Curing wood before carving is a crucial step that ensures the material is stable, durable, and ready for intricate work. The time required to cure wood varies depending on factors such as the wood species, moisture content, and environmental conditions. Hardwoods like oak or walnut typically need 6 to 12 months to air-dry sufficiently, while softer woods like pine may take 3 to 6 months. Kiln-drying can expedite the process to a few weeks but requires specialized equipment. Proper curing reduces the risk of warping, cracking, or splitting during carving, allowing for a smoother and more precise final product. Patience during this phase is essential to achieve the best results in woodworking projects.

| Characteristics | Values |

|---|---|

| Ideal Curing Time | 6 months to 1 year (for most hardwoods) |

| Minimum Curing Time | 3-6 months (for softer woods like pine) |

| Moisture Content Goal | 8-12% moisture content (for stability) |

| Factors Affecting Curing Time | Wood species, initial moisture content, climate, and storage conditions |

| Signs of Properly Cured Wood | Stable weight, no cracks, and consistent color |

| Consequences of Insufficient Curing | Warping, cracking, or splitting during carving |

| Accelerated Drying Methods | Kiln drying (reduces time to weeks) |

| Storage Conditions | Cool, dry, well-ventilated area with protection from pests |

| Wood Species Variability | Hardwoods (e.g., oak, maple) take longer than softwoods (e.g., cedar) |

| Seasoning vs. Curing | Seasoning refers to drying; curing ensures stability for carving |

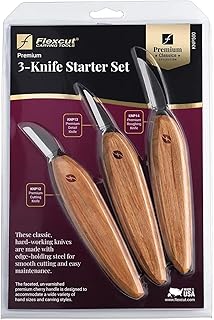

Explore related products

What You'll Learn

Ideal drying time for different wood types

The drying time for wood before carving varies significantly depending on the wood type, its initial moisture content, and the environmental conditions. Hardwoods like oak and maple typically require 6 to 12 months of air drying to reach a suitable moisture level (below 20%) for carving. Softwoods such as pine or cedar dry faster, often within 3 to 6 months, due to their lower density and higher resin content. Always measure moisture levels with a wood moisture meter to ensure the wood is adequately cured, as carving wet wood can lead to warping, cracking, or mold growth.

For exotic woods like teak or mahogany, patience is key. These dense species can take 1 to 2 years to dry properly, especially if harvested from humid regions. Kiln drying can expedite this process to 2–4 weeks, but it’s costly and requires professional equipment. If you’re working with green wood (freshly cut), consider sealing the ends with wax or paint to slow moisture loss and prevent splitting. Remember, rushing the drying process compromises the wood’s stability and your carving experience.

Instructive steps for determining ideal drying times include monitoring the wood’s weight loss and moisture content. Start by weighing the wood immediately after cutting and reweigh it monthly. When the weight stabilizes, test the moisture level. For carving, aim for 8–12% moisture content, matching the ambient humidity of your workspace. If you’re unsure, consult a wood drying chart specific to your wood species and local climate. Properly dried wood will feel lighter, sound hollow when tapped, and show no signs of mold or mildew.

Comparatively, softwoods like basswood are beginner-friendly due to their quick drying time and ease of carving. Hardwoods, while more durable, demand greater investment in time and planning. For instance, walnut takes 9–18 months to cure, while balsa wood can be ready in just 2–3 months. If you’re carving functional pieces like bowls or spoons, prioritize hardwoods for longevity, but allow ample drying time to avoid structural issues. Softwoods are ideal for decorative or practice projects where speed is a priority.

Finally, environmental factors play a critical role in drying time. Store wood in a well-ventilated, covered area, protecting it from rain and direct sunlight. Stack planks with spacers to allow airflow, and rotate them periodically to ensure even drying. In humid climates, consider using a dehumidifier or fan to accelerate the process. Conversely, in dry regions, cover the wood to prevent it from drying too quickly, which can cause checking (surface cracks). By tailoring your approach to the wood type and environment, you’ll achieve optimally cured wood for flawless carving results.

