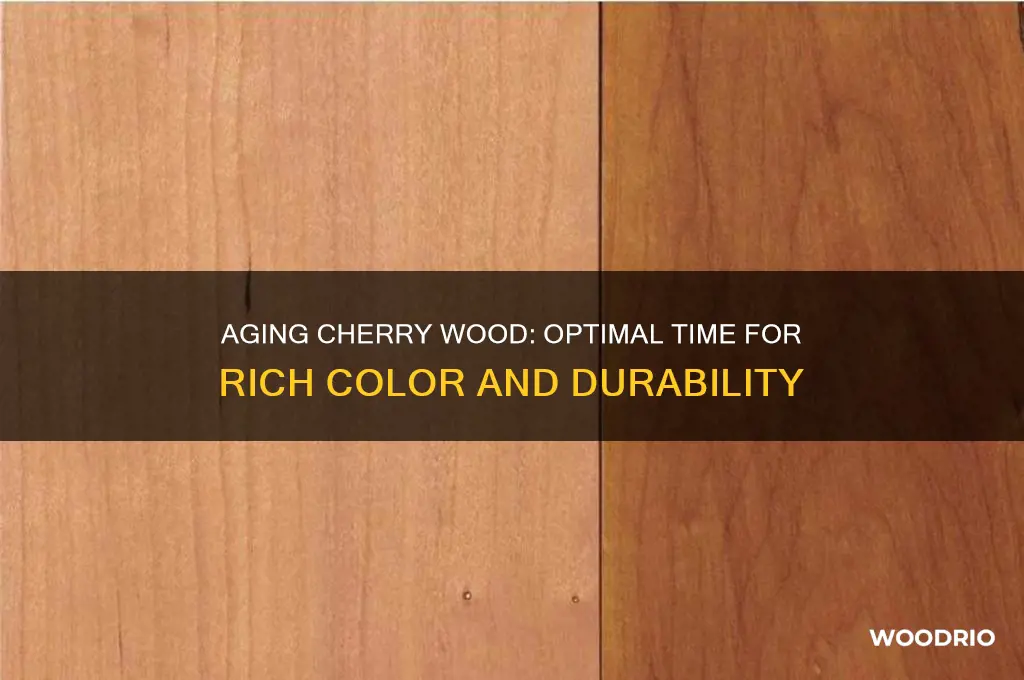

Aging cherry wood is a process that enhances its natural beauty, durability, and value, making it a sought-after material for furniture, cabinetry, and woodworking projects. The length of time required to age cherry wood depends on several factors, including the desired color, grain pattern, and intended use. Typically, cherry wood is aged for at least 6 to 12 months to allow it to dry and stabilize, but some woodworkers prefer to age it for several years to achieve a richer, darker patina. Proper storage during the aging process is crucial, as the wood must be protected from moisture, pests, and extreme temperature fluctuations to prevent warping, cracking, or discoloration. Understanding the aging process and its variables ensures that cherry wood reaches its full potential in both aesthetics and functionality.

Explore related products

What You'll Learn

Ideal Aging Conditions

Cherry wood, prized for its rich color and fine grain, requires specific conditions to age properly. The ideal environment balances humidity, temperature, and airflow to prevent warping, cracking, or mold. Aim for a humidity level between 50% and 70%—this range allows the wood to dry gradually without losing structural integrity. A consistent temperature of 60°F to 80°F (15°C to 27°C) accelerates the aging process while minimizing stress on the wood fibers. Proper airflow is equally critical; stack the wood with spacers to allow air circulation, preventing moisture pockets that could lead to decay.

Consider the aging timeline as a function of these conditions. Under optimal circumstances, cherry wood can air-dry to a usable moisture content (below 12%) within 6 to 12 months for thinner pieces, such as 1-inch boards. Thicker cuts, like 2-inch planks, may require 18 to 24 months. Kiln-drying shortens this process to weeks but demands precise control to avoid overheating, which can darken the wood prematurely. For hobbyists, air-drying is more accessible but requires patience and monitoring.

