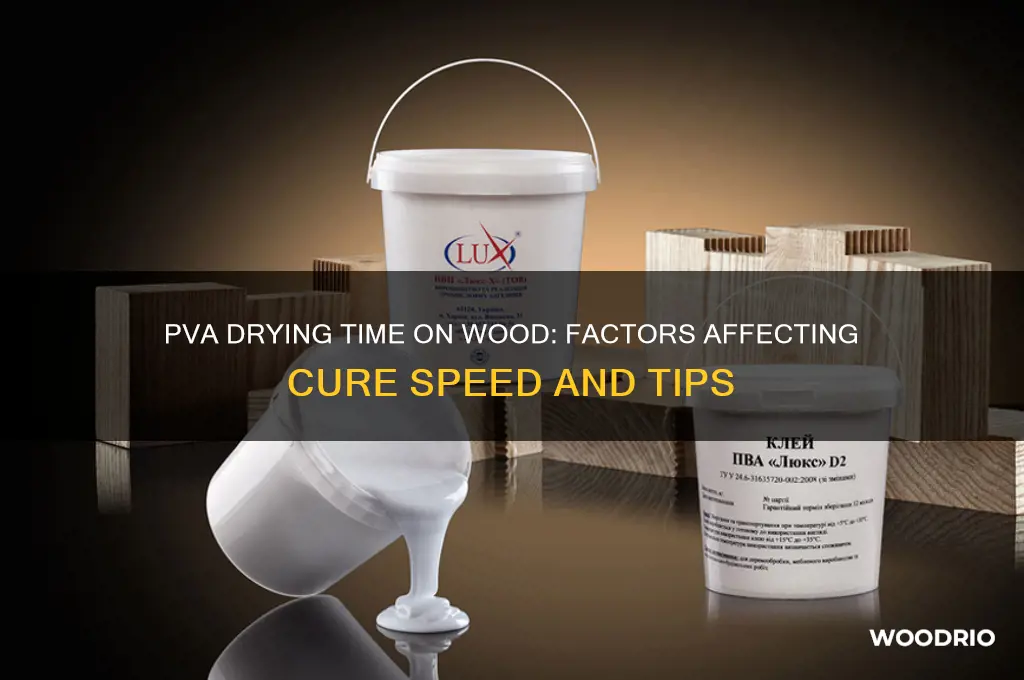

When applying Polyvinyl Acetate (PVA) glue to wood, understanding the drying time is crucial for ensuring a strong and durable bond. The drying time for PVA on wood typically ranges from 30 minutes to 24 hours, depending on various factors such as humidity, temperature, wood type, and the thickness of the glue layer. In ideal conditions—room temperature (around 20-25°C or 68-77°F) and moderate humidity—PVA glue will set within 30 minutes to an hour, but it may take up to 24 hours to fully cure and reach maximum strength. Accelerating the drying process can be achieved by using a fan or warm environment, while high humidity or cold temperatures may significantly prolong it. Always follow manufacturer guidelines and test on a small area to ensure optimal results.

| Characteristics | Values |

|---|---|

| Drying Time (Thin Coat) | 30 minutes to 2 hours (depending on humidity, temperature, and airflow) |

| Drying Time (Thick Coat) | 2 to 24 hours (or longer for very thick applications) |

| Cure Time (Full Hardness) | 24 to 48 hours |

| Optimal Drying Conditions | 65°F to 75°F (18°C to 24°C) with 40-70% humidity |

| Effect of Humidity | Higher humidity slows drying; lower humidity speeds it up |

| Effect of Temperature | Warmer temperatures accelerate drying; colder temperatures slow it down |

| Airflow Impact | Good ventilation reduces drying time |

| Wood Type Influence | Porous woods (e.g., pine) dry faster than dense woods (e.g., oak) |

| PVA Glue Type | Standard PVA dries slower than specialized wood glues |

| Re-coating Time | Wait at least 2 hours or until surface feels dry to the touch |

| Sanding After Drying | Can be sanded after fully cured (24-48 hours) |

| Water Resistance | Not waterproof; dries to a water-resistant bond |

| Bond Strength | Strong bond once fully cured |

Explore related products

$9.78

What You'll Learn

- Ideal Drying Conditions: Temperature, humidity, and airflow impact PVA drying time on wood surfaces

