Seasoning wood is a crucial process that involves drying it to reduce its moisture content, ensuring it burns efficiently and safely. The time required for wood to season depends on various factors, including the type of wood, its initial moisture level, and the environmental conditions where it is stored. Hardwoods like oak or maple typically take longer to season, often requiring 6 to 12 months, while softer woods like pine may season in 3 to 6 months. Proper seasoning involves splitting the wood into logs, stacking it in a well-ventilated area, and protecting it from rain while allowing airflow. Patience is key, as rushing the process can result in inefficient burning and increased creosote buildup in chimneys.

| Characteristics | Values |

|---|---|

| Type of Wood | Hardwoods (e.g., oak, maple) typically take 6–12 months; softwoods (e.g., pine, cedar) take 3–6 months. |

| Moisture Content | Freshly cut wood has 30–200% moisture; seasoned wood should be below 20% for optimal use. |

| Wood Thickness | Thicker logs (e.g., 6+ inches) take longer to season than thinner pieces (e.g., 2–4 inches). |

| Climate Conditions | Warmer, drier climates speed up seasoning (3–6 months); colder, humid climates slow it down (12+ months). |

| Stacking Method | Properly stacked wood with airflow seasons faster than piled or tightly packed wood. |

| Covering | Wood should be covered from rain but exposed to air; improper covering can prolong seasoning. |

| Initial Drying Phase | The first 6–8 weeks are critical for moisture loss, especially for green wood. |

| Testing Readiness | Use a moisture meter; wood is ready when it reads below 20% moisture content. |

| Crack and Split Indicators | End checks (cracks) and splitting indicate drying progress but can also lead to waste if excessive. |

| Storage Location | Elevated, well-ventilated areas (e.g., wood racks) are ideal for faster and more even seasoning. |

Explore related products

What You'll Learn

- Ideal Seasoning Time: Hardwoods take 6–12 months; softwoods 3–6 months for proper drying

- Moisture Content Goal: Aim for 15–20% moisture content for optimal wood burning efficiency

- Stacking Methods: Split and stack wood in a dry, ventilated area for faster seasoning

- Seasonal Considerations: Start seasoning in spring; wood cut in winter dries faster due to lower sap

- Testing Readiness: Use a moisture meter or check for cracks and lighter weight to test dryness

Ideal Seasoning Time: Hardwoods take 6–12 months; softwoods 3–6 months for proper drying

The density of wood directly influences its seasoning time, a fact that underscores the importance of categorizing wood types before drying. Hardwoods, such as oak, maple, and hickory, possess a tighter grain structure and higher moisture content, necessitating a longer seasoning period of 6–12 months. In contrast, softwoods like pine and cedar have a looser grain and lower moisture content, allowing them to dry adequately within 3–6 months. This distinction is critical for woodworkers and homeowners alike, as improperly seasoned wood can warp, crack, or underperform in applications like furniture, flooring, or firewood.

To optimize the seasoning process, stack wood in a single row, allowing air to circulate freely on all sides. For hardwoods, plan ahead by starting the seasoning process at least a year before intended use, especially for projects requiring dimensional stability. Softwoods, while faster to dry, still benefit from proper stacking and occasional rotation to ensure even moisture loss. A moisture meter is an invaluable tool here—aim for a reading of 12–15% moisture content for hardwoods and 8–12% for softwoods to guarantee readiness.

Consider the environmental factors that impact seasoning time. Wood stacked in a dry, well-ventilated area with consistent airflow will season faster than wood left in damp or humid conditions. Covering the stack with a tarp (while leaving the sides open) protects it from rain while still permitting airflow. For those in regions with harsh winters, start seasoning hardwoods in late spring to take advantage of warmer, drier months, ensuring the wood is ready by the following winter.

A comparative analysis reveals that while softwoods are quicker to season, their lower density makes them less durable for certain applications. Hardwoods, despite their longer seasoning time, offer superior strength and longevity, making them ideal for structural or high-wear projects. For instance, oak seasoned for a full year will outperform hastily dried pine in a fireplace, burning hotter and longer due to its reduced moisture content. This highlights the trade-off between time investment and end-use suitability.