The aging process isn’t just about time—it’s about transformation. Cherry wood’s signature reddish-brown hue deepens as it ages, a result of oxidation. To enhance this natural darkening, expose the wood to indirect sunlight during the final stages of drying. Avoid direct sunlight, as it can cause uneven discoloration. For those seeking a more uniform patina, store the wood in a shaded, well-ventilated area.

Practical tips can make the difference between mediocre and exceptional results. Seal the ends of cherry logs or boards with a wax or commercial end sealer to reduce moisture loss from these vulnerable areas. Rotate stacked wood periodically to ensure even drying. If mold appears, lightly sand the affected area and improve airflow. For long-term storage, wrap dried wood in breathable fabric to protect it from dust and pests without trapping moisture.

Ultimately, ideal aging conditions for cherry wood are a blend of science and observation. Monitor the wood’s progress regularly, adjusting humidity and airflow as needed. While the process demands time and attention, the reward is a material that’s stable, beautiful, and ready for craftsmanship. Patience isn’t just a virtue here—it’s a necessity.

Maximizing Hardwood Finish Durability: Optimal Maintenance and Longevity Tips

You may want to see also

Explore related products

Aging Time for Cherry Wood

Cherry wood, prized for its rich color and smooth grain, undergoes a transformative aging process that enhances its aesthetic appeal and structural integrity. The ideal aging time varies depending on the intended use and desired characteristics. For furniture or cabinetry, a minimum of 6 to 12 months of air-drying is recommended to reduce moisture content to around 8-12%, minimizing the risk of warping or cracking. However, for finer applications like musical instruments or carving, longer aging—up to 2 years—is often preferred to achieve a more stable and resonant wood.

The aging process isn’t just about time; environmental conditions play a critical role. Cherry wood should be stacked with stickers (spacers) in a well-ventilated area, protected from direct sunlight and extreme humidity. A consistent relative humidity of 50-70% is ideal. For accelerated aging, kiln-drying can reduce the process to 2-4 weeks, but this method risks uneven drying and loss of the wood’s natural luster. Hand-selecting wood with tight grain patterns and minimal defects before aging ensures the best results.

Aging cherry wood also unlocks its signature color transformation. Freshly cut cherry appears pale yellow-brown but darkens to a deep, reddish-brown over time due to exposure to oxygen and UV light. This patina is highly sought after in woodworking, but it can be uneven if not aged properly. To encourage uniform darkening, rotate the wood periodically during the aging process and avoid covering it with opaque materials. For a more controlled finish, some artisans use light exposure in a controlled environment to accelerate the color change.

Practical considerations must balance the desire for extended aging. Longer aging times improve stability and color but increase storage costs and tie up resources. For hobbyists or small-scale projects, 9-12 months of air-drying strikes a balance between quality and efficiency. Professionals working on high-end pieces may opt for 18-24 months to ensure the wood reaches its full potential. Always test a small sample before committing to a specific aging duration to ensure it meets project requirements.

Finally, aging cherry wood is as much art as science. While guidelines provide a framework, the wood’s response to aging can vary based on its origin, growth rate, and initial moisture content. Regularly inspect the wood for signs of mold, insect damage, or uneven drying, addressing issues promptly. Patience is key—rushing the process compromises the wood’s beauty and durability. With careful attention to time, environment, and condition, aged cherry wood becomes a timeless material, elevating any project it graces.

2004 Pressure Treated Wood Lifespan: Durability and Maintenance Tips

You may want to see also

Explore related products

Effects of Moisture Content

Moisture content in cherry wood is a critical factor that dictates its aging process and final quality. Freshly cut cherry wood typically contains 30-50% moisture, which must be reduced to 8-12% for stability in furniture or cabinetry. This reduction isn’t instantaneous; it requires controlled drying, either through air-drying or kiln-drying. Air-drying, though slower (6-12 months), allows the wood to acclimate naturally, enhancing its color and grain. Kiln-drying, while faster (2-4 weeks), risks uneven moisture loss if not monitored meticulously. The goal is uniformity—wood that dries too quickly or unevenly warps, cracks, or splits, rendering it unusable for fine woodworking.

