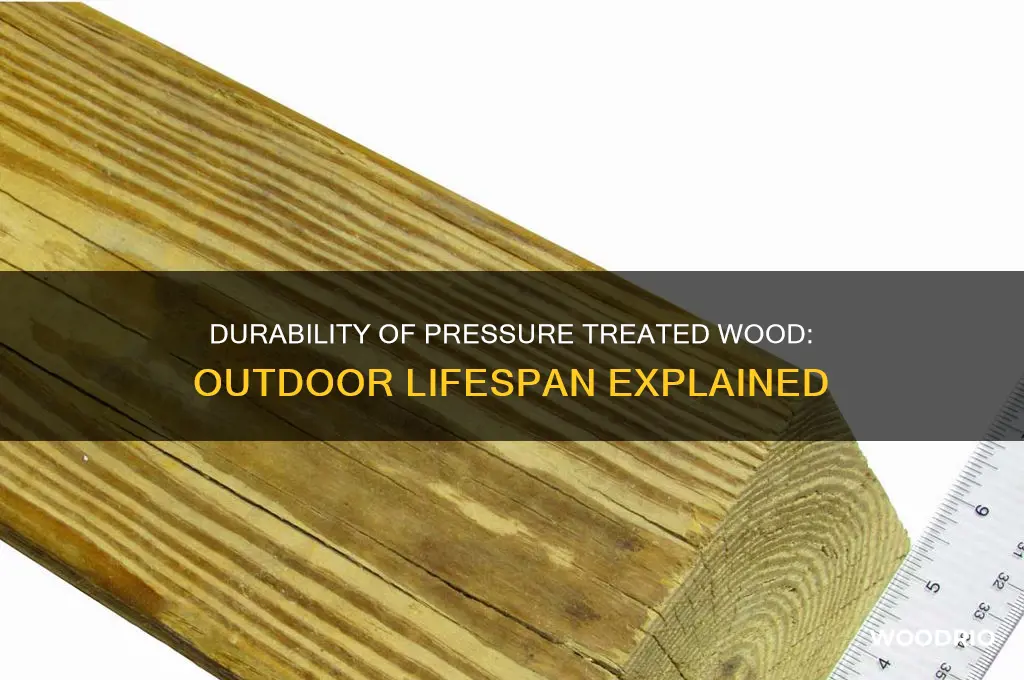

Pressure-treated wood is a popular choice for outdoor construction projects due to its enhanced durability and resistance to rot, decay, and insect damage. The lifespan of pressure-treated wood outside can vary significantly depending on factors such as the type of treatment, environmental conditions, and maintenance practices. On average, properly installed and maintained pressure-treated wood can last anywhere from 15 to 40 years or more. Ground-contact treated wood, which is designed to withstand direct soil contact, typically lasts longer than above-ground treated wood. Exposure to moisture, sunlight, and extreme weather can accelerate deterioration, making regular sealing or staining essential to extend its life. Understanding these factors helps homeowners and builders make informed decisions to maximize the longevity of their outdoor structures.

| Characteristics | Values |

|---|---|

| Average Lifespan | 20-40 years (varies based on environmental conditions and maintenance) |

| Type of Treatment | Alkaline Copper Quaternary (ACQ), Copper Azole (CA-B), or Micronized Copper (MCQ) |

| Resistance to Rot | High resistance to fungal decay and rot |

| Resistance to Insects | Highly resistant to termites and other wood-boring insects |

| Maintenance Required | Periodic sealing or staining every 2-3 years to extend lifespan |

| Exposure to Moisture | Vulnerable to premature decay if constantly exposed to moisture |

| Ground Contact | Specially treated for ground contact lasts 25-40 years; above-ground lasts 10-20 years |

| UV Resistance | Prone to fading and surface degradation without protective coating |

| Environmental Factors | Lifespan reduces in humid, wet, or coastal environments |

| Cost-Effectiveness | More expensive upfront but longer-lasting compared to untreated wood |

| Sustainability | Treated with eco-friendly chemicals (e.g., ACQ, CA-B) in modern treatments |

| Safety Precautions | Requires proper handling during cutting and installation due to chemicals |

| Applications | Decks, fences, outdoor structures, and landscaping projects |

Explore related products

What You'll Learn

Factors affecting durability of pressure treated wood

Pressure-treated wood is a popular choice for outdoor projects due to its enhanced resistance to rot, decay, and insect damage. However, its lifespan can vary significantly based on several key factors. Understanding these factors allows you to maximize the durability of your investment.

