Drying out pine wood for crafting is a crucial step to ensure the wood is stable, durable, and ready for use. Freshly cut pine, also known as green wood, contains a high moisture content, which can lead to warping, cracking, or shrinking as it dries. The drying process, known as seasoning, typically takes several months to a year, depending on factors such as the wood’s thickness, humidity levels, and the method used (air drying or kiln drying). Air drying, the most common method, involves stacking the wood in a well-ventilated area and allowing it to dry naturally, while kiln drying accelerates the process using controlled heat and airflow. Properly dried pine wood will have a moisture content of around 12-15%, making it ideal for crafting projects like furniture, carvings, or woodworking.

| Characteristics | Values |

|---|---|

| Drying Time (Air Drying) | 6 months to 2 years, depending on thickness and humidity |

| Drying Time (Kiln Drying) | 2-4 weeks, depending on kiln settings and wood thickness |

| Moisture Content Goal | 8-12% for crafting (varies by climate and use) |

| Ideal Thickness for Air Drying | 1-2 inches (thicker boards take longer) |

| Stacking Method | Stickers (spacers) between boards for airflow |

| Optimal Air Drying Conditions | Well-ventilated area, 50-70% humidity, protected from direct sunlight |

| Warping/Cracking Risk | Higher in air drying; kiln drying reduces risk |

| Cost Efficiency | Air drying is cheaper; kiln drying is faster but more expensive |

| Wood Movement Post-Drying | Minimal if dried to proper moisture content |

| Common Uses Post-Drying | Carving, furniture making, woodworking projects |

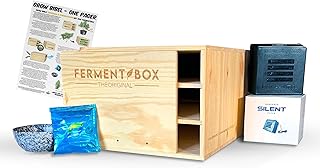

Explore related products

What You'll Learn

- Ideal Moisture Content: Aim for 12-15% moisture for stable crafting wood

- Air Drying Time: Takes 6-12 months depending on thickness and climate

- Kiln Drying Benefits: Speeds up process to 2-4 weeks with controlled conditions

- Stacking Techniques: Proper airflow reduces drying time and prevents warping

- Moisture Testing: Use a moisture meter to ensure wood is fully dried

Ideal Moisture Content: Aim for 12-15% moisture for stable crafting wood

Achieving the ideal moisture content in pine wood is crucial for crafting projects that demand stability and longevity. Wood with a moisture content between 12% and 15% is considered optimal for most indoor crafting applications. At this range, the wood is less prone to warping, cracking, or shrinking, ensuring your creations maintain their intended shape and structure over time. This moisture level also minimizes the risk of fungal growth, which can compromise the wood’s integrity.

To reach this target, understanding the drying process is essential. Freshly cut pine, or "green" wood, typically contains 30% to 200% moisture content, depending on the species and environmental conditions. Drying time varies significantly based on factors like humidity, temperature, and airflow. Air-drying, a common method for hobbyists, can take anywhere from 6 months to 2 years for pine to reach the desired moisture level. Kiln-drying, a faster but more resource-intensive method, reduces this timeframe to days or weeks by controlling heat and humidity.

For crafters without access to a kiln, strategic air-drying techniques can expedite the process. Stack wood stickers (small strips of wood) between boards to allow airflow, and store the wood in a dry, well-ventilated area protected from direct sunlight. Regularly monitor moisture levels using a wood moisture meter, which provides precise readings to ensure you’re on track. If the wood dries too quickly, it may crack, so patience is key.

Comparatively, using wood with moisture content above 15% can lead to unpredictable movement in your projects, while wood below 12% may become brittle. For example, a pine shelf made with 20% moisture content could warp as it dries further indoors, while a carving piece at 10% might develop fine cracks. Striking the 12-15% balance ensures your craftsmanship remains intact, blending functionality with aesthetic appeal.

In practice, achieving this ideal moisture content requires a blend of science and observation. Start by sourcing pine that’s already partially seasoned, if possible, to reduce drying time. For smaller pieces, consider sealing the ends with wax or paint to slow moisture loss from these areas, which dry faster than the sides. Finally, acclimate the wood to your crafting environment for at least a week before use, allowing it to adjust to indoor humidity levels. This meticulous approach ensures your pine wood is ready for crafting, delivering both durability and precision.

Durability of Wooden Railroad Brakeman's Clubs: A Historical Lifespan Overview

You may want to see also

Explore related products

Air Drying Time: Takes 6-12 months depending on thickness and climate

Pine wood, a favorite among crafters for its versatility and availability, requires patience when it comes to air drying. The process isn't instantaneous; it's a slow dance between the wood and its environment. Six to twelve months is the typical timeframe, but this isn't a one-size-fits-all scenario. The thickness of the wood plays a pivotal role—thicker pieces retain moisture longer, extending the drying period. A 1-inch thick board might be ready in six months, while a 4-inch slab could demand the full year. Climate, too, is a silent partner in this process. Humid regions slow down drying, while dry, temperate climates accelerate it. Understanding these variables is crucial for anyone looking to transform raw pine into a crafting masterpiece.