Finally, patience is the key takeaway. Rushing the seasoning process, especially with hardwoods, can lead to costly mistakes. For example, using under-seasoned wood for indoor projects may result in mold growth or structural failure. By adhering to the ideal seasoning times—6–12 months for hardwoods and 3–6 months for softwoods—you ensure the wood’s stability, durability, and performance, ultimately saving time and resources in the long run. Treat seasoning as an investment in the wood’s future, not a step to be skipped or abbreviated.

Treated Wood Drying Time: How Long to Wait Before Covering

You may want to see also

Explore related products

Moisture Content Goal: Aim for 15–20% moisture content for optimal wood burning efficiency

Achieving the right moisture content in firewood is crucial for efficient burning, and the sweet spot lies between 15% and 20%. Wood freshly cut from a tree, known as green wood, typically contains 30% to 50% moisture. This high water content not only reduces the wood’s energy output but also leads to inefficient combustion, creosote buildup, and increased smoke. To reach the optimal range, wood must be seasoned—a process that involves air-drying to evaporate moisture. The time required for seasoning varies depending on wood type, climate, and storage conditions, but the moisture content goal remains constant: 15–20% for maximum efficiency.

Measuring moisture content isn’t guesswork; it’s science. A moisture meter, an affordable tool available at hardware stores, provides precise readings by inserting probes into the wood. For accurate results, test multiple pieces from the center of the stack, as outer layers may dry faster. If the meter reads above 20%, the wood needs more time to season. Below 15%, while rare, indicates overly dry wood, which burns too quickly. Aim for consistency within the 15–20% range to ensure a clean, hot burn that maximizes heat output and minimizes chimney hazards.

Seasoning wood to this moisture level isn’t just about efficiency—it’s about safety and sustainability. Wet wood releases more smoke and harmful particulates, contributing to air pollution and health risks. It also burns at lower temperatures, wasting fuel and increasing heating costs. By contrast, properly seasoned wood with 15–20% moisture content burns hotter, cleaner, and longer, reducing environmental impact and saving money. Think of it as a win-win: better performance for your fireplace or wood stove and a smaller carbon footprint.

Practical tips can accelerate the seasoning process while keeping the moisture goal in mind. Split logs into smaller pieces to increase surface area, allowing moisture to escape faster. Stack wood in a single row, off the ground, and expose it to sunlight and airflow. Cover the top of the stack with a tarp to protect from rain but leave sides open for ventilation. In humid climates, seasoning may take 12–24 months, while drier regions can achieve the 15–20% range in 6–12 months. Patience is key—rushing the process by burning unseasoned wood undermines the very goal of efficient, safe combustion.

