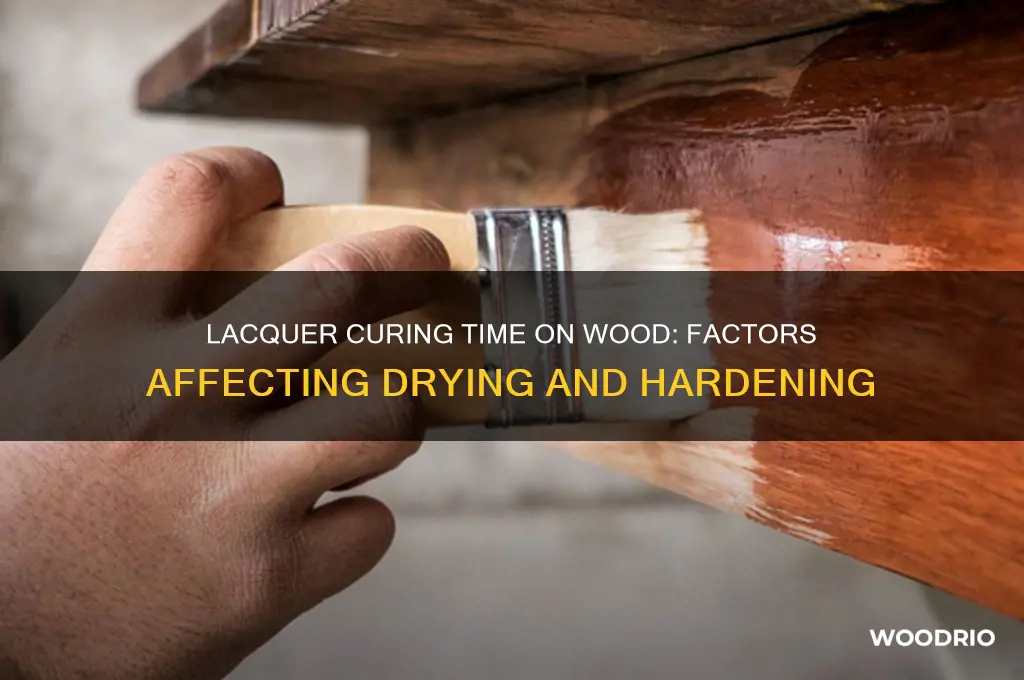

Lacquer curing time on wood is a crucial aspect of the finishing process, as it directly impacts the durability and appearance of the final product. The duration required for lacquer to cure can vary significantly depending on several factors, including the type of lacquer used, environmental conditions such as temperature and humidity, and the thickness of the applied coat. Generally, most lacquers will dry to the touch within 30 minutes to an hour, but achieving a full cure—where the finish is hard, durable, and resistant to damage—can take anywhere from 24 hours to several days. Understanding these variables is essential for achieving a high-quality finish and ensuring the longevity of the wood piece.

| Characteristics | Values |

|---|---|

| Cure Time (Touch Dry) | 30 minutes to 2 hours (depending on humidity, temperature, and thickness) |

| Recoat Time | 1 to 2 hours (light sanding may be required between coats) |

| Hard Dry (Handleable) | 2 to 4 hours |

| Full Cure (Maximum Hardness) | 7 to 14 days (varies based on environmental conditions and lacquer type) |

| Optimal Curing Conditions | 70°F (21°C) and 50% humidity |

| Factors Affecting Cure Time | Temperature, humidity, lacquer thickness, and ventilation |

| Accelerating Cure Time | Warm, dry, and well-ventilated environment |

| Slowing Cure Time | Cold, humid, or poorly ventilated conditions |

| Lacquer Type Influence | Nitrocellulose lacquers cure faster than acrylic or catalyzed lacquers |

Explore related products

What You'll Learn

- Factors Affecting Cure Time: Humidity, temperature, lacquer type, and wood porosity influence drying duration

- Average Cure Times: Lacquer typically dries to touch in 30 minutes, fully cures in 24-48 hours

- Accelerating Cure Time: Use heat, low-humidity environments, or specialized additives to speed up drying

- Multiple Coat Application: Allow 2-4 hours between coats for proper adhesion and curing

- Testing for Full Cure: Ensure hardness, no tackiness, and chemical resistance before use

Factors Affecting Cure Time: Humidity, temperature, lacquer type, and wood porosity influence drying duration

Lacquer cure times on wood are not set in stone; they’re a delicate dance of environmental conditions and material properties. Humidity, for instance, plays a pivotal role. High humidity slows evaporation, trapping solvents in the lacquer and extending cure time. In environments above 70% relative humidity, expect drying to take up to 50% longer than in drier conditions. Conversely, low humidity (below 40%) can cause the lacquer to dry too quickly, leading to a brittle finish. Ideal humidity for lacquer application hovers between 50% and 60%, striking a balance between speed and durability.

