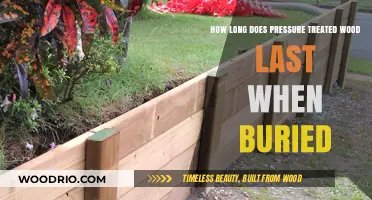

Pressure-treated (PT) wood is a popular choice for outdoor construction projects due to its enhanced durability and resistance to rot, decay, and insect damage. One of the most common questions homeowners and builders have is, How long does PT wood last? The lifespan of pressure-treated wood can vary significantly depending on factors such as the type of treatment, environmental conditions, and maintenance practices. Generally, properly installed and maintained PT wood can last anywhere from 20 to 40 years or more, with some applications even exceeding this range. However, exposure to harsh weather, moisture, and soil contact can shorten its lifespan, making proper installation and regular upkeep essential for maximizing its longevity.

| Characteristics | Values |

|---|---|

| Average Lifespan | 15-20 years (above ground), 40+ years (below ground) |

| Factors Affecting Durability | Moisture exposure, soil contact, climate, maintenance |

| Above Ground Use | Decks, fences, railings, playground equipment |

| Below Ground Use | Posts, poles, retaining walls |

| Maintenance Requirements | Regular cleaning, staining/sealing every 2-3 years |

| Resistance to | Rot, decay, insect damage |

| Environmental Impact | Contains chemicals (typically copper azole or ACQ), may leach over time |

| Cost Compared to Alternatives | Generally more affordable than naturally rot-resistant woods like cedar or redwood |

| Latest Treatment Standards | AWPA (American Wood Protection Association) standards ensure consistent quality |

| Sustainability | Often made from renewable pine, but chemical treatment raises concerns |

Explore related products

What You'll Learn

Factors Affecting PT Wood Lifespan

Pressure-treated (PT) wood is a popular choice for outdoor projects due to its resistance to rot, decay, and insect damage. However, its lifespan can vary significantly based on several key factors. Understanding these factors allows you to maximize the longevity of your PT wood structures.

Environmental Exposure: The single biggest threat to PT wood is moisture. Constant exposure to rain, snow, and humidity accelerates the breakdown of the wood fibers and the protective chemicals within. Areas with high rainfall or proximity to bodies of water will see PT wood degrade faster. For example, a deck in a rainy coastal region will likely require more frequent maintenance and have a shorter lifespan than one in a dry, arid climate.

Ground Contact: PT wood is rated for different levels of ground contact. Wood designated for "above ground" use has less preservative treatment and is suitable for structures like fences or railings. "Ground contact" rated wood has a higher chemical concentration and is necessary for posts, beams, or any wood that will be in direct contact with soil. Using the wrong type of PT wood for the application will drastically shorten its lifespan. Maintenance and Sealing: While PT wood is treated, it's not impervious. Regular maintenance is crucial. Applying a water-repellent sealer every 1-2 years helps protect the wood from moisture penetration and UV damage. Neglecting this step can lead to cracking, warping, and premature deterioration. Think of it like sunscreen for your deck – it prevents sun damage and extends its life. Quality of Installation: Proper installation techniques are vital. Ensuring adequate drainage around PT wood structures prevents water pooling, a major cause of rot. Using corrosion-resistant fasteners like stainless steel or hot-dipped galvanized nails prevents rust stains and wood splitting. Improper installation can create weak points that accelerate decay.

By carefully considering these factors – environmental conditions, ground contact rating, maintenance practices, and installation quality – you can significantly influence the lifespan of your PT wood projects. While PT wood offers excellent durability, it's not maintenance-free. With proper care, you can expect PT wood to last 20 years or more, making it a sound investment for outdoor structures.

Best Wood Long Handle Manual Lawn Edger: Perfect for Precise Garden Edges

You may want to see also

Explore related products

Average Lifespan of PT Wood

Pressure-treated (PT) wood is a popular choice for outdoor projects due to its enhanced durability against rot, decay, and insect damage. However, its lifespan varies significantly based on factors like environmental exposure, maintenance, and the specific type of treatment used. On average, PT wood can last anywhere from 15 to 40 years, with most applications falling in the 20 to 30-year range. This wide variance underscores the importance of understanding the conditions in which the wood will be used and taking proactive steps to maximize its longevity.

