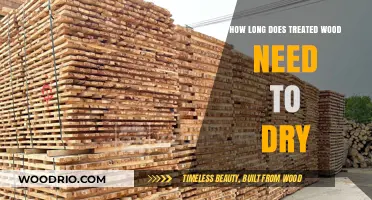

Pressure-treated wood is a popular choice for outdoor construction projects due to its enhanced durability and resistance to rot, decay, and insect damage. The longevity of pressure treatment in wood largely depends on the type of preservative used, the quality of the treatment process, and the environmental conditions to which the wood is exposed. Typically, properly treated wood can last anywhere from 20 to 40 years or more, with some treatments offering even longer protection. Factors such as moisture levels, soil contact, and exposure to sunlight can accelerate degradation, but regular maintenance and proper installation can significantly extend the lifespan of pressure-treated wood. Understanding these variables is essential for maximizing the effectiveness and durability of this widely used building material.

| Characteristics | Values |

|---|---|

| Average Lifespan of Pressure-Treated Wood | 20-40 years (varies based on environmental conditions and maintenance) |

| Ground Contact Resistance | 5-10 years (shorter lifespan when in direct contact with soil) |

| Above-Ground Use | 40+ years (longer lifespan when not in contact with soil or moisture) |

| Resistance to Rot and Decay | High (due to chemical preservatives like ACQ, CA, or MCA) |

| Termite Resistance | 15-20 years (effectiveness diminishes over time) |

| Maintenance Requirements | Periodic sealing or staining every 2-3 years to extend lifespan |

| Environmental Factors Impact | Moisture, sunlight, and temperature can accelerate degradation |

| Chemical Retention | Chemicals penetrate deep into wood, providing long-term protection |

| Warranty Period | Typically 15-20 years (varies by manufacturer and product type) |

| Re-treatment Needed | After 10-15 years for ground contact applications |

Explore related products

$16.99

What You'll Learn

Factors affecting pressure treatment longevity

The lifespan of pressure-treated wood hinges on a delicate interplay of factors, both environmental and inherent. While estimates range from 20 to 40 years, understanding these influences empowers you to maximize its durability.

Let's delve into the key players shaping the longevity of this ubiquitous building material.

Environmental Exposure: The Relentless Assault

Sunlight, moisture, and temperature fluctuations wage a constant war on pressure-treated wood. UV rays break down the chemical preservatives, accelerating deterioration. Constant moisture, whether from rain, humidity, or ground contact, fosters rot and insect infestation. Extreme temperature swings cause the wood to expand and contract, leading to cracks and splintering.

Preservative Type and Retention: The Chemical Shield

Not all pressure treatments are created equal. Common preservatives like ACQ (Alkaline Copper Quaternary) and CA-B (Copper Azole) offer varying levels of protection. The retention level, measured in pounds per cubic foot (pcf), indicates the concentration of preservative within the wood. Higher retention levels generally equate to longer lifespan, with typical ranges falling between 0.25 pcf and 0.60 pcf for residential applications.

Wood Species: Nature's Inherent Strength

The inherent characteristics of the wood species itself play a crucial role. Naturally rot-resistant woods like cedar and redwood inherently outlast less resistant species like pine, even with pressure treatment. Consider the wood's natural durability alongside the chosen preservative for optimal results.

Maintenance: The Proactive Defense

Regular maintenance significantly extends the life of pressure-treated wood. Applying a water-repellent sealant every 2-3 years helps shed moisture and protect against UV damage. Inspecting for cracks, splinters, and signs of insect activity allows for prompt repairs, preventing further deterioration.

Pro Tip: Avoid using harsh chemicals or pressure washers, as these can damage the wood surface and compromise the preservative barrier.

Seasoning Cherry Wood: Timeframe and Tips for Perfect Results

You may want to see also

Explore related products

Common wood preservatives used in treatment

Pressure-treated wood relies heavily on preservatives to extend its lifespan, with several types dominating the market. Chromated Copper Arsenate (CCA) was once the standard, prized for its effectiveness against fungi and insects. However, due to health concerns, particularly arsenic leaching, its residential use was phased out in 2003. Today, CCA remains in industrial applications but is largely replaced by safer alternatives in consumer products. Understanding these preservatives is crucial, as their type directly influences the wood’s durability and environmental impact.

Alkaline Copper Quaternary (ACQ) has emerged as a leading CCA alternative, combining copper oxide with a quaternary ammonium compound. This preservative is highly effective against decay and termites, with treatments typically containing 0.25–0.40% copper oxide. While ACQ-treated wood may initially have a greenish tint, it weathers to a natural gray over time. One drawback is its potential to corrode metal fasteners, necessitating the use of stainless steel or hot-dipped galvanized hardware. Proper installation is key to maximizing its 40+ year lifespan in most environments.

For those seeking an eco-friendlier option, Copper Azole (CA-B and CA-C) preservatives offer a balance of efficacy and sustainability. These water-based treatments use copper paired with an azole compound, such as tebuconazole or propiconazole, to combat fungi and insects. CA-B, with 0.18–0.22% copper, is common in above-ground applications, while CA-C, containing 0.38–0.46% copper, is used for ground-contact lumber. Both types are less corrosive than ACQ and boast a lifespan comparable to CCA when properly maintained. Regular inspection for cracks or wear ensures their longevity.