- Layer Thickness: Thicker PVA applications take longer to dry than thin coats

- Wood Type: Porous woods absorb moisture, potentially extending PVA drying time

- Accelerating Drying: Use fans or heaters to speed up PVA drying on wood

- Drying Time Estimates: PVA typically dries in 30 minutes to 2 hours on wood

Ideal Drying Conditions: Temperature, humidity, and airflow impact PVA drying time on wood surfaces

Polyvinyl acetate (PVA) glue dries through evaporation and polymerization, a process heavily influenced by environmental factors. Temperature plays a pivotal role: at 70°F (21°C), PVA typically achieves a tack-free surface within 30–60 minutes, but full curing can take 18–24 hours. Elevating the temperature to 85°F (29°C) accelerates drying by increasing molecular activity, reducing curing time by up to 30%. However, exceeding 100°F (38°C) risks weakening the bond due to rapid solvent evaporation before proper polymerization. Conversely, temperatures below 50°F (10°C) slow drying significantly, as the glue becomes viscous and less reactive.

Humidity acts as a counterbalance to temperature. High humidity (above 60%) prolongs drying by saturating the air with moisture, hindering solvent evaporation. For instance, in a 75% humidity environment, PVA may take 2–3 times longer to dry compared to 40% humidity. To mitigate this, maintain humidity between 40–50% for optimal drying. Dehumidifiers or air conditioners can be employed in damp conditions, while a humidifier may be unnecessary in already dry climates.

Airflow is the unsung hero of PVA drying. Stagnant air traps solvent vapors around the glue, slowing evaporation. Introducing a gentle airflow—via a fan placed 3–4 feet away—can reduce drying time by 20–40%. However, direct, forceful air can cause uneven drying or surface cracking, particularly on thin wood veneers. Aim for a consistent, low-velocity breeze rather than a strong draft.

Combining these factors yields the ideal drying conditions: a temperature of 70–85°F (21–29°C), humidity between 40–50%, and moderate airflow. For example, a workshop with a fan oscillating at low speed, a thermostat set to 75°F, and a dehumidifier running in the background creates an environment where PVA dries uniformly and efficiently. Always test a small area first to ensure conditions suit the wood type and glue application thickness.

Practical tips include pre-warming wood to room temperature before gluing, as cold surfaces slow initial drying. For large projects, consider applying glue in thin, even layers to promote faster evaporation. Avoid stacking or clamping glued pieces too tightly, as this restricts airflow and traps moisture. By controlling temperature, humidity, and airflow, you can optimize PVA drying time, ensuring a strong, durable bond on wood surfaces.

Seasoning Firewood: Understanding the Time It Takes for Optimal Results

You may want to see also

Explore related products

Layer Thickness: Thicker PVA applications take longer to dry than thin coats

The drying time of PVA glue on wood is directly influenced by the thickness of the applied layer. A thin coat, typically around 0.5–1 mm, can dry to the touch within 30–60 minutes under optimal conditions (room temperature, moderate humidity). However, thicker applications, exceeding 2 mm, may require 2–4 hours or more to achieve surface dryness, with full curing taking up to 24 hours. This disparity arises because thicker layers trap more moisture, slowing evaporation and prolonging the drying process.

To expedite drying, consider applying PVA in multiple thin coats rather than a single thick layer. For example, instead of spreading 3 mm of glue at once, apply three 1 mm coats, allowing each to dry for 1–2 hours before adding the next. This method not only reduces drying time but also improves adhesion and minimizes the risk of wrinkling or cracking. Use a brush or roller to ensure even distribution and avoid pooling, which can further delay drying.

Environmental factors compound the impact of layer thickness on drying time. In humid conditions (above 60% relative humidity), even thin coats may take 2–3 times longer to dry, while thicker applications could remain tacky for over 12 hours. Conversely, in dry environments (below 40% humidity) and with adequate ventilation, drying times can be significantly reduced. To optimize conditions, work in a well-ventilated area with a dehumidifier or fan, especially when applying thicker layers.

