Pressed wood, also known as engineered wood or composite wood, has been in use for centuries, with its origins dating back to ancient civilizations. The earliest forms of pressed wood can be traced to ancient Egypt and Rome, where wood shavings and sawdust were mixed with natural adhesives to create rudimentary panels. However, it wasn't until the 19th century that pressed wood began to take shape as we know it today. In the 1850s, the invention of the first wood-based panels, such as plywood, marked a significant milestone in the development of pressed wood. Since then, advancements in technology and manufacturing processes have led to the creation of various types of pressed wood, including particleboard, MDF (medium-density fiberboard), and OSB (oriented strand board). Today, pressed wood is widely used in construction, furniture making, and interior design, thanks to its affordability, versatility, and sustainability. With a history spanning over a millennium, pressed wood continues to evolve, offering innovative solutions for modern applications while maintaining its position as a staple material in the building and manufacturing industries.

| Characteristics | Values |

|---|---|

| First Use of Pressed Wood | Mid-19th century (1850s) |

| Early Commercial Production | Late 19th century (1880s) |

| Widespread Adoption | Early 20th century (1900s-1920s) |

| Modern Advancements | Mid-20th century (1940s-1950s) with the development of particleboard and MDF |

| Current Status | Widely used globally in furniture, construction, and interior design |

| Key Innovations | Introduction of formaldehyde-based resins (1920s), development of oriented strand board (OSB) in the 1960s |

| Environmental Impact | Concerns over formaldehyde emissions led to stricter regulations in the 1980s and 2000s |

| Estimated Age | Over 170 years since first use |

Explore related products

$12.19 $18.99

What You'll Learn

Early origins of pressed wood

Pressed wood, a staple in modern furniture and construction, traces its roots back to ancient civilizations, where early forms of engineered wood were developed out of necessity and ingenuity. One of the earliest examples dates to ancient Egypt, around 2500 BCE, where artisans used layers of wood veneers glued together to create decorative panels and structural elements. These early composites were not yet pressed under high pressure, but they laid the groundwork for the concept of combining wood fibers to enhance strength and durability. The Egyptians’ use of wood laminates in sarcophagi and temple decorations demonstrates humanity’s long-standing desire to manipulate natural materials for both functional and aesthetic purposes.

The next significant leap in pressed wood technology emerged during the Industrial Revolution in the 19th century. With the advent of steam power and mechanized tools, manufacturers began experimenting with compressing wood fibers under high pressure to create denser, more uniform materials. In 1855, the invention of the first commercial wood pulp process by German chemist Friedrich Gottlob Keller paved the way for particleboard and fiberboard. By the late 1800s, these early forms of pressed wood were being used in Europe for furniture and insulation, marking the transition from handcrafted composites to mass-produced engineered wood products.

A pivotal moment in the history of pressed wood came in the early 20th century with the development of plywood. In 1905, the Portland Manufacturing Company in the United States patented a process for gluing thin layers of wood veneer at right angles, creating a strong, stable material resistant to warping. This innovation revolutionized construction and furniture design, as plywood offered a cost-effective alternative to solid wood. Its widespread adoption during World War I for aircraft construction further solidified its importance, showcasing the versatility and strength of pressed wood in demanding applications.

While these advancements were transformative, it’s important to note that early pressed wood products were not without limitations. The glues used in the 19th and early 20th centuries, such as animal-based adhesives, were prone to degradation over time, particularly in humid conditions. It wasn’t until the mid-20th century, with the introduction of synthetic resins like urea-formaldehyde, that pressed wood became truly durable and versatile. This evolution highlights the iterative nature of innovation, where each breakthrough builds on the successes and failures of its predecessors.

Today, the early origins of pressed wood serve as a reminder of humanity’s enduring quest to harness natural resources more efficiently. From ancient Egyptian veneers to modern particleboard, the journey of pressed wood reflects broader trends in material science and manufacturing. For those looking to incorporate pressed wood into their projects, understanding its history can provide valuable insights into its strengths and limitations. For instance, while plywood remains a go-to choice for structural applications, newer products like MDF (medium-density fiberboard) offer smoother surfaces ideal for painting and detailing. By appreciating the past, we can make more informed decisions about the materials shaping our future.