Into the Woods Broadway Run: Duration and Legacy Explored

You may want to see also

Explore related products

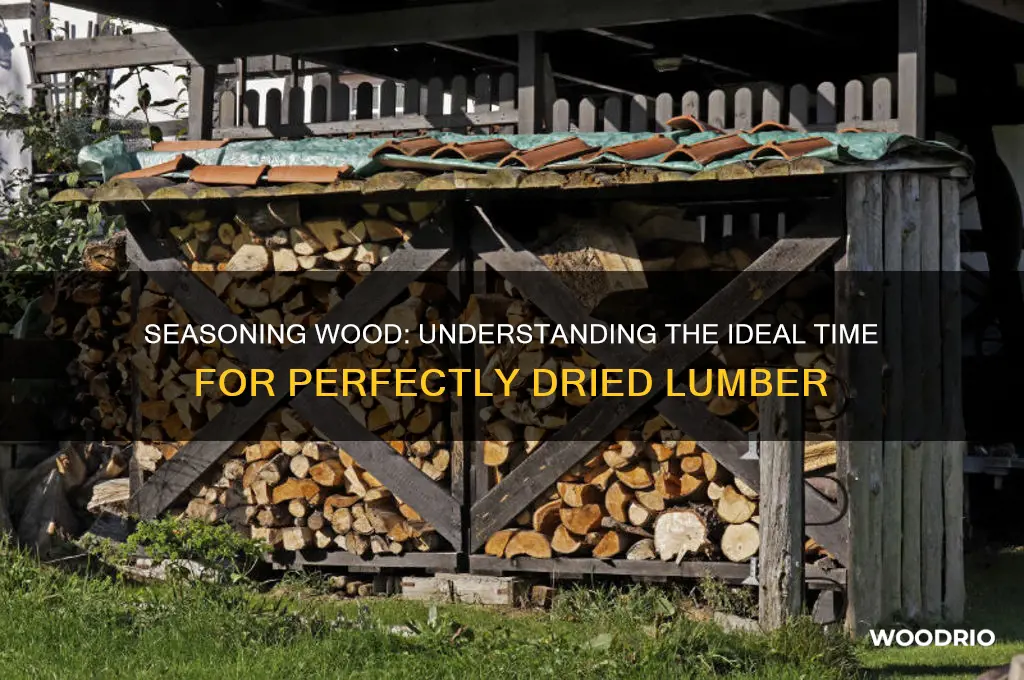

Stacking Methods: Split and stack wood in a dry, ventilated area for faster seasoning

Proper stacking is a critical yet often overlooked step in seasoning wood. The way you arrange split logs can significantly impact drying time, with well-stacked wood seasoning up to 50% faster than haphazard piles. Air circulation is the key principle: wood needs exposure to moving air on all sides to release moisture efficiently. Stacking in a single, neat row with uniform spacing between logs maximizes surface exposure, allowing wind and natural airflow to penetrate the pile. Avoid tight stacking, which traps moisture and creates pockets of humidity conducive to rot and mold.

Consider the stack’s orientation and structure. Position the pile in a north-south direction to benefit from prevailing winds, which typically blow east-west in the Northern Hemisphere. This simple adjustment can increase airflow through the stack. For added stability and ventilation, use a crisscross or "log cabin" stacking method, where layers alternate direction. This creates natural channels for air movement while preventing the pile from toppling. Incorporate wooden pallets or sturdy supports at the base to elevate the wood, keeping it off damp ground and promoting air circulation underneath.

While stacking, pay attention to log size and arrangement. Split wood into consistent lengths (typically 12–18 inches) to ensure even drying. Place larger, denser pieces on the bottom to provide stability, and reserve smaller pieces for the top layers. Leave 2–4 inches of space between logs and rows to allow air to flow freely. For added protection, cover the stack with a waterproof tarp, but only drape it over the top and sides—leave the ends open to maintain cross-ventilation. This prevents rain from soaking the wood while still permitting moisture to escape.

A common mistake is overloading the stack, which restricts airflow and slows seasoning. Limit piles to 4–6 feet high and 8–10 feet long for optimal results. Monitor the wood’s progress by checking moisture levels with a wood moisture meter; seasoned wood should read between 15–20% moisture content. Depending on climate and wood type, this process can take 6 months to 2 years, but proper stacking reduces this timeline significantly. For example, hardwoods like oak or maple may take up to 18 months, while softer woods like pine can season in 6–12 months with ideal conditions.

Finally, location matters. Choose a dry, sunny spot with good drainage to stack your wood. Avoid areas prone to standing water or excessive shade, as these environments prolong drying time and encourage decay. If possible, stack near a structure like a shed or fence to block rain from one side while maintaining openness for airflow. By combining strategic stacking methods with thoughtful placement, you can accelerate seasoning, ensuring a reliable supply of dry, efficient firewood for heating needs.

Understanding Cottonwood Tree Shedding: Duration and Seasonal Patterns

You may want to see also

Explore related products

Seasonal Considerations: Start seasoning in spring; wood cut in winter dries faster due to lower sap

Spring is the ideal time to begin seasoning firewood, a process that requires foresight and an understanding of nature's rhythms. As the days lengthen and temperatures rise, the wood's moisture content starts to decrease, setting the stage for effective drying. This seasonal shift is crucial, as it allows the wood to gradually acclimate to the environment, reducing the risk of cracking or splitting. By starting in spring, you're harnessing the natural warming trend, ensuring the wood is ready for the colder months ahead.

The timing of wood cutting plays a significant role in the seasoning process. Wood cut during winter months, when the sap is down, tends to dry faster. This is because the tree's sap, which acts as a natural preservative, is at its lowest level in winter, making the wood less dense and more porous. As a result, moisture evaporates more readily, shortening the overall seasoning time. For instance, hardwoods like oak or maple, when cut in winter, can season in as little as 6 months, compared to the typical 1-2 years required for wood cut in other seasons.

