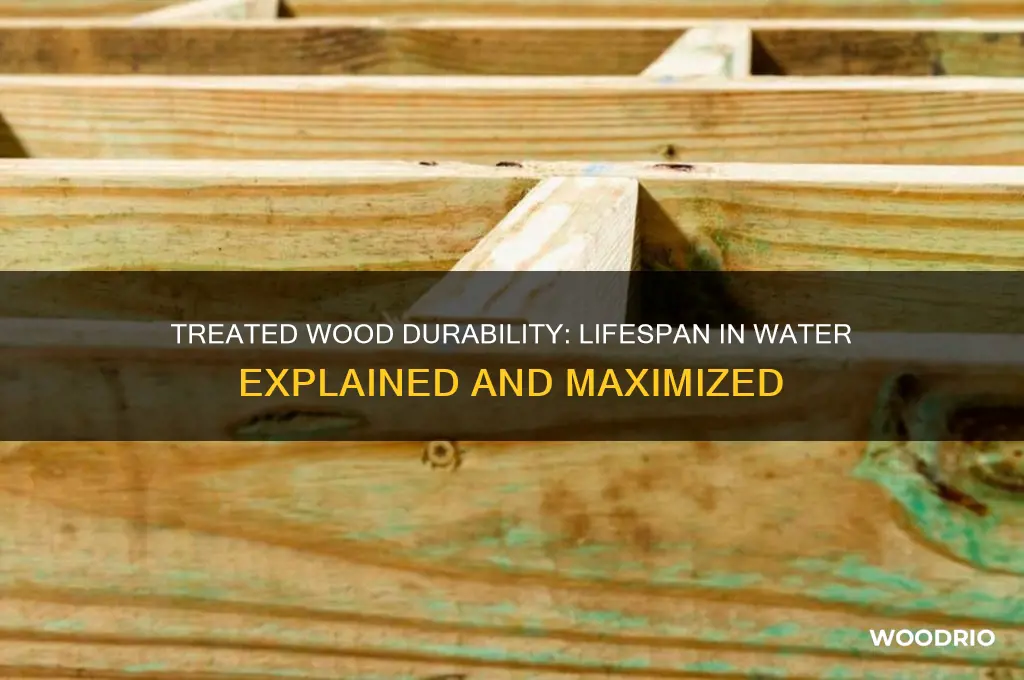

Treated wood is commonly used in outdoor and aquatic environments due to its enhanced resistance to decay, insects, and moisture. When submerged or consistently exposed to water, the longevity of treated wood depends on several factors, including the type of treatment, the specific preservative chemicals used, and the environmental conditions. Generally, properly treated wood can last anywhere from 10 to 40 years in water, with pressure-treated wood being the most durable option. However, factors such as water pH, temperature, and the presence of marine organisms can accelerate degradation. To maximize lifespan, it is essential to choose the appropriate treatment type and ensure proper installation and maintenance.

| Characteristics | Values |

|---|---|

| Type of Treatment | CCA, ACQ, CA-B, or Micronized Copper Azole (MCA) treated wood |

| Expected Lifespan in Water | 20-40 years (CCA), 15-30 years (ACQ/CA-B/MCA) |

| Factors Affecting Durability | Water pH, temperature, oxygen levels, microbial activity, and water flow |

| Resistance to Rot and Decay | High (due to chemical preservatives) |

| Resistance to Marine Borers | Moderate to high (depending on treatment type) |

| Maintenance Required | Minimal; periodic inspection for damage or wear |

| Environmental Impact | CCA is restricted due to arsenic leaching; newer treatments are safer |

| Cost Compared to Untreated Wood | Higher initial cost but longer lifespan reduces long-term expenses |

| Common Applications | Docks, piers, seawalls, underwater structures |

| Regulatory Compliance | Must meet AWPA (American Wood Protection Association) standards |

| Re-treatment Needed | Rarely, but possible after 15-20 years depending on conditions |

| Susceptibility to UV Degradation | Low (since it’s submerged, UV exposure is minimal) |

| Weight in Water | Remains buoyant initially but becomes waterlogged over time |

| Biodegradability | Slow degradation due to preservatives |

| Compatibility with Hardware | Requires stainless steel or galvanized fasteners to prevent corrosion |

Explore related products

$16.99

What You'll Learn

Treatment Types and Durability

Treated wood's lifespan in water hinges on the type of treatment it receives. Pressure-treated wood, the most common option, uses chemicals like chromated copper arsenate (CCA) or alkaline copper quaternary (ACQ) to resist rot and insect damage. CCA, once prevalent, has been largely phased out for residential use due to arsenic concerns. ACQ, a safer alternative, offers comparable durability, lasting 20-40 years in water-saturated environments. However, even ACQ-treated wood requires proper installation and maintenance to maximize its lifespan.