For projects requiring structural strength, patience is key. While surface dryness may occur within hours, thicker PVA layers need 24–48 hours to fully cure and reach maximum bond strength. Avoid subjecting glued joints to stress or weight during this period. If time is critical, consider using a PVA variant formulated for rapid drying, though these may sacrifice some bond strength. Always test drying times on a scrap piece of wood before starting your project to account for specific conditions and application thickness.

Chicken of the Woods Growth Timeline: How Long to Harvest?

You may want to see also

Explore related products

Wood Type: Porous woods absorb moisture, potentially extending PVA drying time

Porous woods, such as pine or oak, act like sponges when it comes to moisture absorption. This characteristic significantly influences how long PVA glue takes to dry. Unlike denser woods like maple or cherry, which repel moisture more effectively, porous woods soak up the water content in PVA, slowing evaporation. As a result, drying times can extend from the typical 30 minutes to 2 hours for a tack-free surface, and up to 24 hours for full curing. Understanding this relationship is crucial for anyone working with wood and PVA, as it directly impacts project timelines and structural integrity.

To mitigate extended drying times on porous woods, consider applying a thin sealant or wood conditioner before gluing. This creates a barrier that reduces moisture absorption, allowing the PVA to dry closer to its standard rate. Another practical tip is to use a fan or dehumidifier to increase air circulation and lower ambient humidity, which accelerates evaporation. For larger projects, clamping the glued pieces firmly ensures even pressure and minimizes gaps, even if drying takes longer. These steps not only speed up the process but also enhance the bond strength, ensuring a more durable result.

Comparing porous and non-porous woods highlights the trade-offs in wood selection. While porous woods like cedar offer natural resistance to decay and a rustic aesthetic, their moisture absorption can complicate gluing. Non-porous woods, such as walnut or mahogany, dry PVA more predictably but may lack certain natural properties. For instance, a pine bookshelf might take twice as long to assemble as one made from maple due to PVA drying times. Choosing the right wood type based on project requirements and environmental conditions can save time and improve outcomes.

Finally, patience is key when working with porous woods and PVA. Rushing the drying process by applying excessive heat or removing clamps prematurely can weaken the bond or warp the wood. Instead, plan for extended drying times and incorporate them into your project schedule. For example, if gluing porous wood joints, allow at least 12 hours before subjecting them to stress. By respecting the material’s properties and adjusting your approach, you can achieve strong, lasting results even with the challenges posed by porous woods.

Warren Beatty and Natalie Wood's Relationship Timeline: How Long?

You may want to see also

Explore related products

Accelerating Drying: Use fans or heaters to speed up PVA drying on wood

PVA glue typically takes 30 minutes to 2 hours to dry on wood, depending on factors like humidity, temperature, and glue thickness. However, when deadlines loom or impatience strikes, accelerating this process becomes crucial. Fans and heaters emerge as practical tools to expedite drying, leveraging the principles of evaporation and heat transfer. By increasing air circulation or raising ambient temperature, you can significantly reduce drying time without compromising bond strength.

To effectively use fans, position them at a 45-degree angle to the wood surface, ensuring even airflow across the glued area. Avoid directing the fan too close, as this can cause uneven drying or bubbling. For optimal results, maintain a distance of 12–18 inches between the fan and the wood. If using multiple fans, arrange them to create a cross-breeze, maximizing air movement around the project. This method can cut drying time by up to 50%, making it ideal for thin glue layers or small projects.

Heaters offer a more aggressive approach, particularly in colder environments where evaporation slows. Set a space heater to a low-medium setting, ensuring the temperature remains between 70°F and 90°F—any higher risks overheating the wood or glue. Place the heater at least 3 feet away to avoid localized hot spots. Combine heater use with a fan for best results, as the warm air accelerates evaporation while the fan prevents moisture buildup. This dual approach can reduce drying time to as little as 15–30 minutes for thin applications.

While fans and heaters are effective, caution is necessary. Excessive heat can weaken the bond or warp the wood, especially with delicate or thin pieces. Always monitor the drying process, and avoid leaving heaters unattended. For thicker glue layers, allow partial air drying before applying heat to prevent cracking. Pair these methods with proper glue application—use a thin, even coat—to ensure both speed and durability.