Temperature acts as the accelerator in this chemical reaction. At 70°F (21°C), most lacquers cure within 24 hours, but drop the temperature to 50°F (10°C), and curing can stretch to 48 hours or more. Heat, however, isn’t always beneficial. Temperatures above 90°F (32°C) can cause the lacquer to dry too rapidly, resulting in a rough, uneven surface. For optimal results, maintain a workspace temperature between 65°F and 75°F (18°C to 24°C), ensuring a smooth, even cure.

Not all lacquers are created equal. Nitrocellulose lacquers, for example, dry in as little as 30 minutes but fully cure within 24 hours. Acrylic lacquers, on the other hand, may take up to 72 hours to fully cure due to their higher solids content. Catalyzed lacquers, which require a hardener, can cure in 8–12 hours but demand precise mixing ratios—typically 10:1 lacquer to catalyst—to avoid incomplete curing or surface defects. Always consult the manufacturer’s guidelines for specific cure times and application instructions.

Wood porosity is the unsung hero of lacquer curing. Dense woods like maple or cherry absorb less lacquer, allowing for faster surface drying but potentially slower curing beneath. Porous woods like pine or oak soak up more lacquer, extending both drying and curing times. To mitigate this, apply a seal coat—a thin, diluted layer of lacquer—to fill the wood’s pores before applying full coats. This reduces absorption, evens out the finish, and can shave hours off the total cure time.

Understanding these factors allows for precise control over lacquer curing. For instance, in a humid, cool environment, using a fast-drying nitrocellulose lacquer on a dense wood like walnut could yield a cured finish in under 24 hours. Conversely, applying a catalyzed lacquer to porous oak in high humidity and low temperatures might require a full 72 hours. By manipulating humidity, temperature, lacquer type, and wood preparation, craftsmen can tailor the curing process to meet project deadlines without compromising quality.

Wood Oil Drying Time: Factors Affecting Cure and Finish Duration

You may want to see also

Explore related products

Average Cure Times: Lacquer typically dries to touch in 30 minutes, fully cures in 24-48 hours

Lacquer's cure time is a critical factor in woodworking, influencing project timelines and finish quality. The average cure times—30 minutes to dry to the touch and 24 to 48 hours for full curing—are benchmarks that balance efficiency and durability. These intervals allow woodworkers to handle pieces sooner while ensuring the finish hardens sufficiently to withstand wear and tear. Understanding this timeline helps in planning subsequent steps, such as sanding or applying additional coats, without compromising the integrity of the finish.

From an analytical perspective, the 30-minute touch-dry time is a result of lacquer's fast-evaporating solvents, which quickly transition from liquid to solid state. This rapid initial drying is advantageous for projects requiring quick turnaround times, such as furniture repairs or high-volume production. However, the 24 to 48-hour full cure period is where the finish achieves its maximum hardness and chemical resistance. During this phase, the lacquer undergoes polymerization, a process where molecules cross-link to form a robust, protective layer. Skipping this waiting period can lead to soft finishes prone to scratches or chemical damage.

For practical application, woodworkers should consider environmental factors that affect cure times. Humidity, temperature, and airflow play significant roles in how quickly lacquer dries and cures. In high-humidity conditions, cure times may extend beyond 48 hours, while warmer temperatures and adequate ventilation can expedite the process. For instance, maintaining a workspace temperature of 70–75°F (21–24°C) and using fans to circulate air can optimize curing without compromising finish quality. Applying thin, even coats also ensures consistent drying and reduces the risk of sags or drips.

Comparatively, lacquer’s cure times are faster than those of oil-based polyurethanes, which can take up to 72 hours to fully cure, but slower than conversion varnishes, which may cure in as little as 12 hours under ideal conditions. This positions lacquer as a versatile middle-ground option, offering quicker handling times than traditional finishes while still providing a durable, high-gloss surface. For projects requiring both speed and resilience, lacquer’s cure times make it a preferred choice, especially when paired with proper application techniques.

