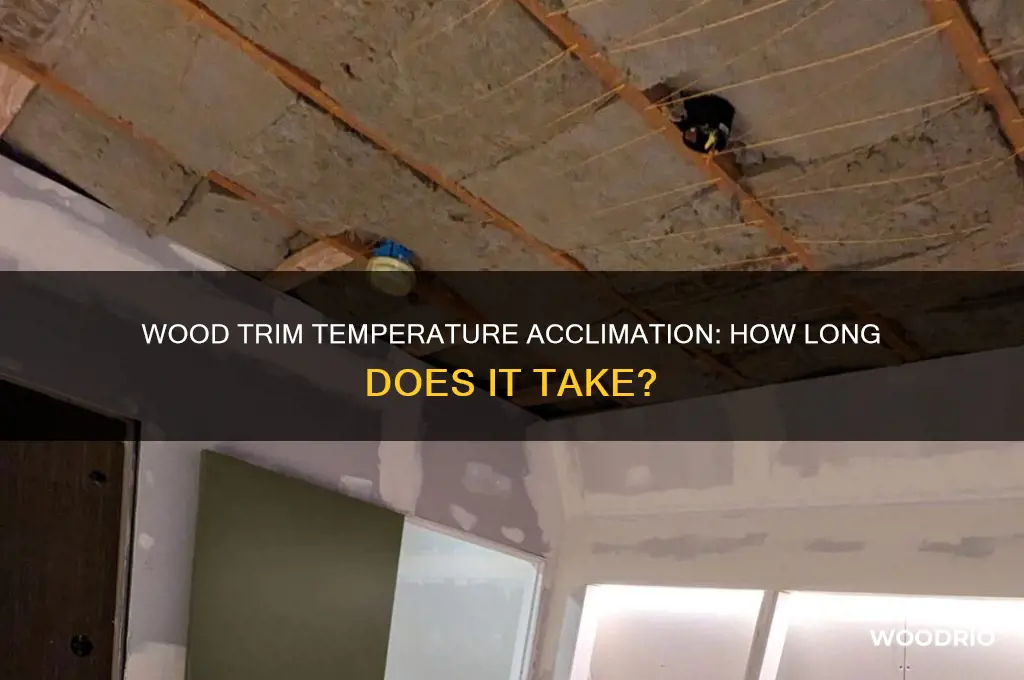

When considering how long it takes for wood trim to acclimate to room temperature, several factors come into play, including the type of wood, the initial temperature and humidity conditions, and the environment in which it is placed. Wood is a hygroscopic material, meaning it naturally absorbs and releases moisture in response to changes in its surroundings. Typically, wood trim requires anywhere from a few days to a couple of weeks to fully adjust to the ambient temperature and humidity levels of a room. This acclimation period is crucial to prevent warping, cracking, or other issues once the trim is installed, as it ensures the wood reaches equilibrium with its environment, minimizing the risk of future damage.

| Characteristics | Values |

|---|---|

| Time to Acclimate | 1-2 weeks (varies based on wood type, humidity, and room conditions) |

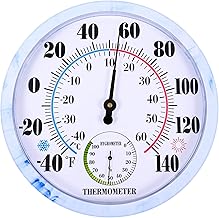

| Ideal Room Temperature | 60-80°F (15-27°C) |

| Ideal Humidity Range | 30-50% relative humidity |

| Wood Moisture Content Goal | Match the room's equilibrium moisture content (EMC), typically 6-8% |

| Factors Affecting Acclimation Time | Wood species, thickness, initial moisture content, and room conditions |

| Recommended Stacking Method | Sticker stacking with spacers to allow air circulation |

| Storage Environment | Dry, well-ventilated area away from direct sunlight or heat sources |

| Inspection Frequency | Check every few days for warping, cracking, or moisture changes |

| Minimum Acclimation Period | 5-7 days (for thinner pieces in stable conditions) |

| Maximum Acclimation Period | Up to 4 weeks (for thicker or denser wood in humid environments) |

Explore related products

What You'll Learn

Factors Affecting Acclimation Time

Wood trim acclimation time is not a one-size-fits-all scenario. Several factors influence how quickly wood adjusts to room temperature and humidity, ensuring a stable and durable installation. Understanding these variables is crucial for anyone working with wood trim, from DIY enthusiasts to professional carpenters.