One critical factor influencing the lifespan of PT wood is its exposure to moisture. Ground contact, for instance, drastically reduces its lifespan compared to above-ground use. PT wood rated for ground contact is treated with higher levels of preservatives, typically 0.40 pounds per cubic foot (PCF) of chemical retention, compared to 0.25 PCF for above-ground applications. Even with this treatment, ground-contact PT wood averages 20 to 25 years, while above-ground PT wood can last 30 to 40 years. Regular sealing or staining every 1 to 3 years can add several years to its life by minimizing water absorption and UV damage.

Another determinant of PT wood’s lifespan is the quality of installation and ongoing maintenance. Poor drainage, direct soil contact, and inadequate ventilation accelerate deterioration. For example, using PT wood for deck joists without proper spacing or in areas prone to standing water can halve its expected lifespan. Conversely, incorporating features like gravel bases, moisture barriers, and periodic inspections can extend its usability. A well-maintained PT wood deck, for instance, can outlast a poorly cared-for one by a decade or more.

Comparatively, PT wood’s lifespan stacks up favorably against untreated alternatives like cedar or redwood, which typically last 10 to 20 years in similar conditions. However, it falls short of composite materials, which can endure 50 years or more. The trade-off lies in cost and aesthetics: PT wood is more affordable and retains a natural wood look, while composites require a higher upfront investment. For budget-conscious homeowners prioritizing longevity within a moderate timeframe, PT wood remains a practical choice when paired with diligent care.

To maximize the lifespan of PT wood, follow these actionable steps: avoid direct soil contact by using concrete or plastic foundations, apply a waterproof sealant annually, and ensure proper ventilation to prevent moisture buildup. Additionally, inspect for cracks, splinters, or signs of insect activity biannually, addressing issues promptly. By combining the right treatment type with strategic maintenance, PT wood can reliably serve its intended purpose for decades, making it a versatile and cost-effective option for outdoor construction.

Thoreau's Walden Pond Retreat: Uncovering His Time in the Woods

You may want to see also

Explore related products

Maintenance Tips for Durability

Pressure-treated (PT) wood is designed to resist rot, decay, and insect damage, but its lifespan—typically 20 to 40 years—hinges heavily on maintenance. Without proper care, even treated wood can deteriorate prematurely, especially in harsh climates or high-moisture environments. The key to maximizing durability lies in proactive measures that address common stressors like water exposure, UV damage, and surface wear.

Sealants and Stains: The First Line of Defense

Applying a high-quality sealant or stain every 2–3 years is critical. These products act as a barrier against moisture infiltration and UV rays, which can cause wood fibers to break down over time. For best results, clean the wood surface thoroughly before application, removing dirt, mildew, or old finishes. Water-repellent sealers are ideal for maintaining the wood’s natural appearance, while semi-transparent stains add color while allowing grain to show. Avoid using paint, as it can peel and require more frequent maintenance.

Moisture Management: Preventing the Unseen Enemy

Water is PT wood’s greatest adversary, accelerating rot and warping even in treated lumber. Ensure proper drainage around structures like decks or fences by grading soil away from the wood and installing gutters or downspouts. For ground-contact applications, use gravel or plastic barriers beneath the wood to minimize soil-to-wood contact. Regularly inspect for standing water or pooling, especially in joints and crevices, and address these issues promptly.

Structural Inspections: Catching Problems Early

Annual inspections can identify issues before they compromise the wood’s integrity. Check for cracks, splinters, or signs of insect activity, particularly in hidden areas like post bases or underside joints. Replace damaged boards immediately to prevent further deterioration. Tighten hardware as needed, as loose connections can cause unnecessary stress on the wood. For decks, ensure all railings and stairs remain secure and compliant with safety standards.

