Wood decay is a natural process influenced by various factors, including the type of wood, environmental conditions, and the presence of decay-causing organisms like fungi and insects. Hardwoods, such as oak and teak, generally take longer to decay, often lasting decades or even centuries in dry, well-ventilated environments. Softwoods, like pine, decay more quickly, typically within a few years to a decade under similar conditions. However, when exposed to moisture, soil, or constant dampness, all wood types can deteriorate much faster, often within a few years. Additionally, treated or preserved wood can significantly extend its lifespan, sometimes lasting 20 to 40 years or more, depending on the treatment method. Understanding these factors is crucial for predicting wood longevity and implementing effective preservation strategies.

| Characteristics | Values |

|---|---|

| Type of Wood | Hardwoods (e.g., oak, teak) decay slower than softwoods (e.g., pine). |

| Environmental Conditions | Decay is faster in moist, warm, and humid environments. |

| Soil Type | Wet or waterlogged soil accelerates decay. |

| Exposure to Elements | Direct exposure to rain, sun, and wind speeds up decay. |

| Insect and Fungal Activity | Presence of termites, beetles, and fungi significantly accelerates decay. |

| Preservative Treatment | Treated wood (e.g., pressure-treated) can last 20–40+ years. |

| Untreated Wood in Soil | Decays within 5–10 years. |

| Untreated Wood Above Ground | Decays within 10–15 years, depending on conditions. |

| Submerged Wood (e.g., in water) | Can last decades or even centuries due to lack of oxygen. |

| Climate | Tropical climates accelerate decay compared to arid climates. |

| Wood Density | Higher density woods (e.g., cedar) resist decay better. |

| Average Lifespan Without Treatment | 5–15 years above ground; 10–20 years in soil. |

| With Treatment | Can last 20–100+ years depending on treatment type. |

Explore related products

What You'll Learn

- Factors Affecting Decay Rate: Moisture, temperature, wood type, and insect activity influence decay speed

- Softwood vs. Hardwood Decay: Softwoods decay faster than hardwoods due to lower density and resin content

- Environmental Conditions: Wet, warm environments accelerate decay; dry, cold conditions slow it down

- Preservation Methods: Treatments like pressure-treating, painting, or sealing can significantly extend wood lifespan

- Decay Timeline Estimates: Wood can decay in 5–50+ years depending on conditions and preservation

Factors Affecting Decay Rate: Moisture, temperature, wood type, and insect activity influence decay speed

Wood decay is a complex process influenced by a myriad of factors, each playing a pivotal role in determining how quickly or slowly wood breaks down. Among these, moisture stands out as the most critical. Wood in a constantly wet environment, such as submerged timber or wood exposed to frequent rain without proper drainage, can decay in as little as 5 to 10 years. Conversely, wood kept dry, like that in arid climates or well-ventilated indoor spaces, may persist for centuries. The key lies in managing moisture levels; even a slight reduction in humidity can significantly slow decay. For instance, treating wood with water-repellent sealants or ensuring proper ventilation can extend its lifespan by decades.

Temperature acts as a silent accelerator in the decay process, with warmer conditions fostering faster breakdown. In tropical regions, where temperatures consistently hover above 70°F (21°C), wood can decay 2 to 3 times faster than in cooler climates. This is because higher temperatures increase microbial activity, speeding up the enzymatic reactions that degrade wood fibers. Conversely, freezing temperatures can temporarily halt decay by slowing microbial growth, though repeated freeze-thaw cycles can physically weaken wood over time. For those in temperate zones, storing wood in shaded, cooler areas can mitigate temperature-driven decay, potentially doubling its durability.

Not all wood is created equal when it comes to decay resistance. Hardwoods like teak, cedar, and oak contain natural oils and tannins that repel fungi and insects, allowing them to last 30 to 50 years or more in outdoor conditions. Softwoods, such as pine and spruce, lack these protective compounds and typically decay within 5 to 15 years without treatment. Pressure-treating softwoods with preservatives like chromated copper arsenate (CCA) can extend their lifespan to 40 years or more, making them a cost-effective alternative for outdoor structures. Choosing the right wood type for the intended use is essential for maximizing longevity.