Humidity Levels: The Primary Driver

The surrounding humidity is the most significant factor. Wood is hygroscopic, meaning it absorbs and releases moisture from the air. In high-humidity environments (above 60%), wood trim will absorb moisture, expanding and potentially warping. Conversely, in dry conditions (below 30%), it releases moisture, leading to shrinkage and cracks. Ideal acclimation occurs when the wood's moisture content matches the room's relative humidity. This process can take anywhere from 3-14 days, depending on the initial moisture content of the wood and the humidity differential.

For optimal results, aim for a room humidity between 40-50% during acclimation. Using a hygrometer to monitor humidity levels is highly recommended.

Temperature Fluctuations: A Secondary Influence

While humidity reigns supreme, temperature fluctuations also play a role. Rapid temperature changes can exacerbate the effects of humidity on wood. Extreme temperature swings can cause the wood to expand and contract more dramatically, increasing the risk of warping and splitting. Ideally, maintain a consistent room temperature between 60-75°F (15-24°C) during acclimation. Avoid placing wood trim near heat sources like radiators or fireplaces, as this can accelerate drying and lead to uneven shrinkage.

Pro Tip: If you're working in a climate with significant temperature variations, consider acclimating the wood in a controlled environment, such as a garage with a space heater or dehumidifier, before bringing it into the installation area.

Wood Species and Thickness: Inherent Characteristics Matter

Different wood species have varying densities and natural moisture contents, affecting acclimation time. Denser woods like oak and maple generally take longer to acclimate than softer woods like pine or cedar. Thicker pieces of trim will also take longer to adjust than thinner ones due to the greater volume of material.

Acclimation Best Practices: A Checklist

- Storage: Store wood trim in a flat, stacked position, allowing for air circulation between pieces.

- Unpacking: Open packaging and allow the wood to breathe upon arrival.

- Location: Choose a well-ventilated area with stable temperature and humidity for acclimation.

- Time: Allow for a minimum of 3 days acclimation, extending to 2 weeks for thicker pieces or extreme humidity differences.

- Monitoring: Regularly check the wood for signs of warping, cracking, or moisture accumulation.

By understanding these factors and following best practices, you can ensure your wood trim acclimates properly, leading to a successful and long-lasting installation.

India Ink Drying Time on Wood: A Comprehensive Guide

You may want to see also

Explore related products

Ideal Room Temperature Range

Wood trim, like any wooden material, acclimates to room temperature at a rate influenced by the ambient conditions. The ideal room temperature range for both comfort and material stability is typically between 68°F and 75°F (20°C and 24°C). At this range, wood trim expands or contracts minimally, reducing the risk of warping, cracking, or gaps. Humidity levels should complement this temperature, ideally staying between 30% and 50%, to ensure the wood neither dries out nor absorbs excess moisture. Achieving this balance allows wood trim to acclimate more predictably, usually within 2 to 3 weeks, depending on the initial temperature and humidity differences.

From an analytical perspective, the ideal room temperature range is not just about comfort but also about preserving the integrity of materials like wood trim. Temperatures below 60°F (15°C) can cause wood to shrink, while temperatures above 80°F (27°C) can lead to expansion. These fluctuations create stress on the wood, accelerating wear and tear. For example, in a newly constructed home, wood trim installed in a cold environment may take longer to acclimate if the indoor temperature is abruptly raised. Gradual temperature adjustments, paired with consistent humidity control, are key to minimizing these risks.

Instructively, maintaining the ideal room temperature range requires a combination of HVAC systems, dehumidifiers, and hygrometers. For wood trim acclimation, start by storing the trim in the room where it will be installed for at least 14 days before beginning work. Use a programmable thermostat to ensure temperature stability, and monitor humidity with a hygrometer, adjusting as needed. Avoid placing wood trim near heat sources like radiators or vents, as localized temperature spikes can disrupt acclimation. If the room’s temperature fluctuates widely, extend the acclimation period by 1 to 2 weeks to ensure the wood stabilizes fully.

Persuasively, investing in temperature and humidity control is not just a matter of aesthetics but also of long-term cost savings. Poorly acclimated wood trim can lead to costly repairs, such as filling gaps or replacing warped pieces. For instance, a homeowner who installs trim without proper acclimation might spend $500 to $1,000 on fixes within a year, compared to the minimal cost of maintaining ideal room conditions. By prioritizing the ideal temperature range, you protect both the structural integrity of your home and your wallet.