Cleaning Protocols: Beyond Surface-Level Care

Dirt, mildew, and algae not only detract from appearance but can also degrade wood surfaces over time. Clean PT wood annually with a mild detergent and water solution, using a stiff brush for stubborn stains. For mildew or algae, a mixture of oxygen bleach and water (1 cup bleach per gallon of water) is effective without harming the wood. Pressure washing is acceptable but use a fan tip nozzle and maintain a distance of 8–12 inches to avoid damaging the wood fibers.

Environmental Considerations: Tailoring Maintenance to Context

The longevity of PT wood varies based on its environment. In coastal areas, saltwater exposure requires more frequent cleaning and sealing to counteract corrosion. In snowy regions, avoid using metal shovels or sharp tools that can gouge the surface during snow removal. For high-traffic areas like decks, consider adding rugs or mats to reduce wear, but ensure they allow airflow to prevent moisture trapping.

By implementing these targeted maintenance practices, PT wood can withstand decades of use, delivering both functionality and aesthetic appeal. Consistency is key—small, regular efforts yield far greater returns than sporadic interventions. With the right care, PT wood remains a reliable, cost-effective choice for outdoor projects.

Redwood Growth Timeline: Understanding the Slow Journey of Giants

You may want to see also

Explore related products

Comparing PT Wood to Alternatives

Pressure-treated (PT) wood is a popular choice for outdoor projects due to its resistance to rot, decay, and insect damage. However, its lifespan—typically 15 to 40 years—depends on factors like climate, maintenance, and application. When comparing PT wood to alternatives like cedar, redwood, composite decking, and tropical hardwoods, durability, cost, and environmental impact emerge as key differentiators. Each material offers unique advantages, making the choice dependent on specific project needs and priorities.

Cedar and Redwood: Natural Beauty with Moderate Durability

Cedar and redwood are prized for their natural resistance to decay and insects, offering a lifespan of 15 to 30 years without chemical treatment. Unlike PT wood, they lack added preservatives, making them a safer option for gardens and playgrounds. However, their cost is significantly higher—often double that of PT wood. For example, while PT wood decking averages $3 to $5 per square foot, cedar can range from $6 to $8. Maintenance is also more intensive; annual sealing or staining is required to maintain their rich color and extend longevity. If you prioritize aesthetics and are willing to invest time and money, cedar or redwood may outperform PT wood in visual appeal, though not necessarily in lifespan.

Composite Decking: Low Maintenance but Higher Upfront Cost

Composite decking, made from wood fibers and recycled plastic, boasts a lifespan of 25 to 50 years, surpassing PT wood in durability. It’s resistant to warping, splintering, and fading, requiring minimal upkeep beyond occasional cleaning. However, the upfront cost is steep—$8 to $14 per square foot—making it a long-term investment. While PT wood may be more budget-friendly initially, composite’s longevity and low maintenance can offset its higher price over time. For instance, a 300-square-foot deck in PT wood might cost $900 to $1,500, whereas composite could range from $2,400 to $4,200. If reducing maintenance is a priority, composite is a strong contender despite its initial expense.

Tropical Hardwoods: Exceptional Durability at a Premium

Tropical hardwoods like ipe and teak offer unparalleled durability, lasting 40 to 75 years with minimal maintenance. Their natural oils resist rot, insects, and weathering, making them ideal for high-moisture environments. However, their cost is prohibitive—$10 to $20 per square foot—and their environmental impact is a concern due to deforestation. PT wood, while less durable, is more sustainable when sourced responsibly. For projects requiring maximum longevity, tropical hardwoods excel, but their ethical and financial implications must be weighed carefully.

Environmental and Practical Considerations

PT wood’s chemical treatment raises environmental and health concerns, particularly during disposal or if it comes into contact with soil or water. Alternatives like cedar, redwood, and composite decking offer greener options, though composite’s plastic content isn’t biodegradable. For those prioritizing sustainability, cedar or redwood sourced from certified forests is a better choice. Practically, PT wood’s versatility and affordability make it suitable for structural applications like fence posts, where appearance is less critical. In contrast, composite or hardwoods are better for high-visibility areas like decks or pergolas.

