (1-2 inches) to ensure even moisture loss. If working with thicker pieces, periodically flip and rotate them to prevent warping. Remember, thicker wood retains moisture longer, so plan projects accordingly and always test moisture levels before use to avoid shrinkage or cracking in finished products.

Cherry Wood Aging: How Long Until It Reaches Its Darkest Hue?

You may want to see also

Explore related products

Seasoning Methods: Air drying vs. kiln drying and their respective timeframes for apple wood

Apple wood, prized for its sweet aroma and robust flavor in smoking meats, requires proper seasoning to unlock its full potential. The drying process, crucial for reducing moisture content and preventing mold, hinges on two primary methods: air drying and kiln drying. Each method offers distinct advantages and timeframes, catering to different needs and resources.

Air Drying: A Patient Approach

Imagine stacking freshly cut apple wood logs in a well-ventilated, shaded area, allowing nature to take its course. This traditional method, air drying, relies on ambient air circulation to gradually extract moisture. Time is the key ingredient here, with seasoning typically taking 1 to 3 years, depending on factors like wood thickness, humidity levels, and airflow. Thinner branches might dry within a year, while larger logs could require the full three-year timeframe.

Kiln Drying: Accelerated Precision

For those seeking faster results, kiln drying emerges as a controlled alternative. This method involves placing the wood in a specialized chamber where temperature and humidity are meticulously regulated. The accelerated drying process significantly reduces the timeframe, with apple wood reaching optimal moisture levels in 2 to 6 weeks. This method is particularly advantageous for commercial operations or individuals needing seasoned wood quickly.

Comparing the Trade-offs

While kiln drying boasts speed, air drying holds its own in terms of cost-effectiveness and accessibility. Air drying requires minimal equipment and energy, making it a budget-friendly option for hobbyists and small-scale woodworkers. However, it demands patience and suitable outdoor space. Kiln drying, on the other hand, necessitates specialized equipment and energy consumption, translating to higher costs.

Choosing the Right Method

The choice between air drying and kiln drying ultimately depends on individual needs and circumstances. For those prioritizing time efficiency and consistent results, kiln drying is the clear winner. However, for those seeking a more traditional, cost-effective approach and willing to wait, air drying remains a viable and rewarding option. Regardless of the method chosen, proper seasoning is paramount to unlocking the full flavor potential of apple wood.

Bailey's Elle Woods Journey: Duration and Impact on Legally Blonde

You may want to see also

Explore related products

Ideal Conditions: Optimal temperature (60-90°F) and humidity (50-70%) for efficient drying

Drying apple wood efficiently hinges on maintaining precise environmental conditions. Temperatures between 60°F and 90°F (15°C to 32°C) strike the ideal balance, fostering moisture evaporation without causing cracks or warping. This range accelerates drying while preserving the wood’s structural integrity, a critical factor for woodworking or smoking applications. Humidity levels of 50% to 70% complement this process, ensuring the wood releases moisture gradually. Deviating from these parameters risks either prolonged drying times or compromised wood quality, underscoring the importance of control.

Achieving these conditions often requires strategic intervention. For instance, stacking wood in a well-ventilated shed with a thermometer and hygrometer allows for real-time monitoring. If humidity exceeds 70%, a dehumidifier can restore balance, while temperatures below 60°F may necessitate a space heater or insulating the drying area. Conversely, in warmer climates, shading the wood or using evaporative cooling can prevent overheating. These adjustments ensure the wood dries uniformly, typically within 6 to 12 months, depending on thickness and initial moisture content.

Comparatively, uncontrolled drying environments yield inconsistent results. Wood dried in excessively hot or humid conditions often develops checks or splits, rendering it unsuitable for precision crafts. Conversely, low humidity and high heat can cause rapid, uneven drying, leading to brittle wood. By contrast, the 60-90°F temperature and 50-70% humidity range mimics natural seasoning processes, promoting stability and durability. This method is particularly advantageous for apple wood, prized for its density and aromatic qualities in smoking meats or crafting.

Practical implementation involves more than just setting the right conditions. Proper stacking techniques, such as spacing logs 1-2 inches apart to allow air circulation, amplify efficiency. Additionally, rotating stacks periodically ensures even exposure to air. For those drying smaller pieces, like kindling or chips, mesh racks can expedite the process by maximizing surface area. Pairing these techniques with optimal temperature and humidity control not only shortens drying time but also enhances the wood’s final quality, making it a worthwhile investment for enthusiasts and professionals alike.