Moisture Exposure: The arch-nemesis of any wood, moisture accelerates deterioration. Constant exposure to rain, snow, or high humidity creates an ideal environment for fungi and bacteria to thrive, breaking down the wood fibers. Projects in direct contact with soil, like fence posts, are particularly vulnerable. Consider using gravel or concrete bases to elevate wood and promote drainage. For decks, ensure proper spacing between boards for airflow and consider a waterproof sealant.

Sunlight and Temperature Fluctuations: UV rays from sunlight break down the lignin in wood, causing it as to become brittle and discolored. Extreme temperature swings, common in many climates, cause the wood to expand and contract, leading to cracks and warping. Choose pressure-treated wood rated for ground contact if your project will be exposed to harsh weather. Applying a UV-resistant stain or sealant every few years can significantly extend its life.

Type of Treatment and Retention Level: Not all pressure-treated wood is created equal. The type of preservative used and its retention level (how much chemical is absorbed) directly impact durability. Common preservatives include ACQ (alkaline copper quat), CA-B (copper azole), and MCA (micronized copper azole). ACQ is a good all-around choice, while CA-B offers superior resistance to fungal decay. Retention levels are typically categorized as Above Ground, Ground Contact, or Freshwater. For maximum longevity, choose Ground Contact or Freshwater rated wood for any project in contact with soil or water.

Wood Species: The inherent properties of the wood species used also play a role. Naturally rot-resistant species like cedar or redwood offer additional protection even before treatment. However, they are generally more expensive. Pine, a common choice for pressure-treated wood, is less naturally resistant but becomes highly durable with proper treatment.

Maintenance and Care: Regular maintenance is crucial for maximizing the lifespan of pressure-treated wood. Inspect your project annually for signs of damage, such as cracks, splinters, or discoloration. Clean the surface regularly to remove dirt, debris, and mildew. Reapply a suitable sealant or stain every 2-3 years, or as recommended by the manufacturer, to maintain protection against moisture and UV rays. By understanding these factors and taking proactive measures, you can ensure your pressure-treated wood projects withstand the elements and provide years of enjoyment.

How Long Does a Rick of Wood Last? A Comprehensive Guide

You may want to see also

Explore related products

Average lifespan in different climates

Pressure-treated wood's longevity outdoors hinges significantly on the climate it endures. In arid regions with minimal rainfall and low humidity, such as deserts, the wood can last upwards of 40 years. The absence of moisture reduces the risk of rot and fungal decay, primary culprits in wood deterioration. However, intense UV exposure in these areas can cause surface graying and brittleness over time. Applying a UV-protective sealant every 2–3 years can mitigate this, extending the wood’s aesthetic and structural integrity.

Contrastingly, humid climates, like those in tropical or coastal areas, pose a greater challenge. High moisture levels accelerate fungal growth and insect infestation, reducing the lifespan to 15–25 years. Proximity to saltwater exacerbates this, as salt can corrode the wood’s preservative chemicals. To combat this, ensure proper drainage around the wood and consider using stainless steel fasteners to prevent corrosion. Annual inspections for signs of decay or termite activity are crucial in these environments.

In temperate climates with moderate rainfall and seasonal temperature fluctuations, pressure-treated wood typically lasts 20–30 years. The cyclical wetting and drying can stress the wood, but the absence of extreme conditions allows it to perform well with minimal maintenance. A water-repellent stain applied every 3–4 years can enhance durability by reducing moisture absorption and protecting against mold.