In summary, while PT wood offers a balance of cost and durability, alternatives like cedar, composite, and tropical hardwoods provide specialized benefits. The choice hinges on budget, maintenance tolerance, and environmental values. By evaluating these factors, you can select the material that best aligns with your project’s long-term goals.

Unabomber's Wilderness Life: How Long Did He Survive in the Woods?

You may want to see also

Explore related products

Signs of PT Wood Deterioration

Pressure-treated (PT) wood is designed to resist decay, insects, and moisture, but it’s not invincible. Over time, even PT wood shows signs of wear, signaling its protective properties are fading. Recognizing these signs early can save you from costly repairs or replacements. Here’s what to look for:

- Surface Cracks and Splinters: One of the first visible signs of PT wood deterioration is the appearance of cracks or splinters on the surface. This occurs as the wood dries out and loses its natural oils, a process accelerated by sun exposure and fluctuating weather conditions. While small cracks may seem cosmetic, they compromise the wood’s structural integrity, allowing moisture to penetrate deeper. Inspect decks, fences, or posts annually, especially after harsh seasons. If cracks exceed 1/8 inch in width, consider sanding or applying a protective sealant to slow further damage.

- Warping or Cupping: PT wood is prone to warping or cupping as its moisture content fluctuates. This distortion happens when one side of the wood absorbs or releases moisture faster than the other, causing it to bend or twist. Warping is particularly common in deck boards exposed to direct sunlight and rain. To prevent this, ensure proper spacing between boards for airflow and apply a water-repellent finish every 2–3 years. If warping is severe, replacement may be necessary, as it poses a safety hazard and indicates advanced deterioration.

- Fungal Growth or Discoloration: Despite its treatment, PT wood can still develop mold, mildew, or fungal growth, especially in damp, shaded areas. Black, green, or white patches on the surface are telltale signs. While not always structural concerns, fungi can weaken the wood over time and indicate moisture infiltration. Clean affected areas with a mixture of bleach and water (1:3 ratio) and a stiff brush. For prevention, trim nearby vegetation to improve sunlight exposure and airflow, reducing humidity around the wood.

- Pest Infestation: PT wood is treated to resist termites and other wood-boring insects, but this protection diminishes over 10–15 years. Look for small holes, sawdust-like frass, or hollow-sounding wood, which suggest pests have infiltrated. Regularly inspect areas close to soil, as these are most vulnerable. If infestation is detected, consult a pest control professional. To extend protection, reapply insecticidal treatments or consider replacing older PT wood with newer, more resistant options.

- Fastener Corrosion and Loosening: The condition of screws, nails, or bolts in PT wood can also indicate deterioration. Corroded or rusted fasteners not only compromise structural stability but also suggest the wood’s moisture barrier has failed. Modern PT wood uses corrosion-resistant fasteners, but older installations may use galvanized or untreated metal. Check for rust stains or loose connections, especially in high-traffic areas like decks. Replace corroded fasteners promptly and consider using stainless steel or coated alternatives for longevity.

By monitoring these signs, you can extend the lifespan of PT wood, typically 20–40 years, depending on maintenance and environmental factors. Early intervention is key—addressing minor issues prevents them from escalating into major structural failures. Regular inspections, proper cleaning, and timely treatments ensure PT wood remains a durable, cost-effective choice for outdoor projects.

Cedar Wood Fence Lifespan: Durability, Maintenance, and Longevity Explained

You may want to see also

Frequently asked questions

PT (pressure-treated) wood typically lasts 15 to 20 years or more, depending on factors like exposure to moisture, weather conditions, and maintenance.

A: Yes, painting or sealing PT wood can extend its lifespan by protecting it from moisture, UV rays, and pests, potentially adding 5 to 10 years to its durability.

A: While PT wood is treated for durability, naturally rot-resistant woods like cedar or redwood can last 20 to 30 years or more, depending on conditions, making them longer-lasting in some cases.