Shellac, a natural resin derived from the lac bug, has been used for centuries as a protective and decorative finish on wood. Its durability and aesthetic appeal make it a popular choice for furniture, cabinetry, and other wooden surfaces. However, the longevity of shellac on wood depends on several factors, including the application technique, the environment in which the wood is placed, and the level of wear and tear it endures. Generally, a well-applied shellac finish can last anywhere from 5 to 10 years, though it may require periodic maintenance, such as reapplication or touch-ups, to maintain its luster and protective qualities. Understanding these variables is essential for anyone looking to preserve the beauty and integrity of their wooden items with a shellac finish.

| Characteristics | Values |

|---|---|

| Durability on Wood | 1-3 years (depending on exposure to moisture, heat, and wear) |

| Resistance to Moisture | Moderate; not suitable for high-moisture areas like kitchens or baths |

| Heat Resistance | Low; can soften or melt under high temperatures |

| Scratch Resistance | Low to moderate; less durable than polyurethane or varnish |

| UV Resistance | Poor; can yellow or degrade with prolonged sun exposure |

| Application Ease | Easy; quick-drying and can be reapplied without stripping |

| Finish Appearance | Natural, glossy, or satin finish depending on application |

| Maintenance Required | Regular reapplication needed for high-traffic or exposed surfaces |

| Environmental Impact | Natural and non-toxic, but alcohol-based versions have solvent fumes |

| Compatibility with Wood Types | Suitable for most wood types, enhances natural grain |

| Drying Time | 30 minutes to 1 hour between coats |

| Cost | Relatively inexpensive compared to other wood finishes |

Explore related products

What You'll Learn

Shellac durability on different wood types

Shellac's longevity on wood isn't a one-size-fits-all scenario. The type of wood plays a significant role in how well shellac adheres and how long it lasts. Hardwoods like maple, oak, and cherry, with their dense grain structure, provide an ideal surface for shellac to bond to. This results in a more durable finish that can withstand wear and tear for several years, often exceeding five years with proper care. Softer woods, such as pine or cedar, present a different challenge. Their porous nature can lead to uneven absorption of shellac, potentially resulting in a less durable finish that may require more frequent reapplication, typically every 2-3 years.

Application Technique Matters

The application method significantly impacts shellac's durability. For optimal results on all wood types, thin coats are key. Aim for 3-4 thin coats, allowing each layer to dry completely before applying the next. This builds a stronger, more resilient finish. Sanding lightly between coats with a fine-grit sandpaper (220-grit or higher) ensures a smooth surface and promotes better adhesion.

Wiping on shellac with a clean cloth or using a foam brush tends to yield better results than spraying, especially on softer woods where overspray can settle in pores and create an uneven finish.

Environmental Factors: The Silent Adversary

While wood type and application are crucial, environmental factors can't be overlooked. Shellac is susceptible to damage from sunlight, heat, and moisture. Direct sunlight can cause fading and discoloration over time, while heat can accelerate drying and potentially lead to cracking. Moisture is particularly detrimental, as shellac is not waterproof. In areas prone to spills or high humidity, consider using a sealant over the shellac for added protection.

Regular cleaning with a damp cloth and mild soap is recommended, avoiding harsh chemicals that can strip the finish.

Maintenance: Extending Shellac's Lifespan

Regular maintenance is essential for maximizing shellac's lifespan on any wood type. Dusting frequently with a soft cloth prevents dirt and grime buildup. For deeper cleaning, use a mild soap solution and a damp cloth, followed by a thorough drying. Avoid abrasive cleaners or scouring pads that can scratch the surface. Periodically inspect the finish for signs of wear or damage. Touch-ups with a small amount of shellac can be applied to localized areas as needed, ensuring a longer-lasting and more uniform appearance.

Durability Unveiled: Lifespan of Wooden Fence Posts Explained

You may want to see also

Explore related products

Factors affecting shellac lifespan on wood

Shellac's durability on wood hinges on several key factors, each playing a role in how long the finish retains its luster and protective qualities. One of the most significant variables is the number of coats applied. A single coat of shellac offers minimal protection and will wear off quickly, especially in high-traffic areas. For optimal results, apply at least three coats, allowing each layer to dry completely before adding the next. This builds a thicker, more resilient barrier against moisture, heat, and physical wear.

