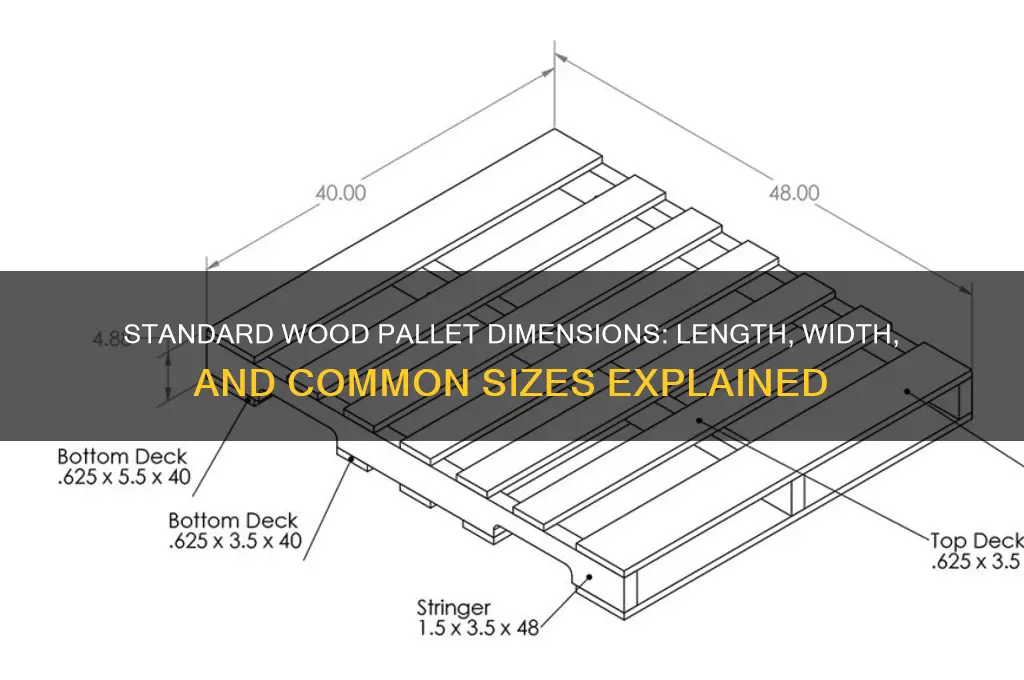

A standard wood pallet, commonly used in shipping and logistics, typically measures 48 inches (121.92 cm) in length and 40 inches (101.6 cm) in width, known as the GMA (Grocery Manufacturers Association) pallet. This size is widely accepted in North America and is designed to efficiently accommodate most goods while fitting standard warehouse and truck dimensions. However, pallet sizes can vary globally, with European standards often using a 120 cm by 80 cm (47.24 inches by 31.5 inches) pallet. Understanding these dimensions is crucial for optimizing storage, transportation, and cost-effectiveness in supply chain operations.

Explore related products

What You'll Learn

Standard pallet dimensions (48 x 40 x 6.4)

A standard wood pallet in North America measures 48 inches in length, 40 inches in width, and 6.4 inches in height. These dimensions are not arbitrary; they are the result of decades of standardization to optimize shipping, storage, and handling efficiency. The 48 x 40 footprint aligns with common forklift and racking systems, while the 6.4-inch height balances stackability with material economy. This size has become the industry benchmark, accounting for over 30% of all pallets in use in the U.S.

Consider the practical implications of these dimensions. A 48-inch length and 40-inch width allow for stable stacking of goods without overhang, reducing the risk of damage during transit. The 6.4-inch height ensures pallets fit into standard trailers and warehouses without wasting vertical space. For businesses, adhering to these dimensions simplifies logistics, reduces costs, and ensures compatibility with existing supply chain infrastructure.

When designing packaging or selecting pallets, the 48 x 40 x 6.4 standard is a critical reference point. For example, if your product’s dimensions exceed 48 inches in length or 40 inches in width, it may require custom pallets or additional handling, increasing expenses. Conversely, smaller items can be efficiently arranged on this pallet size, maximizing load capacity. Always measure your goods and compare them to these dimensions to avoid inefficiencies.

A comparative analysis highlights why this standard prevails. While European pallets (1200 x 800 mm) are common internationally, the 48 x 40 pallet dominates in North America due to its compatibility with domestic trucking and warehousing systems. Its slightly larger footprint accommodates more goods per pallet, though it may not fit seamlessly in global supply chains. For businesses operating domestically, this standard is non-negotiable; for international shippers, it’s a strategic consideration.

Finally, the 48 x 40 x 6.4 pallet’s durability and reparability contribute to its longevity. Made from hardwood or softwood, these pallets can withstand heavy loads and repeated use. Damaged boards can often be replaced, extending their lifespan and reducing waste. For sustainable practices, opting for this standard size supports a robust recycling and repair industry, making it both an economic and environmental choice.

Thompson Water Seal Durability: How Long Does It Protect Wood?

