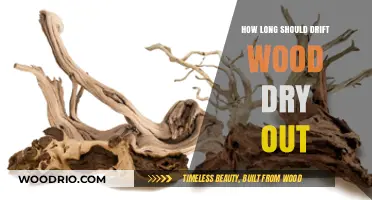

When working with wood, allowing it to acclimate properly after production is crucial to ensure its stability and longevity in its intended environment. Wood is a hygroscopic material, meaning it absorbs and releases moisture in response to changes in humidity and temperature. After production, wood may still contain residual moisture or be in a state that doesn’t match the conditions of its final installation site. Acclimation allows the wood to reach equilibrium moisture content (EMC) with its surroundings, reducing the risk of warping, cracking, or shrinking once installed. The duration of acclimation depends on factors such as the wood species, initial moisture content, and the climate of the installation area, but a general rule of thumb is to let wood acclimate for at least 7 to 14 days, though some projects may require longer periods for optimal results.

| Characteristics | Values |

|---|---|

| Recommended Acclimation Time | 7–14 days (varies by wood type, humidity, and climate) |

| Factors Affecting Acclimation | Humidity, temperature, wood species, thickness, and storage conditions |

| Ideal Humidity Range | 30–50% relative humidity |

| Temperature Considerations | Room temperature (60–80°F or 15–27°C) |

| Wood Species Variability | Hardwoods (e.g., oak, maple) may require longer acclimation than softwoods |

| Thickness Impact | Thicker wood pieces require more time to acclimate |

| Storage During Acclimation | Flat, stacked with spacers, in a controlled environment |

| Signs of Proper Acclimation | No warping, cracking, or cupping after installation |

| Consequences of Skipping Acclimation | Increased risk of warping, gaps, or structural failure post-installation |

| Professional Recommendations | Follow manufacturer guidelines or consult with a wood specialist |

Explore related products

What You'll Learn

- Ideal Acclimation Duration: 7-14 days for most wood types, depending on humidity and temperature

- Factors Affecting Acclimation: Relative humidity, temperature, wood species, and storage conditions influence acclimation time

- Signs of Proper Acclimation: Stable moisture content, no warping, and consistent dimensions indicate readiness

- Accelerating Acclimation: Use controlled environments or dehumidifiers to speed up the process safely

- Consequences of Skipping: Risk of warping, cracking, or gaps after installation due to moisture imbalance

Ideal Acclimation Duration: 7-14 days for most wood types, depending on humidity and temperature

Wood acclimation is a critical step often overlooked in construction and woodworking projects. After production, wood needs time to adjust to its new environment, balancing moisture content with surrounding humidity and temperature. This process, typically lasting 7 to 14 days, prevents warping, cracking, or cupping once the wood is installed. While this range applies to most wood types, factors like species density, initial moisture content, and local climate conditions can influence the exact duration. For instance, denser hardwoods like oak may require closer to 14 days, while softer woods like pine might acclimate in 7 days under optimal conditions.

To determine the ideal acclimation period, monitor both the wood’s moisture content and the ambient conditions. Use a moisture meter to ensure the wood’s moisture level aligns with the expected equilibrium moisture content (EMC) of its environment. For example, in a region with 50% humidity, wood should acclimate until its moisture content stabilizes around 8-10%. If the wood is stored in a climate-controlled space, the process may be faster, but natural fluctuations in temperature and humidity necessitate the full 7-14 day window. Avoid shortcuts; premature installation can lead to costly repairs later.

Practical tips can streamline the acclimation process. Store wood flat and stacked with spacers to allow air circulation, preventing moisture buildup. Keep it away from direct sunlight, heat sources, or drafts, which can cause uneven drying. For larger projects, acclimate wood in the same room where it will be installed to ensure it adjusts to the specific conditions of that space. If time is a constraint, consider using pre-acclimated wood from suppliers, though this may increase costs. Remember, patience during acclimation pays off in the long-term durability and appearance of the finished project.

Comparing acclimation durations across wood types highlights the importance of tailoring the process. Exotic hardwoods, often harvested in humid climates, may require the full 14 days to adjust to drier indoor environments. Conversely, locally sourced softwoods might acclimate more quickly if their production environment closely matches the installation site. This variability underscores why a one-size-fits-all approach falls short. By understanding the wood’s origin and characteristics, you can fine-tune the acclimation period for optimal results.

In conclusion, the 7 to 14-day acclimation window is a rule of thumb, not a rigid prescription. It balances efficiency with the need for thorough adjustment, ensuring wood performs as expected once installed. By factoring in wood type, environmental conditions, and practical storage techniques, you can maximize the benefits of this crucial step. Skipping or rushing acclimation risks undermining the entire project, making this seemingly passive phase an active investment in quality and longevity.