Insect activity often goes hand-in-hand with decay, as pests like termites and carpenter ants create pathways for moisture and fungi to penetrate wood. A single termite colony can consume up to 16 grams of wood per day, leading to structural failure in as little as 3 to 5 years if left unchecked. Preventative measures, such as applying insecticidal treatments or using naturally insect-resistant woods like cypress, can drastically reduce this risk. Regular inspections and prompt removal of infested wood are equally crucial, as early intervention can save both the wood and the surrounding structure from extensive damage.

Understanding these factors allows for proactive measures to preserve wood effectively. For example, combining moisture control with the use of decay-resistant wood types can yield the best results. In humid environments, pairing cedar with a waterproof sealant can extend its lifespan to 50 years or more. Similarly, in warmer climates, opting for treated pine and storing it in shaded areas can provide decades of use. By addressing moisture, temperature, wood type, and insect activity holistically, one can significantly slow decay and ensure wood remains functional and aesthetically pleasing for generations.

Linseed Oil Durability: How Long Does It Protect Wood Surfaces?

You may want to see also

Explore related products

Softwood vs. Hardwood Decay: Softwoods decay faster than hardwoods due to lower density and resin content

Wood decay is a natural process influenced by factors like moisture, fungi, and the wood’s inherent properties. Among these, the distinction between softwood and hardwood plays a critical role in determining how quickly wood breaks down. Softwoods, such as pine and cedar, decay faster than hardwoods like oak or maple due to their lower density and resin content. This difference isn’t just theoretical—it has practical implications for construction, landscaping, and even environmental impact. Understanding why softwoods are more susceptible to decay can help you make informed decisions about material selection and maintenance.

Consider the structural composition of softwoods and hardwoods. Softwoods, derived from coniferous trees, have larger cells and fewer protective compounds, making them more accessible to decay-causing fungi and insects. Hardwoods, on the other hand, are denser and often contain higher levels of natural resins and tannins, which act as barriers against biological invaders. For instance, a pine fence post in a damp environment might last only 5–10 years, while an oak post could endure for 20–30 years under similar conditions. This disparity highlights the importance of matching wood type to its intended use and environment.

If you’re planning a project, the decay rate of softwoods and hardwoods should factor into your material choice. Softwoods are ideal for temporary structures or applications where frequent replacement is feasible, such as garden beds or lightweight framing. However, for long-term projects like decking, flooring, or outdoor furniture, hardwoods are the better investment despite their higher cost. To extend the life of softwoods, consider treating them with preservatives like creosote or copper azole, which can add 5–10 years to their lifespan. For hardwoods, regular sealing or oiling can maintain their natural resistance and prevent moisture infiltration.

A comparative analysis reveals that while softwoods decay faster, they also offer advantages in terms of cost and workability. Softwoods are generally cheaper and easier to cut, nail, and shape, making them popular for DIY projects. Hardwoods, though more durable, require sharper tools and more effort to manipulate. For example, a softwood like spruce is often used for interior framing because it’s unlikely to be exposed to moisture, while a hardwood like teak is reserved for high-end outdoor applications due to its exceptional decay resistance. Balancing these trade-offs ensures you choose the right wood for the right job.

Finally, environmental factors can exacerbate the decay of softwoods, making proper placement and maintenance crucial. Softwoods in direct contact with soil or constantly exposed to moisture will deteriorate rapidly, while hardwoods can withstand such conditions for much longer. If you’re working with softwoods in a high-moisture environment, elevate the wood off the ground and ensure adequate ventilation. For hardwoods, periodic inspection for cracks or splits can prevent water penetration and prolong their life. By understanding the decay dynamics of softwoods and hardwoods, you can maximize the longevity of your wood projects while minimizing waste and cost.