Consider the steps involved in air drying pine wood as a delicate balance of science and art. Start by stacking the wood off the ground, preferably on stickers (small strips of wood) to allow airflow. Ensure the stack is in a well-ventilated area, protected from direct rain but exposed to natural air movement. Pro tip: Seal the ends of the boards with a wax or latex paint to prevent rapid moisture loss, which can cause splitting. Monitor the wood periodically, checking for cracks or warping. In humid climates, using a moisture meter can be invaluable—aim for a moisture content of 12-15% for optimal crafting conditions. This methodical approach ensures the wood dries evenly, preserving its integrity for intricate projects.

The persuasive argument for air drying pine wood lies in its cost-effectiveness and environmental benefits. Kiln drying, while faster, can be expensive and energy-intensive. Air drying, on the other hand, relies on natural processes, making it a sustainable choice for eco-conscious crafters. However, it requires commitment. Caution: Rushing the process by using heat or forcing airflow can lead to brittle, unusable wood. Patience isn’t just a virtue here—it’s a necessity. For those willing to wait, the reward is wood that’s stable, workable, and ready to bring creative visions to life.

Comparing air drying to other methods highlights its unique advantages and challenges. While kiln drying can reduce drying time to weeks, it often lacks the nuanced control needed for crafting. Air drying, though slower, allows the wood to acclimate gradually, reducing the risk of internal stresses that cause warping. In contrast, leaving wood uncovered in direct sunlight can lead to surface checking and uneven drying. Takeaway: Air drying is an investment in quality, ideal for crafters who prioritize durability and natural aesthetics. It’s a testament to the adage that good things come to those who wait.

Finally, the descriptive beauty of air-dried pine wood lies in its transformation. Over months, the wood shifts from a heavy, moisture-laden state to a lighter, more resilient material. Its color deepens, grains become more pronounced, and the texture smooths out. This evolution is a reminder of the craftsmanship involved in working with natural materials. For those embarking on this journey, the wait isn’t just about drying wood—it’s about cultivating respect for the process and the material itself. Six to twelve months may seem like a long time, but the result is a piece of wood that’s not just dried, but truly ready for crafting.

Understanding the Lifespan of Wood Borers: A Comprehensive Guide

You may want to see also

Explore related products

Kiln Drying Benefits: Speeds up process to 2-4 weeks with controlled conditions

Pine wood, prized for its versatility and affordability, requires careful drying before crafting to prevent warping, cracking, and decay. Traditionally, air drying can take months, leaving woodworkers waiting impatiently for usable material. Kiln drying, however, revolutionizes this process, slashing drying times to a mere 2–4 weeks. This method leverages controlled temperature, humidity, and airflow to extract moisture efficiently, ensuring the wood reaches optimal crafting conditions swiftly.

The science behind kiln drying lies in its precision. By maintaining specific temperature gradients—typically starting around 120°F (49°C) and gradually increasing—kilns accelerate moisture evaporation without damaging the wood fibers. Humidity levels are meticulously adjusted to match the wood’s moisture content, preventing case-hardening (a brittle outer layer) and internal stresses. For pine, which naturally dries unevenly due to its resinous nature, this controlled environment is a game-changer, producing uniformly dried wood ready for carving, turning, or joinery.

For crafters, the benefits extend beyond speed. Kiln-dried pine boasts a moisture content of 6–8%, ideal for stability and dimensional accuracy in projects. Compare this to air-dried wood, which may retain 12–15% moisture, leading to shrinkage and distortion post-crafting. Additionally, kiln drying eliminates pests and fungi, common culprits in prolonged air drying. This ensures the wood is not only structurally sound but also safe for indoor use, such as furniture or decorative items.

Practical considerations for kiln drying include wood thickness and initial moisture content. Thicker pine boards may require longer kiln cycles, while freshly cut wood with high moisture levels demands a slower, more gradual drying schedule. Crafters should also monitor the wood’s weight loss during drying, aiming for a consistent reduction to the target moisture level. While kiln drying incurs costs—whether through professional services or personal kiln investment—the time saved and quality achieved often outweigh the expense, especially for large-scale or time-sensitive projects.

Incorporating kiln-dried pine into your crafting workflow unlocks efficiency and reliability. Whether you’re a hobbyist or professional, understanding this method’s mechanics and advantages empowers you to choose the best drying approach for your needs. With kiln drying, the wait for perfectly seasoned pine is no longer a hurdle but a manageable step in bringing your creative visions to life.

Maximizing Wood Pellet Efficiency: How Long Should a Bag Last?

You may want to see also

Explore related products

$17.84 $18.99

Stacking Techniques: Proper airflow reduces drying time and prevents warping

Pine wood, with its versatility and affordability, is a favorite among crafters and woodworkers. However, its natural moisture content can lead to warping, cracking, or prolonged drying times if not managed properly. Stacking techniques play a pivotal role in this process, as proper airflow is essential to expedite drying while maintaining the wood’s integrity. The key lies in creating a balanced environment where air circulates freely around each piece, drawing out moisture without causing stress to the wood fibers.