Exploring Muir Woods: Average Walking Time and Trail Tips

You may want to see also

Explore related products

Industrial Revolution advancements

Pressed wood, in its earliest forms, dates back to ancient civilizations, but its industrialization and widespread use are deeply rooted in the advancements of the Industrial Revolution. This period, spanning the late 18th to early 19th centuries, revolutionized manufacturing processes, and pressed wood was no exception. The invention of steam-powered machinery enabled the mass production of wood composites, making materials like particleboard and plywood more accessible and affordable. These innovations laid the groundwork for the modern pressed wood industry, transforming how furniture, construction, and packaging were approached.

One of the most significant Industrial Revolution advancements was the development of hydraulic presses, which allowed for greater precision and efficiency in compressing wood fibers. By the mid-19th century, these presses could exert thousands of pounds of pressure, bonding wood particles with adhesives like animal glue or natural resins. This process not only reduced waste by utilizing wood scraps but also created a stronger, more durable material than solid wood alone. For instance, plywood, invented in the 1850s, became a staple in shipbuilding and later in aviation, showcasing the versatility of pressed wood in industrial applications.

The Industrial Revolution also spurred the creation of synthetic adhesives, a critical component in pressed wood manufacturing. In the late 19th century, casein glues, derived from milk proteins, replaced traditional animal glues, offering better bonding strength and water resistance. By the early 20th century, urea-formaldehyde resins emerged, further enhancing durability and reducing costs. These advancements made pressed wood a viable alternative to solid wood, particularly in mass-produced furniture and housing, where affordability and scalability were paramount.

Comparatively, the pre-industrial methods of creating wood composites were labor-intensive and limited in scale. The Industrial Revolution’s emphasis on mechanization and chemical innovation democratized pressed wood, making it a cornerstone of modern manufacturing. Today, pressed wood products like MDF (medium-density fiberboard) and OSB (oriented strand board) are ubiquitous in construction and design, a testament to the enduring legacy of these advancements. Without the Industrial Revolution’s breakthroughs, pressed wood might have remained a niche material, rather than a global industry worth billions.

To leverage pressed wood effectively in modern applications, consider its historical evolution. For structural uses, opt for plywood or OSB, which retain the strength and layering techniques pioneered in the 19th century. For finer finishes, MDF, a product of 20th-century refinements, offers a smooth surface ideal for painting or veneering. Always prioritize formaldehyde-free or low-emission products, as modern regulations address health concerns tied to early synthetic adhesives. By understanding the Industrial Revolution’s role in shaping pressed wood, you can make informed choices that balance history, functionality, and sustainability.

Durability of Wood Gazebos: Lifespan and Maintenance Tips

You may want to see also

Explore related products

20th-century mass production

Pressed wood, a staple of modern furniture and construction, owes much of its ubiquity to 20th-century mass production techniques. The early 1900s saw the emergence of particleboard, one of the first pressed wood products, which was initially developed in Germany during World War II as a cost-effective alternative to solid wood. By the mid-20th century, advancements in resin technology and mechanization allowed manufacturers to produce pressed wood on an unprecedented scale. This era marked a turning point, as pressed wood transitioned from a niche material to a cornerstone of affordable, accessible furniture and building materials.

The mass production of pressed wood was driven by the need to meet the demands of a growing global population and post-war housing booms. Factories began using large hydraulic presses to compress wood chips, sawdust, and resins into dense, uniform sheets. This process not only reduced waste from lumber mills but also made wood products more affordable for the average consumer. For instance, by the 1950s, particleboard and plywood were widely used in kitchen cabinets, shelving, and even affordable housing projects, democratizing access to durable, functional materials.

