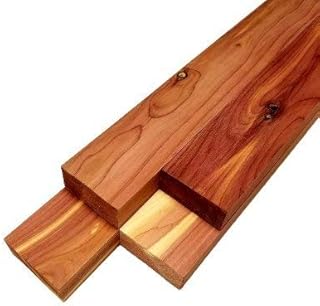

Pressure-treated wood is a popular choice for outdoor construction projects due to its enhanced durability and resistance to rot, decay, and insect damage. The lifespan of pressure-treated wood varies depending on factors such as the type of treatment, environmental conditions, and maintenance practices. Generally, properly installed and maintained pressure-treated wood can last anywhere from 20 to 40 years or more. Ground-contact treated wood, which is designed to withstand direct soil exposure, typically has a shorter lifespan compared to above-ground treated wood. Regular inspections, sealing, and avoiding prolonged moisture exposure can significantly extend its longevity, making it a reliable option for decks, fences, and other outdoor structures.

| Characteristics | Values |

|---|---|

| Average Lifespan (Above Ground) | 10-20 years |

| Average Lifespan (In Ground) | 5-10 years |

| Lifespan with Proper Maintenance | Up to 40 years or more |

| Resistance to Rot & Decay | High (due to chemical treatment) |

| Resistance to Insects | High (repels termites and other wood-boring insects) |

| Moisture Resistance | Moderate (treatment reduces but does not eliminate moisture absorption) |

| UV Resistance | Low (tends to fade and warp over time without sealant) |

| Common Uses | Decks, fences, outdoor structures, landscaping |

| Environmental Impact | Contains chemicals (e.g., ACQ, CA-B) that may leach over time |

| Maintenance Required | Periodic sealing, staining, or painting to extend lifespan |

| Cost | Higher upfront cost compared to untreated wood but longer-lasting |

| Sustainability | Treated wood is not biodegradable due to chemical treatment |

| Safety Precautions | Wear protective gear when cutting or sanding to avoid chemical exposure |

Explore related products

What You'll Learn

- Factors Affecting Durability: Moisture, soil contact, and chemical type impact treated wood lifespan significantly

- Ground Contact Rating: Wood rated for ground contact lasts longer than above-ground treated wood

- Chemical Treatment Types: ACQ, CA-B, and CCA treatments offer varying longevity against decay

- Environmental Conditions: Humidity, temperature, and sunlight exposure affect treated wood durability over time

- Maintenance Tips: Regular inspections, sealing, and proper installation extend pressure-treated wood lifespan

Factors Affecting Durability: Moisture, soil contact, and chemical type impact treated wood lifespan significantly

Moisture is the arch-nemesis of pressure-treated wood, accelerating decay and insect damage. Wood with a moisture content above 19% becomes a breeding ground for fungi and attracts wood-boring insects. To mitigate this, ensure proper drainage around structures and use water-repellent sealants. For ground-contact applications, consider installing a gravel base or using a moisture barrier. Regularly inspect wood in humid environments, such as decks near pools or in rainy climates, and reapply sealants every 2–3 years to maintain protection.

Soil contact is another critical factor, as it exposes wood to constant moisture, microorganisms, and termites. Pressure-treated wood rated for ground contact contains higher concentrations of preservatives, typically 0.40 pounds per cubic foot (PCF) of chemical retention, compared to 0.25 PCF for above-ground use. When burying wood, avoid direct contact with untreated wood or metal, as these can accelerate corrosion or leaching of preservatives. For fence posts or landscaping, pre-drilling holes and using non-corrosive fasteners can extend lifespan by reducing stress points.

The type of chemical preservative used plays a pivotal role in determining durability. Chromated copper arsenate (CCA) was once the standard but has been largely replaced due to health concerns. Modern alternatives include alkaline copper quaternary (ACQ), copper azole (CA-B), and micronized copper azole (MCA). ACQ is cost-effective but requires stainless steel fasteners to prevent corrosion, while CA-B offers better resistance to fungal decay. MCA, with its finer particle size, penetrates deeper into the wood, providing superior protection. Choose preservatives based on the wood’s intended use and environmental exposure.

Combining these factors requires strategic planning. For instance, a deck in a wet climate with partial soil contact should use ground-contact rated wood treated with MCA, sealed annually, and elevated on concrete footings. Conversely, a playground structure in a dry region might suffice with above-ground treated wood and bi-annual inspections. Understanding these interactions allows for tailored solutions that maximize lifespan, ensuring treated wood remains functional and safe for decades.

Drying Rough Sawn Wood: Essential Timeframe for Optimal Results

You may want to see also

Explore related products

Ground Contact Rating: Wood rated for ground contact lasts longer than above-ground treated wood

Pressure-treated wood is a staple in outdoor construction, but not all treated wood is created equal. The ground contact rating is a critical factor that determines how long the wood will last in specific environments. Wood rated for ground contact is designed to withstand direct exposure to soil, moisture, and insects, making it significantly more durable than above-ground treated wood. This distinction is essential for projects like fence posts, deck supports, and retaining walls, where the wood is in constant contact with the ground.

