When working with steamed wood, proper clamping is essential to ensure the material retains its desired shape and stability as it dries. The duration for which steamed wood should remain clamped depends on several factors, including the wood species, thickness, moisture content, and the extent of bending or shaping applied. Generally, steamed wood should be clamped until it has reached a moisture content similar to its surroundings, typically around 12-15% for indoor use. This process can take anywhere from a few days to several weeks, with thicker pieces requiring more time. It’s crucial to monitor the wood’s moisture levels using a moisture meter and gradually release the clamps to avoid springback or warping. Patience and attention to detail during this phase are key to achieving a successful and lasting result.

| Characteristics | Values |

|---|---|

| Clamping Time for Steamed Wood | 1-2 hours per inch of wood thickness |

| Minimum Clamping Time | 24 hours (regardless of thickness) |

| Optimal Clamping Time | 48-72 hours for most projects |

| Factors Affecting Clamping Time | Wood species, moisture content, humidity, temperature, bending severity |

| Hardwood Clamping Time | Longer (up to 72-96 hours) due to higher density |

| Softwood Clamping Time | Shorter (24-48 hours) due to lower density |

| High Humidity Adjustment | Increase clamping time by 25-50% |

| Low Humidity Adjustment | Decrease clamping time by 10-20% (ensure proper moisture retention) |

| Temperature Impact | Warmer temperatures may reduce clamping time; cooler temperatures may increase it |

| Re-clamping After Removal | Not typically necessary if wood is properly clamped initially |

| Checking for Readiness | Wood should retain its shape without springing back |

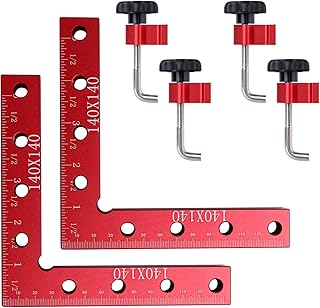

Explore related products

What You'll Learn

- Initial Clamping Time: How long to clamp immediately after steaming wood for stability

- Cooling Period: Duration to keep wood clamped while it cools down post-steaming

- Moisture Content Check: When to measure moisture levels before removing clamps

- Wood Type Considerations: How wood species affect clamping time after steaming

- Project Complexity: Adjusting clamping duration based on the complexity of the wood project

Initial Clamping Time: How long to clamp immediately after steaming wood for stability

The initial clamping time for steamed wood is a critical step in ensuring dimensional stability and preventing warping or cracking. Immediately after steaming, the wood fibers are highly pliable due to the increased moisture content and elevated temperature. Clamping at this stage helps to set the desired shape or alignment before the wood begins to cool and dry. The general rule of thumb is to clamp steamed wood for at least 30 minutes to 1 hour immediately after steaming. This allows the wood to start cooling under controlled pressure, promoting uniformity and reducing internal stresses. However, the exact duration can vary depending on the wood species, thickness, and the specific bending or shaping technique used.

For example, hardwoods like oak or maple may require closer to 1 hour of initial clamping due to their denser structure, while softer woods like pine might stabilize in 30–45 minutes. Thicker pieces will also need longer clamping times compared to thinner ones, as they retain heat and moisture for a more extended period. It’s essential to monitor the wood’s temperature during this phase; clamping should begin when the wood is still warm but not scalding hot, typically around 140–160°F (60–70°C). Using a thermometer to check the wood’s surface temperature can help ensure you’re applying pressure at the optimal moment.

A practical tip is to pre-clamp the wood slightly before steaming, especially if you’re working on complex bends. This allows for immediate adjustment and full clamping pressure as soon as the wood is removed from the steam source. Avoid over-tightening the clamps initially, as the wood may still be expanding slightly due to residual heat. Gradually increase pressure over the first 10–15 minutes to avoid damaging the fibers. This staged approach ensures even distribution of force without causing stress fractures.

Comparing this to cold bending methods highlights the efficiency of steaming. Cold bending often requires clamping for several days to achieve stability, whereas steamed wood can be secured in a fraction of the time. However, the trade-off is the need for precise timing and temperature control during the initial clamping phase. Failure to clamp promptly or apply adequate pressure can result in springback, where the wood reverts to its original shape as it cools.

In conclusion, the initial clamping time for steamed wood is a delicate balance of timing, temperature, and pressure. Aim for 30–60 minutes of immediate clamping, adjusting based on wood type and thickness. Pre-clamping, monitoring temperature, and gradual pressure application are key techniques to ensure success. This step is non-negotiable for achieving stable, long-lasting results in wood bending or shaping projects.

How Long Does the Spooky Woods Experience Typically Last?

You may want to see also

Explore related products

Cooling Period: Duration to keep wood clamped while it cools down post-steaming

The cooling period after steaming wood is a critical phase that determines the success of your bending or shaping project. Wood, when steamed, becomes pliable due to the breakdown of its lignin structure, but it regains its rigidity as it cools. Clamping during this phase ensures the wood retains its new shape. The duration of clamping depends on the wood species, thickness, and the ambient temperature. For instance, softer woods like pine may require 30 minutes to an hour, while denser woods like oak could need up to 2 hours. A general rule of thumb is to keep the wood clamped until it reaches room temperature, as premature removal can lead to springback, undoing your efforts.

