When considering the durability of a wooden ceiling, it’s important to clarify that wood itself does not rust, as rust is a process specific to iron and steel. However, a wooden ceiling’s lifespan can be affected by factors such as moisture, pests, and environmental conditions. Typically, a well-maintained wooden ceiling can last anywhere from 30 to 100 years or more, depending on the type of wood, quality of installation, and exposure to elements like humidity or termites. Proper ventilation, regular inspections, and timely treatments for pests or water damage are crucial to maximizing its longevity. If the question involves metal components or fasteners used in the ceiling, these could rust over time, potentially compromising the structure, but the wood itself remains unaffected by rust.

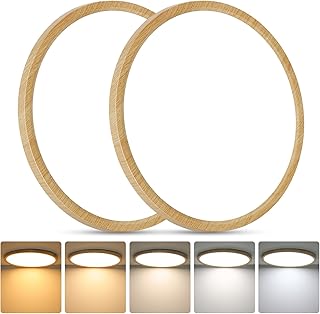

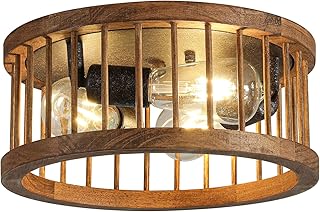

Explore related products

$32.48

What You'll Learn

Factors Affecting Wooden Ceiling Durability

Wooden ceilings, when properly maintained, can last for decades, even centuries. However, their durability is influenced by a combination of environmental, structural, and maintenance factors. Understanding these factors is crucial for maximizing the lifespan of a wooden ceiling and preventing issues like rot, warping, or insect damage.

Environmental Conditions: The Silent Adversaries

Moisture is the primary enemy of wooden ceilings. Prolonged exposure to humidity, leaks, or poor ventilation can lead to mold, mildew, and rot. For instance, in coastal areas or regions with high humidity, untreated wood can deteriorate within 5–10 years. To combat this, ensure proper waterproofing during installation, use moisture-resistant finishes, and maintain indoor humidity levels between 30–50%. Additionally, direct sunlight can cause fading and drying, leading to cracks. Installing UV-protective coatings or using curtains can mitigate this.

Wood Type and Treatment: The Foundation of Durability

Not all wood is created equal. Hardwoods like teak, oak, or cedar are naturally more resistant to decay and pests, lasting up to 50 years or more with minimal treatment. Softer woods like pine require chemical treatments such as pressure-treating or applying borate solutions to enhance durability. For example, pressure-treated pine can last 20–30 years in outdoor conditions, while untreated pine may only last 5–10 years. Always choose wood species and treatments suited to your climate and ceiling location.

Structural Integrity and Installation: The Hidden Risks

Improper installation can shorten a wooden ceiling’s lifespan. Inadequate support, incorrect spacing, or poor fastening can lead to sagging, warping, or detachment. For instance, using galvanized or stainless steel fasteners instead of regular nails can prevent rust and ensure longevity. Similarly, allowing proper expansion gaps (typically 1/8 inch per 10 feet of wood) accommodates natural movement without causing stress fractures. Hiring experienced installers and following manufacturer guidelines is essential.

Maintenance Practices: The Key to Longevity

Regular maintenance is non-negotiable for wooden ceilings. Inspect for cracks, stains, or pest infestations annually. Clean dust and debris using a soft brush or vacuum, and reapply protective finishes every 3–5 years. For painted ceilings, use high-quality, breathable paint to prevent peeling. In areas prone to termites, consider annual pest inspections and treatments. Proactive care can extend a wooden ceiling’s life by 20–30 years, making it a worthwhile investment.

By addressing these factors—environmental conditions, wood type and treatment, structural integrity, and maintenance—you can ensure your wooden ceiling remains a timeless and durable feature of your space.

Chicken of the Woods Growth Timeline: From Spores to Harvest

You may want to see also

Explore related products

Preventing Rust on Metal Components

Rust, the silent adversary of metal, thrives in environments where moisture and oxygen conspire against structural integrity. Preventing its formation on metal components requires a proactive approach that combines material selection, protective coatings, and environmental control. For instance, galvanized steel, coated with a layer of zinc, offers a sacrificial barrier that corrodes instead of the base metal, extending lifespan by decades in humid conditions. Similarly, stainless steel, alloyed with chromium, forms a passive oxide layer that resists rust without external intervention. These examples underscore the importance of choosing rust-resistant materials as the first line of defense.