The longevity of pressure-treated wood hinges on the chemical retention levels during the treatment process. Ground contact-rated wood receives a higher dosage of preservatives, typically around 0.40 pounds per cubic foot (PCF) of active ingredient, compared to 0.25 PCF for above-ground wood. This increased concentration provides better resistance to rot, decay, and termite damage. For example, a ground contact-rated 4x4 post can last 20 years or more in direct soil contact, whereas an above-ground post in the same conditions might fail within 5–10 years.

Choosing the right type of treated wood is a practical decision that impacts both durability and cost. While ground contact-rated wood is more expensive upfront, its extended lifespan often justifies the investment. For instance, using above-ground wood for a fence post in soil will require replacement sooner, increasing long-term maintenance costs. A simple rule of thumb: if the wood will touch the ground or be in a consistently damp environment, opt for ground contact-rated material.

To maximize the lifespan of pressure-treated wood, proper installation is key. Ensure the wood is not buried too deeply, as excessive soil contact can accelerate decay. Elevating the wood slightly or using gravel as a base can improve drainage and reduce moisture retention. Additionally, avoid using above-ground wood in areas where it might come into contact with standing water or soil, even if it’s not fully buried. These precautions, combined with the right wood rating, ensure your project stands the test of time.

In summary, ground contact-rated wood is an investment in longevity for outdoor projects. Its higher preservative levels and enhanced resistance to environmental factors make it the superior choice for applications where wood meets soil. By understanding the differences in treatment levels and following best practices for installation, you can ensure your structures remain sturdy and functional for decades. Always prioritize the ground contact rating when durability is non-negotiable.

Timmy Woods' Purse Legacy: A Journey Through Decades of Craftsmanship

You may want to see also

Explore related products

Chemical Treatment Types: ACQ, CA-B, and CCA treatments offer varying longevity against decay

Pressure-treated wood's lifespan hinges largely on the chemical treatment it receives. Among the most common are ACQ (Alkaline Copper Quaternary), CA-B (Copper Azole Type B), and CCA (Chromated Copper Arsenate), each offering distinct advantages and longevity against decay. Understanding these treatments is crucial for selecting the right wood for your project.

ACQ, a popular choice for residential applications, boasts a lifespan of 40 years or more in above-ground use. This treatment uses copper as its primary preservative, combined with a quaternary ammonium compound to enhance its resistance to fungal decay and termite attack. Its effectiveness lies in the copper’s ability to bind with the wood’s cellulose, creating a durable barrier. However, ACQ-treated wood can be more corrosive to metal fasteners, so using stainless steel or hot-dipped galvanized screws is recommended.

CA-B, another copper-based treatment, offers similar longevity to ACQ, often exceeding 40 years in above-ground applications. It combines copper with an organic azole compound, which provides excellent protection against decay fungi and insects. CA-B is less corrosive than ACQ, making it a better choice for projects where metal fasteners are unavoidable. Its slightly higher cost is offset by its versatility and reduced maintenance needs.

CCA, once the industry standard, has been largely phased out for residential use due to health concerns related to arsenic leaching. However, it remains in use for certain industrial and agricultural applications. CCA-treated wood can last 50 years or more, particularly in ground-contact scenarios, thanks to its potent combination of copper, chromium, and arsenic. Despite its durability, CCA’s restricted use underscores the importance of handling and disposing of it properly to minimize environmental impact.

When choosing among these treatments, consider the project’s exposure to moisture and soil contact. For ground-contact applications, CA-B or CCA (where permitted) offers superior longevity, while ACQ is ideal for above-ground structures like decks and fences. Always follow manufacturer guidelines for installation and maintenance, such as sealing cut ends to prevent moisture intrusion. By matching the treatment type to the specific demands of your project, you can maximize the lifespan of pressure-treated wood and ensure long-term performance.

Petrified Wood Tumbling: Understanding the Agatization Timeframe and Process

You may want to see also

Explore related products

Environmental Conditions: Humidity, temperature, and sunlight exposure affect treated wood durability over time

Pressure-treated wood is designed to resist decay, insects, and moisture, but its longevity is significantly influenced by environmental conditions. Humidity, temperature, and sunlight exposure act as silent adversaries, each contributing uniquely to the material's degradation over time. Understanding these factors allows for better placement, maintenance, and expectations of treated wood structures.

Humidity: The Silent Decay Accelerator

High humidity environments, particularly those with consistent moisture in the air, create ideal conditions for fungal growth and wood rot. Even pressure-treated wood, which contains preservatives like copper azole or ACQ, can succumb to prolonged dampness. In regions with relative humidity levels above 60%, the wood's surface remains moist longer, allowing preservatives to leach out faster and weakening the wood fibers. For instance, a deck in a coastal area with 80% average humidity may show signs of wear after 10–15 years, compared to 20+ years in drier climates. To mitigate this, ensure proper ventilation around structures and apply water-repellent sealants every 2–3 years.