Cold climates with freezing temperatures and snow present unique challenges. Freeze-thaw cycles can cause cracking, while snow accumulation traps moisture against the wood. Despite these risks, pressure-treated wood can still last 25–35 years in such areas. Elevating wooden structures off the ground and using gravel bases for drainage can prevent prolonged moisture contact. Additionally, avoiding the use of de-icing salts, which can leach preservatives, is essential for longevity.

Ultimately, understanding your climate’s specific demands allows for tailored maintenance strategies. While pressure-treated wood is inherently durable, its lifespan is not set in stone. By addressing climate-specific risks—whether through sealants, drainage, or inspections—you can maximize its outdoor performance and ensure it withstands the test of time.

How Long Does a Half Cord of Wood Typically Last?

You may want to see also

Explore related products

Maintenance tips to extend longevity

Pressure-treated wood can last 20 to 40 years outdoors, but its lifespan hinges on proactive maintenance. Left unchecked, moisture intrusion, UV damage, and environmental wear accelerate decay. By implementing targeted care strategies, you can maximize durability and delay replacement.

Sealants: The First Line of Defense

Apply a high-quality wood sealant within 6 months of installation, reapplying every 2–3 years. Choose a product with UV inhibitors and water repellents to combat sun fading and moisture absorption. For horizontal surfaces like decks, opt for thicker, more resilient coatings to withstand foot traffic. Vertical structures, such as fences, benefit from lighter, penetrating sealers that preserve wood grain. Always clean the surface with a mild detergent and allow it to dry completely before application.

Inspection and Repair: Catch Issues Early

Inspect your wood structures annually for cracks, splinters, or warping. Pay close attention to areas where water pools, such as joints and low-lying boards. Replace damaged boards promptly to prevent rot from spreading. For minor cracks, use epoxy wood fillers to restore structural integrity. Tighten loose hardware and ensure proper drainage around the structure to minimize water retention.

Cleaning: Preventing Mold and Mildew

Dirt and organic debris create a breeding ground for mold and mildew, which degrade wood fibers. Clean surfaces twice a year using a solution of oxygen bleach (1 cup per gallon of water) and a stiff brush. Avoid pressure washers, as they can force water into the wood grain, causing splitting. For stubborn stains, apply a commercial wood cleaner following manufacturer instructions. Rinse thoroughly and allow the wood to dry before resealing.

Environmental Considerations: Adapt to Your Climate

In humid climates, prioritize moisture management by ensuring adequate ventilation and installing gutters to divert rainwater. In arid regions, focus on UV protection with tinted sealants and shade structures. For snowy areas, avoid using rock salt for de-icing, as it can corrode fasteners and leach into the wood. Instead, opt for sand or calcium chloride, which are less damaging.

By combining these maintenance practices, you can significantly extend the life of pressure-treated wood, ensuring it remains functional and aesthetically pleasing for decades. Consistency is key—small, regular efforts yield far greater results than sporadic interventions.

How Long Does a Cord of Wood Last: Burning Time Explained

You may want to see also

Explore related products

Comparison with untreated wood lifespan

Pressure-treated wood typically lasts 20 to 40 years outdoors, a lifespan significantly longer than untreated wood, which often deteriorates within 5 to 10 years under similar conditions. This stark difference stems from the chemical preservatives infused into pressure-treated wood, which resist rot, insects, and fungal decay. Untreated wood, lacking these protections, succumbs quickly to moisture, pests, and environmental stressors, making it unsuitable for long-term outdoor applications like decking, fencing, or structural supports.

Consider the practical implications for a homeowner deciding between the two. While untreated wood may cost less upfront, its short lifespan necessitates frequent replacements, repairs, or maintenance. For instance, an untreated wooden fence might require replacement every 5 to 7 years, whereas a pressure-treated counterpart could endure for decades with minimal upkeep. This makes pressure-treated wood a more cost-effective choice over time, despite its higher initial investment.