You may want to see also

Explore related products

Weight capacity (varies, typically 3,000-5,000 lbs)

A standard wood pallet's weight capacity is a critical factor in logistics and warehousing, often determining its suitability for specific applications. Typically, these pallets can handle between 3,000 and 5,000 pounds, but this range is not set in stone. Several variables, including the type of wood, construction quality, and intended use, influence this capacity. For instance, pallets made from hardwoods like oak or maple generally support more weight than those made from softer woods like pine. Understanding these nuances ensures that you select the right pallet for your needs, avoiding costly mistakes like overloading or underutilization.

When assessing weight capacity, consider the pallet's design and reinforcement features. Pallets with double-faced construction, where both the top and bottom decks are fully decked, often have higher weight limits compared to single-faced pallets. Additionally, pallets with reinforced corners or center blocks can distribute weight more evenly, enhancing their load-bearing capabilities. For heavy-duty applications, such as in manufacturing or construction, opting for pallets with these features can provide the necessary durability and safety margins.

It’s essential to differentiate between static and dynamic weight capacity. Static capacity refers to the maximum weight a pallet can hold when stationary, typically ranging from 3,000 to 5,000 pounds. Dynamic capacity, on the other hand, is the weight it can support while in motion, such as on a forklift, and is usually lower—often around 2,000 to 4,000 pounds. Misunderstanding these distinctions can lead to accidents or damage. Always check the manufacturer’s specifications to ensure the pallet meets both static and dynamic requirements for your specific use case.

Practical tips can help maximize a pallet’s weight capacity while ensuring safety. Distribute weight evenly across the pallet’s surface to prevent stress points that could lead to breakage. Avoid placing heavy items near the edges, as this can compromise stability. For loads exceeding 4,000 pounds, consider using pallets with additional support structures or opting for specialized heavy-duty pallets. Regularly inspect pallets for signs of wear, such as cracks or splinters, and replace them if they show significant damage. These precautions not only extend the pallet’s lifespan but also reduce the risk of workplace accidents.

Finally, while standard wood pallets are versatile, they are not one-size-fits-all. For loads approaching or exceeding 5,000 pounds, alternative materials like plastic or metal pallets may be more suitable. These materials often offer higher weight capacities and greater durability, though at a higher cost. Evaluate your specific needs, including load weight, frequency of use, and environmental conditions, to determine the best option. By carefully considering weight capacity and its influencing factors, you can optimize efficiency and safety in your operations.

Durability Unveiled: How Long Does Laminate Wood Flooring Last?

You may want to see also

Explore related products

Material types (softwood, hardwood, or recycled wood)

Softwood pallets dominate the market due to their cost-effectiveness and availability. Derived from coniferous trees like pine and spruce, these pallets are lighter and easier to handle, making them ideal for one-time or short-term use. However, their lower density means they’re more prone to splintering and damage, limiting their lifespan to about 3–5 years under moderate use. For businesses prioritizing budget over durability, softwood is the go-to choice, but frequent replacements should be factored into long-term planning.

Hardwood pallets, crafted from deciduous trees such as oak or maple, offer superior strength and durability compared to softwood. Their denser composition makes them resistant to wear and tear, extending their lifespan to 7–10 years or more, even under heavy use. This robustness comes at a higher cost, both financially and environmentally, as hardwood trees take longer to mature. Industries requiring heavy-duty solutions, like manufacturing or international shipping, often justify the investment due to reduced replacement frequency and lower risk of product damage.

Recycled wood pallets emerge as a sustainable alternative, repurposing materials from broken or decommissioned pallets. While they vary in quality and lifespan, proper refurbishment can yield pallets lasting 5–8 years. This option reduces waste and often costs less than new hardwood or softwood pallets. However, inconsistencies in material strength and size can pose challenges, particularly in automated systems. For eco-conscious businesses with flexible specifications, recycled pallets strike a balance between sustainability and functionality.

Choosing the right material hinges on specific needs: softwood for affordability, hardwood for durability, and recycled wood for sustainability. Each type has trade-offs, from softwood’s susceptibility to damage to hardwood’s higher price tag. Recycled pallets, while environmentally friendly, require careful inspection to ensure structural integrity. By aligning material choice with operational demands, businesses can optimize pallet performance while minimizing costs and environmental impact.

Seasoning Firewood: Understanding the Time It Takes for Optimal Results

You may want to see also

Explore related products

Industry standards (GMA, ISO, or custom sizes)

Standard wood pallet dimensions are far from arbitrary. They are the result of decades of industry collaboration, logistical optimization, and global standardization efforts. At the heart of this standardization are three key players: the Grocery Manufacturers Association (GMA), the International Organization for Standardization (ISO), and the growing trend of custom pallet sizes. Each has shaped the landscape of pallet dimensions in distinct ways, catering to diverse industry needs while striving for interoperability.