Beyond pressure treatment, alternative methods like thermal modification and acetylation are gaining traction. Thermal modification involves heating wood to high temperatures in a controlled environment, altering its cellular structure to resist moisture absorption. This process can extend the wood's lifespan in water by up to 30 years. Acetylation, a more complex process, involves chemically modifying the wood's hydroxyl groups, making it highly resistant to water uptake. While more expensive, acetylated wood boasts a lifespan exceeding 50 years in water, making it ideal for demanding applications like docks and bridges.

In addition to treatment type, factors like wood species and environmental conditions significantly impact durability. Naturally rot-resistant species like cedar and redwood offer inherent advantages, even without treatment. However, even these species benefit from treatment for prolonged water exposure.

For optimal performance, consider the following:

- Choose the right treatment: Match the treatment type to the specific water exposure level and desired lifespan.

- Follow installation guidelines: Proper spacing, ventilation, and fastening techniques are crucial for preventing moisture buildup and promoting longevity.

- Apply protective coatings: Sealants and stains can further enhance water resistance and protect against UV damage.

- Regularly inspect and maintain: Periodically check for signs of deterioration and address any issues promptly to prevent further damage.

By understanding the nuances of treatment types and their impact on durability, you can make informed decisions when selecting treated wood for water-exposed applications, ensuring long-lasting performance and minimizing the need for costly replacements.

Pressure Treated Wood Lifespan in Soil: Durability and Longevity Explained

You may want to see also

Explore related products

Water Exposure Effects on Treated Wood

Treated wood, when exposed to water, undergoes a complex interplay of preservation and degradation. The longevity of treated wood in aquatic environments hinges on the type of treatment, the wood species, and the specific water conditions. For instance, wood treated with chromated copper arsenate (CCA) can last up to 40 years in water, thanks to its resistance to fungal decay and insect damage. However, newer treatments like alkaline copper quaternary (ACQ) and copper azole (CA) offer similar durability but with reduced environmental toxicity. Understanding these treatments is crucial for selecting the right material for water-exposed structures like docks, bridges, or retaining walls.

Water exposure accelerates the leaching of preservatives from treated wood, which can compromise its effectiveness over time. Studies show that in freshwater environments, CCA-treated wood loses approximately 10-15% of its preservative chemicals within the first year. To mitigate this, consider using barriers like waterproof coatings or encapsulating systems, which can extend the wood’s lifespan by reducing direct water contact. For marine environments, where saltwater increases corrosion, opt for higher retention levels of preservatives and inspect the wood annually for signs of wear.

The moisture content of wood is another critical factor in water exposure. Treated wood can absorb and release water, leading to swelling, shrinking, and cracking. This movement weakens the wood’s structure and can expose untreated areas to decay. To combat this, ensure proper installation with adequate spacing for drainage and ventilation. Additionally, pre-drilling holes for fasteners reduces splitting, while using stainless steel or hot-dipped galvanized hardware prevents rust and prolongs the assembly’s integrity.

Comparing treated wood to alternative materials like composite lumber or concrete reveals trade-offs in cost, maintenance, and environmental impact. While treated wood is cost-effective and readily available, composites offer greater resistance to moisture and rot but at a higher upfront cost. Concrete, though durable, lacks the aesthetic appeal of wood and requires significant maintenance to prevent cracking. For projects requiring both durability and natural beauty, treated wood remains a top choice, provided it’s properly maintained and suited to the water conditions it will face.

Practical tips for maximizing the lifespan of treated wood in water include regular inspections for cracks, splinters, or discoloration, which indicate potential decay. Applying a fresh coat of water-repellent sealant every 2-3 years can significantly reduce moisture absorption. In areas with high water flow, consider using sacrificial boards that can be replaced without dismantling the entire structure. By combining the right treatment, installation techniques, and maintenance practices, treated wood can withstand water exposure for decades, making it a reliable choice for aquatic applications.