Micronized copper preservatives represent a technological advancement, using finely ground copper particles (1–5 microns) for deeper wood penetration. This method reduces leaching and increases resistance to mold, decay, and termites. Treatments typically contain 0.15–0.25% copper, making them lightweight yet highly effective. Micronized copper is ideal for decking, fencing, and playground equipment, offering a 25–40 year lifespan with minimal environmental impact. However, its cost is higher than traditional treatments, reflecting its specialized production process.

Borate preservatives, such as sodium borate or disodium octaborate tetrahydrate, are another option, particularly for interior or dry-use wood. Borates diffuse into the wood, killing fungi and insects upon ingestion. While effective, they are water-soluble and unsuitable for ground-contact applications unless sealed. Treatments often involve dipping or spraying, with concentrations around 1–2% boric acid equivalent. Borate-treated wood is commonly used in attics, crawl spaces, and raised-floor systems, where moisture exposure is minimal. Periodic reapplication may be needed in high-humidity environments.

Choosing the right preservative depends on the wood’s intended use, environmental exposure, and maintenance capacity. ACQ and CA offer broad-spectrum protection for exterior projects, while micronized copper provides a premium, low-maintenance solution. Borates excel in controlled, dry settings. Regardless of type, all treated wood requires proper handling, including wearing protective gear during cutting and ensuring adequate ventilation. By understanding these preservatives, homeowners and builders can make informed decisions to maximize the lifespan of their wooden structures.

Wood Duck Egg Hatching Timeline: What to Expect and When

You may want to see also

Explore related products

Expected lifespan of treated wood types

Pressure-treated wood is a cornerstone of outdoor construction, prized for its resistance to rot, insects, and decay. However, not all treated wood is created equal. The expected lifespan varies significantly depending on the type of treatment, the wood species, and environmental factors. For instance, wood treated with chromated copper arsenate (CCA) historically lasted 40 years or more, but its use in residential projects was phased out in 2003 due to health concerns. Modern alternatives like alkaline copper quaternary (ACQ) and copper azole (CA-B) offer comparable durability, typically enduring 20–30 years in ground-contact applications and up to 40 years above ground. These treatments rely on copper-based compounds to repel pests and fungi, but their longevity depends on proper installation and maintenance.

When selecting treated wood, consider the retention level, measured in pounds of preservative per cubic foot (pcf). For example, .25 pcf is suitable for above-ground use, while .40 pcf is recommended for ground contact. Higher retention levels generally extend lifespan but come at a higher cost. Southern yellow pine, a common choice for treated wood, absorbs preservatives well, making it a durable option for decks, fences, and structural supports. In contrast, denser woods like cedar or redwood naturally resist decay but benefit from treatment for added protection, especially in harsh climates.

Environmental exposure plays a critical role in determining lifespan. Wood in direct contact with soil or water, such as fence posts or retaining walls, degrades faster than wood used in dry, elevated structures. To maximize durability, ensure proper drainage, use corrosion-resistant fasteners, and apply a water-repellent sealant annually. For example, a deck treated with ACQ and maintained regularly can last 30–40 years, while a poorly sealed fence post in wet soil may fail within 10–15 years.

Comparing treated wood types reveals trade-offs between cost, lifespan, and environmental impact. CCA-treated wood, though long-lasting, poses disposal challenges due to its arsenic content. ACQ and CA-B are safer alternatives but may require more frequent maintenance in humid or wet conditions. Micronized copper azole (MCA) offers a middle ground, with a lifespan similar to ACQ but better resistance to corrosion of metal fasteners. For those prioritizing sustainability, consider borate-treated wood, which lasts 15–20 years above ground and is less toxic, though it’s not suitable for ground contact.

Ultimately, the lifespan of treated wood hinges on informed selection and proactive care. Choose the right treatment type and retention level for your project, factor in environmental conditions, and commit to regular maintenance. By doing so, you can ensure your investment stands the test of time, whether it’s a backyard deck or a commercial retaining wall.

Wood Pellets vs. Propane: Comparing Fuel Longevity for Grilling

You may want to see also

Explore related products

Environmental impact on treatment durability

The durability of pressure-treated wood is significantly influenced by its surrounding environment, with factors like moisture, temperature, and soil conditions playing pivotal roles. For instance, wood exposed to constant moisture, such as in coastal areas or near bodies of water, is more prone to leaching of preservatives and accelerated degradation. Studies show that in high-moisture environments, the effective lifespan of pressure-treated wood can decrease by up to 30% compared to drier climates. To mitigate this, ensure proper drainage around wooden structures and consider using water-repellent sealants to minimize moisture absorption.

Temperature extremes also impact treatment longevity. In regions with frequent freeze-thaw cycles, the wood expands and contracts, causing micro-cracks that expose untreated layers. This phenomenon is particularly evident in northern climates, where pressure-treated wood may degrade 15–20% faster than in temperate zones. To counteract this, apply a flexible, temperature-resistant coating annually, especially in areas with seasonal temperature fluctuations. Additionally, avoid using pressure-treated wood in direct contact with soil in colder regions, as soil moisture exacerbates the issue.