Comparatively, the ideal room temperature range for wood trim acclimation aligns with human comfort standards but requires stricter humidity control. While humans can tolerate a broader range of 65°F to 78°F (18°C to 26°C), wood trim demands consistency to avoid material stress. For example, a room maintained at 72°F (22°C) with 45% humidity is ideal for both occupants and wood materials, whereas a room at 78°F (26°C) with 60% humidity may feel comfortable to people but could cause wood to swell. This comparison highlights the need for tailored environmental control when working with sensitive materials like wood trim.

Spider Wood Waterlogging: Understanding the Timeframe for Aquarium Use

You may want to see also

Explore related products

Wood Moisture Content Impact

Wood moisture content is a critical factor in determining how long it takes for wood trim to acclimate to room temperature. Freshly milled wood can have a moisture content as high as 20%, while the equilibrium moisture content (EMC) for indoor wood in most climates ranges between 6% and 12%. This disparity creates a gradient that drives moisture movement, either into or out of the wood, until it reaches equilibrium with its environment. For example, wood installed in a humid climate without proper acclimation may swell, while wood installed in a dry environment can shrink, leading to gaps or warping. Understanding this dynamic is essential for preventing structural and aesthetic issues in woodworking projects.

To calculate acclimation time, consider the initial moisture content of the wood, the target EMC, and the environmental conditions. A rule of thumb is that wood loses approximately 1% of its moisture content per week in a controlled indoor environment. For instance, if wood trim has a moisture content of 15% and the target EMC is 9%, it would take roughly six weeks to acclimate. However, this timeline can vary based on factors like humidity, temperature, and airflow. Using a moisture meter to monitor the wood’s moisture content during acclimation ensures accuracy and reduces the risk of installation failures.

Practical steps for acclimating wood trim include storing it in the installation environment for the calculated period, stacking it with spacers to allow air circulation, and avoiding direct contact with walls or floors to prevent moisture absorption. In humid climates, a dehumidifier can expedite the drying process, while in dry climates, a humidifier may be necessary to prevent excessive moisture loss. For larger projects, consult a wood moisture content chart to determine the optimal acclimation period based on specific conditions. Proper acclimation not only preserves the integrity of the wood but also ensures long-term stability and performance.

Comparing acclimated and non-acclimated wood highlights the importance of this process. Non-acclimated wood is prone to dimensional changes post-installation, such as cupping, cracking, or separation from adjacent materials. For example, a study found that wood trim installed without acclimation in a dry environment experienced a 2% shrinkage rate within the first year, leading to visible gaps. In contrast, acclimated wood maintains its shape and structural integrity, reducing maintenance costs and enhancing the overall quality of the finished project. This comparison underscores the value of patience and planning in woodworking.

Finally, for those working with exotic or high-moisture wood species, additional precautions are necessary. Tropical hardwoods, such as teak or mahogany, often have higher natural moisture contents and may require extended acclimation periods—up to 12 weeks in some cases. Applying a moisture-resistant finish after acclimation can further protect the wood from environmental fluctuations. By prioritizing moisture content management, craftsmen and builders can ensure that wood trim not only reaches room temperature but also remains stable and durable for years to come.

Termites and Exterior Wood: Do They Create Long Holes?

You may want to see also

Explore related products

Acclimation Duration Guidelines

Wood trim acclimation is a critical step often overlooked in interior finishing projects. The duration required for wood trim to reach room temperature and humidity levels varies significantly based on factors like wood species, initial moisture content, and environmental conditions. Hardwoods such as oak or maple typically take longer to acclimate than softwoods like pine due to their denser cellular structure. As a rule of thumb, plan for 5 to 7 days of acclimation for every 4% difference in moisture content between the wood and the room. For instance, if the wood is at 12% moisture content and the room is at 8%, allow at least 10 days for proper acclimation.

To ensure accurate acclimation, follow these steps: first, store the wood trim in the room where it will be installed, stacking it horizontally with spacers to allow air circulation. Second, monitor the room’s humidity levels, aiming for a consistent range of 30% to 50% relative humidity. Third, avoid placing the wood near heat sources or in direct sunlight, as these can accelerate drying unevenly and cause warping. Finally, use a moisture meter to verify the wood’s moisture content matches the room’s equilibrium moisture content (EMC) before installation.

Comparing acclimation durations across different wood species highlights the importance of tailoring the process. Tropical hardwoods like mahogany or teak may require 2 to 3 weeks due to their high natural moisture content, while domestically sourced softwoods like cedar or fir often acclimate within 1 to 2 weeks. Engineered wood trim, with its layered construction, typically acclimates faster, often within 3 to 5 days, as it is designed to resist moisture fluctuations. Understanding these differences ensures the wood expands or contracts minimally after installation, preventing gaps or buckling.