To optimize the seasoning process, consider the following steps: stack the wood in a dry, well-ventilated area, preferably off the ground to prevent moisture absorption; ensure the stack is loosely covered to protect it from rain while still allowing airflow; and periodically check the wood's moisture content using a moisture meter, aiming for a reading below 20% for optimal burning efficiency. By following these guidelines, you can significantly reduce the time required for seasoning, especially when combined with the natural advantages of spring and winter wood cutting.

A comparative analysis of seasoning times reveals the impact of seasonal considerations. Wood cut in spring or summer, when sap levels are high, can take up to 2 years to season properly. In contrast, winter-cut wood, with its lower sap content, can be ready in as little as 6-8 months. This disparity highlights the importance of strategic planning in firewood preparation. By aligning your wood cutting and seasoning activities with the natural cycles of the tree, you can minimize waste, reduce the risk of pest infestations, and ensure a steady supply of high-quality firewood.

In practice, this means that homeowners and woodworkers should plan their wood cutting activities around the winter months, taking advantage of the tree's natural state. For those who rely on firewood as a primary heat source, this seasonal approach can be a game-changer, providing a more efficient and cost-effective solution. By starting the seasoning process in spring with winter-cut wood, you're not only saving time but also ensuring a more consistent and reliable fuel source for the upcoming winter season. This strategic planning, combined with proper stacking and storage techniques, can make all the difference in achieving optimally seasoned firewood.

Exploring the Length of Wooden Flutes: A Comprehensive Guide

You may want to see also

Explore related products

Testing Readiness: Use a moisture meter or check for cracks and lighter weight to test dryness

Wood seasoning is a waiting game, but you don’t have to rely on guesswork to know when it’s ready. A moisture meter is your most precise tool, measuring the wood’s internal moisture content (MC) directly. For firewood, aim for an MC below 20%; for woodworking projects, 12–15% is ideal. Simply insert the meter’s probes into the wood, ensuring they penetrate at least 1 inch for accurate readings. This method eliminates ambiguity, making it the gold standard for professionals and hobbyists alike.

If you lack a moisture meter, sensory tests offer a practical alternative. Seasoned wood feels lighter due to reduced water weight, so compare it to a fresh piece of the same species. Additionally, inspect the wood for cracks or checks, which form as moisture escapes and the wood shrinks. These cracks are most visible at the ends of logs or boards and indicate advanced drying. However, beware: cracks alone don’t guarantee readiness; they merely suggest progress. Combine this observation with weight and appearance for a more reliable assessment.

For those without tools or experience, a comparative approach can suffice. Stack a piece of your seasoned wood alongside freshly cut wood of the same type. The contrast in weight and texture will be striking. Seasoned wood often has a duller, grayish surface compared to the fresh, vibrant color of green wood. While this method is less precise, it’s accessible and effective for casual users, such as homeowners preparing firewood for winter.

A cautionary note: relying solely on time or visual cues can lead to errors. Wood dries at different rates based on species, thickness, and environmental conditions. For instance, dense hardwoods like oak take significantly longer to season than softwoods like pine. Always test multiple pieces from your stack, as drying can be uneven. Combining moisture meter readings with sensory checks ensures you’re not fooled by surface-level dryness while the core remains damp.

In conclusion, testing wood readiness is a blend of science and observation. A moisture meter provides definitive data, while weight, cracks, and appearance offer supplementary clues. Tailor your approach to your needs and resources, but always prioritize accuracy to avoid the pitfalls of using unseasoned wood. Whether for a fireplace or a fine furniture project, knowing when your wood is truly dry is the key to success.

Durability of Dip-Treated Wood: Lifespan and Maintenance Tips

You may want to see also

Frequently asked questions

Wood typically needs to season for 6 to 12 months, depending on the type of wood, moisture content, and environmental conditions.

Yes, wood can season faster in warmer, drier climates, but proper stacking and airflow are still essential to ensure even drying.

Burning unseasoned wood can lead to inefficient combustion, increased creosote buildup in chimneys, and more smoke, so it’s best to wait until it’s fully seasoned.

Yes, hardwoods like oak or maple generally take longer to season (up to 12–24 months) compared to softwoods like pine, which can season in 6–12 months.