Analyzing the science behind this process reveals why patience is key. As steam penetrates the wood fibers, it raises the wood’s moisture content and temperature, making it flexible. When clamped in the desired shape, the wood begins to cool and dry, gradually returning to its rigid state. If released too soon, residual heat and moisture can cause the wood to revert partially or fully to its original form. For example, a 1-inch thick piece of maple should remain clamped for at least 90 minutes to ensure complete cooling and stabilization. Monitoring the wood’s temperature with a thermometer can provide precise timing, ensuring optimal results.

From a practical standpoint, here’s a step-by-step guide to mastering the cooling period. First, remove the steamed wood from the steamer and immediately place it into the prepared mold or jig. Secure it firmly with clamps, ensuring even pressure across the entire surface. Next, cover the wood with a thermal blanket or insulating material to slow the cooling process, promoting uniform drying. Finally, leave the setup undisturbed until the wood feels cool to the touch, typically 1–2 hours for most projects. For thicker pieces or hardwoods, extend this period to 3–4 hours. Always err on the side of caution—extra time clamped is better than a warped or sprung piece.

Comparing this process to other wood bending methods highlights its advantages and challenges. Unlike cold bending, which relies on brute force and often results in cracks, steaming offers a gentler, more controlled approach. However, it demands precision in timing and technique. For example, while laminating with epoxy allows for immediate release, steamed wood requires a prolonged clamping period. This comparison underscores the importance of respecting the cooling phase, as it directly impacts the final shape and structural integrity of the wood.

Finally, a persuasive argument for investing time in the cooling period lies in its impact on project longevity. Properly cooled and clamped wood retains its shape for decades, even under stress. Consider a steamed and bent chair leg—if clamped inadequately, it may warp over time, compromising both aesthetics and safety. By contrast, a well-cooled piece becomes a testament to craftsmanship, enduring years of use. This small but crucial step separates amateur work from professional-grade results, making it a non-negotiable aspect of wood steaming projects.

Cedar Wood Decomposition Timeline: Factors Affecting Breakdown and Decay Process

You may want to see also

Explore related products

Moisture Content Check: When to measure moisture levels before removing clamps

Measuring moisture content before removing clamps is a critical step in ensuring the stability and longevity of steamed wood. Wood that is clamped while still moist can warp, crack, or distort if released too early. The ideal moisture content for most woodworking projects is between 6% and 8%, aligning with the ambient relative humidity of the wood’s intended environment. Measuring too early can yield inaccurate results, as the wood’s moisture gradient (drier exterior, wetter interior) equalizes slowly. Conversely, waiting too long risks over-drying, which can cause shrinkage and joint failure. Timing this check correctly is a balance of science and patience.

To determine the optimal moment for measurement, consider the wood species and thickness. Denser hardwoods like oak or maple retain moisture longer than softer woods like pine. As a rule of thumb, allow 24 hours of clamping per inch of wood thickness before testing. For example, a 2-inch thick board should remain clamped for at least 48 hours. Use a pin-type or pinless moisture meter for accuracy, taking readings from multiple spots to account for variability. If the meter shows a consistent reading within the target range (6%–8%), proceed with caution; if not, extend clamping time and retest every 12–24 hours.

Practical tips can streamline this process. First, acclimate the wood to the workshop’s humidity for at least 7 days before steaming to minimize moisture shock. Second, apply a uniform clamping pressure to avoid localized drying. Third, monitor ambient conditions—high humidity slows drying, while low humidity accelerates it. If using a kiln or dehumidifier to speed drying, reduce clamping time proportionally but always verify with a meter. Remember, moisture content is a leading indicator of wood stability; guesswork here can undo hours of careful work.

Comparing this approach to traditional methods highlights its efficiency. Historically, woodworkers relied on visual cues or weight checks, which are less precise. Modern moisture meters provide real-time data, reducing the risk of error. For instance, a 1% moisture difference can cause 0.1% dimensional change in wood—enough to compromise a joint. By integrating technology with time-tested practices, you ensure the wood’s structural integrity while minimizing downtime. This method is particularly valuable for complex bends or high-stakes projects where failure is costly.

In conclusion, measuring moisture levels before removing clamps is not just a step—it’s a safeguard. By adhering to species-specific guidelines, using reliable tools, and accounting for environmental factors, you can predict wood behavior with confidence. The goal is not just to remove clamps but to release wood that is stable, ready for finishing, and built to last. Treat this check as the final exam for your steamed wood; passing it ensures your project’s success.