Wood Hardener Drying Time: Factors Affecting Cure and Dry Speed

You may want to see also

Explore related products

Lifespan in Freshwater vs. Saltwater

Treated wood's longevity in water hinges critically on the salinity of its environment. Freshwater, with its lower mineral content, poses a less corrosive threat to preservatives like copper azole or creosote. These chemicals, designed to repel fungi and insects, can remain effective for 20 to 40 years in freshwater settings, such as ponds or lakes. However, saltwater, with its high chloride concentration, accelerates the breakdown of these protective compounds. Chlorides in seawater react with preservatives, particularly copper-based treatments, leading to leaching and reduced efficacy. Consequently, treated wood in saltwater environments, like coastal piers or marine structures, typically lasts only 10 to 15 years before showing significant degradation.

To maximize lifespan in saltwater, consider using specialized treatments like CCA (chromated copper arsenate), though its environmental concerns limit its modern use. Alternatively, opt for non-metallic preservatives or composite materials designed for marine conditions. For freshwater applications, standard pressure-treated wood suffices, but ensure it’s rated for ground or water contact. Regular inspections are crucial in both environments, as early detection of cracks or fungal growth can extend usability. Applying waterproof sealants annually can also mitigate moisture penetration, though this is more effective in freshwater than saltwater due to the latter’s relentless corrosiveness.

A comparative analysis reveals that saltwater’s impact on treated wood is not just chemical but also mechanical. Tidal movements and wave action in marine environments subject wood to constant stress, exacerbating wear. Freshwater, by contrast, offers a more stable setting, reducing physical strain on the material. This distinction underscores the need for site-specific material selection: while treated wood may thrive in a freshwater reservoir, it would falter in a tidal zone without additional protective measures. Understanding these environmental nuances is key to predicting and prolonging wood’s lifespan in aquatic settings.

For practical implementation, prioritize proper installation techniques regardless of water type. Ensure wood is fully submerged or consistently exposed, as the alternating wet-dry conditions of intertidal zones accelerate decay. In saltwater, elevate structures where possible to minimize contact with corrosive water. In freshwater, avoid areas with high sedimentation, as abrasive particles can wear down protective coatings. Finally, factor in replacement timelines during project planning—saltwater structures may require more frequent rebuilding, while freshwater installations can offer decades of service with minimal intervention. Tailoring your approach to the specific demands of each environment ensures both durability and cost-effectiveness.

Durability of Roof Wood: Lifespan, Maintenance, and Replacement Tips

You may want to see also

Explore related products

Maintenance Tips for Prolonged Use

Treated wood submerged in water faces relentless decay from moisture, microorganisms, and mechanical wear. To maximize its lifespan, prioritize regular inspections and proactive repairs. Annually examine surfaces for cracks, splinters, or signs of fungal growth, addressing issues immediately with wood preservatives or epoxy fillers. For structures like docks or bridges, inspect hardware connections for corrosion, replacing galvanized fasteners every 5–7 years in saltwater environments.

Waterborne chemicals accelerate treated wood degradation, particularly in polluted or saltwater settings. Rinse surfaces quarterly with fresh water to remove salts or contaminants, and apply a marine-grade sealant every 2–3 years to restore water repellency. In high-moisture zones, consider installing sacrificial anodes near metal components to mitigate galvanic corrosion, which indirectly protects the wood substrate.

Biological threats like algae, barnacles, or fungi thrive in aquatic conditions, compromising wood integrity. Treat affected areas with a 1:4 solution of bleach to water, followed by thorough rinsing, to inhibit organic growth. For preventative care, incorporate copper-based antifouling paints into maintenance routines, reapplying annually in high-splash zones. Avoid pressure washing, as it can strip protective treatments and expose fibers.

Structural stability hinges on managing waterlogged conditions. Ensure proper drainage by elevating wood structures on gravel bases or installing weep holes in retaining walls. For submerged pilings, wrap the first 12–18 inches below the waterline with geotextile fabric to deter marine borers, replacing the wrap every 3–5 years. Periodically monitor moisture levels with a wood moisture meter, aiming to keep readings below 20% to discourage rot.