Epoxy Wood Drying Time: Factors Affecting Curing and Hardening Process

You may want to see also

Explore related products

Factors Affecting Acclimation: Relative humidity, temperature, wood species, and storage conditions influence acclimation time

Wood acclimation is a delicate dance between the material and its environment, and several factors dictate how long this process should take. Relative humidity plays a starring role, as wood naturally seeks equilibrium with its surroundings. For every 5% change in moisture content, allow at least 1-2 weeks of acclimation. In regions with high humidity (above 60%), wood may absorb moisture, leading to expansion, while drier climates (below 30%) can cause shrinkage. A hygrometer is your ally here—aim to keep the wood’s moisture content within 2-4% of the ambient humidity for stability.

Temperature is another silent influencer, accelerating or slowing acclimation depending on its extremes. Warmer environments (70°F–80°F) speed up moisture exchange, reducing acclimation time by up to 30%, but beware of rapid changes that can stress the wood. Conversely, cooler temperatures (below 60°F) slow the process, requiring an additional week or two. Avoid placing wood near heat sources like radiators or vents, as uneven drying can lead to warping or cracking.

Not all wood species acclimate at the same pace. Dense hardwoods like oak or maple take longer to adjust—typically 2-4 weeks—due to their lower permeability. Softwoods such as pine or cedar, being more porous, often acclimate within 1-2 weeks. Exotic species like teak or mahogany may require up to 6 weeks due to their natural oils and density. Always research the specific wood you’re working with to tailor the acclimation period accordingly.

Storage conditions can make or break the acclimation process. Proper stacking is critical—allow 1-2 inches of space between boards for air circulation. Store wood in a controlled environment, ideally with consistent humidity (40-50%) and temperature (60°F–70°F). Avoid plastic wrapping, which traps moisture, and opt for breathable materials like cloth or paper. If storing outdoors, use a waterproof cover and elevate the wood off the ground to prevent moisture absorption from below.

In practice, acclimation is as much art as science. Monitor the wood regularly for signs of stress—cupping, splitting, or warping—and adjust conditions as needed. For large projects, acclimate wood in the space where it will be installed, as even minor environmental differences can affect performance. Patience is key; rushing acclimation can lead to costly repairs down the line. By understanding these factors, you ensure the wood not only survives but thrives in its new environment.

Durability of Wood Fences in Florida's Climate: Lifespan Explained

You may want to see also

Explore related products

Signs of Proper Acclimation: Stable moisture content, no warping, and consistent dimensions indicate readiness

Wood acclimation is a critical step in ensuring the longevity and stability of wood products, yet its signs of readiness are often overlooked. One of the most definitive indicators of proper acclimation is stable moisture content. Wood naturally absorbs and releases moisture based on its environment, but excessive fluctuations can lead to structural issues. To measure this, use a moisture meter to check the wood’s moisture content (MC) over several days. A stable MC, typically within 2-4% of the ambient humidity level, signals that the wood has equilibrated with its surroundings. For example, if your local climate averages 60% relative humidity, the wood’s MC should stabilize around 12% (a common target for interior use).

Another unmistakable sign of proper acclimation is the absence of warping. Warping occurs when different parts of the wood expand or contract unevenly due to moisture imbalance. Inspect the wood for any bowing, cupping, or twisting. Properly acclimated wood will lie flat and maintain its original shape. A practical tip: stack wood with spacers between boards to allow air circulation, reducing the risk of uneven moisture absorption. If you notice warping after a week of acclimation, extend the process and re-evaluate the storage conditions.

Consistent dimensions across all pieces of wood are equally vital. Measure the width, length, and thickness of several boards at the beginning of the acclimation period and again after a week. If the dimensions remain unchanged, the wood has likely reached equilibrium. Inconsistent measurements suggest ongoing moisture movement, requiring additional acclimation time. For precision, use calipers to detect even minor changes, especially in high-humidity environments where wood tends to expand more noticeably.

While acclimation times vary—typically 1-2 weeks for most projects—these signs provide a clear, objective way to determine readiness. Ignoring them can lead to costly issues like gaps in flooring, cracks in furniture, or structural instability. By focusing on stable moisture content, absence of warping, and consistent dimensions, you ensure the wood is not just acclimated, but truly ready for use. This methodical approach transforms guesswork into certainty, safeguarding your investment in both time and materials.

Drying Fresh Wood: Essential Tips for Optimal Curing Time

You may want to see also

Explore related products

Accelerating Acclimation: Use controlled environments or dehumidifiers to speed up the process safely

Wood acclimation is a critical step in ensuring the stability and longevity of wood products, but it can be time-consuming. For instance, hardwood flooring typically requires 2–3 weeks to acclimate to its new environment, depending on humidity and temperature differences. However, in industries where time is of the essence, such a lengthy process can disrupt project timelines. This is where accelerating acclimation through controlled environments or dehumidifiers becomes invaluable. By manipulating the surrounding conditions, you can safely reduce acclimation time from weeks to days without compromising wood integrity.

