Wood dust, a byproduct of woodworking activities, poses significant health risks if not managed properly, making it crucial to understand how long it takes to settle. The settling time of wood dust depends on various factors, including particle size, air movement, and humidity levels. Finer particles, such as those generated by sanding or sawing, can remain suspended in the air for hours or even days, increasing the risk of inhalation and respiratory issues. In contrast, larger particles tend to settle more quickly, often within minutes to hours. Proper ventilation, dust extraction systems, and regular cleaning are essential to minimize airborne wood dust and ensure a safer working environment. Understanding these dynamics helps in implementing effective dust control measures to protect both workers and the workspace.

| Characteristics | Values |

|---|---|

| Settling Time (General) | 1-2 hours for larger particles; up to 24 hours for finer particles |

| Particle Size | Larger particles (50-100 microns) settle faster than finer particles (<10 microns) |

| Air Movement | Increased air movement (e.g., fans, drafts) delays settling |

| Humidity | Higher humidity can cause particles to clump and settle faster |

| Temperature | Warmer temperatures may increase air movement, delaying settling |

| Dust Concentration | Higher concentrations may lead to faster settling due to particle collisions |

| Surface Area | Larger surface areas (e.g., floors) collect dust faster than smaller areas |

| Ventilation | Proper ventilation reduces airborne dust, accelerating settling |

| Type of Wood | Harder woods produce finer dust, which takes longer to settle |

| Cleaning Frequency | Regular cleaning reduces accumulation, aiding faster settling |

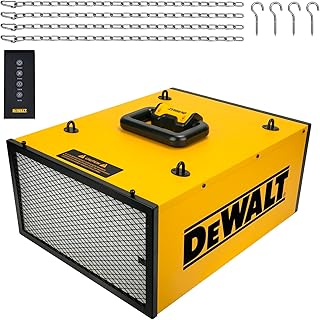

| Use of Dust Collection Systems | Systems like HEPA filters significantly reduce settling time |

| Static Electricity | Static can keep particles airborne longer, delaying settling |

| Room Size | Larger rooms may take longer for dust to settle due to increased air volume |

| Activity Level | High activity (e.g., woodworking) increases airborne dust, delaying settling |

Explore related products

$13.79

What You'll Learn

Factors affecting settling time

Wood dust settling time is not a fixed value; it’s a dynamic process influenced by multiple variables. Particle size, for instance, plays a critical role. Finer particles, typically under 10 microns, can remain suspended in air for hours or even days due to their low settling velocity, calculated using Stokes' Law. Coarser particles, such as sawdust from rough cutting operations, settle much faster, often within minutes. Understanding this relationship is essential for designing effective dust extraction systems in woodworking environments.

Airflow and ventilation significantly alter settling dynamics. In a poorly ventilated workshop, wood dust can linger indefinitely, creating a persistent health hazard. Conversely, high-velocity air movement, such as that from fans or open windows, accelerates settling by increasing particle collision and aggregation. However, this approach must be balanced; excessive airflow can redistribute dust rather than remove it. OSHA recommends maintaining air velocities below 200 feet per minute in dust collection systems to prevent recirculation.

Humidity acts as a double-edged sword in wood dust settling. Low humidity (below 30%) keeps particles dry and airborne, while high humidity (above 60%) causes dust to clump and settle faster. For example, in a humid environment, wood dust particles may absorb moisture, increasing their mass and reducing suspension time. However, excessive moisture can lead to mold growth, complicating cleanup. Maintaining relative humidity between 40–60% is ideal for optimizing settling without introducing secondary risks.

Surface characteristics of the workspace also impact settling time. Smooth, non-porous surfaces like metal or polished wood allow dust to settle and be easily wiped away. In contrast, porous materials such as untreated wood or fabric trap particles, delaying visible settling and requiring more aggressive cleaning methods. Regularly sealing or covering porous surfaces can mitigate this issue, reducing the time dust remains airborne and improving overall air quality.

Finally, temperature gradients affect settling behavior. Warm air rises, carrying lighter dust particles with it, while cooler air near the floor creates a settling zone. In environments with significant temperature stratification, such as unheated workshops in winter, dust may accumulate in specific layers rather than settling uniformly. Installing thermal barriers or using heated dust collectors can counteract this effect, ensuring more consistent and predictable settling times.

Durability of Wood Roof Shingles in the Philippines: Lifespan Guide

You may want to see also

Explore related products

Particle size impact on settling

Wood dust particles vary widely in size, typically ranging from 0.1 to 100 micrometers (μm). This diversity in particle size directly influences how quickly dust settles out of the air. Larger particles, such as those around 100 μm, settle rapidly due to gravity, often within minutes. In contrast, finer particles, especially those under 10 μm, can remain suspended for hours or even days. This distinction is critical in understanding the persistence of wood dust in a workspace and the associated health risks, as smaller particles are more likely to be inhaled and reach deeper into the respiratory system.