Beyond material selection, protective coatings play a pivotal role in rust prevention. Epoxy paints, for example, provide a durable, moisture-resistant barrier when applied in two coats, each 2-3 mils thick. For smaller components, immersion in a rust-inhibiting oil or wax creates a hydrophobic seal, ideal for tools stored in damp environments. Powder coating, another effective method, involves baking a polymer onto the metal surface at 400°F, resulting in a finish that withstands both corrosion and abrasion. However, improper surface preparation—such as failing to remove grease or old paint—can render these coatings ineffective, emphasizing the need for meticulous cleaning before application.

Environmental control complements these measures by minimizing the conditions that foster rust. In industrial settings, dehumidifiers maintain relative humidity below 50%, a threshold at which rust formation accelerates. For outdoor structures, strategic design elements like overhangs and drainage systems reduce water accumulation on metal surfaces. Even simple practices, such as storing tools in airtight containers with silica gel packets, can significantly prolong their rust-free life. These methods, while varied, share a common goal: disrupting the moisture-oxygen interaction that initiates corrosion.

Despite these preventive measures, no solution is infallible. Regular inspection and maintenance are critical to identifying early signs of rust, such as discoloration or flaking paint. When detected, affected areas should be sanded down to bare metal, treated with a rust converter (a phosphoric acid solution that neutralizes corrosion), and recoated. This cyclical process ensures that metal components remain functional and aesthetically intact, even in challenging environments. By integrating material science, protective technologies, and environmental management, rust prevention becomes not just possible, but practical.

Durability of Wooden Railroad Ties: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Maintenance Tips for Longevity

Wooden ceilings, while aesthetically pleasing, are susceptible to moisture, pests, and wear over time. To ensure their longevity, proactive maintenance is essential. Regular inspections are the cornerstone of this process. At least twice a year, examine your wooden ceiling for signs of warping, discoloration, or pest activity. Pay close attention to areas near bathrooms, kitchens, or exterior walls, as these are prone to higher humidity levels. Early detection of issues like mold or termite damage can prevent costly repairs and extend the ceiling’s lifespan by decades.

Moisture control is critical in preserving wooden ceilings. Install a dehumidifier in spaces with high humidity, aiming to keep indoor moisture levels below 50%. For added protection, apply a waterproof sealant or varnish every 3–5 years, depending on the manufacturer’s recommendations. If your ceiling is in a particularly damp area, consider using a mildew-resistant primer before sealing. This two-step approach not only repels moisture but also inhibits fungal growth, a common culprit in wood deterioration.

Pest prevention is another vital aspect of maintenance. Termites and wood-boring beetles can silently compromise the structural integrity of your ceiling. To deter these pests, ensure the wood is treated with a borate-based solution during installation or as a retrofit treatment. Additionally, keep the surrounding area clean and free of wood debris, which can attract pests. For ongoing protection, consult a pest control professional to set up bait stations or apply preventive treatments every 12–18 months.

Finally, address minor damages promptly to avoid larger issues. Small cracks or chips in the wood can be filled with epoxy wood filler, followed by sanding and resealing. For more significant damage, such as rotting sections, replace the affected planks immediately. When repairing or replacing wood, ensure the new pieces match the original in terms of type, grain, and finish to maintain aesthetic consistency. By combining these targeted maintenance strategies, you can significantly prolong the life of your wooden ceiling, often exceeding 50 years with proper care.

Granville T. Woods: Revolutionizing Long-Distance Communication with Innovative Inventions

You may want to see also

Explore related products

Signs of Wooden Ceiling Deterioration

Wooden ceilings, while aesthetically pleasing, are susceptible to deterioration over time. Recognizing the early signs of wear can prevent costly repairs and ensure longevity. One of the first indicators is discoloration or dark spots, often caused by moisture infiltration or mold growth. These stains may appear as small patches initially but can spread rapidly if left unaddressed. Inspect areas near windows, skylights, or plumbing fixtures, as these are common entry points for water.