Understanding the Stacked Length of a Cord of Wood

You may want to see also

Explore related products

Impact of moisture content on carving quality

Wood's moisture content is a silent sculptor, shaping the outcome of your carving project long before your tools touch the surface. Freshly cut wood, often called green wood, can contain upwards of 50% moisture. This high moisture content makes the wood pliable, easier to carve, and less prone to splitting. However, this is a double-edged sword. As the wood dries, it shrinks, potentially warping or cracking your carefully crafted piece. Understanding this natural process is crucial for achieving the desired carving quality.

Imagine carving a delicate floral pattern into a damp piece of wood. The moisture allows for smooth, flowing cuts and intricate details. Now, picture attempting the same design on bone-dry wood. The wood chips and splinters, resisting your tools and frustrating your artistic vision. This stark contrast highlights the profound impact moisture content has on the carving experience and the final product.

The ideal moisture content for carving falls between 12-15%. At this range, the wood is stable enough to resist significant warping while still retaining some pliability for easier carving. Achieving this balance requires patience and careful drying techniques. Air drying, the most common method, can take months or even years depending on the wood species and thickness. Kiln drying accelerates the process but requires specialized equipment and careful monitoring to prevent overheating and cracking.

Moisture meters are invaluable tools for determining the wood's readiness for carving. These handheld devices provide an accurate reading of the wood's moisture content, allowing you to make informed decisions about when to begin carving. Remember, rushing the drying process can lead to disastrous results, while waiting too long can result in overly dry, brittle wood.

Ultimately, mastering the relationship between moisture content and carving quality is a journey of observation, experimentation, and respect for the natural properties of wood. By understanding the wood's unique characteristics and employing appropriate drying techniques, you can unlock its full potential and create carvings that are both beautiful and enduring.

Understanding the Duration of a Woods Raid: Key Factors Explained

You may want to see also

Explore related products

Air-drying vs. kiln-drying methods compared

The moisture content of wood is a critical factor in its readiness for carving, and the method of drying significantly influences this process. Air-drying and kiln-drying are two primary techniques, each with distinct advantages and drawbacks. Air-drying, the traditional method, involves stacking wood in a well-ventilated area and allowing it to dry naturally over time. This process can take anywhere from 6 months to 2 years, depending on the wood species, thickness, and local climate. For instance, a 1-inch thick board of oak might take 6–12 months to reach a moisture content of 12–15%, ideal for carving. While air-drying is cost-effective and environmentally friendly, it requires patience and space, making it less practical for those with time constraints or limited storage.

In contrast, kiln-drying accelerates the process by using a controlled environment to remove moisture rapidly. A kiln can reduce the drying time to just 2–4 weeks for the same 1-inch oak board, achieving a consistent moisture content of 8–10%. This method is particularly advantageous for carvers who need wood quickly or work with species prone to warping or cracking during air-drying. However, kiln-drying requires specialized equipment and consumes more energy, increasing costs. Additionally, improper kiln settings can lead to over-drying or internal stresses in the wood, compromising its stability for intricate carving projects.

For carvers, the choice between air-drying and kiln-drying hinges on project timelines and wood characteristics. Air-drying is ideal for hobbyists or those working with hardwoods that benefit from slow, gradual drying. For example, walnut and cherry woods develop richer colors and more stable grain patterns when air-dried. Conversely, kiln-drying is better suited for professionals or projects requiring immediate use of the wood, such as custom commissions or large-scale carvings. Softwoods like pine or cedar, which are more susceptible to decay during prolonged air-drying, also benefit from the quicker kiln process.

Practical considerations further differentiate the two methods. Air-drying demands careful stacking and regular monitoring to prevent mold or uneven drying. Stickers (small pieces of wood) placed between boards promote airflow, while a covered but ventilated storage area protects the wood from rain and direct sunlight. Kiln-drying, on the other hand, requires precise control of temperature and humidity, often necessitating professional services unless the carver invests in a kiln. Despite its higher cost, kiln-drying ensures uniformity, making it the preferred choice for commercial woodworkers or those prioritizing consistency over tradition.

Ultimately, the decision between air-drying and kiln-drying should align with the carver’s goals, resources, and the specific demands of the wood. While air-drying fosters a deeper connection to the material and its natural processes, kiln-drying offers efficiency and reliability. Both methods, when executed correctly, yield wood ready for carving, but the journey to that point reflects the carver’s priorities—whether it’s preserving tradition, embracing technology, or balancing the two.