The settling time of wood dust can be estimated using Stokes' Law, which relates settling velocity to particle size, density, and fluid viscosity. For example, a 10 μm particle of wood dust (density ~1.5 g/cm³) in air (viscosity ~0.018 cP) settles at approximately 0.01 meters per second. This translates to about 10 minutes to fall one meter. However, particles smaller than 1 μm settle so slowly that air currents and Brownian motion often keep them suspended indefinitely. Practical implications include the need for continuous ventilation in woodworking shops to remove finer particles that don't settle naturally.

In real-world scenarios, particle size distribution in wood dust is rarely uniform. A mixture of sizes means settling occurs in stages. Coarse particles drop quickly, creating a false sense of cleanliness, while finer particles linger, posing a prolonged exposure risk. For instance, after sanding hardwood, visible dust may disappear within 20 minutes, but respirable particles (<2.5 μm) can persist for hours. Employers should use this knowledge to implement multi-stage dust control measures, such as combining immediate cleanup with HEPA filtration systems to capture smaller particles.

To mitigate risks, particle size should guide safety protocols. For tasks generating fine dust (e.g., routing or planing), use local exhaust ventilation with filters rated for sub-micron particles. In areas where dust cannot be fully contained, respiratory protection with N95 or P100 filters is essential. Regular air quality monitoring, particularly for PM2.5 and PM10 levels, ensures compliance with OSHA standards (e.g., 5 mg/m³ for wood dust over 8 hours). Understanding particle behavior allows for targeted interventions, reducing both immediate and long-term health hazards in woodworking environments.

White Wood Glue Drying Time: Quick Tips for Efficient Crafting

You may want to see also

Explore related products

Airflow influence on dust movement

Wood dust particles, typically ranging from 1 to 100 micrometers in size, are subject to the whims of airflow, which significantly dictates their settling time. In a stagnant environment, finer particles (under 10 micrometers) can remain suspended for hours or even days due to their low mass and the influence of Brownian motion. However, introduce airflow, and the dynamics shift dramatically. Even a gentle breeze of 0.5 meters per second can keep particles aloft indefinitely, while stronger currents, such as those from industrial fans or HVAC systems, can redistribute dust across large areas, delaying settling by hours or days. Understanding this relationship is crucial for managing dust in woodworking environments, where prolonged suspension increases inhalation risks and fire hazards.

To mitigate the impact of airflow on wood dust movement, consider these practical steps. First, assess the workspace for natural or mechanical airflow sources, such as open windows, vents, or machinery exhausts. Next, strategically position dust extraction systems, like cyclone collectors or HEPA filters, to counteract dominant airflow patterns. For example, placing a collector downwind of a table saw can capture dust before it disperses. Additionally, use physical barriers like curtains or partitions to redirect airflow and contain dust within specific zones. Regularly monitor airflow velocity with an anemometer, aiming to keep it below 1 meter per second in critical areas to encourage faster settling.

A comparative analysis reveals that airflow’s influence on wood dust is not uniform across particle sizes. Coarser particles (50–100 micrometers) settle rapidly, even in moderate airflow, due to their greater mass and lower surface-area-to-volume ratio. In contrast, finer particles (1–10 micrometers) are more susceptible to air currents and can be carried over long distances, posing greater health risks. For instance, in a workshop with a 2-meter-per-second airflow, coarse particles may settle within minutes, while fine particles could remain airborne for hours. This disparity underscores the need for multi-stage filtration systems that target both particle sizes effectively.

Persuasively, ignoring airflow’s role in dust movement can have dire consequences. In woodworking facilities, suspended wood dust increases the risk of respiratory illnesses, such as occupational asthma or nasal cancer, particularly for workers exposed daily. Moreover, airborne dust is a combustible hazard; a single spark can ignite a dust cloud, leading to catastrophic explosions. For example, the 2008 Georgia sugar refinery explosion, caused by accumulated sugar dust, resulted in 14 fatalities and highlighted the dangers of neglecting airflow management. By prioritizing airflow control, employers not only comply with OSHA standards (e.g., maintaining dust levels below 5 mg/m³ for wood dust) but also safeguard lives and livelihoods.

Descriptively, envision a woodworking shop where airflow is meticulously managed. Dust extraction hoods hum quietly near each machine, capturing particles at the source. Transparent plastic curtains sway gently, channeling air toward collectors instead of allowing it to disperse. Workers move freely, their breathing unencumbered by floating debris, while a digital display monitors airflow velocity in real time. This scene contrasts sharply with an unmanaged space, where dust clouds linger, coating surfaces and infiltrating lungs. Such a controlled environment not only accelerates dust settling but also fosters a healthier, more productive workspace, proving that airflow management is both an art and a science.

Transforming Woods to Pasture: Understanding the Timeframe for Land Conversion

You may want to see also

Explore related products

Humidity role in settling speed

Wood dust particles, like any airborne particulate, eventually settle due to gravity. However, the time it takes for this to occur is significantly influenced by humidity levels. Higher humidity causes wood dust particles to absorb moisture, increasing their size and weight. This phenomenon, known as hygroscopicity, accelerates settling because larger, heavier particles fall more quickly. For instance, in a woodworking shop with 70% humidity, fine wood dust particles (1-10 microns) may settle within 15-30 minutes, whereas in a drier environment (30% humidity), the same particles could remain suspended for several hours.