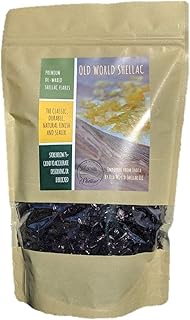

The type of shellac and its concentration also impact longevity. Shellac comes in various forms, including dewaxed flakes, pre-mixed solutions, and alcohol-based formulas. Dewaxed shellac, for instance, is more soluble and adheres better to wood, while pre-mixed solutions often contain additives that can affect drying time and durability. The concentration of shellac in the solution matters too—a 1-pound cut (1 pound of shellac flakes dissolved in 1 gallon of alcohol) is standard, but a 2-pound cut provides a thicker, more durable finish.

Environmental conditions play a critical role in shellac's lifespan. Humidity and temperature can accelerate wear, as shellac is sensitive to moisture and heat. In humid environments, shellac may become sticky or degrade faster, while extreme heat can cause it to soften or discolor. To mitigate these effects, apply shellac in a controlled environment with moderate humidity (around 50%) and room temperature. Additionally, avoid placing shellac-finished wood in direct sunlight or near heat sources like radiators.

The type of wood and its preparation are equally important. Porous woods like pine absorb shellac more readily, requiring additional coats for even coverage. Harder woods like maple or oak may need light sanding to ensure proper adhesion. Always clean the wood surface thoroughly before application, removing dust, grease, or old finishes. A poorly prepared surface will compromise shellac's ability to bond, reducing its lifespan significantly.

Finally, usage and maintenance dictate how well shellac holds up over time. High-traffic surfaces like tabletops or floors will wear faster than less-used areas like decorative trim. Regular cleaning with a soft, damp cloth and mild soap can extend shellac's life, but avoid harsh chemicals or abrasive cleaners that can strip the finish. For heavily used items, consider reapplying a coat of shellac annually to refresh the protection and appearance.

By understanding these factors—coats applied, shellac type, environmental conditions, wood preparation, and maintenance—you can maximize shellac's lifespan on wood, ensuring a beautiful and durable finish for years to come.

The Development Journey of Night in the Woods: Timeline Revealed

You may want to see also

Explore related products

$17.99 $18.99

Maintenance tips to extend shellac longevity

Shellac, a natural resin derived from lac bugs, has been a staple in wood finishing for centuries, prized for its rich luster and protective qualities. However, its longevity on wood surfaces depends heavily on maintenance. Without proper care, shellac can degrade prematurely, losing its sheen and protective capabilities. To maximize its lifespan, consider the following targeted strategies.

Preventative Measures: The First Line of Defense

Shellac is sensitive to moisture, heat, and chemicals, making proactive protection essential. Use coasters under glasses, trivets under hot dishes, and placemats under heavy objects to shield surfaces from direct damage. For high-traffic areas like tabletops, apply a sacrificial layer of wax every 6–12 months. This creates a barrier that absorbs wear and tear instead of the shellac itself. Regularly dust surfaces with a soft, dry cloth to prevent abrasive particles from scratching the finish.

Cleaning Techniques: Gentle Yet Effective

Improper cleaning is a common culprit behind shellac deterioration. Avoid harsh chemicals like ammonia, bleach, or vinegar, which can dissolve or dull the finish. Instead, use a mild soap diluted in warm water, applied sparingly with a damp (not wet) microfiber cloth. Wipe in the direction of the wood grain, and immediately dry the surface to prevent moisture absorption. For stubborn stains, test a small area with denatured alcohol before applying it more broadly, as shellac is alcohol-soluble.

Repair and Refresh: Addressing Wear Over Time

Even with meticulous care, shellac may show signs of wear, such as white water rings or localized dullness. For minor damage, gently rub the affected area with a cloth dampened with denatured alcohol to remove the old shellac, then reapply a thin coat of shellac, allowing it to dry completely. For larger areas, consider stripping the entire surface with alcohol and refinishing it. Reapply shellac every 1–2 years in high-use areas, or as needed, to maintain its protective and aesthetic qualities.

Environmental Control: The Hidden Factor

Shellac’s durability is closely tied to its environment. Fluctuations in humidity and temperature can cause wood to expand and contract, stressing the finish. Maintain indoor humidity between 40–60% to minimize wood movement. Avoid placing shellac-finished pieces near heat sources, such as radiators or sunny windows, which can cause the finish to crack or peel. In particularly dry climates, use a humidifier to stabilize moisture levels and preserve the shellac’s integrity.

By combining preventative measures, proper cleaning, timely repairs, and environmental control, you can significantly extend the life of shellac on wood. While no finish is indestructible, thoughtful maintenance ensures shellac remains both functional and beautiful for years to come.