The GMA pallet, measuring 48 inches by 40 inches (1219 mm by 1016 mm), reigns supreme in North America. This size wasn't chosen arbitrarily. It's a product of careful consideration of truck and railcar dimensions, warehouse racking systems, and the need for efficient material handling. The GMA pallet's widespread adoption has streamlined supply chains, reduced handling costs, and become the de facto standard for consumer goods distribution. Its dimensions are so ingrained in North American logistics that deviating from them can lead to inefficiencies and increased costs.

For businesses operating within this region, adhering to GMA standards is not just a recommendation; it's a logistical necessity.

While the GMA pallet dominates North America, the ISO takes a more global approach. ISO standards, such as the ISO 6780 pallet (1200 mm by 800 mm and 1200 mm by 1000 mm), are designed for international compatibility. These dimensions are optimized for European trucking and warehousing systems, reflecting the continent's narrower roads and smaller storage spaces. *Companies engaged in international trade must be mindful of these regional variations to avoid costly delays and handling issues.* The ISO's focus on global harmonization highlights the importance of considering destination markets when selecting pallet sizes.

A pallet that's standard in one country might be an anomaly in another.

Despite the prevalence of GMA and ISO standards, custom pallet sizes are gaining traction. Industries with unique product dimensions or specialized handling requirements often opt for bespoke pallets. For example, the automotive industry frequently uses longer pallets to accommodate car parts, while the pharmaceutical industry may require smaller pallets for temperature-controlled storage. *While custom pallets offer flexibility, they come with trade-offs. They can be more expensive to produce and may not be compatible with standard handling equipment, potentially leading to increased logistics complexity.*

Careful consideration of cost, compatibility, and long-term logistical implications is crucial before opting for custom solutions.

The world of standard wood pallets is far more nuanced than a simple set of dimensions. It's a reflection of global trade patterns, regional infrastructure, and industry-specific needs. Understanding the rationale behind GMA, ISO, and custom sizes empowers businesses to make informed decisions, ensuring their pallet choices align with their operational realities and strategic goals.

Wooden Windows Durability: Screens Enhance or Shorten Lifespan?

You may want to see also

Explore related products

Durability and lifespan (3-5 years with proper use)

A standard wood pallet, when properly maintained, can serve reliably for 3 to 5 years in industrial or commercial settings. This lifespan hinges on factors like material quality, construction, and usage conditions. Hardwoods such as oak or hickory typically outlast softer woods like pine, though proper handling and storage play equally critical roles. For instance, pallets stored indoors away from moisture and pests will degrade far slower than those left outdoors. Regular inspections for cracks, splinters, or loose nails can extend usability, as can immediate repairs to minor damage.

To maximize durability, implement a rotation system where older pallets are assigned lighter loads or less frequent use. Avoid overloading, as exceeding weight limits accelerates structural failure. For businesses, tracking pallet age and condition through barcode or RFID systems can streamline maintenance. Additionally, consider environmental factors: pallets in humid climates benefit from moisture-resistant treatments, while those in dry regions may require less intervention. Proper stacking and handling practices, such as using forklifts correctly, prevent premature wear.

Comparatively, plastic or metal pallets may offer longer lifespans, but wood remains cost-effective and recyclable. However, wood’s organic nature makes it susceptible to rot, insect damage, and warping if neglected. For operations with high turnover or harsh conditions, investing in higher-grade wood or protective coatings can offset replacement costs. Small businesses might prioritize affordability with pine pallets, accepting a shorter lifespan, while larger enterprises could opt for hardwoods to reduce long-term expenses.

Persuasively, extending a pallet’s lifespan isn’t just about cost savings—it’s an eco-friendly practice. Each year of additional use reduces the demand for new timber and minimizes waste. Companies can further enhance sustainability by repairing damaged pallets instead of discarding them. For example, replacing broken boards or reinforcing joints with metal plates can add months or even years to a pallet’s service life. Such practices align with circular economy principles, turning a disposable item into a reusable asset.

Instructively, here’s a step-by-step guide to preserving pallet durability: First, inspect pallets quarterly for structural integrity. Second, clean them regularly to remove debris and contaminants. Third, store pallets in dry, well-ventilated areas to prevent mold or insect infestations. Fourth, train staff on proper handling techniques to avoid unnecessary damage. Finally, establish a repair protocol for minor issues, such as nailing loose boards or sanding rough edges. By following these steps, businesses can ensure their pallets remain functional for the full expected lifespan, balancing operational efficiency with environmental responsibility.

Seasoning Cherry Wood: Timeframe and Tips for Perfect Results

You may want to see also

Frequently asked questions

A standard wood pallet typically measures 48 inches (121.92 cm) in length.

The width of a standard wood pallet is usually 40 inches (101.6 cm).

No, while 48" x 40" is the most common size in North America, other sizes like 42" x 42" or 36" x 36" are also used depending on regional standards or specific needs.

The height of a standard wood pallet is typically between 5 to 7 inches (12.7 to 17.78 cm), depending on the design and construction.

No, pallet sizes vary by country. For example, the European standard is 120 cm x 80 cm (47.24" x 31.5"), while North America uses 48" x 40" as the standard.