One of the most significant innovations during this period was the development of medium-density fiberboard (MDF) in the 1960s. MDF, made by breaking down wood into fine fibers and bonding them with resin under heat and pressure, offered a smoother surface and greater consistency than earlier pressed wood products. This made it ideal for applications requiring intricate detailing, such as decorative moldings and furniture. The ability to mass-produce MDF at low cost further solidified pressed wood’s role in the 20th-century manufacturing landscape.

However, the rise of mass production was not without challenges. Early pressed wood products often contained high levels of formaldehyde-based adhesives, which raised health and environmental concerns. By the late 20th century, regulations such as the U.S. Clean Air Act prompted manufacturers to develop low-emission alternatives, ensuring that pressed wood remained a viable and safe material. Today, these innovations continue to influence the production of pressed wood, balancing efficiency with sustainability.

In practical terms, understanding the legacy of 20th-century mass production can guide consumers in choosing pressed wood products. Look for certifications like CARB Phase 2 or EPA TSCA Title VI, which indicate low formaldehyde emissions. Additionally, consider the intended use: MDF is ideal for painted surfaces, while plywood offers greater strength for structural applications. By leveraging the advancements of the past century, pressed wood remains a versatile, cost-effective solution for modern needs.

Air-Drying Seasoned Wood: Understanding the Timeframe for Optimal Results

You may want to see also

Explore related products

Modern pressed wood innovations

Pressed wood has been a staple in construction and furniture-making for over a century, with early forms dating back to the late 19th century. However, modern innovations have transformed this traditional material into a high-tech, sustainable, and versatile resource. One of the most significant advancements is the development of nanotechnology-enhanced pressed wood, where nanoparticles are embedded into the wood fibers to improve durability, water resistance, and strength. For instance, silica nanoparticles can increase the wood’s hardness by up to 30%, making it suitable for high-traffic flooring or outdoor applications. This innovation not only extends the lifespan of pressed wood products but also reduces the need for chemical treatments, aligning with eco-friendly manufacturing practices.

Another groundbreaking innovation is the use of 3D printing technology with pressed wood composites. By combining wood fibers with biodegradable binders, manufacturers can now create intricate, custom designs that were previously impossible with traditional methods. This process allows for minimal material waste and opens up new possibilities in architecture and interior design. For example, 3D-printed pressed wood panels can be tailored to specific acoustic or thermal requirements, making them ideal for modern office spaces or residential buildings. To implement this, designers should start by selecting a high-resolution 3D printer capable of handling wood-based filaments and experiment with layer thickness (0.2–0.4 mm) for optimal structural integrity.

Self-healing pressed wood is another cutting-edge development that addresses the issue of cracks and damage over time. By incorporating microcapsules filled with healing agents into the wood matrix, minor cracks can be automatically repaired when exposed to heat or moisture. This technology is particularly useful for furniture and structural components in humid environments. For DIY enthusiasts, applying a self-healing coating (available in kits with epoxy-based capsules) can extend the life of pressed wood items. Simply mix the capsules with a compatible adhesive and apply a thin layer to the wood surface, allowing it to cure for 24 hours.

Comparatively, bio-based adhesives have revolutionized the way pressed wood is manufactured, replacing formaldehyde-based binders with natural alternatives like soy protein or lignin. These adhesives not only reduce harmful emissions but also improve the wood’s flexibility and bonding strength. For instance, soy-based adhesives can increase the internal bond strength of pressed wood by 15–20%, making it more resistant to delamination. Manufacturers should transition to these adhesives gradually, starting with a 50/50 mix of traditional and bio-based binders to ensure compatibility with existing production lines.

Finally, smart pressed wood integrates sensors and conductive materials to create interactive surfaces. By embedding piezoelectric fibers or graphene layers, pressed wood can now detect pressure, temperature, or even monitor structural integrity in real time. This innovation is particularly valuable in smart homes, where floors or walls can double as touch-sensitive controls or health monitoring systems. For a practical application, homeowners can install smart pressed wood panels in high-use areas like kitchens or hallways, connecting them to a central hub via Bluetooth or Wi-Fi. This not only enhances functionality but also adds a futuristic aesthetic to interior spaces.