Wood Chips and Nitrogen: Understanding Soil Nutrient Lock-Up Duration

You may want to see also

Explore related products

Comparing shellac to other wood finishes

Shellac, derived from the resin secretions of the lac bug, has been a staple in wood finishing for centuries. Its longevity on wood typically ranges from 1 to 5 years, depending on factors like exposure to sunlight, moisture, and wear. While shellac offers a rich, amber hue and a smooth finish, it is less durable than modern alternatives like polyurethane or varnish. This makes it ideal for low-traffic items such as antique furniture or decorative pieces but less suitable for high-use surfaces like floors or kitchen tables.

When comparing shellac to polyurethane, the latter emerges as a more robust option for durability. Polyurethane, a synthetic finish, can last up to 10 years on wood, providing superior resistance to scratches, heat, and chemicals. However, it lacks the natural, warm tone of shellac and often requires multiple coats to achieve a smooth finish. For projects where longevity and protection are paramount, polyurethane is the clear winner, but shellac remains unmatched in its ability to enhance the wood’s natural beauty.

Varnish, another popular wood finish, strikes a balance between shellac and polyurethane. It lasts 5 to 8 years and offers better moisture resistance than shellac while maintaining a clearer finish than polyurethane. However, varnish can yellow over time, especially when exposed to UV light, which may detract from the wood’s appearance. For outdoor furniture or pieces exposed to sunlight, varnish is a practical choice, but shellac’s quick drying time and ease of application make it preferable for indoor projects requiring frequent touch-ups.

For those seeking an eco-friendly option, natural oils like linseed or tung oil are worth considering. These finishes penetrate the wood, providing a matte, natural look that lasts 1 to 3 years. While they require more frequent reapplication than shellac, they are non-toxic and easy to maintain. Shellac, though not as durable as oils in high-moisture environments, offers a harder surface and a more polished appearance. The choice between the two depends on whether you prioritize aesthetics or ease of maintenance.

In summary, shellac’s longevity on wood is modest compared to modern finishes, but its unique qualities—such as its warm tone and ease of application—make it irreplaceable in certain contexts. Polyurethane excels in durability, varnish balances protection and clarity, and natural oils offer an eco-friendly alternative. When selecting a finish, consider the wood’s intended use, exposure conditions, and desired aesthetic to determine whether shellac or another option aligns best with your needs.

How Quickly Does Mold Grow on Wood Surfaces?

You may want to see also

Explore related products

Shellac application techniques for maximum durability

Shellac's longevity on wood hinges on meticulous application. While factors like wear and tear play a role, proper technique significantly extends its lifespan.

Imagine a finely crafted wooden table, its surface gleaming with a rich, amber hue. This lustrous finish, achieved with shellac, can endure for decades if applied correctly.

The Foundation: Preparation is Key

Before brushing on the first coat, meticulous preparation is paramount. Sand the wood meticulously, progressing through grits from coarse to fine (80 to 220 grit is a common range). This creates a smooth, even surface for the shellac to adhere to. Remove all dust with a tack cloth, ensuring no particles interfere with the bond.

For maximum durability, consider sealing the wood with a thin coat of dewaxed shellac cut with denatured alcohol (1 pound of shellac flakes to 1 quart of alcohol). This initial seal penetrates the wood, providing a stronger base for subsequent coats.

The Art of Application: Technique Matters

Shellac application requires patience and precision. Use a high-quality natural bristle brush, applying thin, even coats. Avoid overloading the brush, as this can lead to drips and uneven coverage. Allow each coat to dry completely (typically 30 minutes to an hour, depending on humidity) before applying the next.

Building Layers: Strength in Numbers

Multiple thin coats are the secret to a durable shellac finish. Aim for a minimum of three coats, sanding lightly with 400-grit sandpaper between each coat to ensure a smooth, seamless surface. For high-traffic areas or pieces exposed to moisture, consider applying up to five coats for added protection.

The Final Touch: Sealing the Deal

Once the desired number of coats are applied and dried, protect your work with a final coat of paste wax. This adds a subtle sheen and provides an extra layer of defense against scratches and stains. Buff the wax to a gentle luster for a classic, timeless finish.

Boiling Palo Azul Wood Chips: Optimal Time for Best Results

You may want to see also

Frequently asked questions

Shellac on wood typically lasts 1 to 3 years, depending on factors like exposure to sunlight, moisture, and wear.

Yes, shellac lasts longer on indoor wood (2-3 years) compared to outdoor wood (1 year or less) due to harsher environmental conditions.

Yes, shellac can be reapplied over existing layers to refresh and extend its lifespan, provided the surface is cleaned and lightly sanded first.

Yes, applying multiple thin coats of shellac increases its durability, with 3-4 coats being ideal for longer-lasting protection.

Regular cleaning with a soft cloth and avoiding harsh chemicals can significantly extend the life of shellac on wood surfaces.