To accelerate acclimation effectively, start by assessing the wood’s moisture content (MC) and the target environment’s relative humidity (RH). For example, if the wood’s MC is 12% and the target RH is 45%, use a dehumidifier to gradually lower the ambient humidity around the wood. Set the dehumidifier to maintain an RH of 50–55% initially, then slowly decrease it to match the target. This gradual approach prevents rapid moisture loss, which can cause warping or cracking. Pairing a dehumidifier with a hygrometer ensures precise control, allowing you to monitor progress and adjust settings as needed.

Controlled environments, such as climate-controlled storage rooms or acclimation chambers, offer another effective method. These spaces allow you to regulate temperature and humidity with precision, creating optimal conditions for rapid acclimation. For instance, maintaining a temperature of 70°F (21°C) and an RH of 50% can reduce acclimation time by up to 50%. However, this method requires an initial investment in equipment, making it more suitable for large-scale operations or high-value projects. For smaller applications, portable dehumidifiers or even sealed rooms with desiccant packs can achieve similar results at a lower cost.

While accelerating acclimation is efficient, caution is essential. Avoid extreme measures, such as using heaters or fans to dry wood quickly, as these can cause uneven moisture loss and damage. Always follow manufacturer guidelines for dehumidifier usage, ensuring the unit is appropriately sized for the space. For example, a 70-pint dehumidifier is ideal for a 1,000 sq. ft. area with moderate humidity. Additionally, inspect the wood periodically during the process, looking for signs of stress such as cupping or splitting. With careful management, controlled environments and dehumidifiers can transform acclimation from a waiting game into a streamlined, predictable process.

A Walk in the Woods Play Duration: How Long Is It?

You may want to see also

Explore related products

Consequences of Skipping: Risk of warping, cracking, or gaps after installation due to moisture imbalance

Wood is a hygroscopic material, meaning it naturally absorbs and releases moisture from its environment. When wood is freshly produced or transported, its moisture content may not align with the humidity levels of its final installation site. Skipping the acclimation process can lead to severe consequences, primarily due to moisture imbalance. Warping, cracking, and gaps are the most common issues that arise when wood is installed without proper acclimation. These problems not only compromise the aesthetic appeal of the installation but also its structural integrity.

Consider a scenario where hardwood flooring is installed immediately after delivery in a dry, heated indoor environment. The wood, still holding moisture from its production or storage conditions, begins to shrink as it adjusts to the lower humidity. This shrinkage causes gaps between planks, creating an uneven surface and potentially weakening the floor’s stability. Conversely, in a humid environment, wood can expand, leading to warping or buckling if there’s no room for movement. These issues are not merely cosmetic; they can render the installation unusable, requiring costly repairs or replacements.

The risk of moisture imbalance extends beyond flooring to other wood applications, such as cabinetry, furniture, and structural elements. For instance, custom-built cabinets installed without acclimation may warp or crack, causing doors to misalign or drawers to stick. In structural uses, like beams or framing, warping can compromise the building’s safety. The financial and time costs of addressing these problems far outweigh the effort of allowing wood to acclimate properly.

To mitigate these risks, follow a structured acclimation process. Place the wood in its intended installation environment for at least 7–14 days, depending on the species and local humidity levels. Use a moisture meter to ensure the wood’s moisture content matches the ambient conditions—ideally within 2–4% of the equilibrium moisture content (EMC) for the area. Maintain consistent temperature and humidity during acclimation; avoid placing wood near heat sources or in drafty areas. For larger projects, consult a professional to determine the optimal acclimation period and conditions.

Skipping acclimation is a gamble with predictable outcomes: warping, cracking, or gaps that undermine the wood’s beauty and function. By investing time in proper acclimation, you ensure the longevity and performance of your wood installation, saving both money and frustration in the long run. Treat acclimation as a non-negotiable step, not an optional one, in any wood-based project.

Drying Unseasoned Wood: Timeframe and Tips for Perfectly Seasoned Lumber

You may want to see also

Frequently asked questions

Wood should typically acclimate for 7 to 14 days in the environment where it will be used. This allows it to adjust to the humidity and temperature, reducing the risk of warping or cracking.

Yes, denser hardwoods may require a longer acclimation period (up to 21 days), while softer woods may acclimate faster. In humid climates, wood may need more time to stabilize, whereas drier climates may require less.

Skipping acclimation increases the risk of moisture-related issues like warping, splitting, or gaps in the finished project. It’s best to allow the recommended acclimation time to ensure the wood performs well long-term.