Soil type and pH levels directly affect the chemical stability of wood preservatives. Acidic soils, common in pine forests and certain agricultural areas, can neutralize copper-based preservatives, reducing their effectiveness. In such environments, the treatment may last only 10–15 years, compared to 20–30 years in neutral or alkaline soils. If installing wooden structures in acidic soil, incorporate a gravel barrier between the wood and ground to reduce direct contact. Alternatively, opt for newer preservative formulations designed to withstand acidic conditions, such as those containing micronized copper azole (MCA), which offers improved resistance.

Sunlight exposure, particularly UV radiation, breaks down the surface of pressure-treated wood, leading to discoloration and surface erosion. In sunny climates, untreated surfaces can degrade within 5–7 years, even if the core remains intact. To preserve both appearance and structural integrity, apply a UV-resistant stain or paint every 2–3 years. Dark-colored finishes absorb more heat, so choose lighter shades in hotter regions to minimize thermal stress. Regularly inspect sun-exposed areas for signs of wear and reapply protective coatings as needed.

Finally, biological factors like fungi and insects thrive in humid, warm environments, posing additional threats to treated wood. In tropical or subtropical regions, termite infestations and fungal decay can reduce the lifespan of pressure-treated wood by 40–50%. To enhance resistance, use wood treated with dual-purpose preservatives like chromated copper arsenate (CCA) or alkaline copper quat (ACQ), which offer both fungal and insect protection. Periodically inspect wooden structures for signs of biological activity, such as discoloration or hollowed areas, and treat promptly with appropriate fungicides or insecticides.

By understanding and addressing these environmental factors, you can maximize the durability of pressure-treated wood, ensuring it performs effectively for decades rather than years. Tailoring maintenance practices to specific environmental conditions is key to preserving both the structural integrity and aesthetic appeal of treated wood installations.

Benjamin Banneker's Wooden Watch: Its Functionality and Lifespan Explored

You may want to see also

Explore related products

$59.98

Maintenance tips to extend treatment life

Pressure-treated wood typically lasts 20 to 40 years, but its lifespan hinges on maintenance. Left unchecked, moisture intrusion, UV exposure, and physical wear accelerate deterioration. Proactive care can significantly extend its service life, ensuring the wood remains structurally sound and aesthetically pleasing.

Sealants and Stains: The First Line of Defense

Applying a high-quality sealant or stain every 2–3 years is critical. These products act as barriers against water infiltration and UV rays, the primary culprits behind wood degradation. Opt for semi-transparent stains with UV inhibitors for optimal protection. For best results, clean the wood surface thoroughly before application, removing dirt, mildew, and old finishes. Use a pressure washer on a low setting (under 1,500 PSI) to avoid damaging the wood fibers.

Inspect and Repair: Address Issues Early

Regular inspections can prevent minor issues from becoming major problems. Check for cracks, splinters, or signs of insect activity at least twice a year, particularly after harsh weather seasons. Fill small cracks with epoxy wood filler and replace severely damaged boards promptly. For structures like decks, ensure all hardware (screws, nails) remains tight and rust-free, as loose connections can lead to uneven weight distribution and accelerated wear.

Manage Moisture: Keep Water at Bay

Moisture is the enemy of treated wood. Ensure proper drainage around wooden structures by grading soil away from decks or fences. Install gutters and downspouts to redirect rainwater. For ground-contact applications, consider adding a gravel base or moisture barrier beneath the wood to minimize soil-to-wood contact. Avoid planting vegetation too close to wooden structures, as roots and irrigation can introduce excess moisture.

Physical Protection: Reduce Wear and Tear

High-traffic areas, such as deck stairs or fence gates, endure more stress. Install protective caps on post tops and use rubber mats in heavy-use zones to minimize abrasion. For decks, avoid dragging heavy furniture and use furniture pads to prevent scratches. Periodically redistribute planters, grills, and other stationary items to avoid concentrated pressure points that can weaken the wood over time.

By combining these maintenance strategies, you can maximize the longevity of pressure-treated wood, ensuring it remains functional and attractive for decades. The key lies in consistency—regular care trumps sporadic intervention every time.

Durability of Wooden Condos: Lifespan and Maintenance Tips Revealed

You may want to see also

Frequently asked questions

Pressure-treated wood typically lasts 20 to 40 years, depending on factors like exposure to moisture, soil contact, and maintenance.

Yes, the lifespan varies; wood in ground contact (e.g., fence posts) may last 15–20 years, while above-ground applications (e.g., decks) can last 30–40 years.

Yes, regular maintenance, such as sealing or staining, can extend the lifespan of pressure-treated wood by protecting it from moisture and UV damage.

Yes, newer preservatives like ACQ (Alkaline Copper Quaternary) or CA-B (Copper Azole) generally provide longer-lasting protection compared to older treatments like CCA (Chromated Copper Arsenate).