Mastering Pork Smoking: Optimal Timing for Adding Wood Chips

You may want to see also

Explore related products

Global adoption and usage trends

Pressed wood, also known as engineered wood, has been a staple in construction and furniture-making for over a century. Its global adoption and usage trends reveal a fascinating journey from niche innovation to ubiquitous material. The earliest forms of pressed wood emerged in the late 19th century, with the invention of particleboard in 1887 by Germany’s Hubert Wilhelm E. K. Pabst. However, it wasn’t until the mid-20th century that pressed wood gained widespread traction, driven by post-World War II housing demands and technological advancements in adhesives and manufacturing processes.

Analyzing regional adoption patterns, Europe and North America led the charge in the 1950s and 1960s, with pressed wood becoming a cost-effective solution for rebuilding efforts and suburban expansion. For instance, plywood and MDF (medium-density fiberboard) became staples in American home construction, prized for their affordability and versatility. In contrast, Asia’s adoption accelerated in the 1980s and 1990s, fueled by rapid urbanization in countries like China and India. Today, Asia accounts for over 50% of global pressed wood consumption, with China alone producing approximately 150 million cubic meters annually, primarily for furniture and interior design.

A comparative analysis of usage trends highlights distinct regional preferences. In North America, pressed wood is predominantly used in structural applications, such as subflooring and sheathing, while Europe favors it for eco-friendly furniture and cabinetry. Meanwhile, in Asia, the material is heavily utilized in prefabricated housing and decorative panels. For example, Japan’s *tatemono* (traditional wooden buildings) increasingly incorporate pressed wood for seismic resilience, blending tradition with modernity. This diversity underscores the material’s adaptability to local needs and cultural contexts.

Persuasively, sustainability has become a driving force in pressed wood’s global adoption. As deforestation concerns grow, manufacturers are turning to recycled wood fibers and low-emission adhesives to meet eco-certifications like FSC (Forest Stewardship Council) and CARB (California Air Resources Board). For instance, IKEA, a global furniture giant, has committed to using only sustainable wood sources by 2025, significantly influencing supply chains worldwide. Consumers, particularly in Europe and North America, are increasingly prioritizing green products, pushing the industry toward more responsible practices.

Practically, for those considering pressed wood in construction or design, understanding regional standards is crucial. In the U.S., ASTM International provides guidelines for moisture resistance and durability, while Europe adheres to EN standards for formaldehyde emissions. In Asia, local regulations vary, with China’s GB standards focusing on structural integrity. A pro tip: Always verify compliance with local building codes and opt for certified products to ensure longevity and safety. As pressed wood continues to evolve, its global trends reflect a balance between innovation, sustainability, and cultural adaptation.

Durability of PT Wood: How Long Does It Last Outdoors?

You may want to see also

Frequently asked questions

Pressed wood, also known as engineered wood, has been around since the late 19th century, with early forms appearing in the 1850s.

Pressed wood was first commercially produced in the early 20th century, gaining popularity in the 1920s and 1930s as a cost-effective alternative to solid wood.

The earliest form of pressed wood was particleboard, which was developed in the 1850s but became more widely used in the mid-20th century.

Pressed wood production has evolved significantly since its inception, with advancements in technology and materials leading to improved durability, strength, and environmental sustainability in the 20th and 21st centuries.

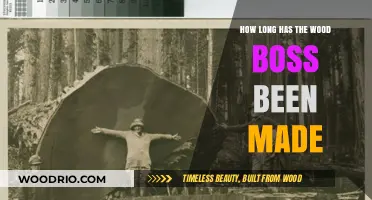

![Lumber, Laths, Doors, Sash, Blinds, Moulding and Interior Finish, Exterior Finish Brackets, Sawed and Turned Work and Pressed Wood Ornaments, Etc. 1898 [Leather Bound]](https://m.media-amazon.com/images/I/617DLHXyzlL._AC_UY218_.jpg)