Walnut Wood Drying Time: Factors Affecting the Process and Duration

You may want to see also

Explore related products

Wood Type Considerations: How wood species affect clamping time after steaming

Different wood species respond uniquely to steaming and clamping, making it essential to tailor your approach based on the wood’s inherent properties. Hardwoods like oak and maple, known for their density and rigidity, require longer clamping times after steaming—typically 24 to 48 hours—to ensure the wood retains its new shape. Softer woods, such as pine or cedar, are more pliable and may only need 12 to 24 hours under clamps. This variation stems from differences in cell structure and moisture absorption rates, which dictate how quickly the wood stabilizes post-steaming.

Consider the wood’s natural grain and fiber orientation as well. Woods with straight, uniform grain patterns, like cherry or walnut, tend to bend more predictably and may require less clamping time compared to woods with irregular grain, such as ash or hickory. Irregular grain can cause uneven stress distribution during bending, necessitating extended clamping to prevent springback. Always assess the wood’s grain direction before steaming and plan clamping duration accordingly to achieve the desired result.

Moisture content plays a critical role in clamping time, and this varies significantly by species. Tropical hardwoods like teak or mahogany, which naturally resist moisture absorption, may need additional clamping time—up to 72 hours—to ensure the steam’s effects are fully realized. Conversely, woods like birch or poplar, which absorb moisture quickly, often stabilize faster and can be released from clamps sooner. Use a moisture meter to monitor the wood’s hydration levels during the process, aiming for a consistent reading before removing clamps.

Practical tips can further refine your approach. For example, pre-drying dense woods like ebony or rosewood before steaming can reduce clamping time by minimizing excess moisture. Applying even pressure with clamps and using cauls to distribute force evenly is crucial for all species but especially for brittle woods like beech or elm, which are prone to cracking. Finally, always allow steamed wood to acclimate to room conditions for at least 24 hours after unclamping to ensure dimensional stability, regardless of species.

In summary, understanding the unique characteristics of each wood species—density, grain pattern, and moisture behavior—is key to determining optimal clamping time after steaming. By adapting your technique to the wood’s natural properties, you can achieve precise bends and shapes while minimizing the risk of distortion or damage. This species-specific approach ensures both efficiency and success in your woodworking projects.

Wood Look Tile Lengths: Are Options Longer Than 48 Inches Available?

You may want to see also

Explore related products

Project Complexity: Adjusting clamping duration based on the complexity of the wood project

The complexity of a wood project directly influences how long you should keep steamed wood clamped. Simple projects, like bending a single piece for a chair leg, require less clamping time compared to intricate assemblies, such as a multi-layered curved cabinet door. Understanding this relationship ensures the wood retains its shape without unnecessary stress or warping.

For straightforward bends involving minimal joints or layers, 24 to 48 hours of clamping is typically sufficient. The wood fibers, softened by steam, set into their new shape as they cool and dry. However, complex projects with multiple bends, compound curves, or glued joints demand extended clamping durations—often 72 hours or more. This allows adhesives to cure fully and ensures each component stabilizes in its intended position.

Consider a project like a steam-bent rocking chair with interlocking joints. Here, clamping isn’t just about holding the curve; it’s about maintaining alignment across multiple connection points. Rushing this process risks gaps, misalignment, or structural weakness. Conversely, over-clamping simple pieces can lead to brittleness or unnecessary strain on the wood fibers.

Practical tip: Use moisture meters to monitor the wood’s drying progress. Aim for a moisture content of 8–12% before removing clamps, as this indicates the wood has stabilized. For complex projects, incrementally reduce clamping pressure over the final 24 hours to minimize spring-back without compromising structural integrity.

In essence, treat clamping duration as a variable tailored to the project’s demands. Simple bends require brevity; intricate assemblies demand patience. By aligning clamping time with complexity, you ensure both aesthetic precision and long-term durability.

Maine Winter Wood Supply: How Long Does a Cord Last?

You may want to see also

Frequently asked questions

Steamed wood should typically remain clamped until it has completely cooled and dried, which can take anywhere from 24 to 48 hours, depending on the wood species and thickness.

Yes, denser hardwoods like oak or maple may require longer clamping times (up to 48 hours) compared to softer woods like pine, which may only need 24 hours.

No, removing clamps prematurely can cause the wood to spring back or lose its shape. Always allow the wood to cool and dry completely while clamped to ensure the bend holds.

![Right Angle Clamp, Housolution [4 PACK] Single Handle 90° Aluminum Alloy Corner Clamp, Clamps for Woodworking Adjustable Swing Jaw, Woodworking Tools Photo Frame Vise Holder, Gifts for Men Dad](https://m.media-amazon.com/images/I/71xNSiBOZ+L._AC_UL320_.jpg)

![Housolution Right Angle Clamp, [2 PACK] Single Handle 90° Aluminum Alloy Corner Clamp, Clamps for Woodworking Adjustable Swing Jaw, Woodworking Tools Photo Frame Vise Holder, Gifts for Men Dad](https://m.media-amazon.com/images/I/71nW-qkVwnL._AC_UL320_.jpg)