Standard Wood Mop Handle Length: A Comprehensive Guide for Buyers

You may want to see also

Explore related products

Signs wood is ready for carving

Wood curing time varies widely depending on species, moisture content, and environmental conditions, but knowing when it’s ready for carving is more about observation than strict timelines. One clear sign is weight stability: properly cured wood feels lighter than freshly cut timber because excess moisture has evaporated. To test, weigh a sample piece periodically; when its weight remains consistent over several weeks, it’s likely ready. This method is particularly useful for dense hardwoods like oak or walnut, which retain moisture longer than softwoods like pine.

Another critical indicator is texture and appearance. Cured wood develops a dull, matte surface compared to the shiny, wet look of green wood. Run your hand along the grain—if it feels smooth and free of tackiness, the wood has dried sufficiently. Cracks or checks along the surface can indicate over-drying, but minor surface checks are often acceptable for carving, especially if they follow the grain. For projects requiring structural integrity, however, avoid wood with deep or widespread cracks.

Sound and resonance offer a surprising but effective test. Tap the wood with a mallet or your knuckles; cured wood produces a sharp, clear sound, while green wood sounds dull and thudding. This method works best for smaller pieces or thin sections, as thicker wood may still retain moisture internally despite sounding dry externally. Combine this test with others for a more accurate assessment, especially for larger carving projects.

Finally, moisture meter readings provide a scientific confirmation. Aim for a moisture content (MC) of 12–15% for most carving projects, though softer woods like basswood can be carved at slightly higher MC levels. If you lack a meter, the other signs—weight, texture, and sound—are reliable alternatives. Remember, carving wood too soon can lead to warping, splitting, or tools clogging with sap, so patience and thorough evaluation are key.

Mulberry Wood Drying Time: A Comprehensive Guide to Perfect Results

You may want to see also

Explore related products

Preventing cracks during curing process

Wood's natural tendency to crack during curing can derail even the most meticulously planned carving project. This internal battle between moisture release and structural integrity demands proactive measures. Kiln-dried wood, while convenient, often lacks the gradual drying process that minimizes stress. Air-drying, though slower, allows wood fibers to adjust, reducing the risk of cracks. For optimal results, aim for a moisture content of 8-12% before carving, using a moisture meter to monitor progress.

Woodworkers often underestimate the impact of environmental factors on curing. Fluctuating humidity levels can exacerbate cracking, particularly in dry climates. To combat this, create a controlled drying environment. Seal the wood's ends with a commercial sealant or wax to slow moisture loss from these vulnerable areas. Store the wood in a cool, dry space, ideally with consistent humidity levels between 40-60%. Consider using a dehumidifier or humidifier to maintain this range, especially during extreme weather conditions.

The curing process isn't a passive waiting game; it requires strategic intervention. Periodically inspect the wood for signs of checking or warping. If cracks appear, address them promptly. Small cracks can be filled with wood filler or epoxy, while more severe cases may require re-sawing or discarding the affected section. Remember, prevention is key. Proper stacking and sticker placement during air-drying promote even moisture loss, reducing the likelihood of cracks. Stickers should be placed every 12-18 inches, allowing for adequate airflow.

For those seeking a more hands-on approach, consider the ancient technique of water quenching. This method involves submerging the wood in water for a brief period, followed by a slow, controlled drying process. While counterintuitive, this shocks the wood fibers, reducing internal stresses and minimizing cracking. However, this technique requires precision and should be attempted only by experienced woodworkers. Ultimately, preventing cracks during curing demands a combination of patience, environmental control, and proactive measures. By understanding the wood's natural tendencies and implementing strategic interventions, carvers can ensure their creations emerge from the curing process intact and ready for the transformative touch of the chisel.

Durability of Engineered Wood Chips: Lifespan and Maintenance Tips

You may want to see also

Frequently asked questions

Wood should ideally be cured for at least 6 to 12 months before carving, depending on the wood type and thickness.

Carving uncured wood is possible, but it may warp, crack, or shrink as it dries, affecting the final piece.

Yes, denser hardwoods like oak or walnut may require 12+ months, while softer woods like pine may only need 6 months.

Wood is fully cured when its moisture content is below 20%. Use a moisture meter to check, or look for signs like stable weight and lack of warping.