In practice, accelerating PVA drying with fans or heaters is a balance of science and technique. Fans excel in controlled environments, while heaters shine in colder settings. By understanding their mechanics and limitations, you can tailor your approach to the project’s needs, achieving faster results without sacrificing quality. Whether crafting furniture or repairing woodwork, this strategy transforms waiting time into productive progress.

Perfecting Activated Charcoal: Optimal Wood Cooking Time Explained

You may want to see also

Explore related products

Drying Time Estimates: PVA typically dries in 30 minutes to 2 hours on wood

PVA glue, a versatile adhesive commonly used in woodworking, typically dries on wood within a timeframe of 30 minutes to 2 hours. This range is influenced by several factors, including the wood's porosity, the glue's thickness, and environmental conditions such as humidity and temperature. Understanding these variables can help you optimize the drying process for your specific project.

Analytical Perspective:

The drying time of PVA on wood is not a fixed constant but a spectrum. For instance, softwoods like pine, which absorb moisture more readily, may accelerate drying to the lower end of the range (30–45 minutes). Conversely, hardwoods like oak, with denser fibers, can extend drying times closer to 2 hours. Thicker applications of glue also require more time to cure, as the adhesive needs to release moisture evenly. Monitoring these factors allows for better project planning, especially when working with multiple wood types or layers.

Instructive Approach:

To ensure optimal drying, apply PVA glue in a thin, even layer—no more than 1–2 mm thick. Use a clamp or weight to hold the wood pieces together firmly, as this prevents gaps and promotes even adhesion. In humid conditions (above 60% relative humidity), consider using a dehumidifier or fan to circulate air, reducing drying time. Conversely, in dry environments, lightly misting the wood surface before gluing can slow moisture evaporation, giving the glue more time to bond effectively.

Comparative Insight:

Compared to other wood adhesives, PVA’s drying time is relatively moderate. Epoxy resins, for example, can take 24 hours or more to fully cure, while hot glue sets almost instantly. PVA strikes a balance, offering sufficient working time for adjustments while still curing faster than many alternatives. This makes it ideal for projects requiring precision, such as furniture assembly or intricate joinery, where quick setting isn’t necessary but excessive wait times are impractical.

Practical Tips for Efficiency:

For time-sensitive projects, pre-fit your wood pieces to ensure a snug joint before gluing. Warming the glue slightly (to room temperature or slightly above) can also speed up drying, as PVA becomes more fluid and penetrates wood fibers faster. Avoid overheating, as this can degrade the adhesive’s properties. If working on a large surface, apply glue in sections to manage drying time and maintain control over alignment. Finally, always test a small area first to confirm drying behavior under your specific conditions.

By tailoring your approach to the unique demands of your project and environment, you can harness PVA’s drying characteristics effectively, ensuring strong, durable bonds every time.

Wooden Cliff Platforms: Understanding Their Decay Timeline in Nature

You may want to see also

Frequently asked questions

PVA glue typically takes about 30 minutes to 1 hour to dry to the touch on wood, but it can take 24 hours or more to fully cure, depending on humidity, temperature, and wood type.

Yes, higher temperatures (around 70–80°F or 21–27°C) speed up drying, while colder temperatures can significantly slow it down. Avoid extreme heat, as it may weaken the bond.

Yes, you can use a fan, warm air, or a hairdryer on a low setting to speed up surface drying, but avoid excessive heat. Clamping the wood also helps by ensuring even pressure and contact.

PVA glue is fully dry when it becomes clear and hard. Test by pressing lightly on the glued area—if it doesn’t indent or feel tacky, it’s likely cured.

Yes, denser woods like oak may slow drying slightly due to less moisture absorption, while softer woods like pine may dry faster. Properly prepared surfaces also improve drying time.

![[8.5 oz] Book Binding Glue, PH Neutral PVA Glue, Strong & Permanent Bond Bookbinding Adhesive Repair, Acid-Free, Dries Clear & Flexible for Book Repair, Framing, Collages, Paper Crafts and Art](https://m.media-amazon.com/images/I/61dmUQk5pKL._AC_UL320_.jpg)