When considering the process of cremation, one may wonder about the environmental impact, particularly regarding the use of green wood in the cremation container or urn. After cremation, green wood, which is wood that has not been fully dried or seasoned, can take varying amounts of time to decompose or biodegrade, depending on factors such as the type of wood, environmental conditions, and the specific cremation process. Typically, green wood used in cremation containers or urns may take several months to a few years to fully break down, with the exact timeline influenced by factors like moisture levels, temperature, and microbial activity. Understanding this timeline is essential for those seeking eco-friendly cremation options, as it highlights the importance of choosing materials that align with their environmental values and the desired rate of decomposition.

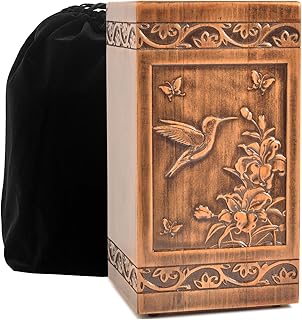

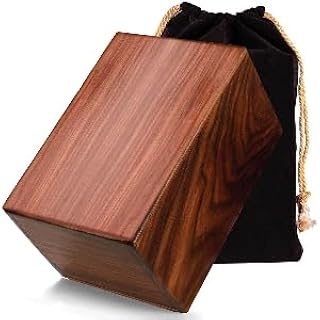

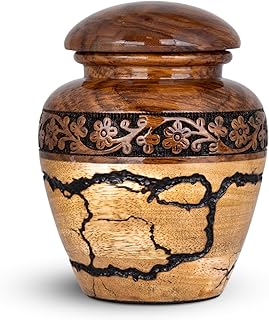

Explore related products

What You'll Learn

- Factors Affecting Drying Time: Moisture content, wood type, and environmental conditions impact green wood drying duration

- Cremation Heat Impact: High cremation temperatures accelerate moisture evaporation, reducing wood drying time significantly

- Wood Type Variations: Softwoods dry faster than hardwoods due to lower density and moisture retention

- Environmental Conditions: Humidity, temperature, and airflow influence how quickly green wood dries post-cremation

- Safety Precautions: Ensure wood is fully dried before handling to prevent burns or structural instability

Factors Affecting Drying Time: Moisture content, wood type, and environmental conditions impact green wood drying duration

Green wood's drying time is a critical factor in its post-cremation use, whether for memorial art or keepsakes. The process hinges on three primary variables: moisture content, wood type, and environmental conditions. Each plays a distinct role, and understanding their interplay ensures optimal results.

Moisture Content: The Foundation of Drying

The initial moisture level in green wood dictates how long it takes to dry. Freshly cut wood can contain up to 100% moisture relative to its dry weight, meaning it holds as much water as its own mass. For cremation-related crafts, wood with 20-30% moisture content is ideal, as it’s stable yet still workable. Reducing moisture from 100% to 30% can take weeks to months, depending on drying methods. Air-drying, for instance, removes about 1% moisture per week, while kiln-drying accelerates this to 5-10% per day. For cremation keepsakes, start with wood that’s already partially seasoned to save time.

Wood Type: Density and Structure Matter

Not all wood dries at the same rate. Softwoods like pine dry faster due to their lower density and larger cell structure, making them easier to process for cremation memorials. Hardwoods, such as oak or walnut, take longer because of their denser grain and higher natural oils. For example, pine may dry sufficiently in 6-8 weeks, while oak could require 6-12 months. If time is a constraint, opt for softwoods or pre-dried hardwoods. Always consider the wood’s final purpose—delicate cremation jewelry requires stable, fully dried wood to prevent cracking.

Environmental Conditions: The Invisible Hand

Temperature, humidity, and airflow are the unsung heroes of wood drying. Ideal conditions for green wood are temperatures between 60-90°F (15-32°C) and humidity below 60%. Higher temperatures speed evaporation but risk checking (surface cracks), while low humidity accelerates moisture loss. For cremation projects, maintain consistent airflow to prevent mold or uneven drying. A dehumidifier and fan in a well-ventilated space can cut drying time by half. Avoid direct sunlight, as it causes warping. For urgent needs, kiln-drying under controlled conditions is the most reliable method.

Practical Tips for Cremation Crafts

To ensure green wood is ready for cremation-related use, start by selecting wood with known moisture content or invest in a moisture meter (aim for 10-15% for stability). For hardwoods, plan at least 3-6 months ahead. Softwoods can be ready in 4-6 weeks if air-dried in optimal conditions. If time is critical, kiln-dried wood is the best option, though it may lack the natural aesthetic of slower-dried pieces. Always test small samples before committing to larger projects, as improperly dried wood can warp or crack during crafting. Patience and precision yield the best results for honoring memories through wood.