The effects of moisture content extend beyond structural integrity; they influence the wood’s aesthetic appeal. Cherry wood is prized for its ability to darken and enrich in color over time, a process accelerated by proper moisture management. Wood with residual moisture above 15% may develop mold or fungal stains, marring its appearance. Conversely, wood dried below 8% becomes brittle and loses its natural luster. Achieving the ideal moisture content ensures the wood ages gracefully, developing a deep, reddish-brown patina that artisans and collectors value.

Practical tips for managing moisture content include monitoring humidity levels during drying. For air-drying, stack wood with stickers to promote airflow, and cover the pile to shield it from rain while allowing ventilation. Kiln operators should adhere to a gradual drying schedule, starting at 100°F and increasing by 5°F daily until reaching 140°F. Use a moisture meter to test wood regularly, aiming for consistency across the board. Once dried, store wood in a climate-controlled environment to prevent reabsorption of moisture, which can cause swelling or distortion.

Comparing the two drying methods reveals trade-offs. Air-drying is cost-effective and preserves the wood’s natural characteristics but demands patience and space. Kiln-drying is efficient and controllable but requires investment in equipment and expertise. For hobbyists, air-drying is often preferable, while professionals may opt for kiln-drying to meet tight deadlines. Regardless of method, the key is to prioritize moisture control, as it directly impacts the wood’s longevity and beauty.

In conclusion, moisture content is not merely a technical detail but a determinant of cherry wood’s aging trajectory. Proper management ensures structural stability, enhances aesthetic qualities, and preserves the wood’s value. Whether air-drying or kiln-drying, the focus should remain on achieving uniform moisture levels within the 8-12% range. By mastering this aspect, woodworkers can unlock the full potential of cherry wood, transforming it into timeless pieces that age with elegance.

Ticks Beyond the Woods: Lifespan and Survival Outside Forest Habitats

You may want to see also

Explore related products

Temperature Impact on Aging

Temperature plays a pivotal role in the aging of cherry wood, influencing both the speed and quality of the process. Higher temperatures accelerate the chemical reactions within the wood, causing it to age more rapidly. For instance, cherry wood stored in a warm, dry environment at 80°F (27°C) will develop its characteristic rich, reddish-brown patina in as little as 6 to 12 months. In contrast, cooler temperatures, such as those found in a climate-controlled storage area around 60°F (15°C), can extend the aging process to 2–3 years, allowing for a more gradual and nuanced color transformation. This temperature-driven variance highlights the importance of environmental control for achieving desired outcomes in wood aging.

To harness temperature effectively, consider the following steps. First, assess your desired aging timeline and the specific hue you aim to achieve. If a quicker turnaround is necessary, aim for a consistent temperature range of 75–85°F (24–29°C) with moderate humidity (40–50%). For a slower, more deliberate aging process, maintain temperatures between 55–65°F (13–18°C) and slightly lower humidity levels (30–40%). Second, monitor the wood regularly, as temperature fluctuations can lead to uneven aging or undesirable grain patterns. Finally, avoid extreme temperatures above 90°F (32°C) or below 40°F (4°C), as these can cause cracking, warping, or stalled chemical reactions.

A comparative analysis reveals that temperature’s impact on cherry wood aging is not just about speed but also about quality. Wood aged in warmer conditions tends to exhibit bolder, more vibrant colors but may lack the depth and complexity achieved through slower aging. Cooler environments, while prolonging the process, often result in a more uniform and refined appearance, with subtle grain enhancements. For example, a cherry wood table aged at 70°F (21°C) might display a striking reddish hue within a year, whereas the same piece aged at 55°F (13°C) could develop a deeper, more nuanced amber tone over three years. This trade-off underscores the need to align temperature choices with aesthetic goals.