Finally, a descriptive approach highlights the transformation lacquer undergoes during curing. Initially, the finish appears wet and reflective, gradually losing its sheen as solvents evaporate. By the 30-minute mark, the surface feels dry to the touch but remains soft and susceptible to marring. Over the next 24 to 48 hours, the lacquer hardens into a smooth, glass-like coating that enhances the wood’s natural beauty while providing protection. This evolution underscores the importance of patience and precision in achieving a flawless finish, making lacquer’s cure times a critical aspect of the woodworking craft.

Drying Wood Logs: Understanding the Time Required for Optimal Results

You may want to see also

Explore related products

Accelerating Cure Time: Use heat, low-humidity environments, or specialized additives to speed up drying

Lacquer cure times on wood can stretch from hours to days, depending on conditions. But what if you need that piece finished faster? Accelerating cure time is achievable through strategic manipulation of heat, humidity, and chemistry. Here's how to harness these factors for quicker results.

Heat: The Catalyst for Faster Curing

Applying heat is a direct and effective method to expedite lacquer curing. The chemical reactions responsible for hardening lacquer are accelerated by higher temperatures. A common approach is to use a heat lamp or place the lacquered wood in a warm environment, such as an oven set to a low temperature (around 100-120°F or 38-49°C). This method can reduce curing time significantly, often by half or more. However, caution is necessary; excessive heat can cause bubbling or discoloration. Always monitor the process closely, especially when using an oven, to avoid damaging the wood or the finish.

Low-Humidity Environments: Aiding Evaporation

Humidity plays a critical role in the curing process, particularly for water-based lacquers. High humidity slows down evaporation, prolonging the drying time. To counteract this, create a low-humidity environment by using a dehumidifier or working in a well-ventilated, air-conditioned space. For optimal results, aim for a humidity level below 50%. This simple adjustment can make a noticeable difference, especially in humid climates. Additionally, ensuring proper ventilation not only speeds up curing but also improves the overall quality of the finish by preventing dust and debris from settling on the wet surface.

Specialized Additives: Chemical Assistance

For those seeking a more hands-off approach, specialized additives can be a game-changer. These products, often referred as accelerators or catalysts, are mixed into the lacquer before application. They work by enhancing the chemical reactions that occur during curing, thereby reducing the overall time required. Common additives include isocyanates and certain types of solvents. When using these, follow the manufacturer’s instructions carefully, as improper dosage can lead to uneven curing or other defects. Typically, a ratio of 1-2% additive to lacquer is recommended, but this can vary based on the product and desired results.

Practical Tips for Success

To maximize the effectiveness of these methods, combine them strategically. For instance, apply heat after the initial tack-free stage to avoid bubbling, and maintain low humidity throughout the process. Always test your approach on a small, inconspicuous area first to ensure compatibility with your specific wood and lacquer. Additionally, consider the environmental impact; excessive heat or chemical additives may not be suitable for all settings. By understanding and controlling these variables, you can significantly reduce lacquer cure times, making your woodworking projects more efficient and timely.

Durability of Wooden Baseball Bats: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Multiple Coat Application: Allow 2-4 hours between coats for proper adhesion and curing

Lacquer application is a delicate balance of patience and precision, especially when multiple coats are involved. The 2-4 hour window between coats isn’t arbitrary—it’s rooted in the chemistry of curing. Lacquer dries in two stages: first, solvents evaporate, leaving a tacky surface; then, the remaining resins harden through oxidation or polymerization. Rushing this process risks poor adhesion, as the underlying layer won’t fully cure, leading to peeling or bubbling. Conversely, waiting too long can cause incompatibility between coats, as the first layer becomes too hard to bond effectively. This timing ensures each coat fuses seamlessly, creating a uniform, durable finish.

From a practical standpoint, the 2-4 hour rule varies slightly depending on environmental conditions. Humidity, temperature, and airflow significantly influence drying times. In a warm, dry environment with good ventilation, two hours may suffice, while cooler, more humid conditions demand closer to four. For example, applying lacquer in a 70°F (21°C) room with a fan circulating air can expedite the process, but in a damp basement, extending the wait time is crucial. Always test a small area to gauge drying speed before committing to a full application. This adaptability ensures consistency across projects, regardless of setting.