Durability of Wood Prints: Longevity and Care Tips Revealed

You may want to see also

Explore related products

Time Estimates: Air drying takes 6-12 months, while kiln drying speeds up to 2-4 weeks

Drying apple wood is a process that demands patience, but the method you choose significantly impacts the timeline. Air drying, the traditional approach, requires 6 to 12 months, depending on factors like humidity, temperature, and wood thickness. This method allows the wood to naturally shed moisture, preserving its structural integrity and flavor profile, making it ideal for smoking meats or crafting furniture. However, it’s a commitment—plan ahead if you’re relying on this technique.

For those seeking efficiency, kiln drying offers a dramatic reduction in time, completing the process in just 2 to 4 weeks. Kilns use controlled heat and airflow to accelerate moisture evaporation, ensuring uniformity and reliability. While this method is faster, it requires specialized equipment and careful monitoring to avoid overheating or cracking the wood. It’s a trade-off: speed versus the need for resources and precision.

Comparing the two, air drying is hands-off but time-intensive, while kiln drying is resource-intensive but quick. If you’re a hobbyist with no immediate deadline, air drying aligns with a more organic, cost-effective approach. Professionals or those with time constraints may find kiln drying indispensable, despite the initial investment.

Practical tip: For air drying, stack wood in a well-ventilated, shaded area, ensuring each piece is spaced to allow airflow. For kiln drying, maintain temperatures between 120°F and 160°F, gradually increasing over the drying period. Always monitor moisture levels—aim for 10-15% moisture content for optimal results. Choose your method based on your timeline, resources, and desired outcome.

Termite Damage Timeline: How Quickly Can They Destroy Wood?

You may want to see also

Explore related products

Testing Dryness: Check moisture content (below 20%) using a wood moisture meter for readiness

Drying apple wood is a process that demands patience, but knowing when it’s truly ready for use is a science. A wood moisture meter becomes your most reliable tool here, ensuring the wood’s moisture content falls below 20%—the threshold for safe, efficient burning or crafting. Without this check, you risk using wood that’s still too wet, leading to inefficient combustion, warping, or even mold growth.

To test dryness, follow these steps: first, select a wood moisture meter with a range suitable for hardwoods, as apple wood typically falls into this category. Insert the meter’s probes into the wood at multiple points, focusing on the thickest sections where moisture lingers longest. Aim for readings consistently below 20%, as this indicates the wood has reached equilibrium with its environment. If readings vary widely, allow more drying time and retest.

Comparing methods, a moisture meter offers precision that visual or tactile checks cannot. While cracked ends or a lighter weight might suggest dryness, these signs are subjective and unreliable. A meter provides concrete data, eliminating guesswork. For example, wood with 25% moisture content will burn poorly, producing more smoke and less heat, whereas wood at 18% burns cleanly and efficiently.

Practical tips: store wood in a well-ventilated area during drying to expedite moisture loss. Stack pieces off the ground with spacers to allow airflow. If using a kiln, monitor temperature and humidity closely to avoid over-drying, which can make wood brittle. For natural air-drying, expect 6–12 months, depending on climate and wood thickness. Always test moisture content before use, as environmental conditions can prolong drying time unpredictably.

In conclusion, testing dryness with a wood moisture meter is not just a step—it’s the definitive measure of readiness. By ensuring moisture levels are below 20%, you safeguard the wood’s quality and functionality, whether for firewood, smoking, or woodworking. Invest in a reliable meter and use it consistently to transform waiting time into confidence in your results.

Exploring the Length of Night in the Woods: A Detailed Guide

You may want to see also

Frequently asked questions

Air drying apple wood typically takes 6 to 12 months, depending on factors like humidity, temperature, and the thickness of the wood pieces.

Yes, apple wood can be kiln-dried, which reduces the drying time to 2 to 4 weeks, depending on the kiln settings and moisture content.

Freshly cut apple wood (green wood) is not ideal for immediate use due to high moisture content. It requires at least 6 months of drying for better combustion and flavor when used for smoking or firewood.