Practical tips can further optimize temperature-driven aging. Use a dehumidifier or humidifier to maintain consistent moisture levels alongside temperature control, as these factors work in tandem. For small-scale projects, consider using insulated storage boxes with heating or cooling elements to create microclimates. Larger operations may benefit from investing in climate-controlled warehouses or workshops. Additionally, document the aging process with periodic photographs to track progress and adjust conditions as needed. By mastering temperature control, craftsmen and woodworkers can achieve precise, predictable results in cherry wood aging, elevating both the functionality and beauty of their creations.

Wood's Wear and Tear Timeline: Factors Affecting Durability and Aging

You may want to see also

Explore related products

Benefits of Proper Aging

Aging cherry wood is not merely a waiting game; it’s a deliberate process that transforms raw timber into a material of exceptional quality. Proper aging stabilizes the wood’s moisture content, reducing the risk of warping, cracking, or splitting once it’s crafted into furniture or flooring. Freshly cut cherry wood can contain up to 50% moisture, but through controlled aging, this is gradually lowered to 6–8%, aligning with indoor humidity levels. This ensures longevity and structural integrity, making the wood more reliable for high-end applications.

Consider the aesthetic benefits, which are as crucial as the structural ones. Cherry wood is prized for its rich, reddish-brown patina that deepens over time. Proper aging accelerates this natural darkening process, enhancing the wood’s visual appeal without artificial stains or finishes. For example, air-dried cherry wood aged for 2–3 years will develop a more uniform and vibrant color compared to hastily processed timber. This natural beauty is why aged cherry wood commands a premium in cabinetry, musical instruments, and fine woodworking.

From a practical standpoint, aging cherry wood improves its workability. Freshly cut wood is often brittle and prone to tearing when machined, but aged wood becomes more pliable and predictable. Woodworkers note that cherry aged for at least 18 months is easier to carve, sand, and join, reducing the likelihood of errors during crafting. This not only saves time but also minimizes material waste, making the aging process an eco-friendly choice for sustainable woodworking practices.

Finally, proper aging enhances the wood’s resistance to pests and decay. As cherry wood dries, it becomes less hospitable to insects and fungi, which thrive in damp environments. Kiln-dried wood, aged under controlled conditions, is particularly effective in this regard, as the heat treatment eliminates existing pests and inhibits future infestations. For outdoor applications, such as decking or garden furniture, aging cherry wood for at least 2 years can significantly extend its lifespan, even in humid climates.

In summary, the benefits of proper aging for cherry wood are multifaceted—stabilizing moisture, enhancing beauty, improving workability, and boosting durability. While the process requires patience, the results justify the wait, ensuring that the final product is not only functional but also a testament to craftsmanship. Whether you’re a woodworker or a consumer, understanding and valuing this process can elevate your appreciation for this timeless material.

Elmer's Glue on Wood: Durability and Adhesion Time Explained

You may want to see also

Frequently asked questions

Cherry wood typically requires 3 to 5 years of air drying to reach a suitable moisture content for woodworking, though kiln drying can reduce this time to a few weeks.

Yes, aging cherry wood allows it to develop its signature rich, reddish-brown patina and enhances its grain pattern, making it more desirable for furniture and cabinetry.

Freshly cut cherry wood (green wood) has a high moisture content and is prone to warping, cracking, or shrinking. It should be aged or dried before use to ensure stability.

Air drying is a slower, natural process that takes 3 to 5 years, while kiln drying uses controlled heat and humidity to dry the wood in weeks. Kiln drying is faster but can be more expensive.

Cherry wood is ready when its moisture content is between 6% and 8%, which can be tested with a moisture meter. Properly aged wood will feel lighter, be less prone to movement, and have a more consistent appearance.