Rustoleum Drying Time on Wood: A Comprehensive Guide for DIYers

You may want to see also

Explore related products

Cremation Heat Impact: High cremation temperatures accelerate moisture evaporation, reducing wood drying time significantly

Cremation temperatures typically reach between 1,400°F and 1,800°F, a range far exceeding the heat used in traditional wood-drying methods. This extreme heat acts as a catalyst, rapidly breaking the hydrogen bonds that hold moisture within the cellular structure of green wood. As a result, water molecules are expelled at an accelerated rate, significantly reducing the time required for the wood to dry. For context, air-drying green wood can take months or even years, depending on the species and thickness, while cremation temperatures can achieve similar moisture reduction in a matter of hours.

Consider the practical implications for artisans or woodworkers who might repurpose cremation remnants. When green wood is exposed to such high temperatures, its drying process becomes nearly instantaneous, though the structural integrity of the wood is compromised due to the rapid loss of moisture. This means that while the wood may appear dry, it is more prone to cracking, warping, or splitting if not handled with care. To mitigate these risks, post-cremation wood should be stabilized using techniques like resin impregnation or slow cooling in a controlled environment.

From a comparative standpoint, the heat impact of cremation on green wood is akin to the effects of kiln drying but on a much shorter timescale. Kiln drying, which operates at temperatures between 120°F and 200°F, gradually removes moisture over days or weeks, allowing the wood to acclimate without severe structural damage. Cremation, however, is a brutal process that prioritizes speed over preservation. This makes cremation-dried wood unsuitable for most woodworking applications but potentially useful in niche scenarios, such as creating memorial artifacts where sentimental value outweighs material durability.

For those considering the use of cremation-dried wood, it’s essential to understand its limitations. The wood’s rapid drying process leaves it brittle and prone to degradation, making it ill-suited for load-bearing structures or fine craftsmanship. Instead, focus on applications that celebrate its symbolic significance rather than its physical properties. Small, decorative items like keepsake boxes or engraved tokens can be crafted, provided the wood is treated with a stabilizing agent to minimize further deterioration. Always wear protective gear when handling cremation remnants, as the wood may contain residual ash or chemicals from the cremation process.

In conclusion, while cremation temperatures drastically reduce the drying time of green wood, the trade-off is a material that lacks the stability and strength of traditionally dried wood. This unique characteristic, however, opens doors for creative and meaningful uses in memorial art or personal mementos. By understanding the science behind cremation’s heat impact and adopting appropriate stabilization techniques, artisans can transform this rapidly dried wood into lasting tributes that honor its origins.

OSB Wood Soaking Time: Factors Affecting Absorption and Durability

You may want to see also

Explore related products

Wood Type Variations: Softwoods dry faster than hardwoods due to lower density and moisture retention

Softwoods, such as pine or spruce, inherently dry more quickly than hardwoods like oak or maple due to their lower density and reduced moisture retention. This characteristic makes them a practical choice for applications where rapid drying is essential, including certain stages of cremation urn preparation. The cellular structure of softwoods contains larger, more open pores, allowing moisture to escape more freely. In contrast, hardwoods have denser, tighter grain patterns that trap moisture, prolonging the drying process. Understanding this distinction is crucial when selecting wood for cremation-related crafts, as it directly impacts the timeline for the wood to stabilize and become ready for use.

For those crafting cremation urns or memorial items, the drying time of green wood is a critical factor. Softwoods can air-dry in as little as 6 to 12 months, depending on thickness and environmental conditions, while hardwoods may require 1 to 2 years or more. Kiln-drying accelerates this process, reducing softwood drying time to weeks and hardwood to several months. However, kiln-drying must be carefully monitored to avoid warping or cracking, especially in denser hardwoods. If you’re working with green wood for a cremation project, prioritize softwoods for faster turnaround or plan well in advance if using hardwoods to ensure the wood is fully stabilized before crafting.

The choice between softwoods and hardwoods also influences the aesthetic and durability of the final product. Softwoods, while faster to dry, are less dense and more prone to dents or scratches, making them better suited for painted or protected finishes. Hardwoods, though slower to dry, offer superior durability and a richer, more polished appearance when finished. For cremation urns, consider the emotional significance of the piece: if time is a constraint, softwoods provide a practical solution, but for a long-lasting heirloom, hardwoods are worth the wait. Always seal the wood with a protective finish to enhance longevity, regardless of type.

Practical tips for managing wood drying times include storing wood in a well-ventilated, temperature-controlled environment to promote even moisture loss. Stacking softwoods with spacers allows air to circulate, speeding up drying, while hardwoods benefit from slower, more controlled conditions to prevent cracking. For urgent projects, pre-dried or kiln-dried wood is a reliable alternative, though it may lack the freshness of green wood. By aligning your wood choice with the project timeline and desired outcome, you can ensure the final piece honors its purpose with both beauty and stability.

Drying Cholla Wood: Timeframe and Tips for Perfect Preservation

You may want to see also

Explore related products

Environmental Conditions: Humidity, temperature, and airflow influence how quickly green wood dries post-cremation

Green wood, even after cremation, retains moisture that must evaporate before it can be considered fully dry. This process is heavily influenced by environmental conditions, particularly humidity, temperature, and airflow. Understanding these factors can help predict drying times and ensure the wood is safe for use or handling.