However, the comparison isn’t solely about durability. Untreated wood, often sourced from sustainable forests, appeals to environmentally conscious consumers. Pressure-treated wood, on the other hand, contains chemicals like alkaline copper quaternary (ACQ) or chromated copper arsenate (CCA), which raise concerns about leaching into soil or water. For projects like raised garden beds or playground structures, untreated wood paired with regular sealing might be preferable, despite its shorter lifespan, to avoid chemical exposure.

Another factor is aesthetics. Untreated wood, particularly hardwoods like cedar or redwood, offers natural beauty and resistance to decay without chemicals. While not as durable as pressure-treated wood, these species can last 15 to 20 years outdoors with proper care, bridging the gap between untreated softwoods and treated lumber. For visible projects like pergolas or outdoor furniture, this trade-off between appearance and longevity becomes critical.

In summary, the choice between pressure-treated and untreated wood hinges on balancing durability, cost, environmental impact, and aesthetics. Pressure-treated wood excels in longevity but carries chemical concerns, while untreated wood offers natural appeal and sustainability at the expense of frequent maintenance or replacement. Assess your project’s specific needs—whether it’s a hidden structural element or a visible centerpiece—to make an informed decision.

Durability of Wood: Factors Affecting Longevity and Preservation Techniques

You may want to see also

Explore related products

Signs of decay and replacement needs

Pressure-treated wood, while designed to resist rot and insect damage, isn’t invincible. Over time, exposure to the elements takes its toll, and knowing when it’s nearing the end of its lifespan is crucial for safety and aesthetics. The first sign of decay is often surface cracking or splintering, particularly along edges or high-traffic areas. These fissures may seem minor, but they’re early warnings that the wood’s integrity is compromised. Inspect structures like decks or fences annually, running your hand along surfaces to detect rough patches or raised grains. If splinters are frequent, it’s a red flag.

Another telltale sign is warping or bowing, which occurs as moisture penetrates the wood and causes uneven expansion or contraction. This is especially common in horizontal surfaces like decking boards or garden borders. Measure the flatness of boards with a straightedge; if gaps exceed ¼ inch or boards no longer align, the wood is likely failing. Warping isn’t just unsightly—it creates tripping hazards and weakens structural connections. For load-bearing elements, such as posts or joists, warping demands immediate replacement.

Discoloration and fungal growth are more than cosmetic issues. Dark streaks, green patches, or white fuzz indicate mold, mildew, or rot. While pressure-treated wood resists fungal decay better than untreated wood, it’s not immune. Use a screwdriver to probe suspicious areas; if the tool sinks in easily or the wood feels spongy, the internal structure is compromised. Fungicides can treat surface mold, but deep rot requires replacement. Regularly clean surfaces with a bleach solution (1 cup bleach per gallon of water) to prevent fungal colonization.

Finally, fastener failure is a critical indicator of wood decay. Nails or screws that pop out, rust excessively, or no longer hold tight suggest the wood around them has deteriorated. Check connections at joints, where moisture often pools. If fasteners can be pulled out by hand or wiggle loose, the surrounding wood has lost density. Replace these sections promptly, as compromised joints can lead to structural collapse. For preventative maintenance, use stainless steel or hot-dipped galvanized fasteners, which resist corrosion longer than standard hardware.

Knowing these signs allows you to address issues before they escalate. While pressure-treated wood can last 20–40 years, its lifespan varies based on climate, usage, and maintenance. Proactive inspections and timely replacements ensure longevity and safety, turning potential hazards into manageable tasks.

Wood Rot Timeline: Factors Affecting Decay and Prevention Tips

You may want to see also

Frequently asked questions

Pressure treated wood typically lasts 20 to 40 years outdoors, depending on factors like climate, exposure to moisture, and maintenance.

Yes, the lifespan can vary; for example, decking may last 15 to 25 years due to higher foot traffic and moisture exposure, while fencing can last 20 to 30 years with proper care.

Yes, applying a sealant or stain every 2 to 3 years can protect the wood from UV rays, moisture, and rot, potentially extending its lifespan by 5 to 10 years.