A common mistake is assuming that surface dryness equals readiness for the next coat. Lacquer may feel dry to the touch within 30 minutes, but this is merely the evaporation of solvents. The underlying resins require additional time to cure sufficiently for another layer. To test readiness, lightly press a finger against the surface—if no imprint remains, it’s safe to proceed. This tactile check is more reliable than visual inspection, as lacquer’s glossy appearance can be deceiving. Ignoring this step often results in a cloudy or uneven finish, undermining the effort invested in the project.

For optimal results, maintain a consistent application technique across coats. Use the same brush or sprayer, and apply even, thin layers to avoid drips or buildup. Overloading the wood with lacquer not only prolongs curing but also increases the risk of defects. Each coat should enhance the previous one, building toward a smooth, protective finish. Patience in this process isn’t just a virtue—it’s a necessity. By respecting the 2-4 hour interval, craftsmen ensure a professional-grade outcome that stands the test of time.

Mastering Smoking: Optimal Soaking Time for Wood Chunks Revealed

You may want to see also

Explore related products

Testing for Full Cure: Ensure hardness, no tackiness, and chemical resistance before use

Lacquer curing times vary widely, influenced by factors like humidity, temperature, and product type. However, knowing when it’s fully cured is critical to avoid damage or failure. Testing for full cure involves three key checks: hardness, tackiness, and chemical resistance. Each test ensures the lacquer has reached its maximum durability and is ready for use.

Hardness is the first indicator of a fully cured lacquer. Press your fingernail gently into the surface. If it leaves no indentation, the lacquer has hardened sufficiently. For a more precise test, use a coin to scratch the surface lightly. If the scratch is minimal or non-existent, the lacquer has cured. This method is simple yet effective, providing immediate feedback on the lacquer’s structural integrity. Avoid testing in areas that will remain visible, as even minor scratches can detract from the finish.

Tackiness, or stickiness, is a sign of incomplete curing. Run your finger across the surface after 24 hours of drying. If it feels smooth and non-sticky, the lacquer is likely cured. For a more thorough test, place a piece of tape on the surface, press firmly, and remove it quickly. If no residue sticks to the tape, the lacquer is fully cured. This test is particularly important in humid environments, where curing times can be prolonged. Ensure the area is well-ventilated during testing to avoid introducing contaminants.

Chemical resistance is the final test for full cure. After confirming hardness and absence of tackiness, expose a small area to common household chemicals like water, alcohol, or vinegar. Apply a few drops, let them sit for 10–15 minutes, then wipe them away. If the lacquer shows no signs of swelling, discoloration, or softening, it has achieved chemical resistance. This step is crucial for surfaces like tabletops or countertops that will encounter spills. Always test in an inconspicuous area to avoid damaging the finish.

In summary, testing for full cure requires a systematic approach: check hardness with a scratch test, ensure no tackiness with a tape or touch test, and verify chemical resistance with a controlled exposure. These steps guarantee the lacquer is ready for daily use, protecting your wood surface for years to come. Patience and thoroughness in testing will save time and effort in the long run, ensuring a flawless and durable finish.

Understanding FF Wood Biscuit Sizes and Their Standard Lengths

You may want to see also

Frequently asked questions

Lacquer generally takes 24 to 48 hours to cure on wood under normal conditions (70°F/21°C and 50% humidity). However, full curing can take up to 7 days for maximum hardness and durability.

Yes, temperature significantly affects curing time. Higher temperatures (75°F/24°C or above) can speed up curing, while lower temperatures slow it down. Avoid applying lacquer in cold or humid conditions, as it may extend curing time or cause imperfections.

Yes, you can accelerate curing by increasing ventilation, using a fan to circulate air, or applying heat (e.g., a heat lamp). However, avoid excessive heat, as it can cause bubbling or uneven drying.

Lacquer is fully cured when it feels hard to the touch, has no tackiness, and does not indent under light pressure. Additionally, the surface will have a consistent, glossy finish without any soft spots. Testing a small area is recommended before subjecting the wood to heavy use.

![12.25 Oz Clear Wood Finish Satin [Set of 6]](https://m.media-amazon.com/images/I/71A10edQXrL._AC_UL320_.jpg)