To achieve optimal airflow, start by selecting a flat, elevated surface for stacking. Wooden stickers—small, uniform pieces of wood—are commonly placed between layers to create gaps. These gaps should be approximately 1 to 1.5 inches wide, allowing air to flow vertically and horizontally. Avoid stacking wood directly on the ground, as this can lead to moisture absorption from the soil. Instead, use pallets or a foundation of bricks to elevate the stack, ensuring air can circulate beneath the lowest layer.

The orientation of the wood also matters. Stack boards with their widest faces perpendicular to the prevailing wind or airflow direction. This maximizes exposure to air, accelerating the drying process. For smaller pieces or craft-sized planks, consider alternating the direction of each layer in a crisscross pattern. This not only enhances airflow but also distributes weight evenly, reducing the risk of warping.

While proper stacking is crucial, it’s equally important to monitor the wood’s moisture content regularly. Use a moisture meter to track progress, aiming for a target range of 8–12% moisture content for most crafting projects. Depending on humidity and temperature, this process can take anywhere from several weeks to several months. In humid climates, consider using a dehumidifier or moving the stack to a drier location to speed up drying.

Finally, patience is paramount. Rushing the drying process by stacking too tightly or exposing the wood to excessive heat can lead to irreversible damage. By prioritizing airflow through thoughtful stacking techniques, you not only reduce drying time but also ensure the wood remains stable and ready for your next crafting endeavor. Master this step, and you’ll set the foundation for a successful project from the very beginning.

Seasoning Wood in the UK: Understanding the Ideal Drying Time

You may want to see also

Explore related products

Moisture Testing: Use a moisture meter to ensure wood is fully dried

Before crafting with pine wood, ensuring it’s fully dried is critical to prevent warping, cracking, or mold. A moisture meter becomes your most reliable tool in this process, offering precise readings that guesswork cannot match. Pine wood, when freshly cut, can have a moisture content (MC) of 30% to 200%, depending on the tree’s growing conditions. For crafting, the ideal MC ranges between 6% and 12%, aligning with the ambient humidity of most indoor environments. Without a moisture meter, you risk using wood that appears dry but retains hidden moisture, leading to long-term structural issues in your projects.

To use a moisture meter effectively, follow these steps: first, select a pin-type or pinless meter based on your preference for accuracy or surface scanning. Pin-type meters provide deeper readings but leave small holes, while pinless meters are non-invasive but may lack depth. Insert the pins or place the sensor on the wood’s surface, ensuring contact with the material. Take multiple readings across different areas of the wood, especially the end grain, which dries more slowly. Compare these readings to the recommended MC range for crafting. If the meter consistently shows values above 12%, the wood requires further drying.

Analyzing moisture meter results requires understanding the wood’s behavior. Pine, being a softwood, dries faster than hardwoods but is more prone to checking (surface cracks) if dried too quickly. If your meter indicates an MC above 19%, slow the drying process by increasing air circulation and reducing heat to prevent surface damage. Below 12%, the wood is safe for crafting, but monitor for equilibrium moisture content (EMC), which stabilizes the wood to its environment. A sudden drop in MC without environmental changes may signal uneven drying, necessitating further inspection.

Persuasively, investing in a moisture meter is not just a precaution—it’s a safeguard for your craftsmanship. A $20 to $100 meter can save you from costly mistakes, such as a warped tabletop or a cracked sculpture. Consider it an essential tool in your workshop, alongside saws and sanders. For beginners, start with a pinless meter for ease of use, upgrading to a pin-type as your projects demand precision. Regularly calibrate your meter according to the manufacturer’s instructions to ensure accurate readings, as drift can occur over time.

Finally, moisture testing is a dynamic process, not a one-time check. After initial drying, retest the wood weekly until the MC stabilizes. Environmental factors like humidity and temperature influence drying time, which can range from 6 months to 2 years for pine, depending on thickness and conditions. Pair moisture testing with proper stacking (stickered piles for airflow) and storage (in a dry, well-ventilated space) to maximize efficiency. By integrating moisture meters into your workflow, you ensure every piece of pine wood is ready for crafting, preserving both your materials and your reputation.

Weathering Cherry Wood: Optimal Outdoor Time for Rich Darkening Results

You may want to see also

Frequently asked questions

Air drying pine wood typically takes 6 to 12 months, depending on factors like humidity, temperature, and the thickness of the wood.

Yes, pine wood can be kiln-dried, and the process usually takes 2 to 4 weeks, depending on the kiln settings and wood thickness.

Yes, drying pine wood is essential to reduce moisture content, prevent warping, cracking, and ensure stability for crafting projects.

The ideal moisture content for pine wood used in crafting is between 8% and 12%, depending on the local climate and intended use.

Yes, you can speed up drying by splitting the wood into smaller pieces, storing it in a well-ventilated area, or using a kiln. However, avoid rushing the process to prevent damage.