Mastering the Art of Steering a Long Wood-Wheeled Wagon

You may want to see also

Explore related products

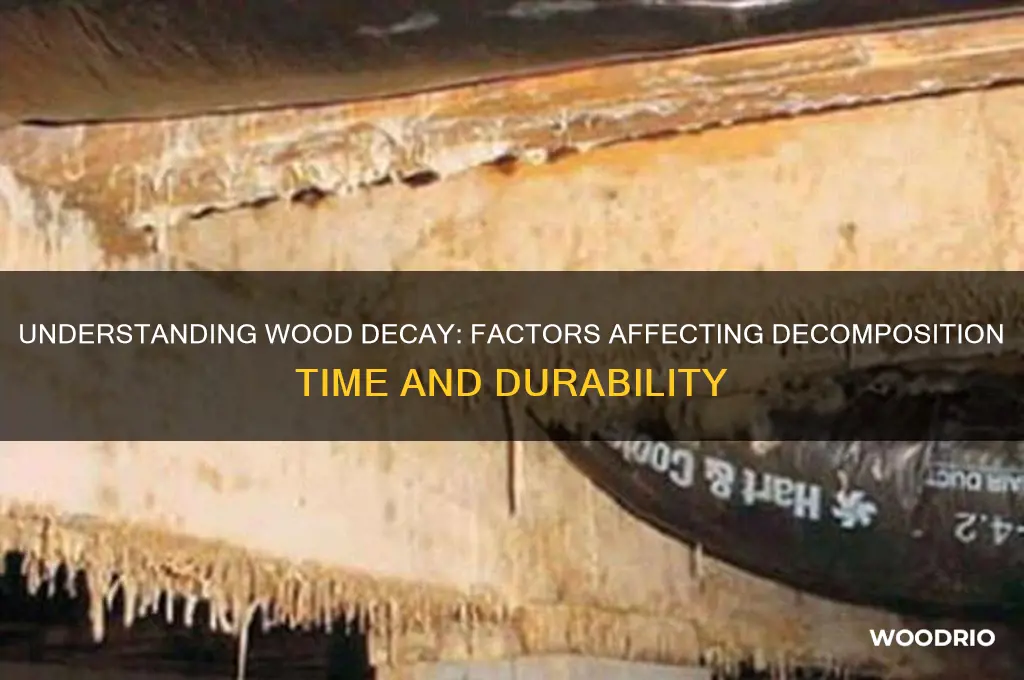

Environmental Conditions: Wet, warm environments accelerate decay; dry, cold conditions slow it down

Wood decay is a race between microorganisms and environmental conditions, with moisture and temperature as the key players. In wet, warm environments, fungi and bacteria thrive, breaking down cellulose and lignin—wood’s structural components—at an alarming pace. For instance, untreated lumber buried in damp soil in a tropical climate can decompose in as little as 5 to 10 years. Conversely, wood in arid, cold regions, like desert or tundra environments, may persist for centuries. The Arctic’s 40,000-year-old preserved forests are a testament to how dry, cold conditions act as a natural preservative, halting decay almost entirely.

To slow wood decay in wet, warm climates, proactive measures are essential. Elevate wooden structures off the ground to reduce soil contact, which minimizes moisture absorption. Apply water-repellent sealants or preservatives containing copper azole or creosote, which can extend wood life by 20–40 years. For outdoor furniture or decking, ensure proper drainage and ventilation to prevent water pooling. In contrast, wood in dry, cold environments requires less intervention but benefits from UV protection, as sunlight can still cause surface degradation over time. A single coat of UV-resistant stain can double its lifespan in such conditions.

The science behind these conditions lies in microbial activity and chemical reactions. Fungi, the primary agents of wood decay, require moisture to transport nutrients and spores. At temperatures above 70°F (21°C), their metabolic rates spike, accelerating decomposition. Below 40°F (4°C), most decay fungi become dormant, halting the process. Similarly, dry conditions deprive microorganisms of the water needed for enzymatic breakdown, effectively preserving wood. This is why ancient shipwrecks in cold, deep waters remain intact while those in shallow, warm seas disintegrate rapidly.