Humidity plays a critical role in moisture evaporation. High humidity levels slow down the drying process because the air is already saturated with water vapor, leaving little room for additional moisture from the wood to escape. For instance, in regions with 70% humidity or higher, green wood may take several weeks to dry, even under optimal temperature conditions. Conversely, in arid climates with humidity levels below 30%, the drying time can be significantly reduced, often to a matter of days. To expedite drying in humid environments, consider using dehumidifiers or storing the wood in a climate-controlled space.

Temperature directly affects the rate of evaporation. Higher temperatures increase the kinetic energy of water molecules, causing them to evaporate more quickly. For example, wood exposed to temperatures of 80°F (27°C) or above will dry faster than wood kept at 60°F (15°C). However, extreme heat can cause cracking or warping, so it’s essential to balance temperature with airflow. A consistent temperature range of 70–80°F (21–27°C) is ideal for efficient drying without damaging the wood. Avoid placing wood near direct heat sources like radiators or ovens, as this can lead to uneven drying.

Airflow is the unsung hero of the drying process. Proper ventilation ensures that moist air around the wood is continually replaced with drier air, accelerating evaporation. In stagnant environments, moisture becomes trapped, prolonging drying times. For optimal results, position the wood in a well-ventilated area, such as a workshop with open windows or a room with fans. If drying indoors, use oscillating fans to circulate air evenly around the wood. For larger pieces, elevate the wood on racks or blocks to allow air to flow underneath, reducing the risk of mold or mildew.

Practical tips for managing environmental conditions include monitoring humidity levels with a hygrometer and adjusting strategies accordingly. In high-humidity areas, pair dehumidifiers with fans for maximum efficiency. During colder months, maintain warmth with space heaters set to moderate temperatures. For outdoor drying, choose a shaded, breezy spot to prevent overheating while still benefiting from natural airflow. By controlling these environmental factors, you can significantly reduce the time it takes for green wood to dry post-cremation, ensuring it’s ready for its intended purpose.

Durable Wood Blinds: Lifespan, Maintenance, and Longevity Tips

You may want to see also

Explore related products

Safety Precautions: Ensure wood is fully dried before handling to prevent burns or structural instability

Green wood, freshly cut and still retaining moisture, poses significant risks when handled prematurely, especially in contexts like cremation or woodworking. Moisture content in wood can exceed 50% immediately after cutting, making it structurally weak and prone to warping. When used in cremation, damp wood can lead to incomplete combustion, releasing harmful gases or causing uneven burning. Handling such wood without proper drying increases the risk of burns from steam release or sudden structural failure, potentially causing injury.

To mitigate these risks, follow a systematic drying process. Air-drying is the most accessible method, requiring stacking wood in a well-ventilated area with spacers between pieces to allow airflow. For softwoods, this process takes 6–12 months; hardwoods may require 1–2 years. Kiln-drying accelerates this timeline to days or weeks but demands precise temperature and humidity control to avoid cracking. Moisture meters, available for $20–$100, are essential tools to confirm wood has reached a safe moisture level of 15–20% before use.

Instructive adherence to safety protocols cannot be overstated. Wear heat-resistant gloves and long sleeves when handling wood near heat sources, even if partially dried. Avoid using green wood in high-temperature applications like cremation until fully seasoned. For cremation purposes, consult cremation facility guidelines, as some prohibit green wood due to safety and environmental concerns. Always prioritize structural integrity: damp wood is 40–60% weaker than dried wood, making it hazardous for load-bearing or high-stress applications.

Comparatively, the risks of using green wood are akin to driving with worn brakes—both invite disaster through neglect of basic precautions. Just as brakes require maintenance, wood demands proper drying to ensure safety. Persuasively, consider the long-term benefits: dried wood burns cleaner, lasts longer, and reduces the likelihood of accidents. By investing time in drying, you safeguard both the material’s quality and your well-being, turning a potential hazard into a reliable resource.

Descriptively, imagine a stack of freshly cut logs, their surfaces glistening with moisture, contrasted with the same wood months later—smooth, lightweight, and ready for use. This transformation is not merely aesthetic but functional, marking the difference between danger and utility. Practical tips include covering drying wood to protect it from rain while allowing airflow, and rotating stacks periodically to ensure even drying. In cremation contexts, always verify wood moisture levels 24–48 hours before use, as residual moisture can compromise the process. By respecting the drying timeline, you ensure safety, efficiency, and peace of mind.

Understanding Balsa Wood Growth: Timeframe, Process, and Harvesting Insights

You may want to see also

Frequently asked questions

Green wood, which contains high moisture content, takes longer to combust compared to dry wood. It can take 30 minutes to 1 hour for green wood to fully ignite and begin contributing to the cremation process.

Yes, using green wood can extend the cremation time by 15–30 minutes due to the energy required to evaporate the moisture before combustion occurs.

While green wood can be used, dry wood is preferred for cremation as it burns more efficiently and reduces the overall time and energy consumption of the process.

Mixing green and dry wood can slow down the cremation process slightly, but the dry wood will help compensate for the moisture in the green wood, allowing the cremation to proceed more smoothly than using green wood alone.