A common mistake is rushing the acclimation process, which can lead to costly repairs later. For example, installing wood trim too soon in a newly constructed home with high humidity can result in shrinkage as the wood dries, leaving unsightly gaps. Conversely, installing trim in a dry environment without proper acclimation can cause the wood to absorb moisture and swell, leading to warping or splitting. Patience during this phase is not just a suggestion—it’s a necessity for long-term durability and aesthetic appeal.

Incorporating practical tips can streamline the acclimation process. For instance, if time is limited, consider using a dehumidifier or humidifier to stabilize the room’s conditions more quickly. Additionally, pre-finishing the wood trim before acclimation can help seal the wood, reducing moisture absorption or release. Always consult the manufacturer’s guidelines, as some pre-finished trims may have specific acclimation requirements. By adhering to these guidelines, you ensure the wood trim not only reaches room temperature but also harmonizes with its environment for a flawless finish.

Creosote's Longevity: How Long Does It Protect Wood Effectively?

You may want to see also

Explore related products

Signs of Proper Acclimation

Wood trim acclimates to room temperature when it reaches moisture equilibrium with its environment, typically taking 1-2 weeks depending on humidity, temperature, and wood species. Proper acclimation is crucial to prevent warping, cracking, or gaps after installation. Recognizing the signs of acclimation ensures the wood is ready for use, saving time and materials. Here’s how to identify when wood trim has fully adjusted.

Stability in Dimensions

One of the most reliable signs of proper acclimation is dimensional stability. Measure the width and thickness of the wood trim at the start of the acclimation period. After 1-2 weeks, remeasure the same pieces. If the dimensions remain consistent, the wood has likely reached equilibrium. Avoid using trim that continues to expand or contract, as this indicates ongoing moisture absorption or release. For precise results, use a moisture meter to confirm the wood’s moisture content matches the room’s relative humidity (ideally 6-8% for interior trim).

Absence of Visible Stress

Inspect the wood for signs of stress, such as cupping, bowing, or splitting. Properly acclimated trim will lie flat and show no visible distortion. Run your hand along the surface to check for smoothness and uniformity. If the wood feels even and free of raised edges or gaps, it’s ready for installation. Conversely, if you notice any warping or twisting, allow more time for acclimation or adjust the room’s humidity levels to facilitate the process.

Consistent Weight

Weight changes indicate moisture movement within the wood. Weigh a sample piece of trim at the beginning of the acclimation period and again after 1-2 weeks. If the weight remains stable, the wood has likely reached equilibrium. Significant weight loss suggests drying, while weight gain indicates moisture absorption. For best results, weigh the wood in the morning and evening to account for daily humidity fluctuations.

Response to Environmental Changes

Test the wood’s acclimation by exposing it to minor environmental changes. Place a piece of trim near a heater or air conditioner for a few hours and observe its reaction. Properly acclimated wood will show no signs of movement or stress. If the wood expands, contracts, or warps, it hasn’t fully adjusted. This test is particularly useful in climates with fluctuating humidity levels, ensuring the trim can withstand everyday conditions.

Practical Installation Test

Before committing to a full installation, fit a few pieces of trim together as a trial. Properly acclimated wood will join seamlessly without forcing or leaving gaps. If the pieces fit snugly and maintain their alignment, the trim is ready. Any resistance or misalignment indicates further acclimation is needed. This step not only confirms readiness but also prevents costly mistakes during installation.

Recognizing these signs ensures wood trim performs as expected, enhancing both durability and aesthetics. Patience during the acclimation process pays off in the long run, guaranteeing a professional finish.

Metal vs. Wood Porch Swings: Which Lasts Longer Outdoors?

You may want to see also

Frequently asked questions

Wood trim usually takes 3 to 7 days to acclimate to room temperature, depending on the humidity, temperature, and thickness of the wood.

Yes, denser hardwoods like oak may take longer to acclimate compared to softer woods like pine, but the difference is generally minimal, typically within the same 3 to 7-day range.

While you can’t drastically speed up acclimation, storing the wood in the room where it will be installed and maintaining consistent temperature and humidity levels can help it acclimate more efficiently.

Installing wood trim too soon can lead to warping, cracking, or gaps as the wood expands or contracts after installation. Always allow proper acclimation time to avoid these issues.