Temperature Extremes: A Double-Edged Sword

Temperature fluctuations cause wood to expand and contract, leading to cracks and splits that expose untreated layers. In freezing climates, ice formation within the wood exacerbates this process, while in hot regions, UV-induced degradation is accelerated. For example, pressure-treated wood in Arizona’s desert climate, with temperatures exceeding 100°F, may degrade 25–30% faster than in temperate zones due to increased chemical breakdown. Conversely, in colder regions like Minnesota, freeze-thaw cycles can reduce lifespan by 15–20%. To combat this, choose wood rated for ground contact in extreme climates and inspect for cracks annually, filling them with epoxy-based wood fillers.

Sunlight Exposure: The Invisible Erosion

Direct sunlight is a relentless adversary, breaking down lignin—a key component of wood—and causing discoloration, warping, and surface erosion. UV rays penetrate the wood’s surface, degrading preservatives and reducing structural integrity. A fencepost in full sun may lose 40% of its strength after 10 years, while a shaded counterpart remains robust. To protect against UV damage, apply a UV-inhibiting stain or paint every 1–2 years. For horizontal surfaces like decks, consider using shade cloths or pergolas to reduce direct exposure.

Practical Takeaways for Maximizing Durability

To optimize the lifespan of pressure-treated wood, assess your local climate and tailor maintenance accordingly. In humid areas, prioritize moisture management; in temperature-extreme regions, focus on crack prevention; and in sunny locales, shield against UV damage. Regular inspections, timely resealing, and strategic placement can extend the wood’s life by 5–10 years. For instance, elevating structures off the ground in wet climates or using composite materials in high-UV areas can provide additional longevity. By addressing these environmental factors proactively, you ensure treated wood remains a durable, cost-effective choice for outdoor projects.

Termite Damage Timeline: How Quickly Can They Destroy Wood?

You may want to see also

Explore related products

Maintenance Tips: Regular inspections, sealing, and proper installation extend pressure-treated wood lifespan

Pressure-treated wood, when properly maintained, can last 20 to 40 years or more, depending on environmental conditions and usage. However, this longevity isn’t automatic—it requires proactive care. Regular inspections are the cornerstone of this maintenance. At least twice a year, examine the wood for signs of wear, such as cracks, splinters, or discoloration. Pay special attention to areas in constant contact with soil or moisture, as these are prone to decay. Early detection of issues allows for timely repairs, preventing minor problems from escalating into major damage.

Sealing is another critical step in preserving pressure-treated wood. While the treatment process protects against rot and insects, it doesn’t shield against moisture penetration or UV damage. Apply a high-quality wood sealer every 1 to 2 years, depending on exposure. For horizontal surfaces like decks, which bear the brunt of weather, consider sealing annually. Choose a sealant with UV inhibitors to prevent graying and a water-repellent formula to minimize warping. Always clean the wood thoroughly before application to ensure proper adhesion.

Proper installation is equally vital to maximizing lifespan. Ensure the wood is installed with adequate spacing to allow for air circulation and water runoff, reducing the risk of moisture accumulation. Use corrosion-resistant fasteners, such as stainless steel or hot-dipped galvanized screws, to avoid rust stains and structural weakening. When building structures like decks or fences, elevate the wood at least 6 inches above ground level to minimize soil contact, which accelerates decay. Following manufacturer guidelines for installation ensures the wood performs as intended.

Combining these practices—regular inspections, diligent sealing, and meticulous installation—creates a synergistic effect that significantly extends the life of pressure-treated wood. Neglecting any one of these steps can shorten its lifespan dramatically. For instance, unsealed wood exposed to harsh weather may degrade within a decade, while properly maintained wood can endure for multiple decades. By investing time and effort into these maintenance tips, you not only protect your investment but also ensure the wood remains functional and aesthetically pleasing for years to come.

Understanding the Lifespan of Cottonwood Trees: A Comprehensive Guide

You may want to see also

Frequently asked questions

Pressure treated wood typically lasts 20 to 40 years, depending on factors like exposure to moisture, soil contact, and maintenance.

Yes, painting or sealing pressure treated wood can extend its lifespan by protecting it from moisture, UV rays, and pests, potentially adding 5 to 10 years.

Pressure treated wood rated for ground contact can last 25 to 40 years, as it is treated with higher levels of preservatives to resist rot and insect damage.

Yes, pressure treated wood tends to last longer in dry climates because reduced moisture exposure slows down decay and fungal growth.

In decks or outdoor structures, pressure treated wood can last 15 to 30 years, depending on maintenance, weather exposure, and the quality of the initial treatment.