Another telltale sign is warping or buckling of the wood. This occurs when the wooden planks absorb moisture, causing them to expand and distort. Warped ceilings not only compromise the structural integrity but also detract from the visual appeal. To test for warping, run your hand along the surface; any noticeable ridges or uneven areas warrant immediate attention. Addressing the moisture source and replacing affected planks can mitigate further damage.

Pest infestations, particularly termites or carpenter ants, pose a significant threat to wooden ceilings. Look for small holes, sawdust-like frass, or hollow-sounding wood when tapped. These pests can weaken the structure from within, often going unnoticed until extensive damage has occurred. Regular inspections by a pest control professional are advisable, especially in older homes or humid climates.

Finally, cracks or splitting in the wood signal aging or exposure to extreme temperature fluctuations. While minor cracks may be cosmetic, larger splits can allow moisture or pests to penetrate deeper layers. Applying a protective sealant or varnish can help prevent cracking, but severe cases may require partial or full replacement. Monitoring these signs ensures your wooden ceiling remains both functional and beautiful for years to come.

Citristrip on Wood: Optimal Time for Effective Paint Removal

You may want to see also

Explore related products

Best Practices for Rust Prevention

Wooden ceilings, while aesthetically pleasing, are not inherently susceptible to rust since rust is a corrosion process specific to iron and its alloys. However, metal components like nails, brackets, or fasteners used in wooden ceilings can rust, compromising structural integrity and appearance. Preventing rust on these elements is crucial for longevity. Here’s how to do it effectively.

Material Selection: The First Line of Defense

Choose galvanized or stainless steel fasteners instead of standard carbon steel. Galvanized steel has a zinc coating that acts as a sacrificial layer, corroding before the underlying metal does. Stainless steel, with its chromium content, forms a passive oxide layer resistant to rust. For existing installations, inspect and replace rusted fasteners immediately. If using wood adhesives instead of metal, ensure they’re rated for structural applications and compatible with your ceiling’s environment.

Environmental Control: Managing Moisture and Exposure

Rust thrives in damp, oxygen-rich environments. In areas prone to humidity, such as kitchens or basements, install a vapor barrier or dehumidifier to reduce moisture levels. Proper ventilation is equally critical—ensure exhaust fans are functional and air circulates freely. For outdoor wooden ceilings, apply a waterproof sealant to the wood and use silicone-based coatings on metal components to repel water. Regularly inspect for leaks or water damage, addressing issues within 48 hours to prevent prolonged exposure.

Protective Coatings: A Barrier Against Corrosion

Apply rust-inhibiting primers and paints to metal parts before installation. Products containing phosphates or tannic acid convert rust into a stable compound, halting its spread. For maintenance, reapply coatings every 2–3 years, sanding lightly to ensure adhesion. Avoid oil-based products in humid areas, as they can trap moisture. Instead, opt for epoxy or polyurethane coatings, which provide superior moisture resistance and durability.

Maintenance and Inspection: Proactive Preservation

Schedule biannual inspections to catch early signs of rust. Use a wire brush or sandpaper to remove surface rust, then treat with a rust converter before repainting. For severe cases, replace affected components entirely. Keep a maintenance log noting areas of concern and actions taken. In coastal regions, where salt accelerates corrosion, increase inspections to quarterly and consider using marine-grade metals and coatings.

By combining strategic material choices, environmental management, protective coatings, and vigilant maintenance, you can significantly extend the lifespan of metal components in wooden ceilings. While wood itself won’t rust, safeguarding its associated metals ensures the ceiling remains both functional and beautiful for decades.

Wood Pigeon Egg Incubation: Understanding Their Nesting Duration

You may want to see also

Frequently asked questions

A wooden ceiling can last 30 to 100 years or more, depending on factors like wood quality, maintenance, and environmental conditions.

No, wood does not rust; rust is a process that occurs in metal. However, wood can rot, warp, or decay if exposed to moisture or pests.

Premature deterioration can be caused by water damage, termite infestations, poor ventilation, UV exposure, or lack of proper sealing and maintenance.

Regularly inspect for damage, apply protective finishes or sealants, ensure proper ventilation, address moisture issues promptly, and treat for pests if necessary.