For practical applications, consider the environment when choosing wood treatments. In humid regions like Florida or Southeast Asia, opt for pressure-treated wood with a higher chemical concentration (e.g., 0.6% copper azole) to combat relentless moisture. In arid areas like Arizona or the Sahara, focus on UV protection rather than moisture resistance. If storing wood long-term, maintain a relative humidity below 20% and temperatures under 50°F (10°C) to mimic preservation conditions found in museums or archaeological sites. By aligning wood care with environmental factors, you can predict and control its decay timeline effectively.

Ickey Woods' NFL Career: Duration and Legacy Explored

You may want to see also

Explore related products

Preservation Methods: Treatments like pressure-treating, painting, or sealing can significantly extend wood lifespan

Wood, left untreated, succumbs to decay at varying rates depending on species, environment, and exposure. In humid climates, untreated pine might deteriorate within 5–10 years, while cedar, naturally resistant to rot, can last 15–20 years. Preservation methods, however, can dramatically alter this timeline, turning wood from a temporary material into a long-lasting resource. Treatments like pressure-treating, painting, or sealing act as shields, slowing the processes of rot, insect damage, and weathering that shorten wood’s lifespan.

Pressure-treating stands out as one of the most effective methods, particularly for outdoor applications. This process involves forcing preservatives, such as alkaline copper quaternary (ACQ) or chromated copper arsenate (CCA), deep into the wood’s cellular structure. ACQ, a safer alternative to CCA, is commonly used today due to its reduced environmental impact. Treated this way, wood can last 20–40 years or more, depending on exposure. For instance, pressure-treated lumber used in ground contact (like fence posts) will degrade faster than that used above ground (like decking). To maximize effectiveness, ensure the wood is properly sealed after cutting to prevent moisture intrusion at exposed ends.

Painting and sealing offer more accessible, DIY-friendly preservation options. Paint acts as a barrier, protecting wood from UV rays, moisture, and temperature fluctuations. For best results, apply a primer specifically designed for exterior wood, followed by two coats of high-quality exterior paint. Sealers, such as polyurethane or linseed oil, penetrate the wood to repel water and block fungal growth. Reapply these treatments every 2–3 years, or when signs of wear appear. For example, a cedar deck sealed annually can last 30–40 years, compared to 15–20 years without treatment. Always clean and sand the wood before application to ensure proper adhesion.

Comparing these methods reveals trade-offs. Pressure-treating provides the longest lifespan but requires professional application and limits the wood’s aesthetic appeal due to its greenish tint. Painting and sealing are more versatile and allow for customization but demand regular maintenance. For instance, a painted wooden fence may need repainting every 3–5 years, while a sealed outdoor table might require annual touch-ups. The choice depends on the wood’s intended use, desired appearance, and maintenance commitment.

In practice, combining these methods can yield optimal results. For example, pressure-treated lumber can be painted or stained to enhance durability and aesthetics. Similarly, sealing painted wood adds an extra layer of moisture protection. Regardless of the method chosen, the key to extending wood’s lifespan lies in proactive care. Regular inspections for cracks, splinters, or signs of rot, coupled with timely treatments, ensure wood remains functional and beautiful for decades. With the right preservation strategy, wood’s natural beauty and strength can endure far beyond its untreated lifespan.

How Long Does Stain Smell Linger on Treated Wood?

You may want to see also

Explore related products

Decay Timeline Estimates: Wood can decay in 5–50+ years depending on conditions and preservation

Wood decay is a natural process influenced by a myriad of factors, from environmental conditions to preservation techniques. Understanding the timeline of this decay is crucial for anyone working with wood, whether in construction, furniture making, or outdoor projects. The lifespan of wood can vary dramatically, ranging from as little as 5 years to over 50 years, depending on these conditions. This wide range highlights the importance of considering both the environment in which the wood is placed and the methods used to protect it.