Understanding this relationship is crucial for both safety and efficiency. In high-humidity environments, such as tropical climates or poorly ventilated workshops, wood dust settles faster, reducing airborne exposure risks but potentially clogging filters and surfaces more quickly. Conversely, low-humidity settings, like air-conditioned spaces or arid regions, prolong dust suspension, increasing the risk of inhalation and requiring more frequent air filtration. To mitigate these issues, maintaining optimal humidity levels (40-60%) can balance settling speed and air quality, ensuring both worker safety and equipment longevity.

Practical steps to manage humidity include using dehumidifiers in damp environments and humidifiers in dry ones. For example, a woodworking facility in a humid region might install a dehumidifier to keep humidity below 60%, reducing the rapid settling of dust on machinery. Conversely, a shop in a dry climate could use a humidifier to increase moisture levels, encouraging dust to settle before it becomes a respiratory hazard. Regular monitoring with a hygrometer is essential to adjust these devices effectively.

A comparative analysis reveals that humidity’s impact on settling speed is not linear. While moderate humidity accelerates settling, extreme levels (above 80% or below 30%) can have adverse effects. High humidity may cause wood dust to clump, making it harder to clean, while very low humidity keeps particles airborne longer, increasing health risks. For optimal results, pair humidity control with proper ventilation and dust collection systems. For instance, combining a dehumidifier with a HEPA filter in a high-humidity workshop can capture settled dust before it recirculates, ensuring a safer workspace.

In conclusion, humidity plays a pivotal role in determining how quickly wood dust settles. By strategically managing moisture levels, woodworkers and facility managers can enhance safety, improve equipment performance, and maintain cleaner environments. Whether through dehumidifiers, humidifiers, or ventilation systems, the key is to strike a balance that leverages humidity’s natural effects without introducing new challenges.

Maximizing Wood Mizer Blade Lifespan: Durability and Maintenance Tips

You may want to see also

Explore related products

Comparison with other dust types

Wood dust, a byproduct of woodworking activities, settles at a rate influenced by particle size, air movement, and humidity. Compared to other dust types, its settling time varies significantly due to its unique characteristics. For instance, wood dust particles are typically larger and more irregular in shape than fine particulate matter like PM2.5, which remains suspended longer. Understanding these differences is crucial for managing indoor air quality and health risks, especially in woodworking environments.

Consider the settling behavior of household dust, which often contains a mix of skin cells, fabric fibers, and soil particles. This composite dust tends to settle faster than wood dust due to its heavier components, such as sand or pet dander. However, wood dust’s lighter, fibrous nature allows it to remain airborne for hours, especially in spaces with poor ventilation. For example, a study found that wood dust particles between 10–100 microns can take 1–6 hours to settle in a static environment, whereas household dust settles within 30–60 minutes under similar conditions.

In contrast, silica dust, commonly found in construction sites, poses a different challenge. Its fine, crystalline structure keeps it suspended for days, increasing inhalation risks. Wood dust, while less persistent, still requires attention due to its allergenic and carcinogenic properties. Practical tips for managing wood dust include using HEPA filters, which capture 99.97% of particles 0.3 microns or larger, and maintaining relative humidity below 50% to prevent dust clumping and re-suspension.

Another comparison is with pollen, a seasonal allergen that settles relatively quickly due to its larger size (10–100 microns). Wood dust, though similar in size, often contains resins or chemicals that alter its density and settling behavior. For instance, treated wood dust may settle slower than untreated varieties. Woodworkers should prioritize frequent surface cleaning and wearing N95 respirators, which filter out 95% of airborne particles, to minimize exposure.

Finally, comparing wood dust to metal dust reveals distinct hazards. Metal dust, such as aluminum or iron particles, is denser and settles faster but poses fire or explosion risks when airborne. Wood dust, while less dense, accumulates more easily on surfaces, requiring regular removal to prevent combustion hazards. A proactive approach includes zoning work areas, using exhaust ventilation, and training workers to recognize settling patterns. By understanding these comparisons, individuals can tailor dust control strategies to specific environments, ensuring safer air quality.

Composite Wood Off-Gassing Timeline: What to Expect and How Long It Lasts

You may want to see also

Frequently asked questions

Wood dust can take anywhere from 15 minutes to several hours to fully settle, depending on factors like particle size, air circulation, and room size.

Yes, larger wood dust particles settle faster, often within minutes, while finer particles can remain suspended in the air for hours.

Yes, increased air movement can keep wood dust suspended longer, delaying settling time, while still air allows it to settle more quickly.

It’s best to wait at least 30 minutes to an hour for wood dust to settle before cleaning to avoid stirring it back into the air and inhaling it.