Longevity ultimately depends on material selection and environmental context. While treated pine lasts 5–10 years in freshwater, denser options like treated cedar or redwood can endure 15–20 years with diligent care. In saltwater, expect lifespans to halve without rigorous maintenance. For critical applications, pair treated wood with composite caps or stainless steel reinforcements, blending durability with routine upkeep to defy aquatic decay.

Titebond Wood Glue Drying Time: Quick Guide for Woodworkers

You may want to see also

Explore related products

Factors Accelerating Wood Decay in Water

Treated wood in water faces a relentless assault from biological and environmental factors that shorten its lifespan. Microorganisms like fungi and bacteria thrive in moist conditions, breaking down cellulose and lignin—the structural components of wood. Even treated wood, despite its preservatives, isn’t immune. Waterlogged environments deprive wood of oxygen, creating anaerobic conditions that foster decay-causing organisms. For instance, *Poria monticola*, a type of brown rot fungus, can penetrate treated wood within 5–10 years in constantly wet environments, significantly reducing its structural integrity.

The type and concentration of wood preservatives play a critical role in determining longevity. Chromated copper arsenate (CCA), once widely used, provides 40+ years of protection in above-ground applications but degrades faster in water due to leaching. Modern alternatives like alkaline copper quaternary (ACQ) and copper azole (CA-B) offer 20–30 years of protection in aquatic settings but are less effective against certain fungi compared to CCA. The American Wood Protection Association (AWPA) recommends using preservatives rated for "ground contact" or "freshwater" for submerged applications, ensuring a minimum retention level of 0.40 pounds per cubic foot (PCF) for optimal resistance.

Water movement accelerates decay by transporting nutrients to microorganisms and leaching preservatives from the wood. Fast-flowing water, such as in rivers or tidal zones, shortens treated wood’s lifespan by up to 50% compared to stagnant water. For example, pilings in coastal areas exposed to wave action and saltwater may fail within 10–15 years, while those in calm freshwater lakes can last 25–30 years. To mitigate this, install protective barriers like geotextile wraps or sacrificial anodes to reduce water contact and galvanic corrosion.

Temperature and pH levels in water environments exacerbate decay. Warm water (above 70°F/21°C) accelerates microbial activity, doubling decay rates compared to colder temperatures. Acidic water (pH < 5.0) weakens preservatives by promoting metal ion leaching, while alkaline water (pH > 8.5) can degrade wood fibers. For instance, treated wood in acidic peat bogs may fail within 15 years, whereas in neutral freshwater ponds, it can last 30+ years. Regularly monitor water pH and temperature to assess risk and adjust maintenance schedules accordingly.

Physical damage and poor installation practices leave treated wood vulnerable to decay. Splitting, cracking, or puncturing the wood exposes untreated inner layers to moisture and microorganisms. Improper spacing or inadequate drainage traps water, prolonging saturation. For marine applications, use stainless steel or hot-dipped galvanized fasteners to prevent corrosion, which can create entry points for decay. Inspect wood annually for damage and apply water-repellent sealants to cracks or cuts, ensuring preservatives remain effective.

By understanding these factors—microbial activity, preservative limitations, water dynamics, environmental conditions, and physical vulnerabilities—you can maximize the lifespan of treated wood in water. Strategic material selection, proper installation, and proactive maintenance are key to combating decay and ensuring long-term performance.

Wood Sealant Drying Time: Essential Tips for Perfect Application and Results

You may want to see also

Frequently asked questions

Treated wood submerged in water can last 20 to 40 years, depending on the type of treatment, water conditions, and maintenance.

Yes, the type of treatment significantly affects durability. Pressure-treated wood with preservatives like ACQ or CCA tends to last longer in water compared to less advanced treatments.

While treated wood is more resistant to rot and decay, prolonged exposure to water, especially in harsh conditions, can still cause degradation over time, reducing its lifespan.

![Clear Waterproofing Wood Sealer [1-Quart] - Premium Outdoor Protective Wood Finish. Semi-Gloss Water-Based Varnish for Exterior Wood with Durability in All Weather Conditions.](https://m.media-amazon.com/images/I/81M5rkkj8dL._AC_UL320_.jpg)