Environmental Factors and Their Impact

Moisture, temperature, and exposure to organisms like fungi and insects are primary drivers of wood decay. In humid climates or areas with frequent rainfall, wood can begin to deteriorate within 5–10 years if left untreated. For instance, untreated pine in a damp, shaded area may show signs of rot within a decade, while the same wood in a dry, sunny environment could last 20 years or more. Temperature fluctuations also play a role; wood in regions with extreme weather cycles (e.g., freezing winters and hot summers) tends to degrade faster due to expansion and contraction. Understanding these environmental stressors is the first step in predicting and mitigating decay.

Preservation Techniques: Extending Wood’s Lifespan

Proper preservation can significantly slow decay, pushing the timeline to 30–50+ years. Pressure-treated wood, for example, is infused with preservatives like copper azole or alkaline copper quaternary (ACQ), which resist rot and insect damage. This treatment can extend the life of wood used in decks, fences, or outdoor structures to 40 years or more. Similarly, sealing wood with waterproof coatings or paints creates a barrier against moisture, while regular maintenance (e.g., reapplying sealants every 2–3 years) ensures longevity. For historical or indoor wood, techniques like borate treatment or heat modification can add decades to its lifespan without altering its appearance.

Comparative Analysis: Treated vs. Untreated Wood

The difference between treated and untreated wood is stark. Untreated softwoods like cedar or spruce may last 5–15 years in outdoor settings, while their treated counterparts can endure for 30–50 years. Hardwoods like teak or oak naturally resist decay better, lasting 20–30 years untreated, but even they benefit from preservation methods. For example, a teak patio set left unsealed may gray and weaken within 15 years, whereas a sealed and oiled set can remain functional for 30+ years. This comparison underscores the value of investing in preservation, especially for long-term projects.

Practical Tips for Maximizing Wood Lifespan

To ensure wood lasts as long as possible, consider these actionable steps:

- Choose the right wood: Opt for naturally durable species (e.g., redwood, cypress) or pressure-treated options for outdoor use.

- Seal and maintain: Apply a high-quality sealant or paint and reapply every 2–3 years to protect against moisture and UV damage.

- Elevate wood: Keep wood off the ground using concrete footings or gravel bases to reduce contact with soil and water.

- Monitor for damage: Regularly inspect for cracks, splinters, or signs of insect infestation, addressing issues promptly.

By tailoring preservation efforts to the specific conditions wood will face, you can effectively manage its decay timeline, ensuring it remains functional and aesthetically pleasing for decades.

Emulsion Drying Time on Wood: Factors Affecting Cure Duration

You may want to see also

Frequently asked questions

In a typical outdoor environment, untreated wood can begin to decay within 5 to 10 years, depending on factors like moisture, temperature, and exposure to insects or fungi. Treated or naturally rot-resistant woods (e.g., cedar or redwood) can last 20 to 30 years or longer.

Wood decays faster in waterlogged conditions because moisture promotes fungal growth, which is a primary cause of decay. In dry conditions, wood can last much longer, though it may still be susceptible to insect damage or UV degradation.

Yes, wood decay can be slowed or prevented through treatments like pressure-treating with preservatives, applying sealants or paints, ensuring proper ventilation to reduce moisture, and using naturally rot-resistant wood species. Regular maintenance also extends wood lifespan.

![Preservation [Import]](https://m.media-amazon.com/images/I/81+IBpvrysL._AC_UL320_.jpg)

![Permanent Preservation Edition 500 Series the Eternal [Blu-ray]](https://m.media-amazon.com/images/I/71qvs2rUzfL._AC_UL320_.jpg)

![Preservation Society [DVD]](https://m.media-amazon.com/images/I/31AJS2ZS1YL._AC_UL320_.jpg)